Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Highly achieved" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

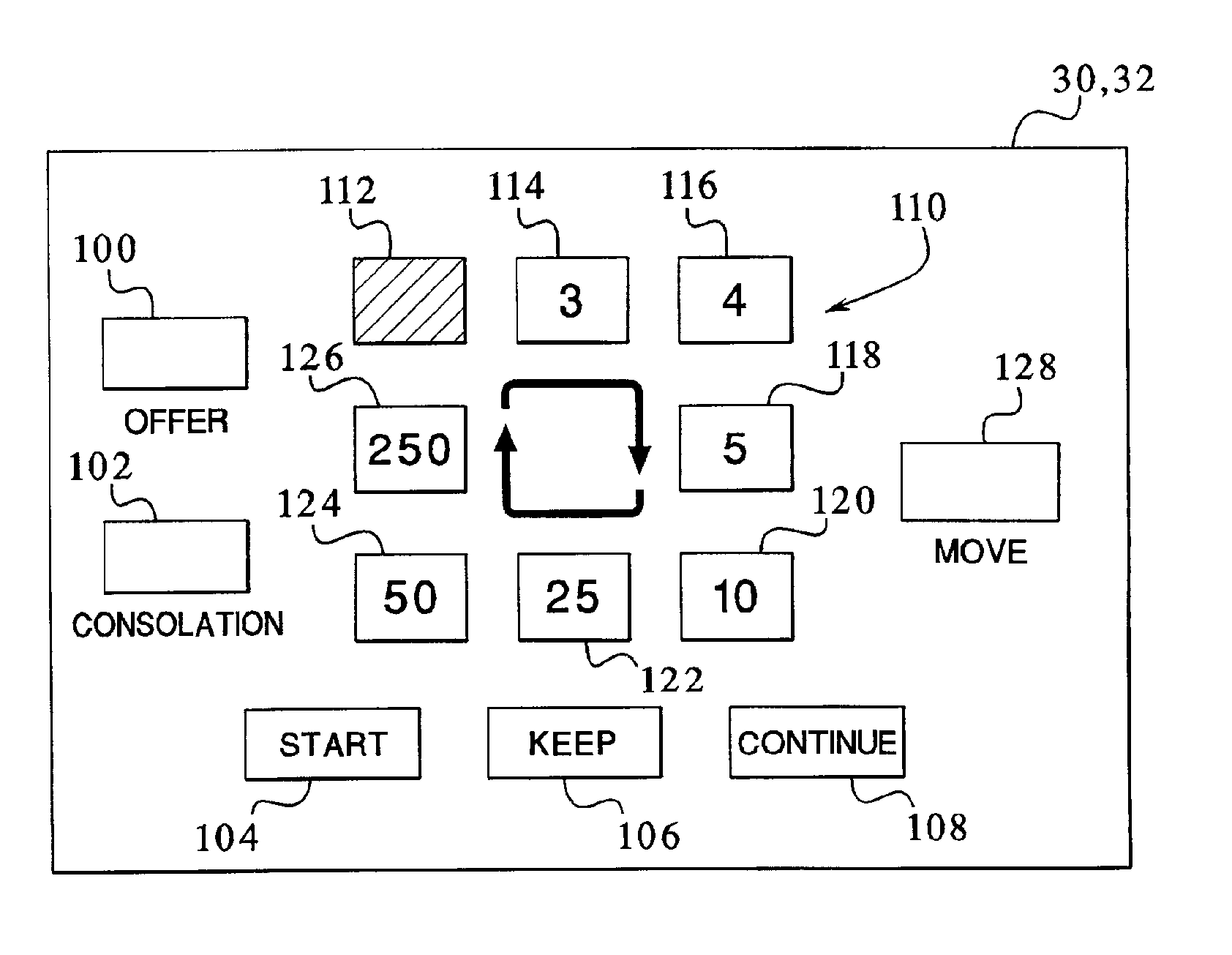

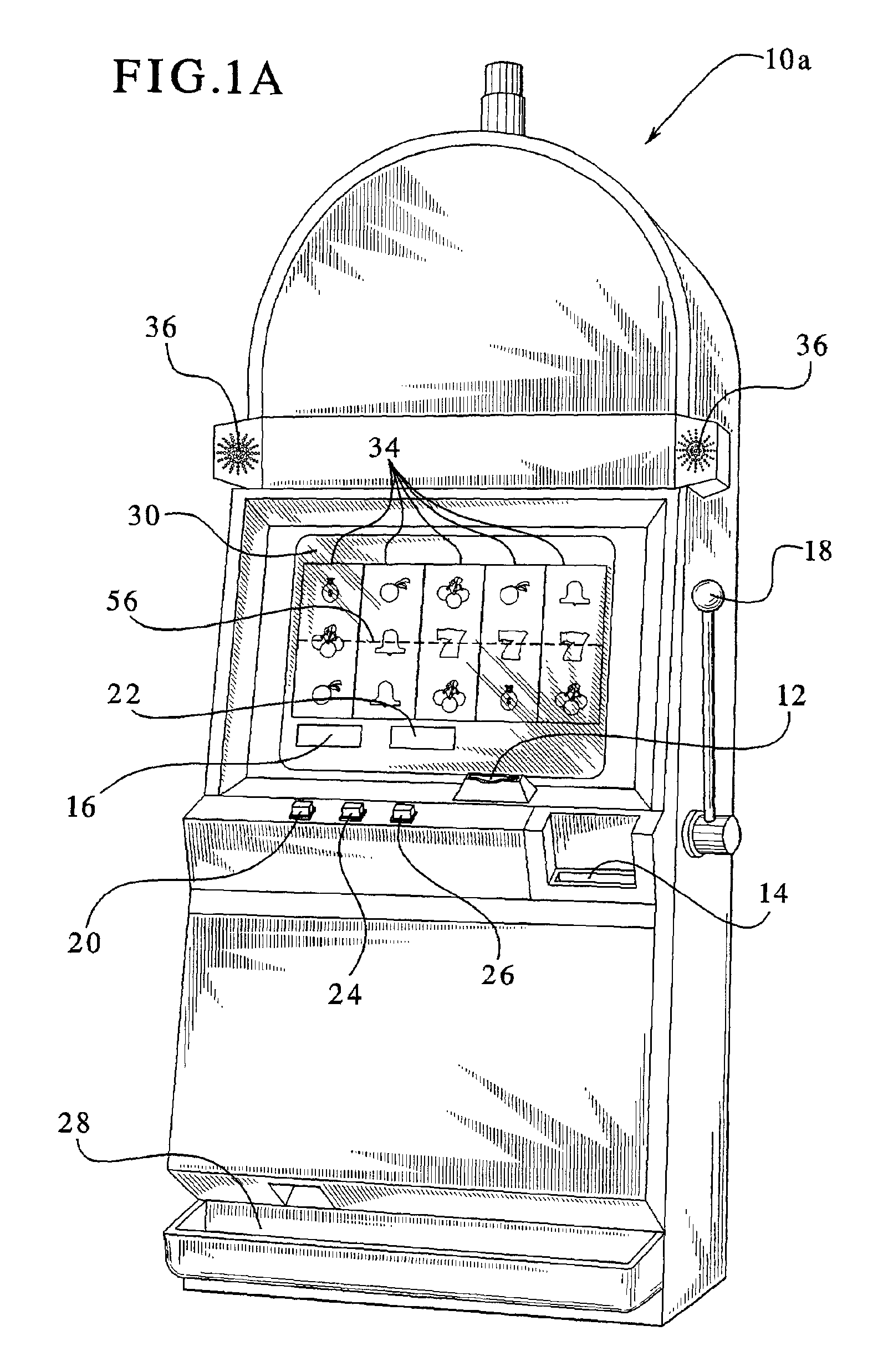

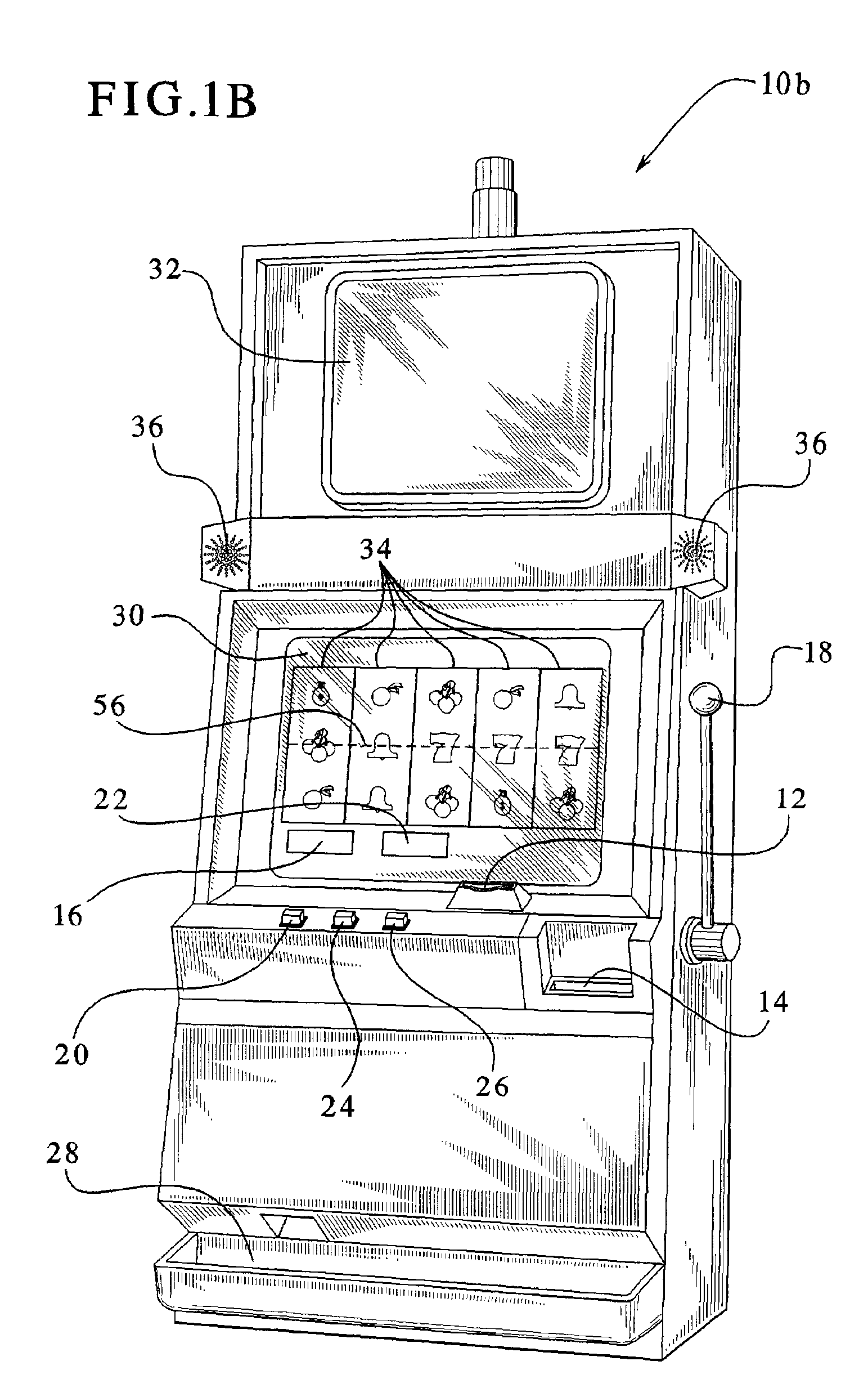

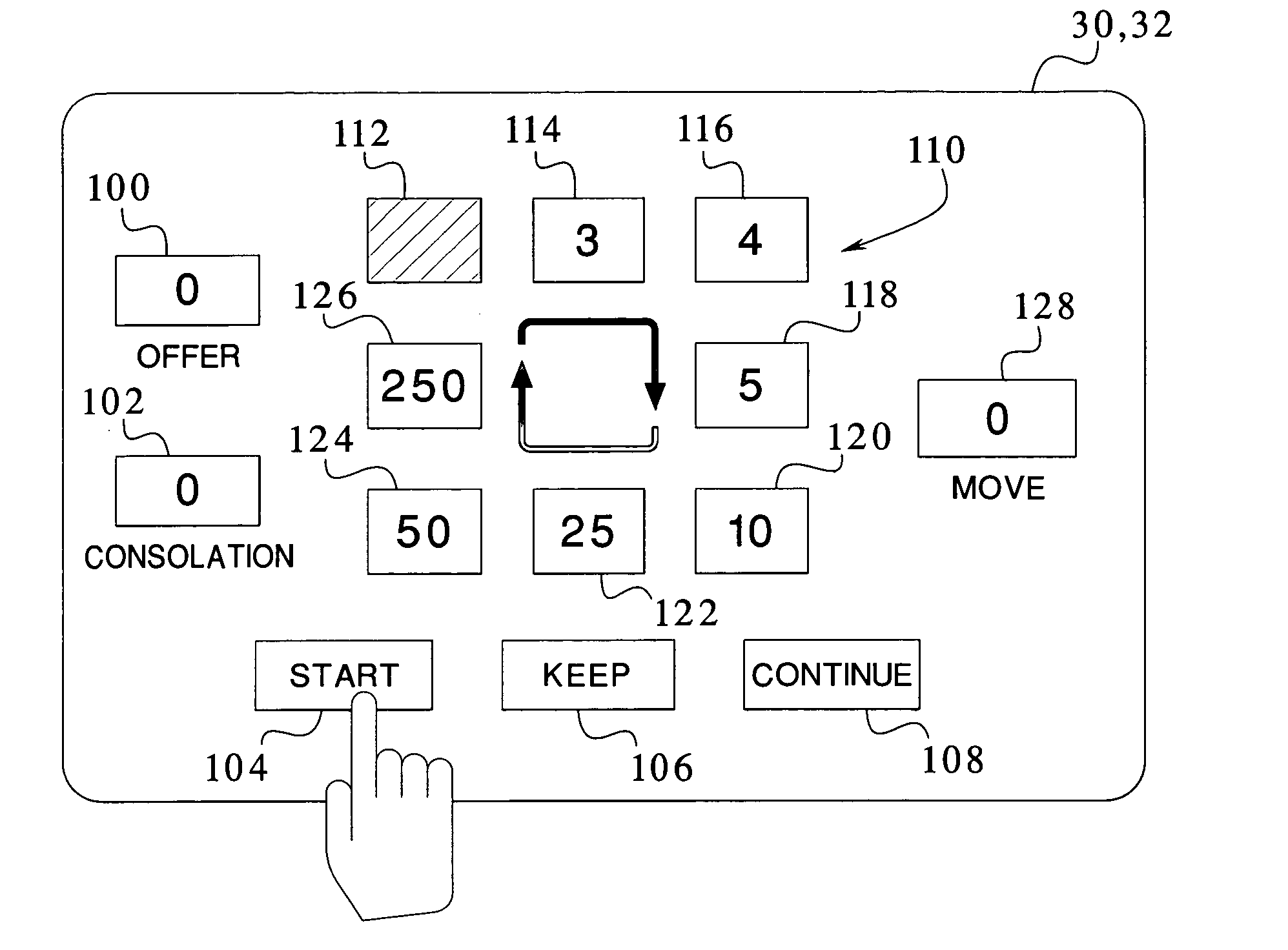

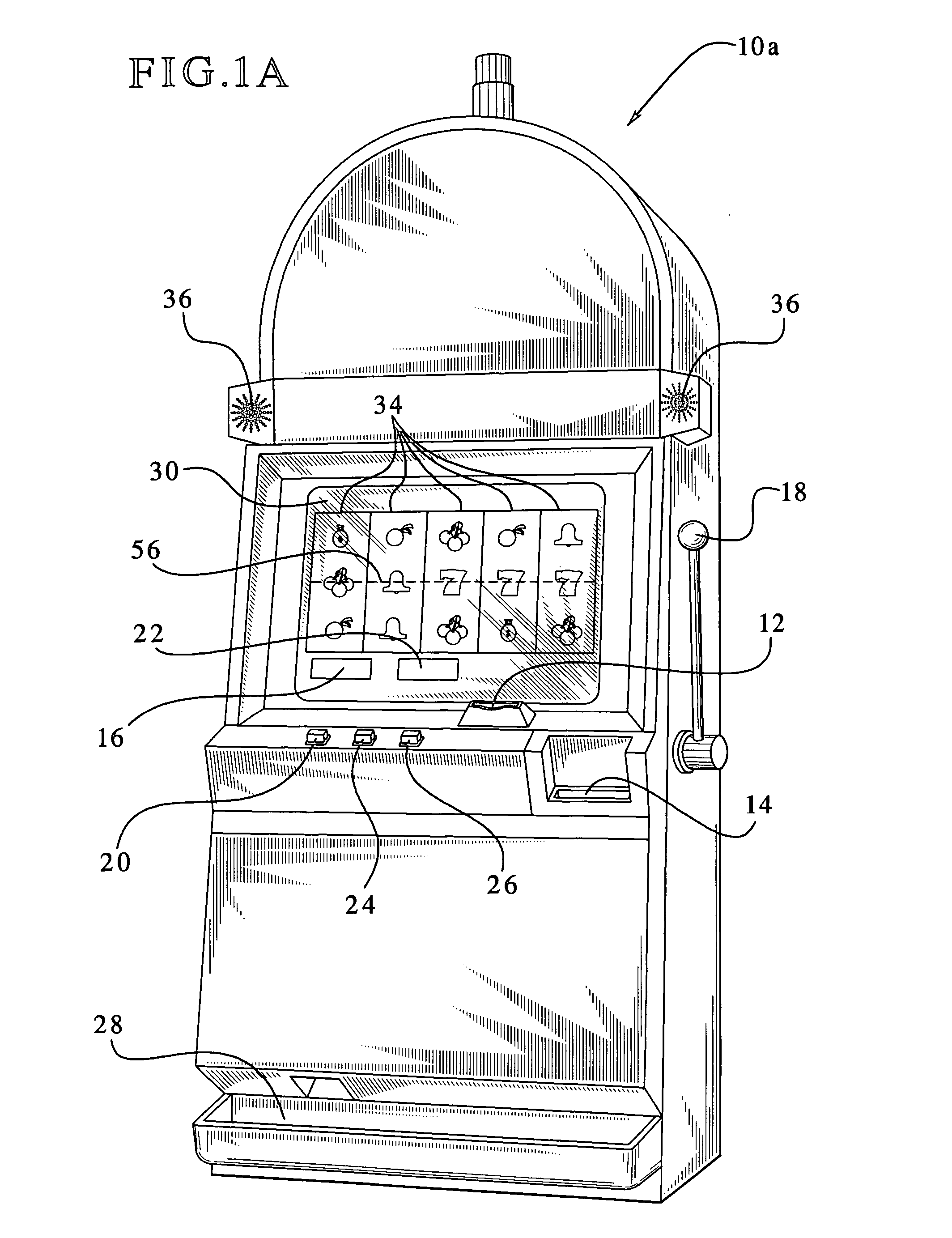

Gaming device having an improved offer/acceptance bonus scheme

InactiveUS6942566B2Highly achievedHigh offerApparatus for meter-controlled dispensingVideo gamesEngineering

Owner:IGT

Gaming device having an improved offer/acceptance bonus scheme

InactiveUS20060003837A1Highly achievedHigh offerApparatus for meter-controlled dispensingVideo gamesEngineering

Owner:IGT

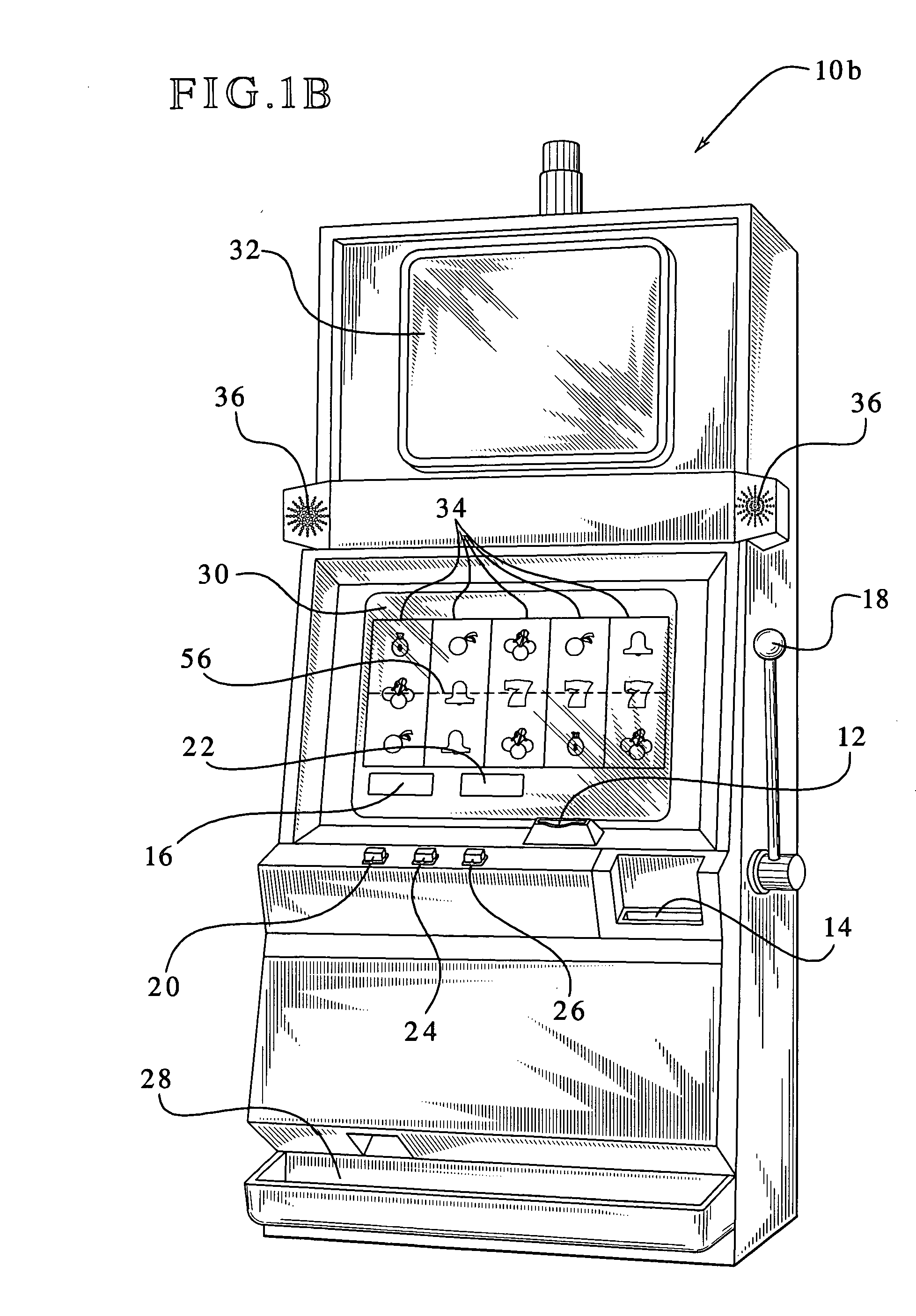

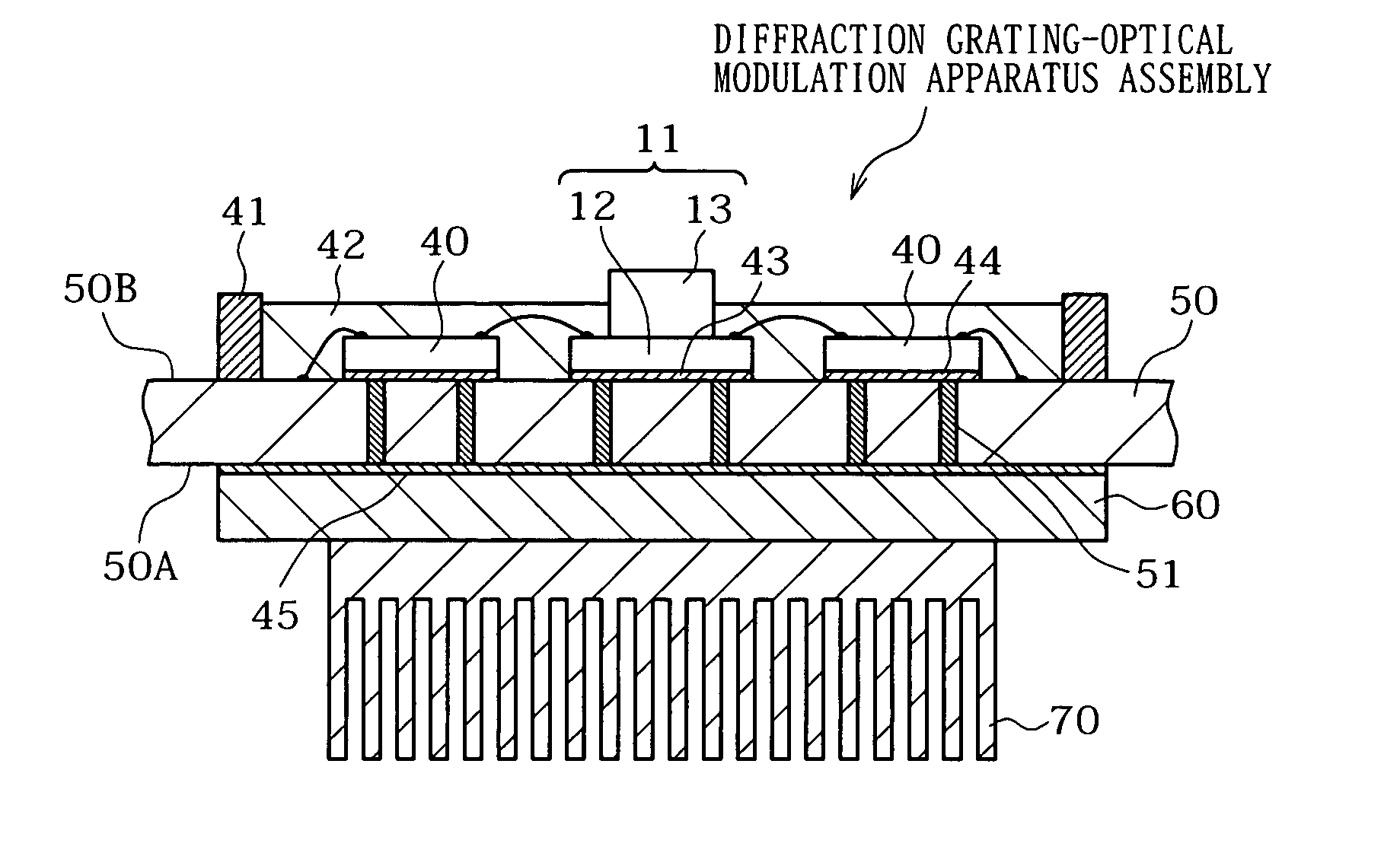

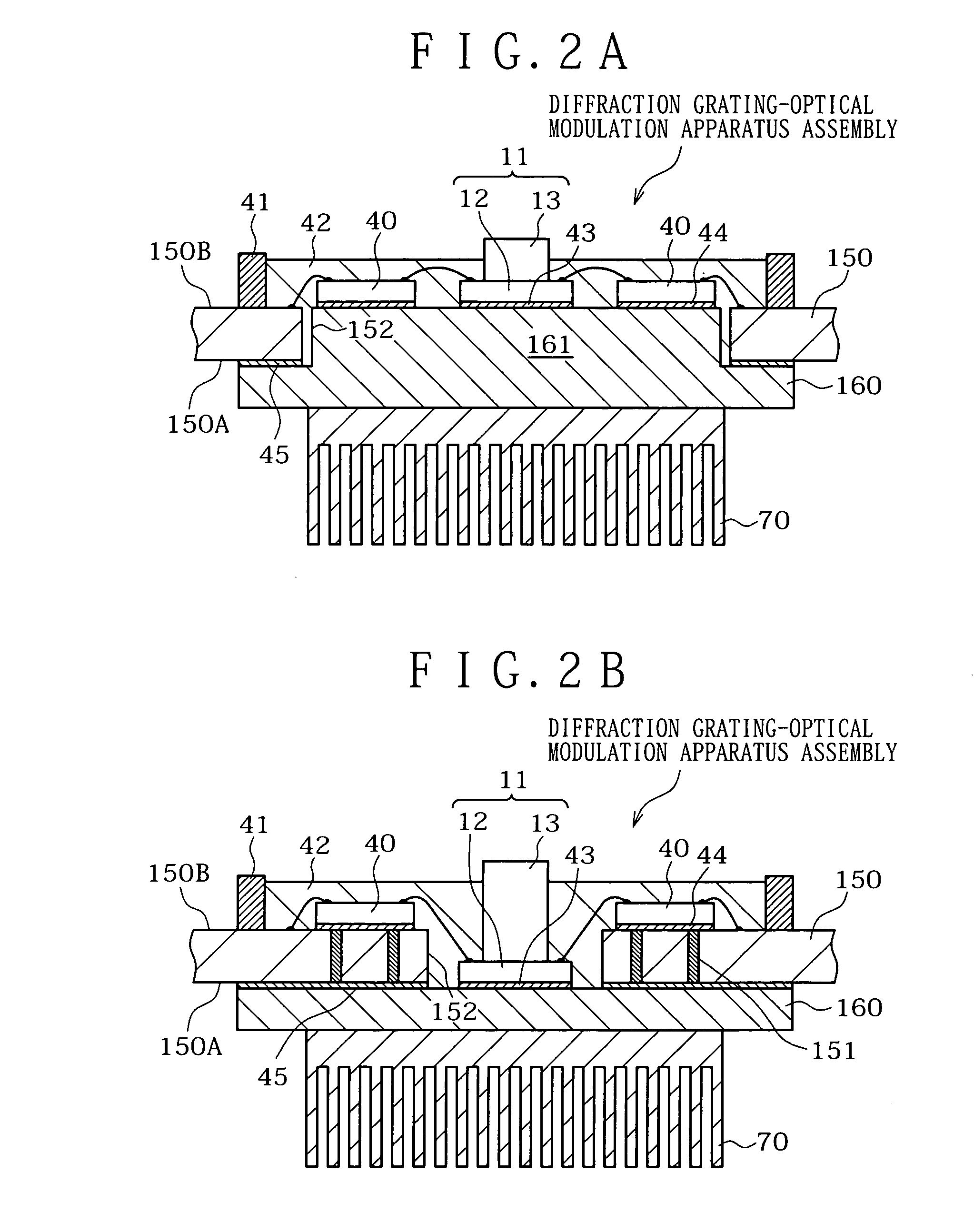

Optical apparatus and image production apparatus

InactiveUS20050133698A1High diffraction efficiencyDisplay imageSolid-state devicesMaterial analysis by optical meansHeat transmissionEngineering

An optical apparatus is disclosed by which, even if heat is generated with optical elements in a diffraction grating-optical modulation apparatus, lights emitted from the optical elements is less likely to suffer from displacement therebetween. The optical apparatus includes an optical element, a mounting substrate, a support member, and a cooling / heat radiating member. The support member is attached to a first face of the mounting substrate while the optical element is attached to a second face of the mounting substrate. The cooling / heat radiating member is attached to the support member. The optical element and the support member are thermally connected to each other by a heat transmission element provided in the inside of the mounting substrate. The support member is made of a material having a thermal conductivity of 230 W / m·K or more.

