Preparation method of micro-capsule coated fat powder and hot spray drying device

A drying device, fat powder technology, applied in household refrigeration devices, chemical instruments and methods, lighting and heating equipment, etc., can solve the problems of a large amount of dust, inconvenient feeding, particle pressure and fragmentation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

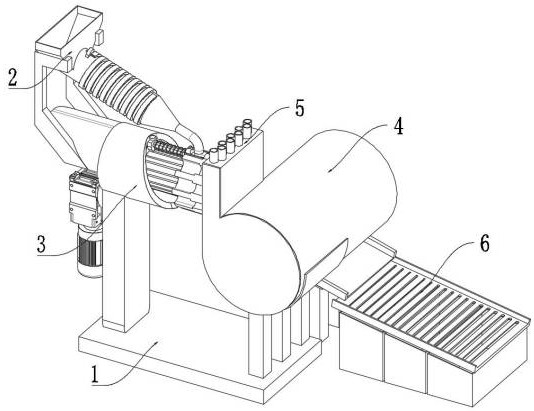

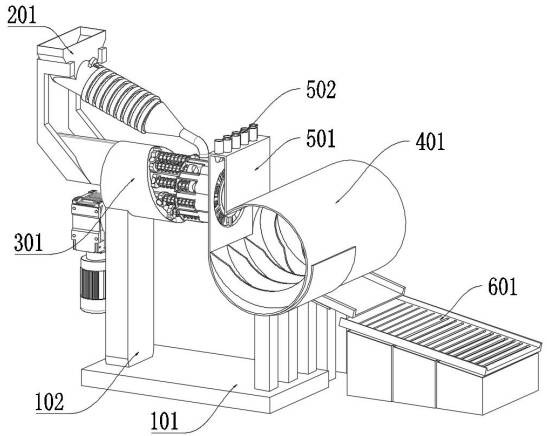

[0052] as attached figure 1 to attach Figure 8 Shown:

[0053] The invention provides a method for preparing microcapsule-coated fat powder and a thermal spray drying device, including a support structure 1;

[0054] The feeding structure 2, the feeding structure 2 is set in an inclined downward shape, and the feeding structure 2 is clamped and installed at the upper left end of the supporting structure 1;

[0055] The push structure 3 is arranged as a horizontal structure, and the push structure 3 is installed at the lower end of the feed structure 2;

[0056] Preparation structure 5, the preparation structure 5 is set in the shape of a hollow rectangular plate, and the rectangular plate is fixed on the right end of the push structure 3;

[0057] The heat dissipation structure 4 is set in a hollow cylindrical shape, and the heat dissipation structure 4 is installed at the lower end of the preparation structure 5. At the same time, the heat dissipation structure 4 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com