Centrifuge scraper mechanism

A centrifuge and scraper technology, used in centrifuges and other directions, can solve the problems of long distance between cutting positions, difficult cleaning, and inability to crush well, so as to prolong the service life and avoid cutting the filter cloth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

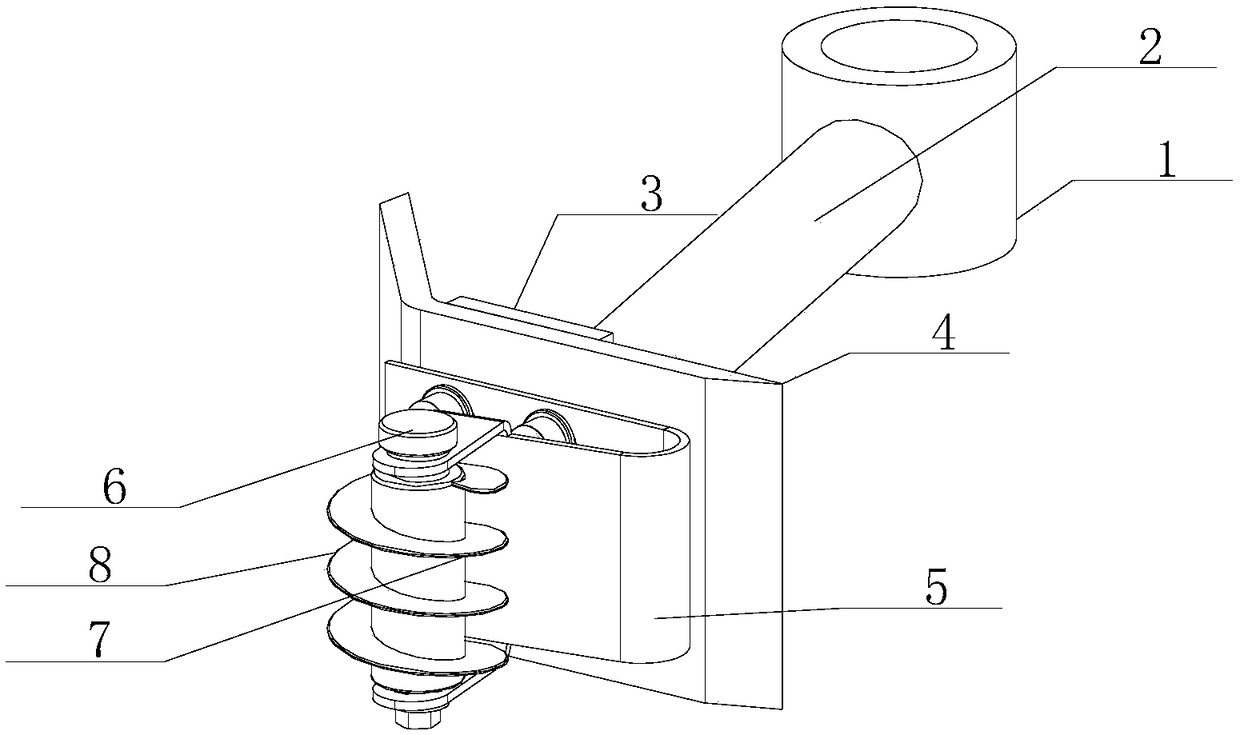

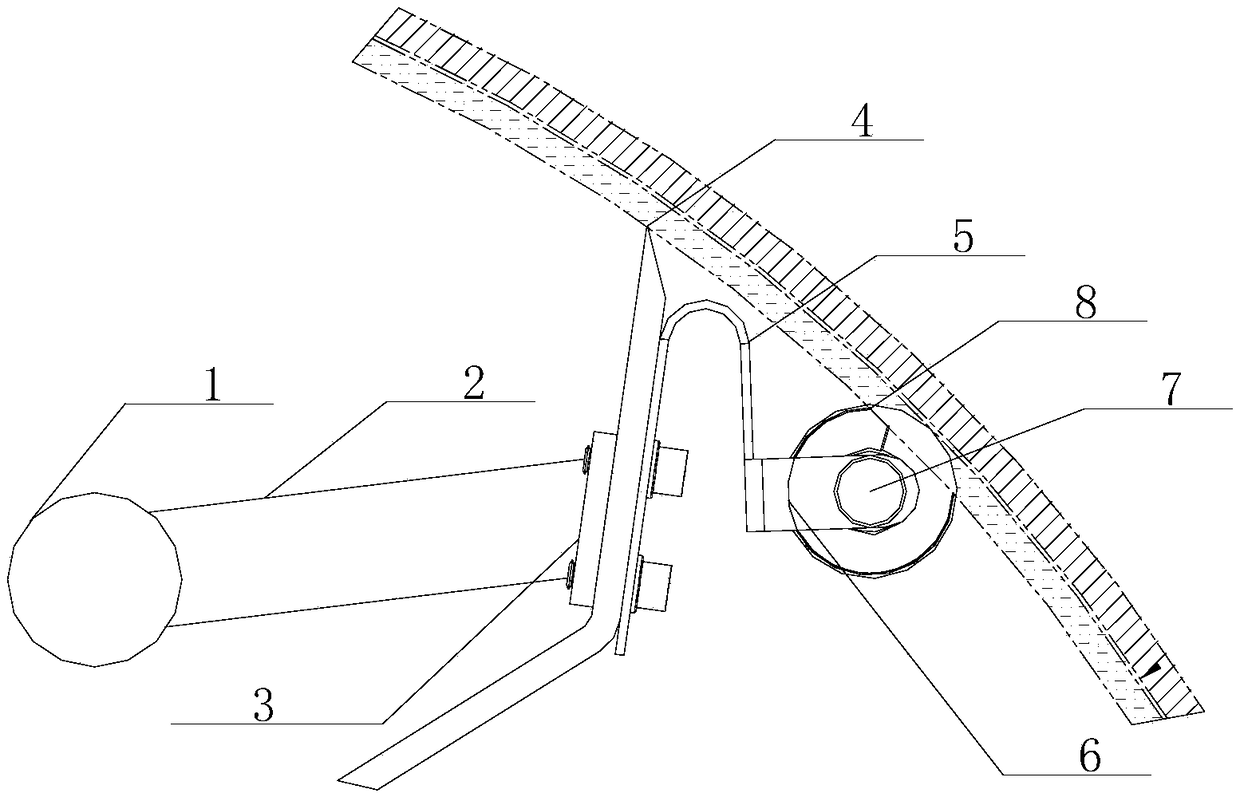

[0014] Such as Figure 1-2 As shown, a scraper mechanism of a centrifuge includes a cylindrical mounting base 1 connected to the scraper driving mechanism, a cutting arm 2 is provided on the cylindrical mounting base 1, and a mounting seat 3 is provided at the end of the cutting arm 2 , the mounting seat 3 is provided with a scraper 4, the scraper 4 includes a main blade that is 100-110° to the main shaft of the cutting arm 2, the main blade is provided with a material guide plate that is 20-35° to the main shaft of the cutting arm 2, and the scraper 4 is An elastic roller seat 5 is provided along the direction of the cutting arm 2, and the roller seat 5 is an elastic bending seat with a U-shaped horizontal section.

[0015] Roller seat 5 is provided with installation frame 6, and rotation on installation frame 6 is provided with material cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com