Owner:SONY CORP

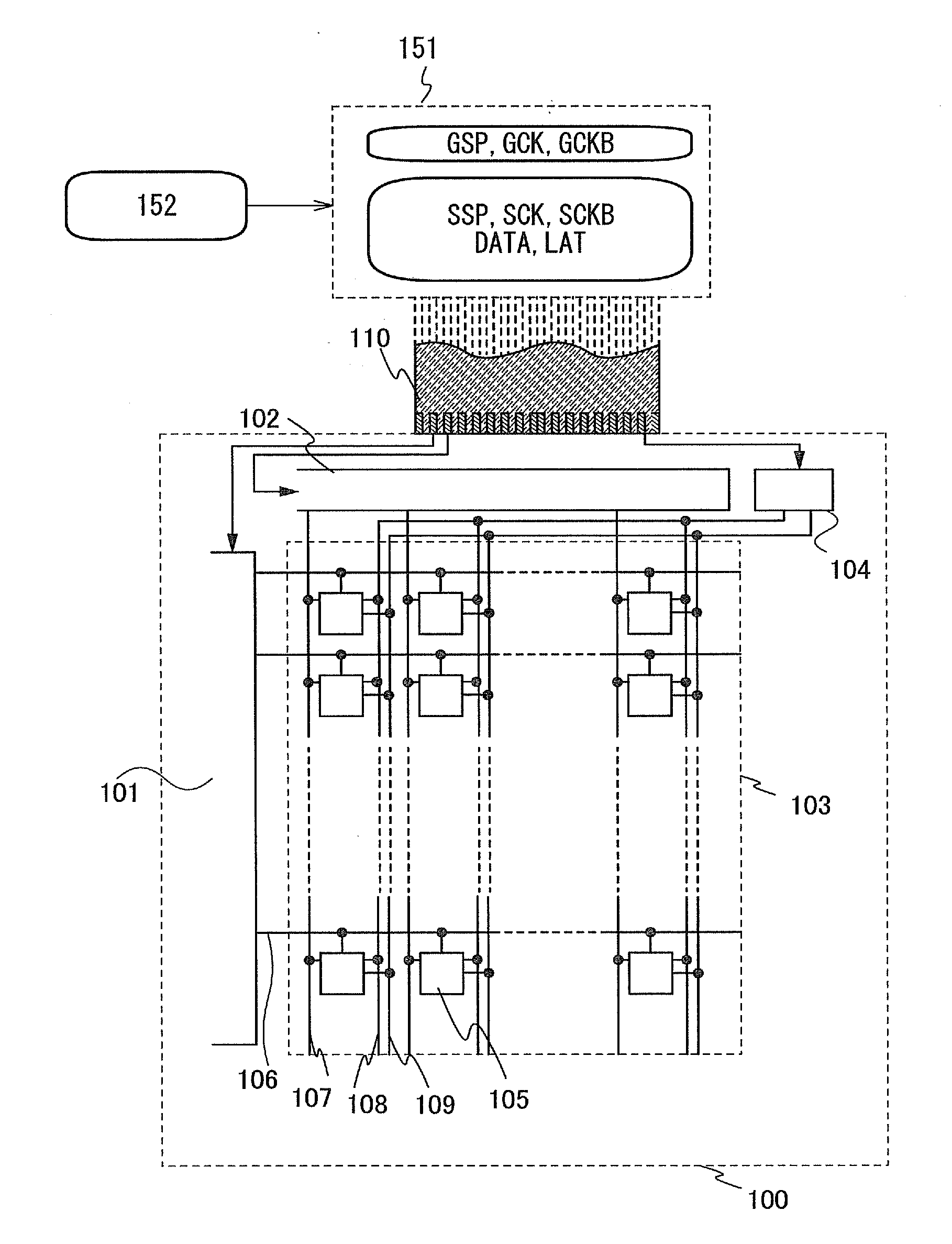

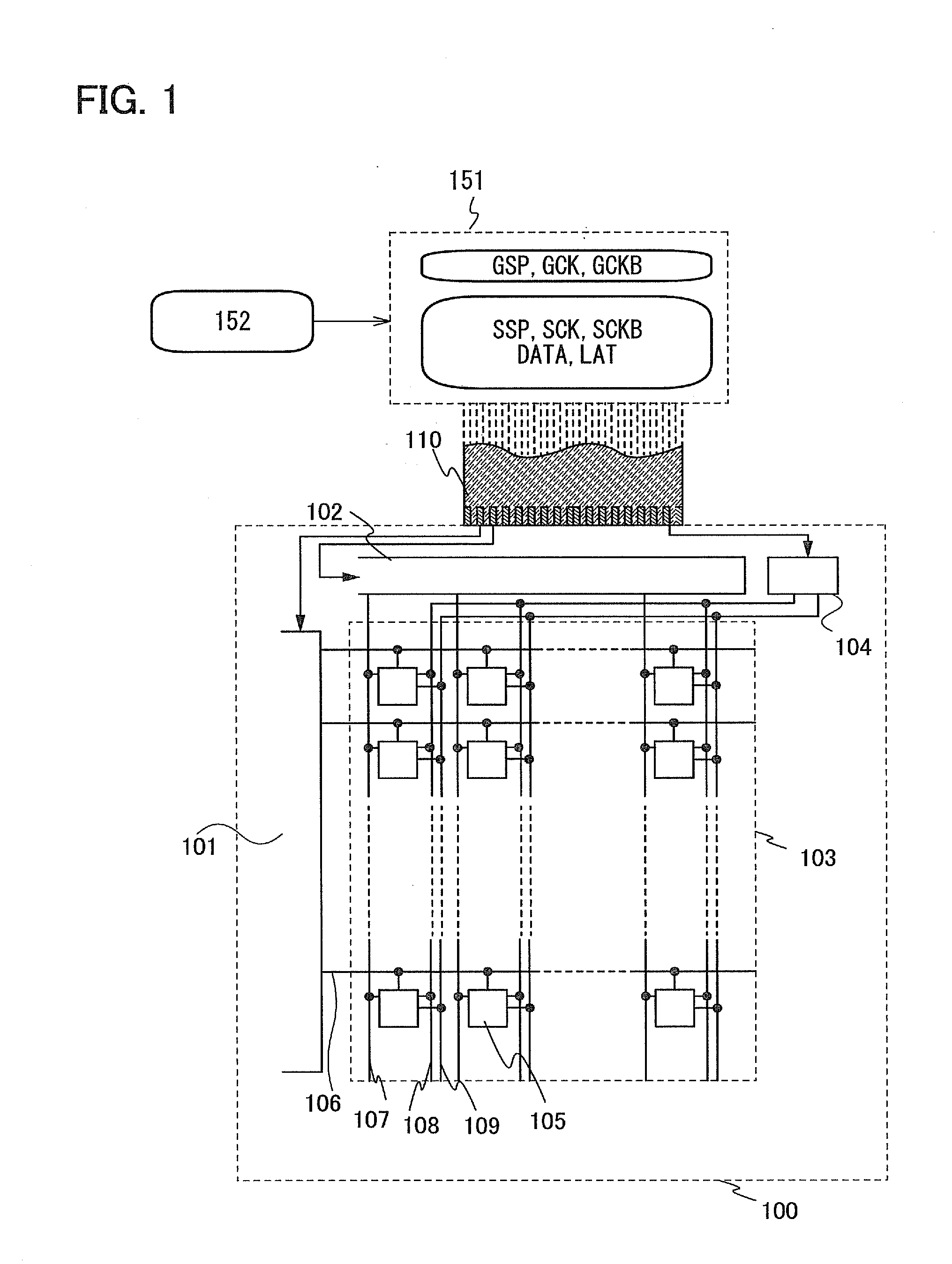

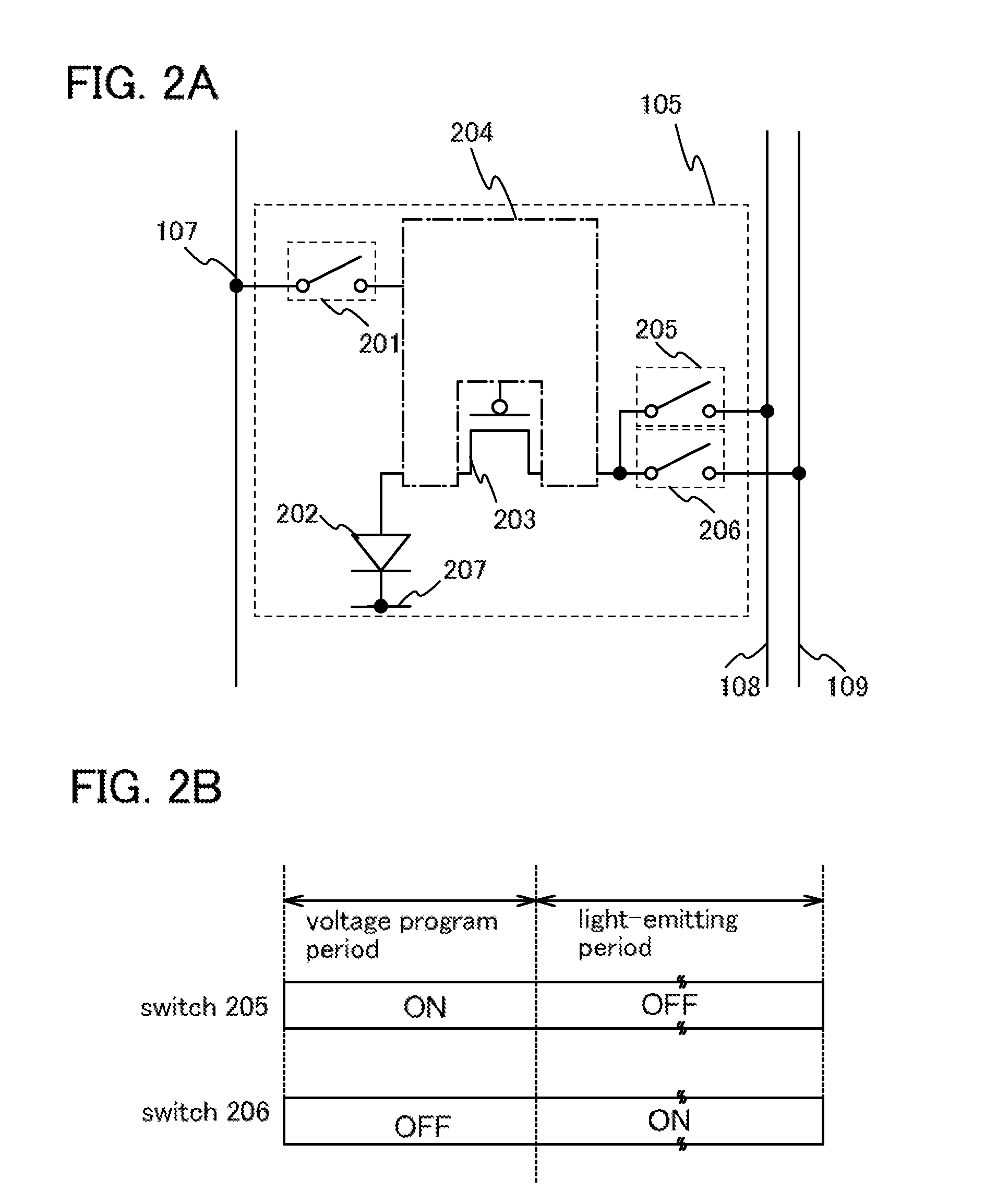

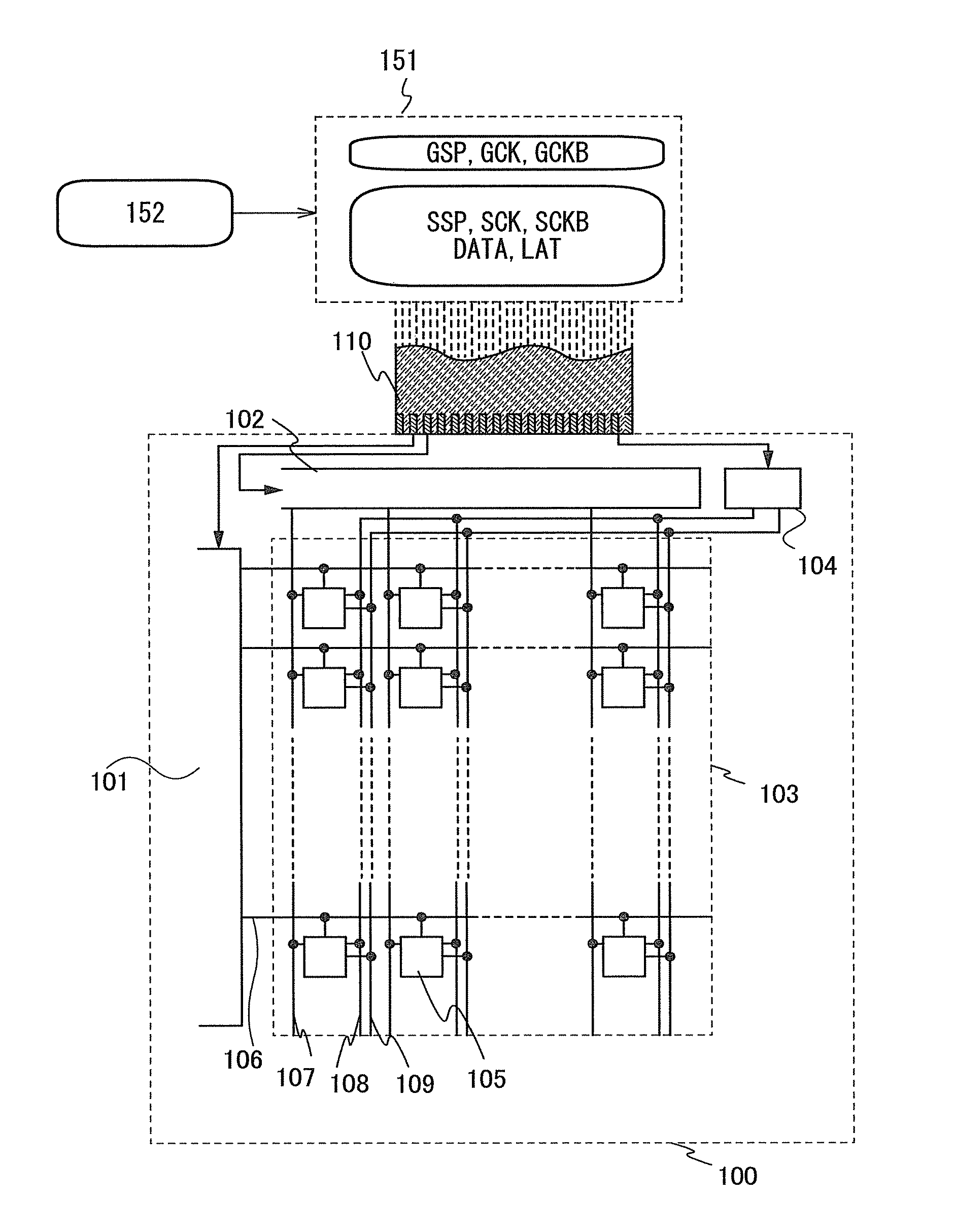

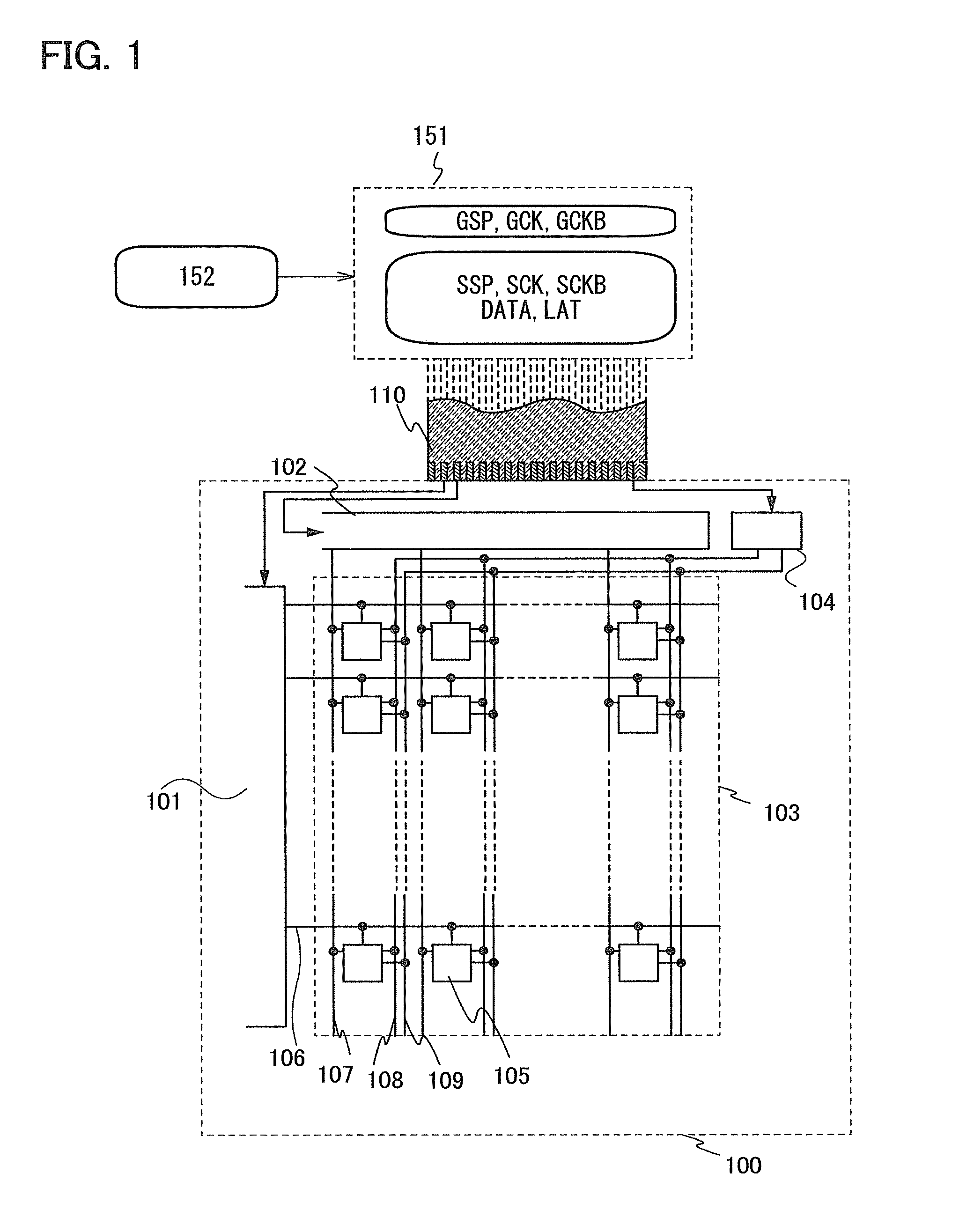

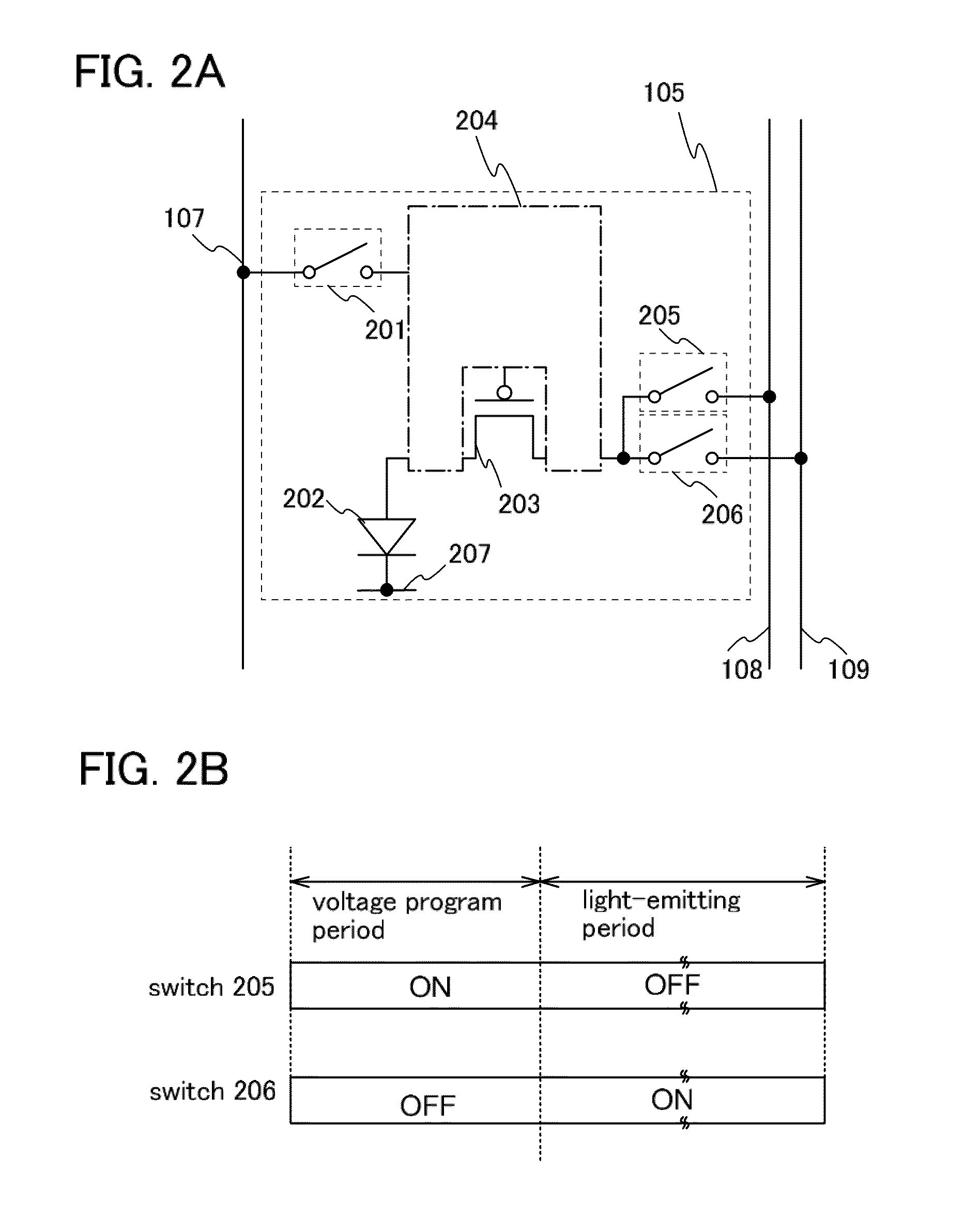

Display device, method for driving the same, and electronic device using the display device and the method

InactiveUS20100141630A1Avoid display qualityIncrease brightnessElectrical apparatusElectroluminescent light sourcesElectrical resistance and conductanceElectricity

An object is to reduce degradation of display quality due to variation in luminance of light-emitting elements, which is caused by variation in voltage because of wiring resistance of current supply lines, and to improve the display quality. In a voltage program period, a terminal serving as a source of a transistor for driving an EL element is electrically connected to a first wiring to which a first potential is supplied. In a light-emitting period, the terminal serving as the source of the driving transistor is electrically connected to a second wiring to which a second potential is supplied. Accordingly, voltage between a gate terminal and the source terminal of the driving transistor can be held without being adversely affected by wiring resistance of the current supply lines.

