Ternary copper catalyst alloy full fusion preparation process

A technology that fully integrates and prepares processes, and is used in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, metal processing equipment, etc., to avoid the entry of air, avoid up and down movement, and reduce oxidation reactions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0034] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

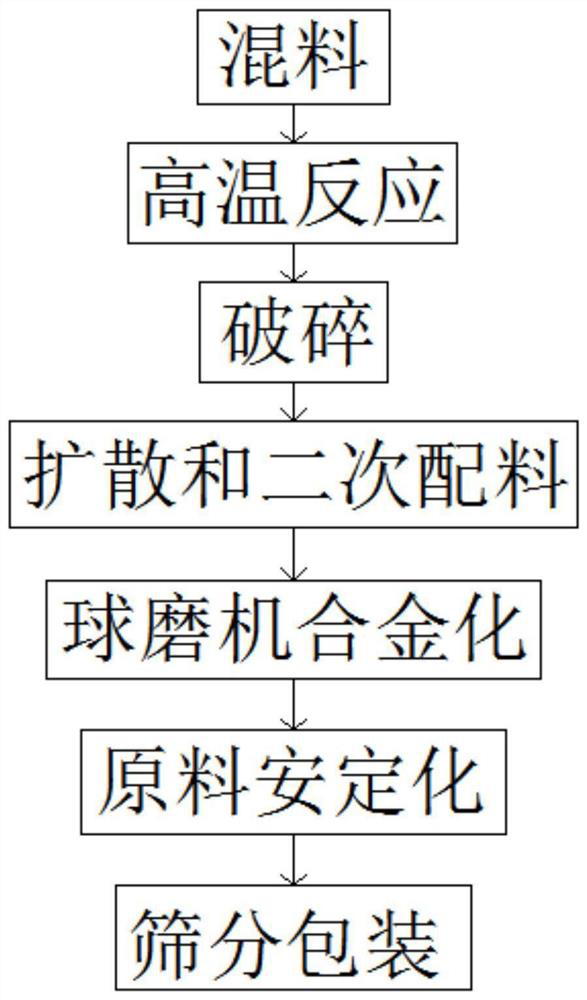

[0035] Such as Figure 1 to Figure 5 As shown, a ternary copper catalyst alloy fully integrated preparation process provided by the embodiment of the present invention includes the following steps:

[0036] a. Mixing materials, mix 40-60% copper powder fine powder and 40-60% oxygen-containing copper according to a certain proportion and stir for about half an hour;

[0037] b. High-temperature reaction, put the mixed raw materials into a high-temperature diffusion furnace, let the aerobic copper and copper powder react at high temperature, under the condition of anaerobic, fill the whole process with nitrogen protection, high-temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com