Automatic plate block press

A molding machine and plate technology, applied in metal processing equipment, feeding devices, forming tools, etc., can solve the problems of insufficient automation, potential safety hazards, and affecting production efficiency, and achieve a high degree of automation, not easy to deflection, Guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

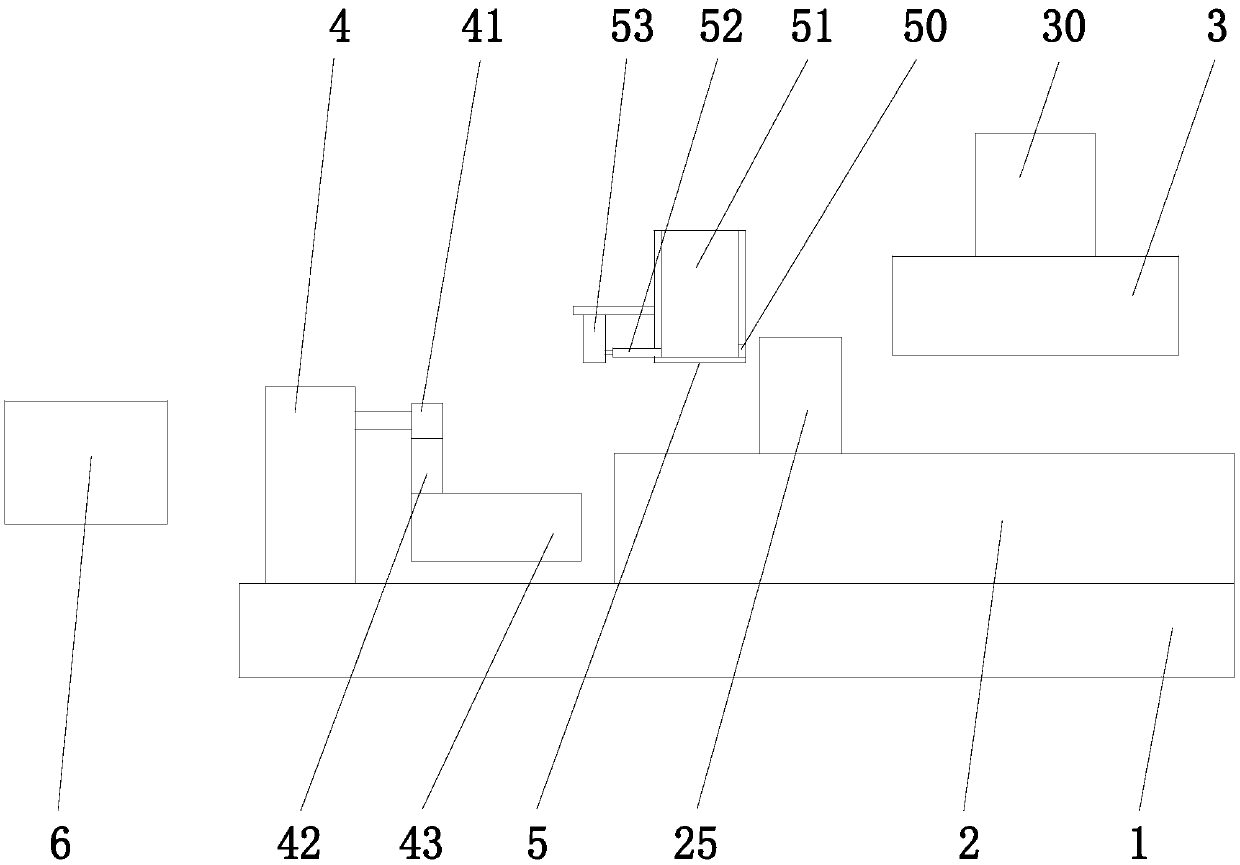

[0016] refer to figure 1 and figure 2 , an automatic plate molding machine of the present invention, comprising a machine platform 1, an upper mold 3, a lower mold 2, a first push-pull device 4, an automatic feeder 5, a pressing device 30, and a control device 6, and the base is equipped with a Detachable lower mold 2, lower mold 2 is elongated, is provided with model groove 20 in lower mold 2, lower mold 2 is horizontally arranged, and the left and right ends of lower mold 2 are all open, and described lower mold 2 is provided with a The upper mold 3 matched with the lower mold 2, the top of the upper mold 3 is connected with the lower pressing device 30, and a first push-pull device 4 is installed on the machine table 1, and the first push-pull device 4 is located on the left side of the lower mold 2, The first push-pull device 4 links to each other with a mounting plate 41, and several pushing plates 42 for pushing the plate 42 materials are installed at the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com