Prefabricated sports field surface material and preparation method thereof

A prefabricated, layered material technology, used in pavements, buildings, roads, etc., can solve the problems of easy wear and damage in the runway area, and achieve the effects of environmental protection, good physical properties and strong elasticity in the preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A preparation method of the above-mentioned prefabricated sports field surface layer material, comprising the following steps:

[0039] (1) mixing described natural rubber, styrene-butadiene rubber, corundum powder, white carbon black, mineral oil, paraffin and functional additives, and banburying;

[0040] (2) Carrying out kneading of the banburying material obtained in step (1), cooling after the sheet is discharged, to obtain an unvulcanized rubber sheet;

[0041] (3) banburying the unvulcanized film with the zinc oxide and accelerator, and then calendering the film to obtain the film;

[0042] (4) vulcanize the film obtained in step (3), and cool it down.

[0043] In some of the embodiments, in step (1), the banburying time is 5-15 minutes, and the banburying temperature is 110-140°C.

[0044] In some of these embodiments, in step (3), the temperature at which the film is mixed with the zinc oxide and the accelerator is ≤70°C.

[0045] In some of these embodiment...

Embodiment 1-4

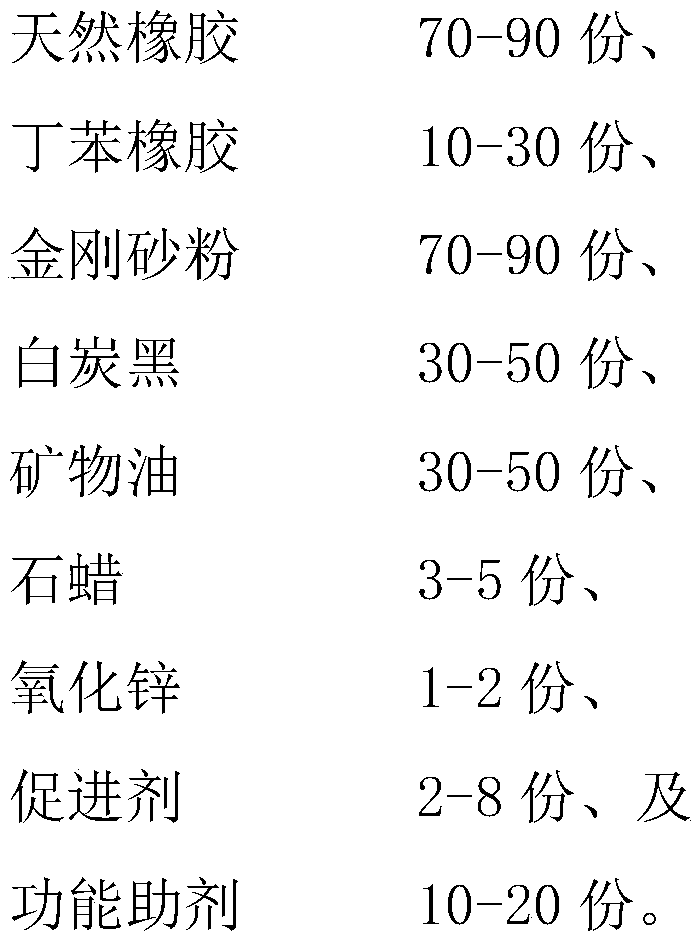

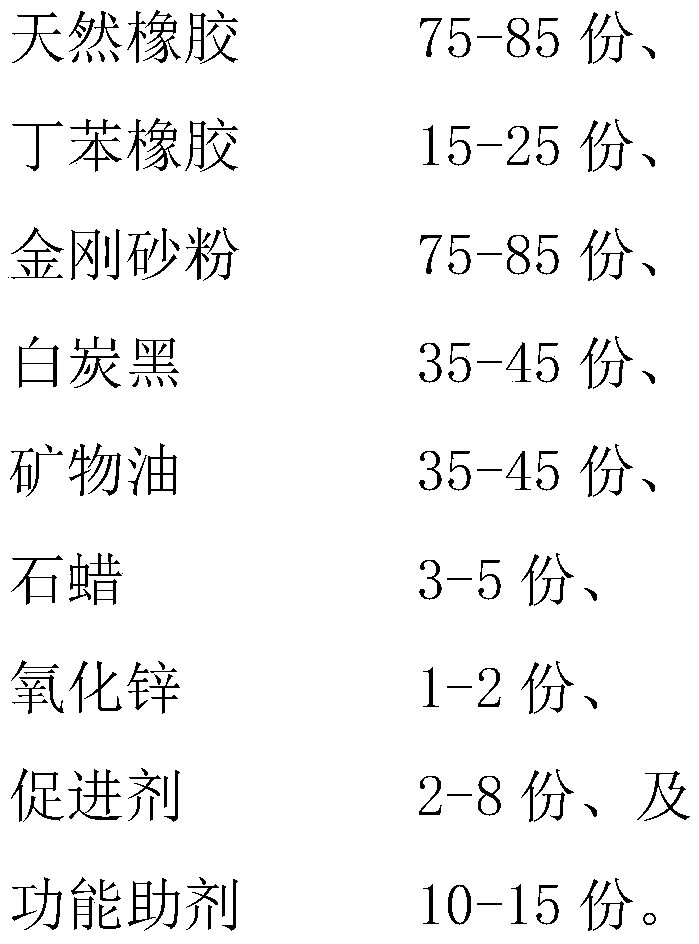

[0055] A kind of prefabricated playground surface layer material, by weight, raw material composition is as shown in table 1:

[0056] Table 1

[0057]

[0058] The preparation method of the prefabricated sports field surface layer material is as follows:

[0059] (1) Weigh natural rubber, styrene-butadiene rubber, emery powder, white carbon black, naphthenic oil, paraffin, pigment, antioxidant 2246 and antioxidant 1010, mix and place in a rubber internal mixer, 110-140 Banburying at ℃ for 10 minutes to obtain banburying materials;

[0060] (2) Place the banburying material in an open mill, roll it out at 40-60°C for 10 minutes, and control the thickness of the film to ≤2mm, cool it until the temperature of the film is ≤50°C, and obtain an unvulcanized film for use;

[0061] (3) Mix the unvulcanized rubber sheet obtained in step (2) with the zinc oxide, TMTD, BZ, M and DM in said parts by weight, place in a rubber mixer, mix at a temperature lower than 70°C, and then extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com