Owner:SEMICON ENERGY LAB CO LTD

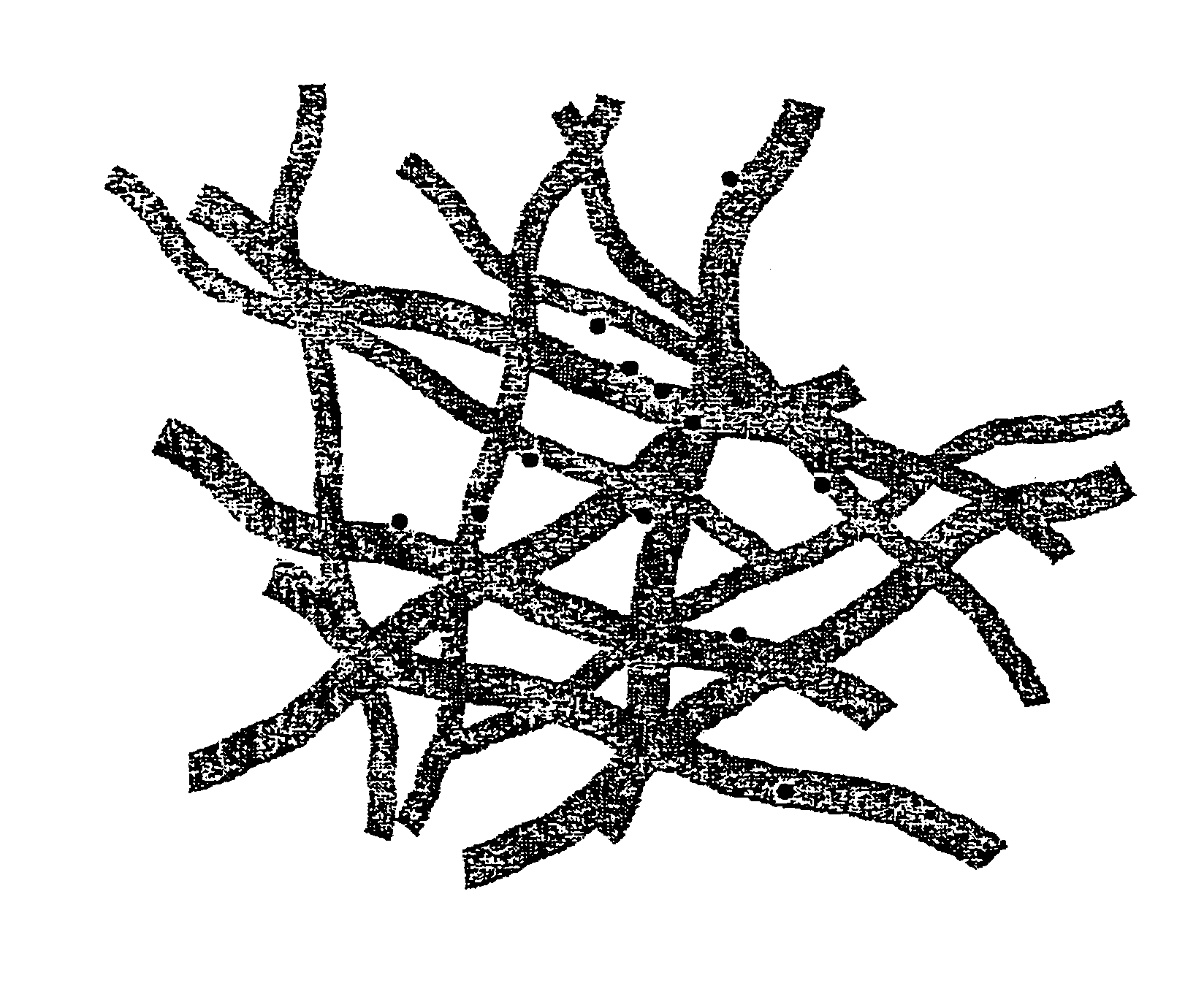

Fiber base material for wet friction material

InactiveUS20040198866A1Increased durabilityLittle thermal shrinkagePaper/cardboardFriction clutchesDecompositionIndustrial machine

A fibrous base material giving a wet frictional material used for clutch, differential gear, brake, etc. of cars, industrial machines, etc. having an excellent durability where plastic deformation of fiber and deterioration by acidic decomposition products of lubricant additives do not take place is provided. A fibrous base material for wet frictional materials which comprises a fiber component, a friction adjusting material and a filler, said fiber component containing 5 to 50% by weight of a homoacrylonitrile fiber where modulus of elasticity at 180° C. is not less than 10 cN / dtex and shrinking rate at 200° C. is within 5% and / or a homoacrylonitrile fiber in a pulp form prepared by fibrillation of said homoacrylonitrile fiber.

