Manufacturing method of non-slip sole

A production method and anti-slip technology, which can be applied to soles, footwear, footwear, etc., can solve the problems of reduced anti-slip effect, rupture, and increased cost of rubber materials, and achieve the effect of significant anti-slip effect, improved anti-slip performance, and economical economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

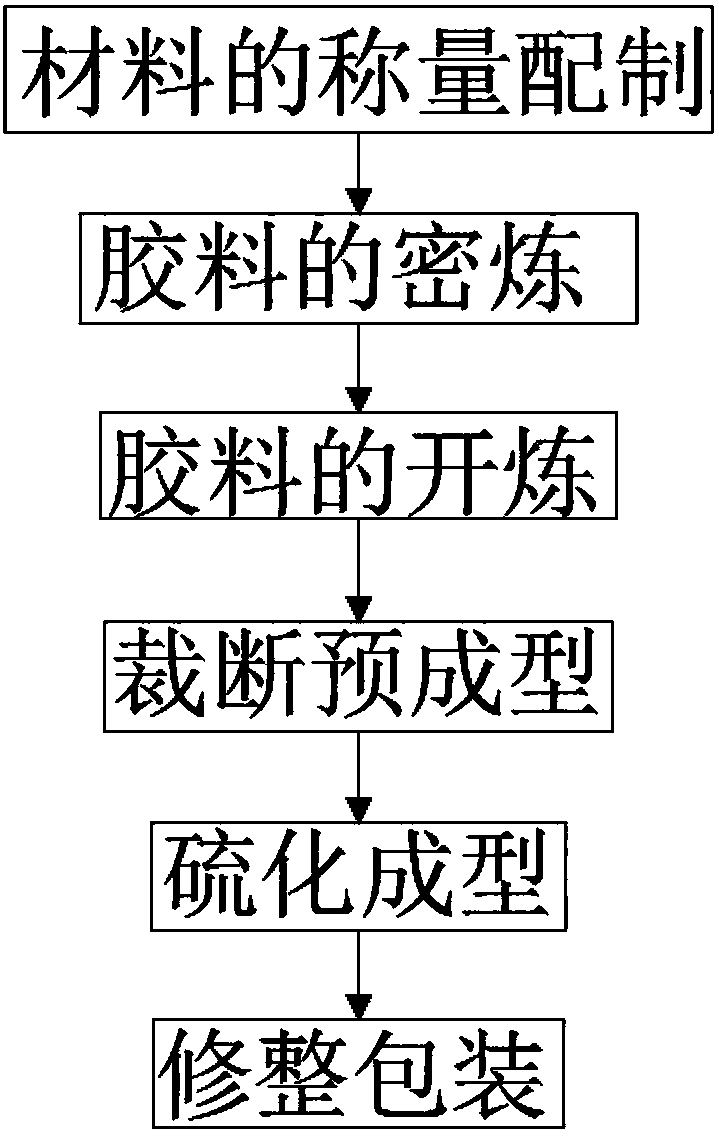

[0044] A method for making a non-slip shoe sole, comprising the following steps:

[0045] Weigh the following sole production materials: nitrile rubber 35L: 40.00kg, white carbon black: 9.00kg, rosin: 1.00kg, black masterbatch: 1.00kg, zinc oxide: 1.50kg, stearic acid: 0.20kg, polyethylene glycol Alcohol: 0.80kg, anti-wear agent: 0.60kg, anti-aging agent: 0.40kg, accelerator: 0.80kg, sulfur: 0.90kg, anti-slip agent: 1.50kg.

[0046] Put the above-mentioned nitrile rubber and rosin into a 75L internal mixer and stir, and heat the nitrile rubber and rosin to raise the temperature in the internal mixer to 60-90°C, and then stir for 2-4min. Since the rosin is solid, First, rosin is blended into the nitrile rubber, which can increase the viscosity and reduce the hardness while ensuring the overall color of the colloid; then white carbon black, polyethylene glycol, antioxidant, stearic acid, zinc oxide, accelerator, anti-slip The agent is added into the internal mixer, and the sole...

Embodiment 2

[0054] A method for making a non-slip shoe sole, comprising the following steps:

[0055] Weigh the following sole production materials: nitrile rubber 35L: 42.00kg, white carbon black: 9.50kg, rosin: 1.50kg, black masterbatch: 1.50kg, zinc oxide: 2.00kg, stearic acid: 0.30kg, polyethylene glycol Alcohol: 0.90kg, wear-resistant agent: 0.70kg, anti-aging agent: 0.50kg, accelerator: 1.00kg, sulfur: 0.95kg, anti-slip agent: 1.80kg

[0056] Put the above-mentioned nitrile rubber and rosin into a 75L internal mixer and stir, and heat the nitrile rubber and rosin to raise the temperature in the internal mixer to 60-90°C, and then stir for 2-4min. Since the rosin is solid, First, rosin is blended into the nitrile rubber, which can increase the viscosity and reduce the hardness while ensuring the overall color of the colloid; then white carbon black, polyethylene glycol, antioxidant, stearic acid, zinc oxide, accelerator, anti-slip The agent is added into the internal mixer, and the ...

Embodiment 3

[0064] A method for making a non-slip shoe sole, comprising the following steps:

[0065] Weigh the following sole production materials: nitrile rubber 35L: 43.00kg, white carbon black: 9.80kg, rosin: 1.70kg, black masterbatch: 1.80kg, zinc oxide: 2.30kg, stearic acid: 0.35kg, polyethylene glycol Alcohol: 0.95kg, anti-wear agent: 0.75kg, anti-aging agent: 0.55kg, accelerator: 1.10kg, sulfur: 0.98kg, anti-slip agent: 1.90kg.

[0066] Put the above-mentioned nitrile rubber and rosin into a 75L internal mixer and stir, and heat the nitrile rubber and rosin to raise the temperature in the internal mixer to 60-90°C, and then stir for 2-4min. Since the rosin is solid, First, rosin is blended into the nitrile rubber, which can increase the viscosity and reduce the hardness while ensuring the overall color of the colloid; then white carbon black, polyethylene glycol, antioxidant, stearic acid, zinc oxide, accelerator, anti-slip The agent is added into the internal mixer, and the sole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com