Owner:JAPAN EXLAN CO LTD

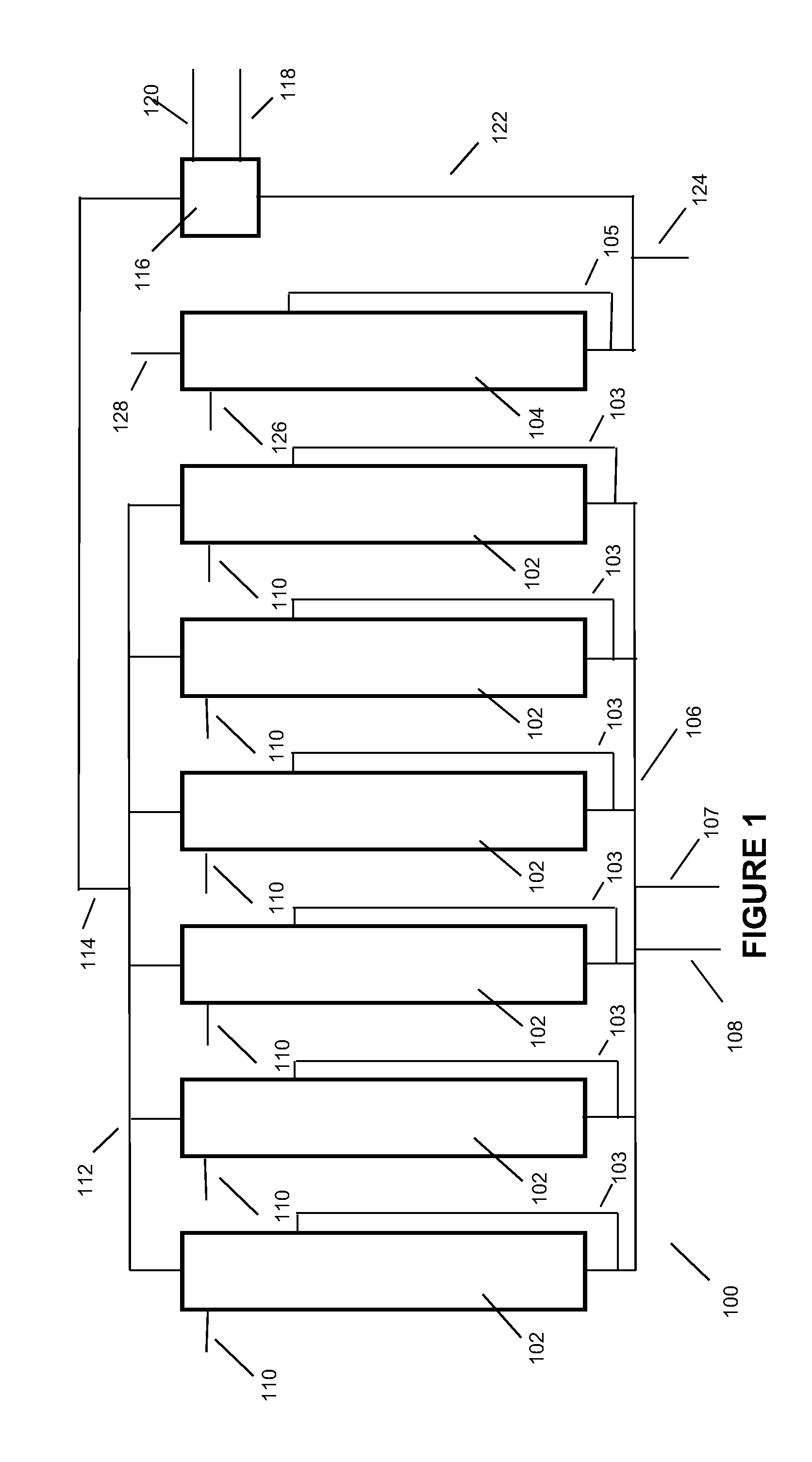

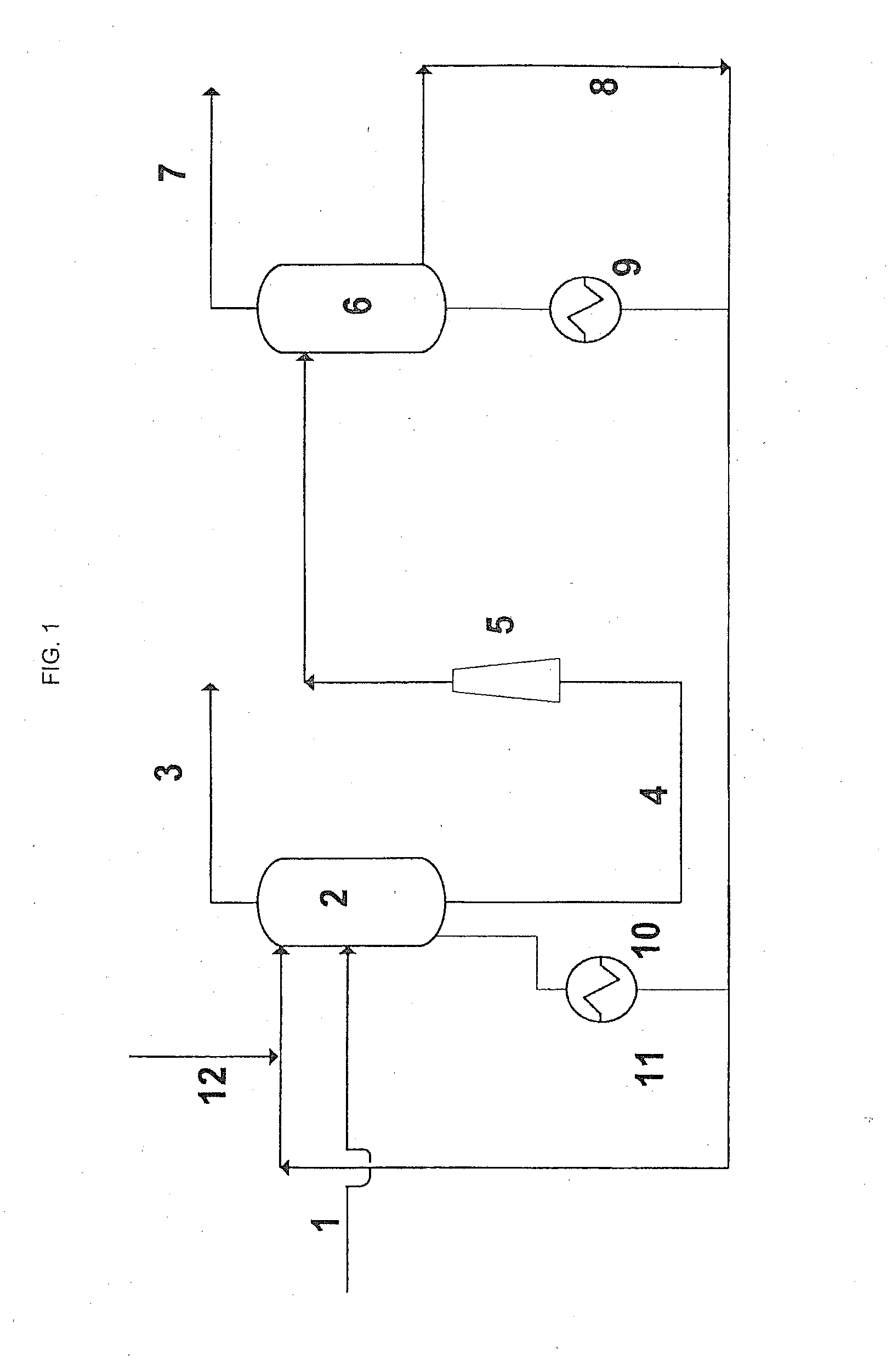

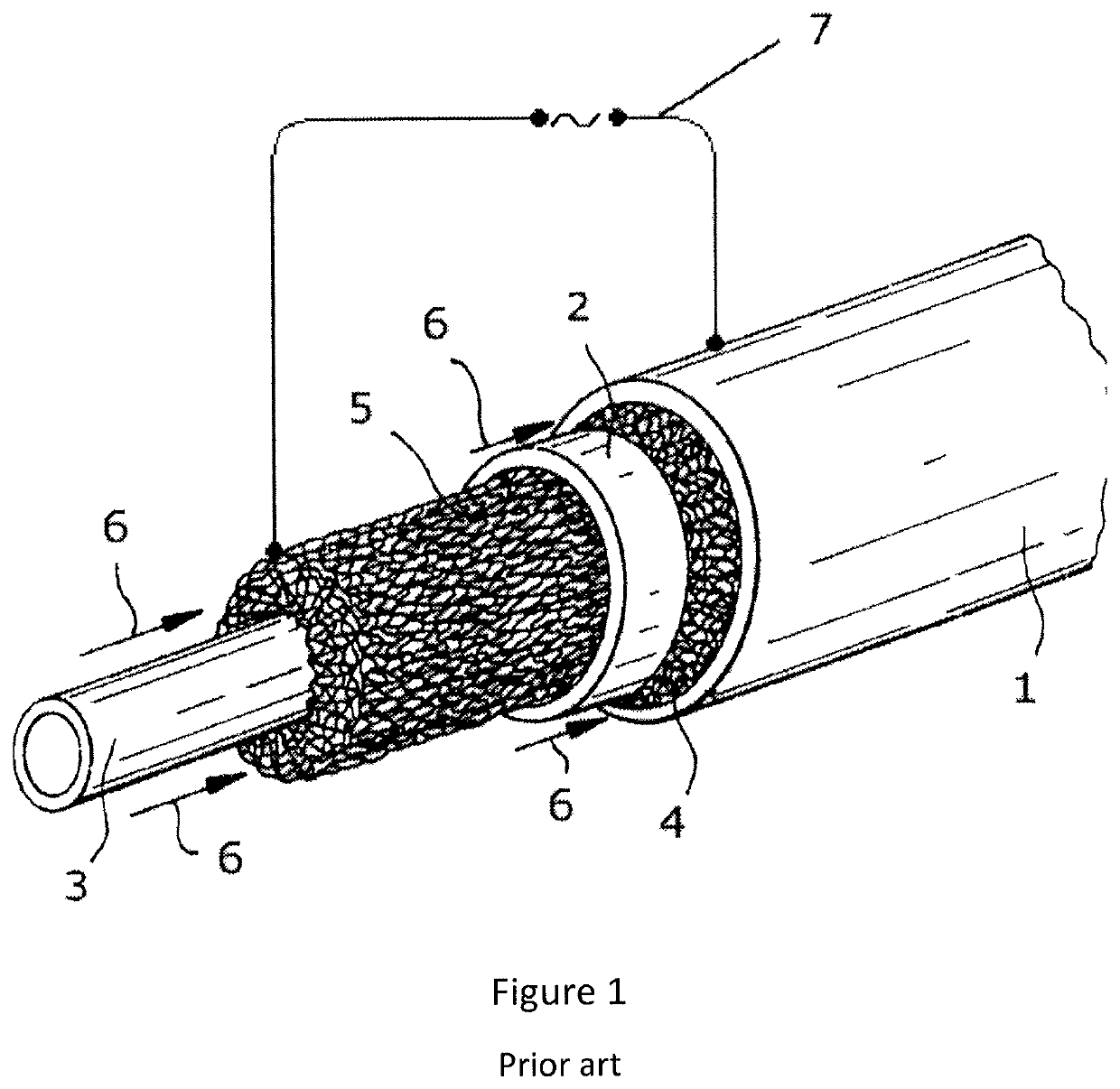

Low energy, high substrate efficiency, anaerobic, deep, bubble column fermentation processes

ActiveUS20130078688A1High conversion of carbon monoxideRisk minimizationBiofuelsChemical recyclingSimple Organic CompoundsHydrogen

Bioconversion processes are disclosed that enable high conversion efficiencies of gas substrate containing both carbon monoxide and hydrogen to oxygenated organic compounds via the carbon monoxide and hydrogen pathways using anaerobic, deep, bubble column fermentation in a cost effective manner. The high conversion efficiency processes of this invention comprise the combination of using at least two deep, bubble column reactors in flow series and using certain feed gas compositions and microbubbles while avoiding carbon monoxide inhibition.

Owner:SYNATA BIO INC

Method and system for achieving heart rate variability coherence during exercise

InactiveUS20050240114A1Optimal psycho-physiological performanceImprove performanceGymnastic exercisingRespiratory organ evaluationRR intervalPhysiology

The invention provides a method and system for bringing an exercising human subject to the state of optimal psycho-physical functioning, in effect the “runner's high”, by facilitating the state of heart rate variability coherence while the subject is exercising. This is achieved by synchronization of the varying breathing cycle with the varying heart rate variability cycle. This is accomplished by providing a biofeedback signal to the exercising subject indicating when to begin inhalation and when to begin exhalation. Additionally, the human subject is provided with a programmable tempo that is in keeping with the heart rate variability cycle to which their physical motion may be synchronized. An instructive method in the optimal application of the present invention is also provided.

Owner:COHERENCE

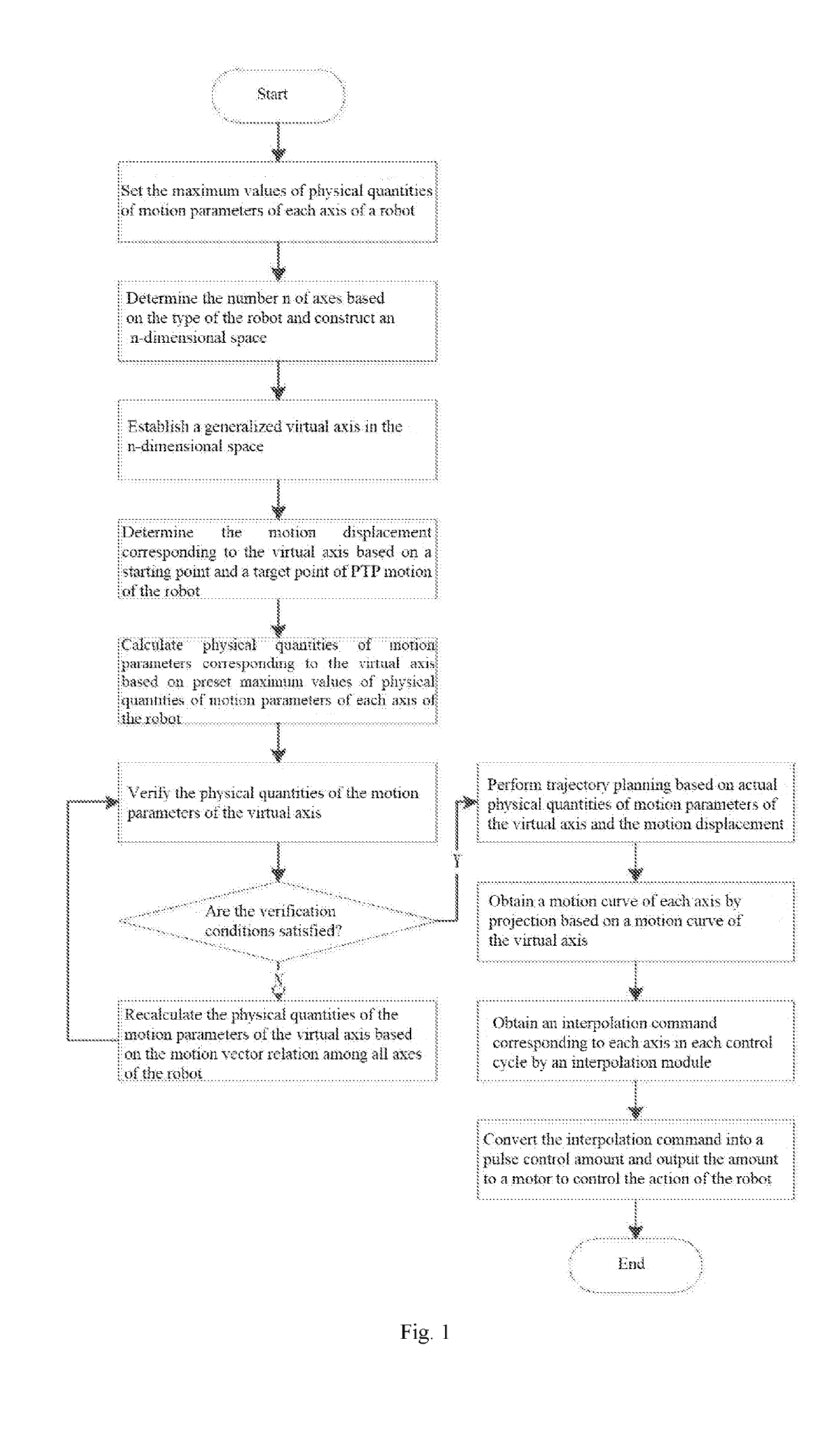

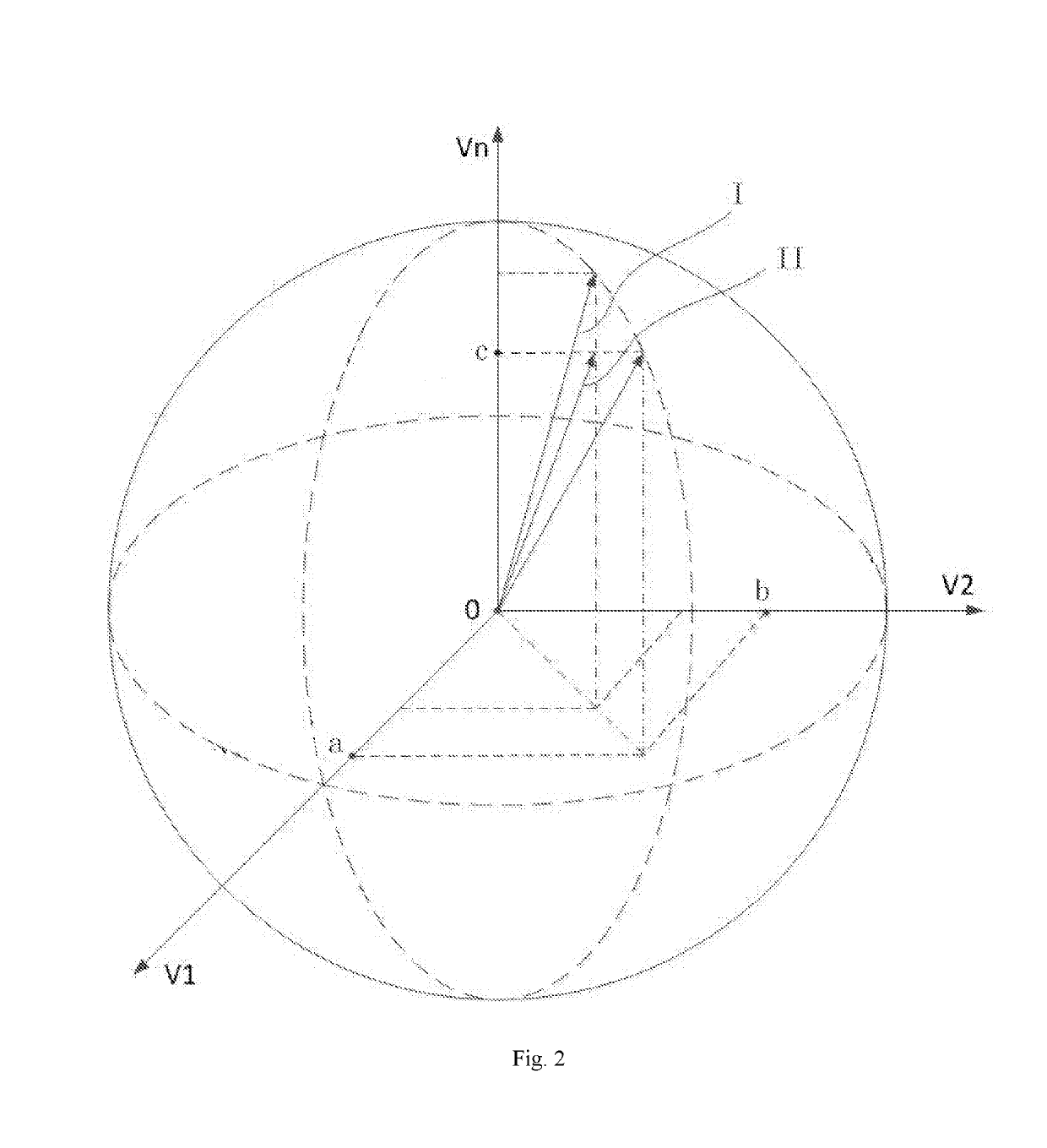

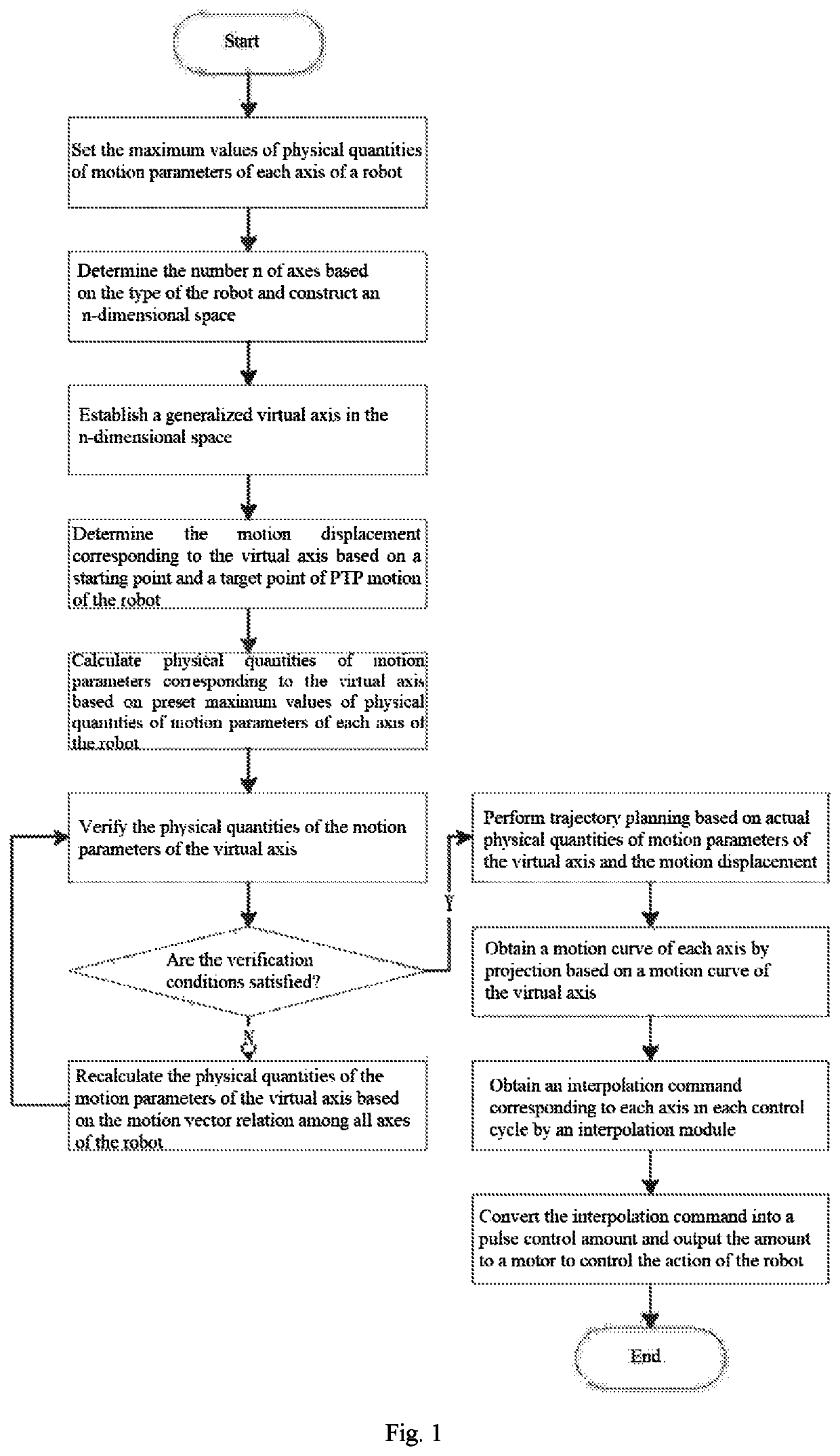

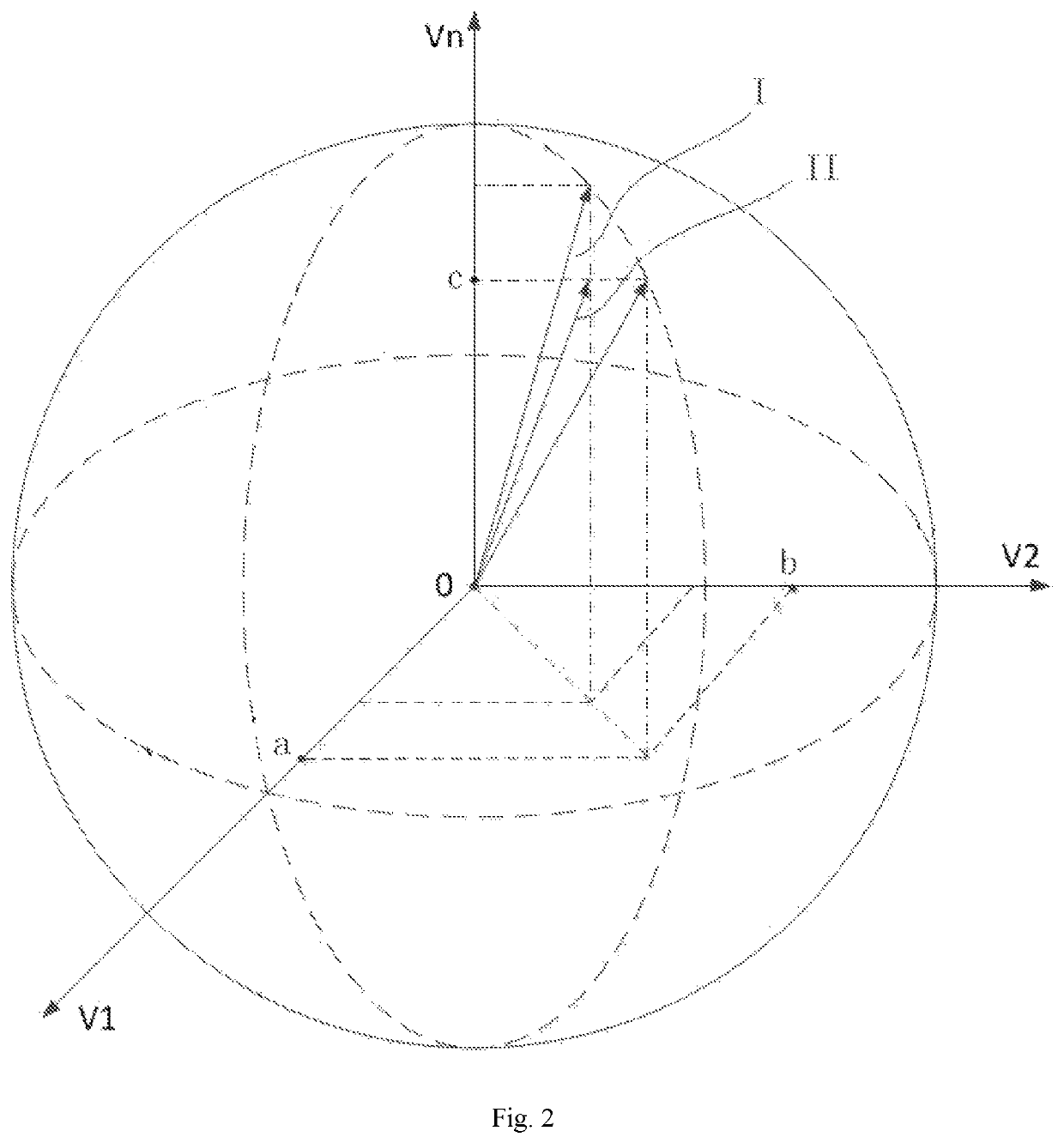

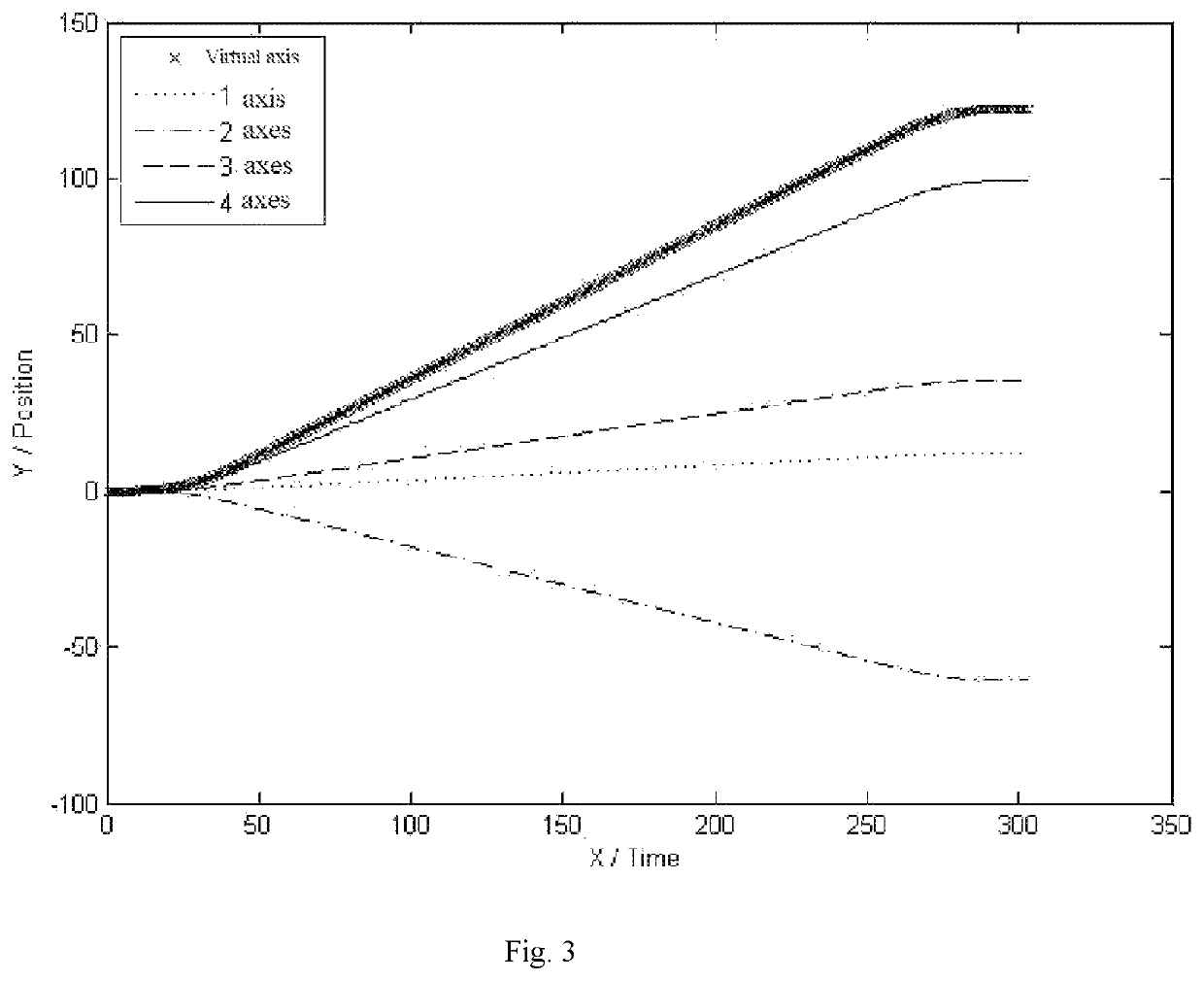

Robot joint space point-to-point movement trajectory planning method

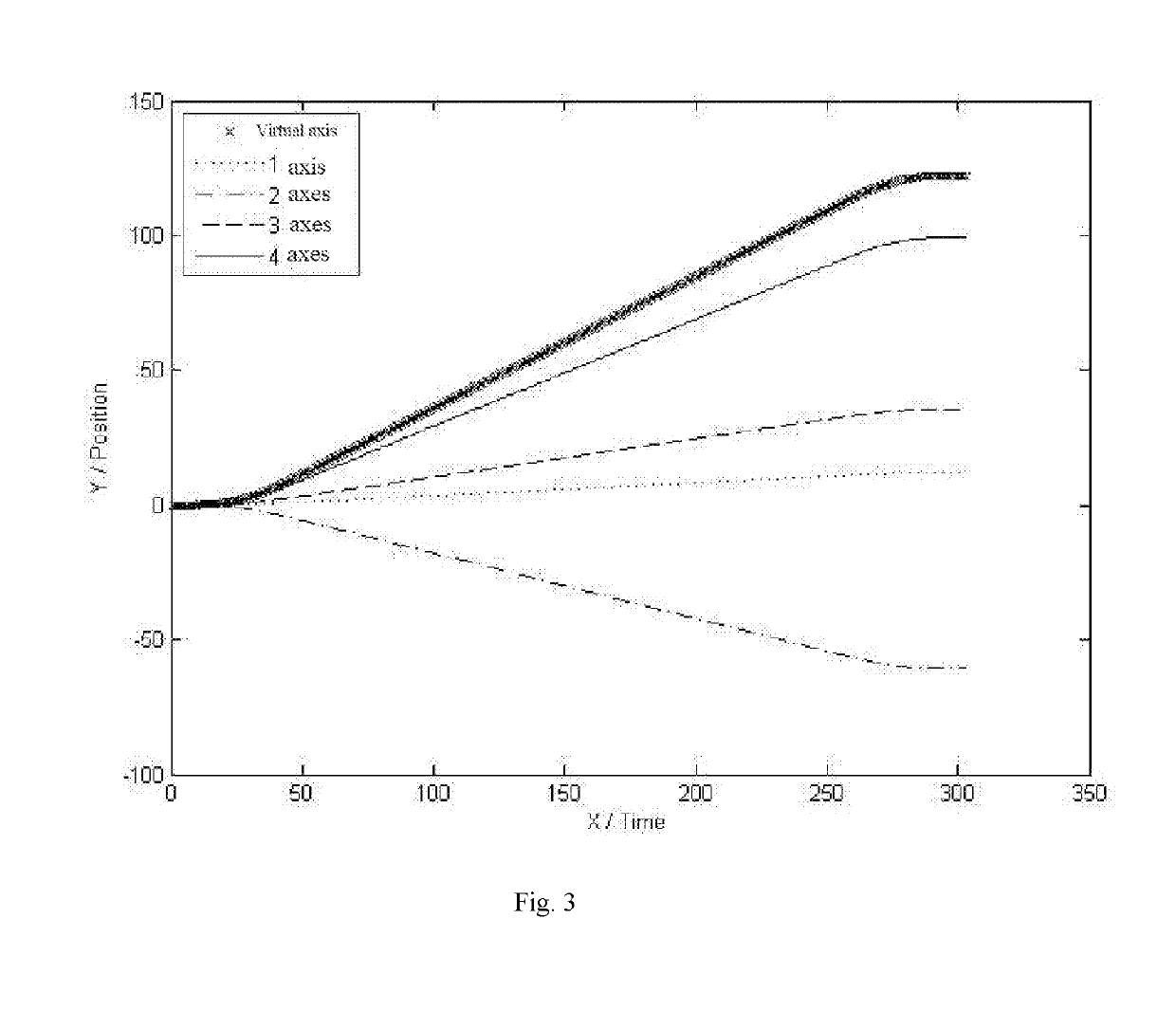

ActiveUS20190160674A1Easy to operateSatisfy constraintsProgramme-controlled manipulatorNumerical controlControl systemPlanning approach

A robot joint space point-to-point movement trajectory planning method. Joint space trajectory planning is performed according to the displacement of a robot from a start point to a target point during PTP movement and a limitation condition of a preset movement parameter physical quantity of each axis in a robot control system. An n-dimensional space is constructed by taking each axis of the robot as a vector, wherein n ≥2, and the movement parameter physical quantity of each axis of the robot is verified according to a vector relationship between the n axes of the robot, so that a trajectory planning curve of each axis of the robot satisfies the limitation condition of the preset movement parameter physical quantity. The method has a small amount of calculations and strong real-time performance, the movement curves are mild, the control time is optimal, and the algorithm execution effect is good.

Owner:NANJING ESTUN ROBOTICS CO LTD

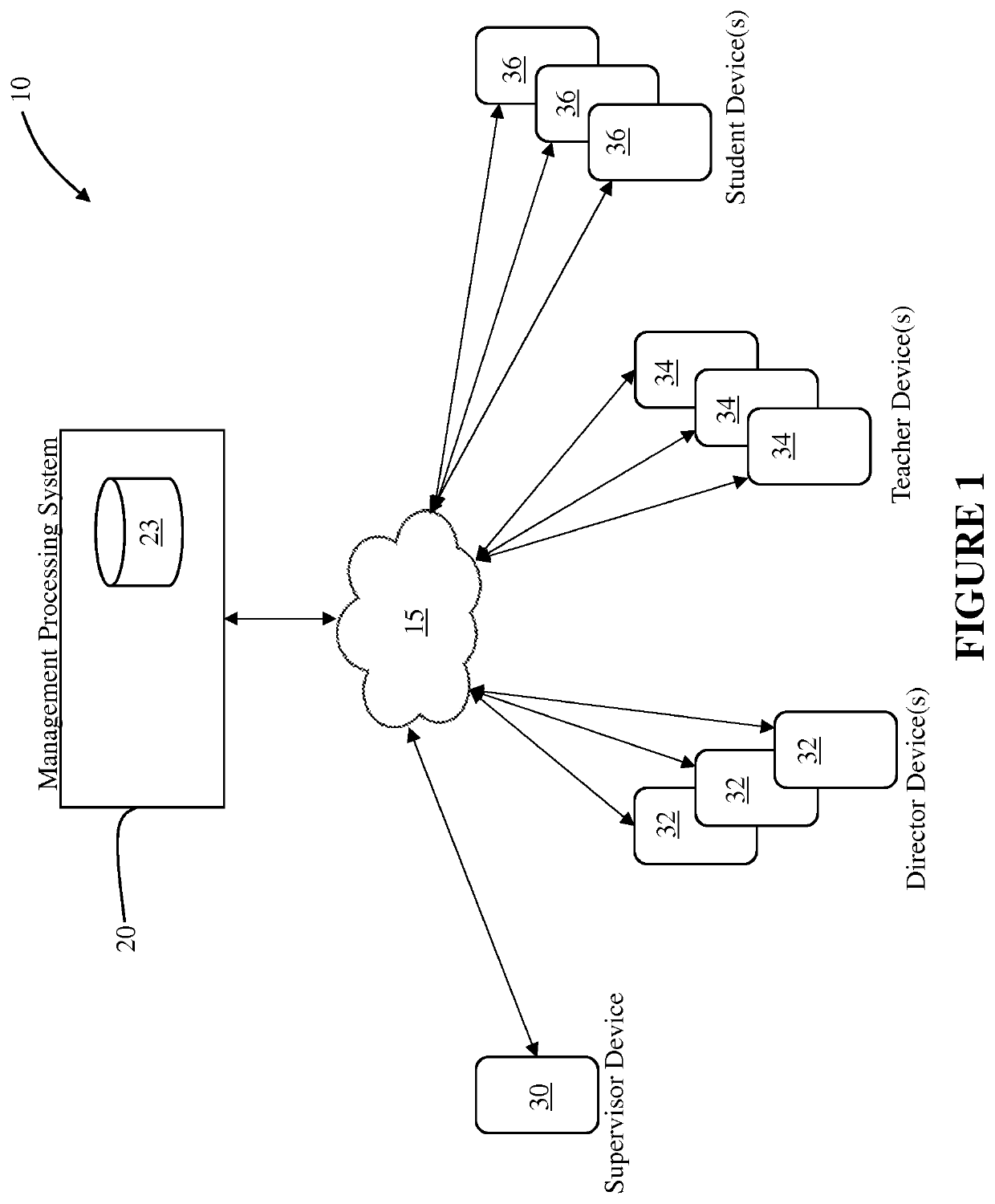

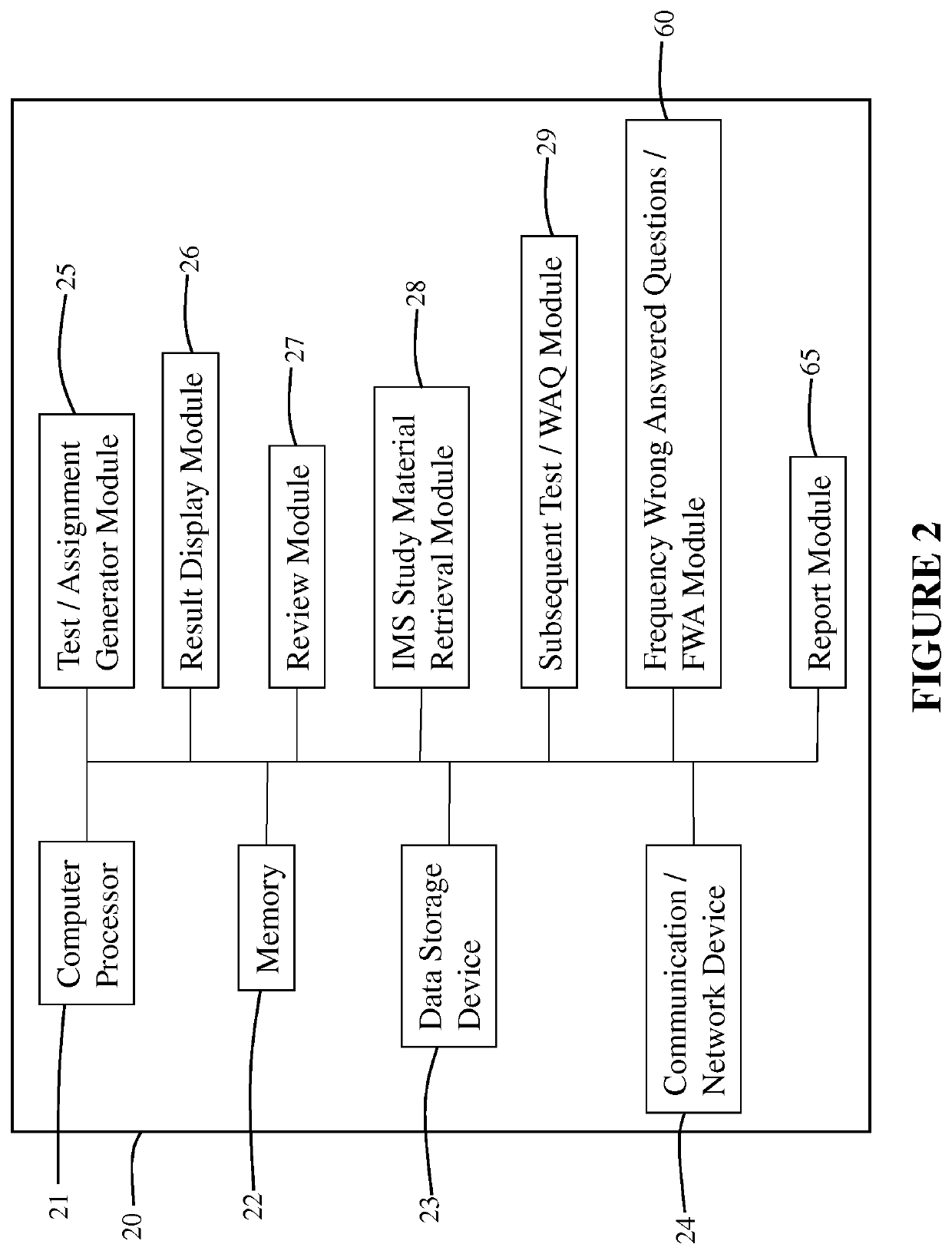

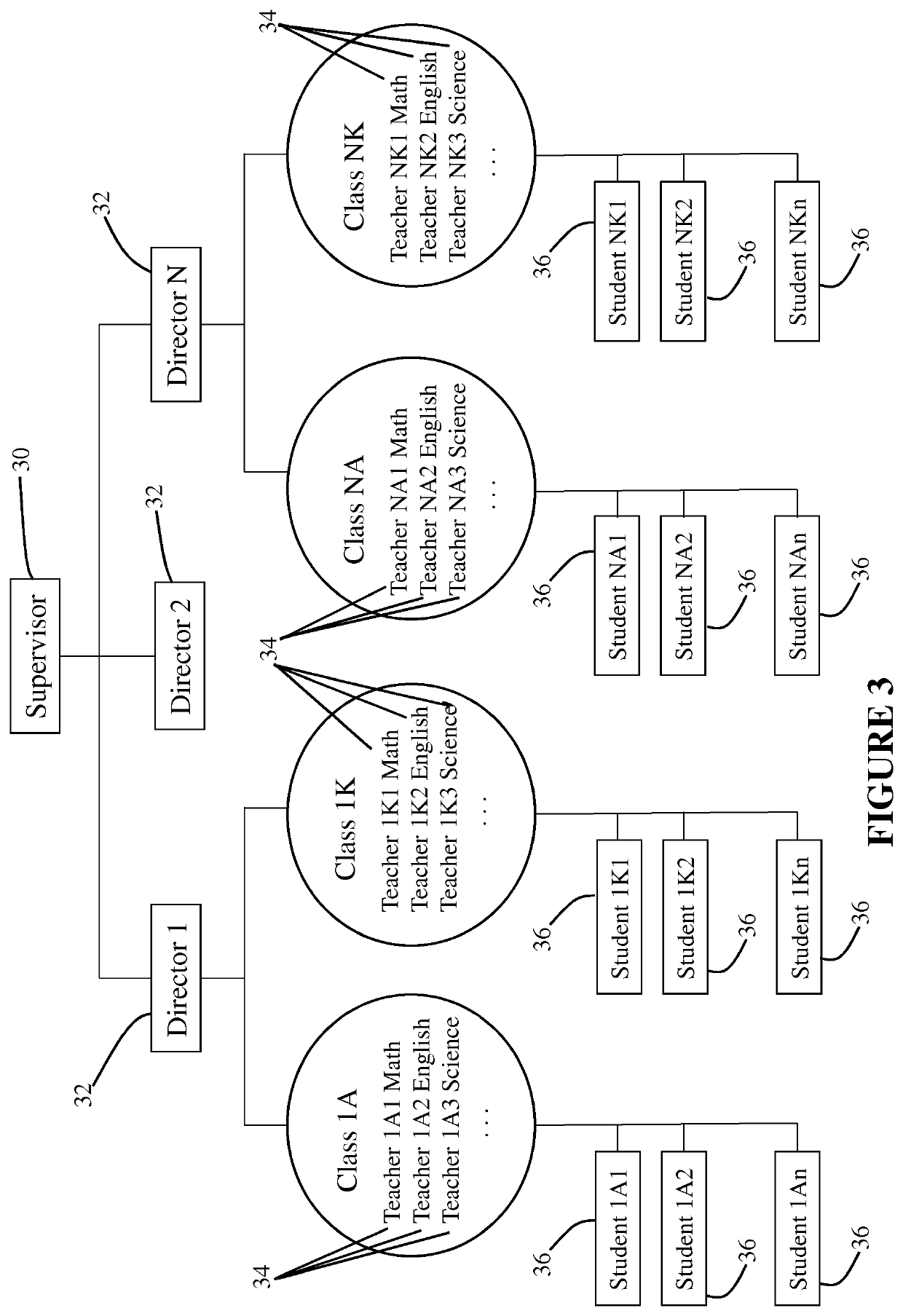

Online test taking and study guide system and method

ActiveUS10679512B1Reduces and eliminates needRemoval costElectrical appliancesOnline testEngineering

A system and method for presenting an online study guide and testing program is presented herein. In particular, the system and method includes a plurality of test questions stored within a database or question bank and a plurality of testing materials corresponding to subject areas, topics, and specific categories. Each of the test questions are coded or otherwise include a study code associated therewith, the study code representing a particular subject area, category or sub-category. Similarly, the study materials are also coded to represent a subject area, category, or sub-category. Accordingly, once a student has completed a test or assignment, the system and method will automatically detect the student's weak areas via wrong answered questions and provide the study code. The student can then obtain study materials relating to that study code in order to advance his or her knowledge in those weak areas.

Owner:YANG TERRY

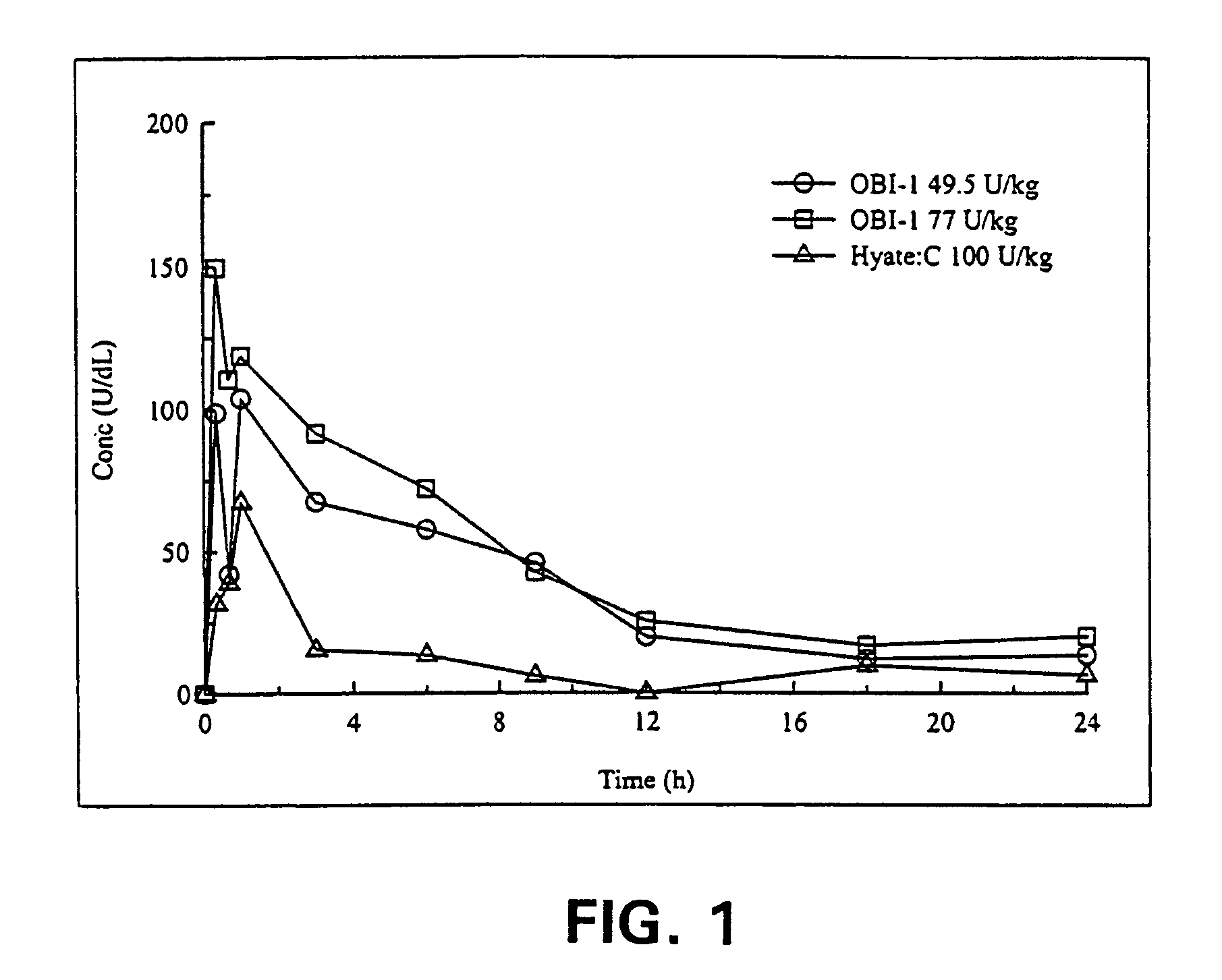

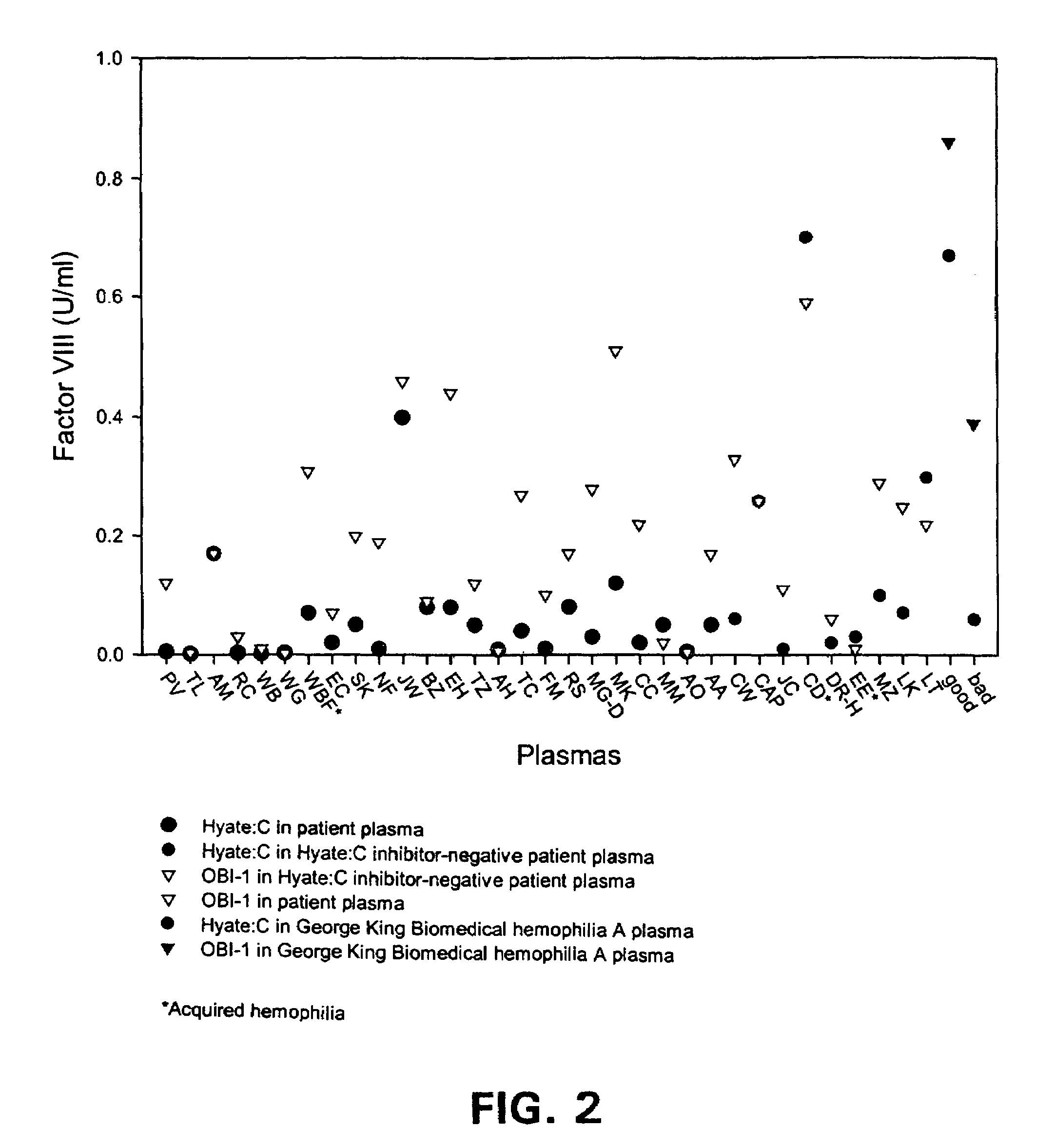

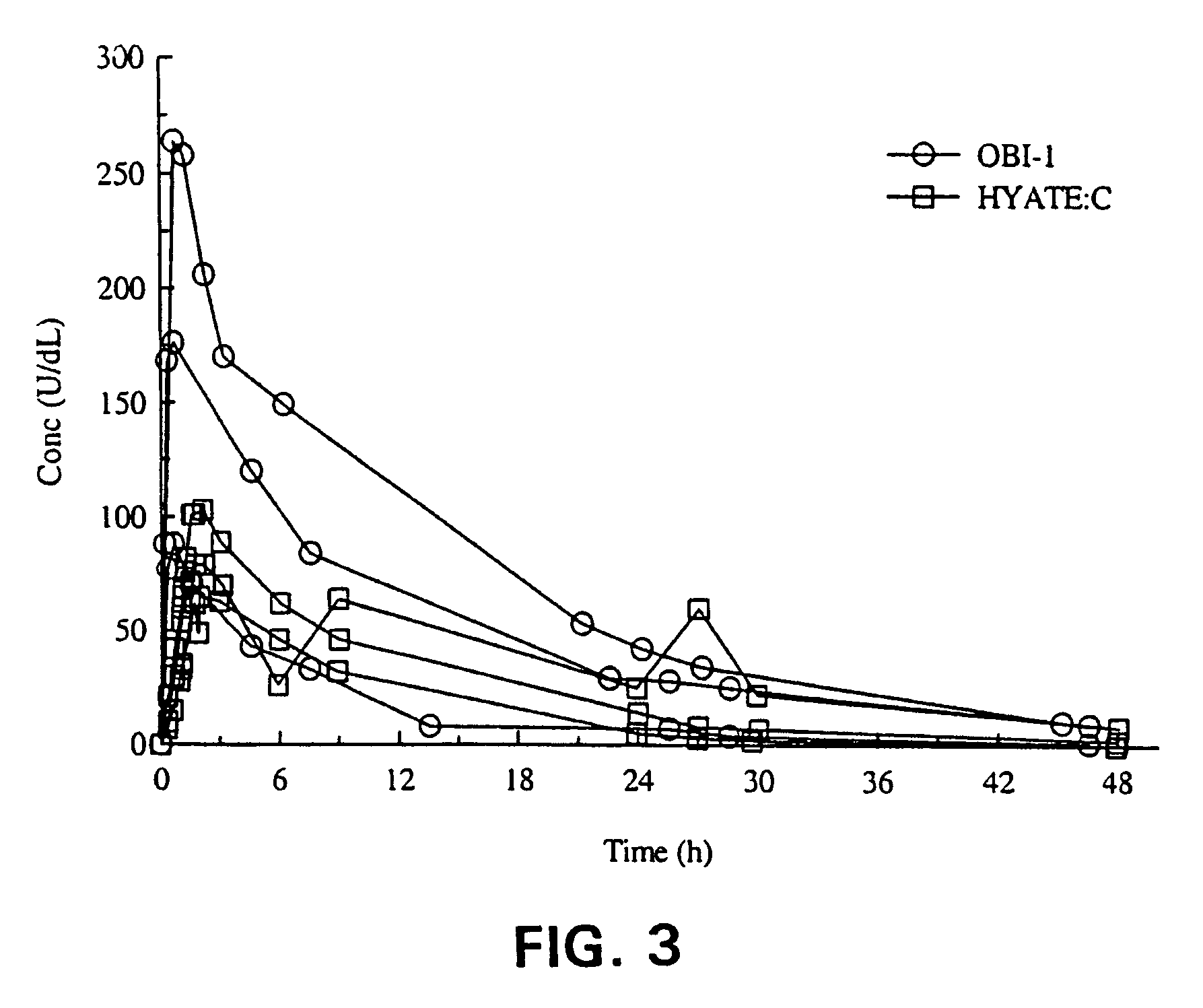

Method of administering porcine B-domainless fVIII

ActiveUS7576181B2Improve bioavailabilityQuick controlFactor VIIPeptide/protein ingredientsFactor VIII deficiencyMedicine

The present invention provides a method of administering porcine B-domainless factor VIII (OBI-1) to a patient having factor VIII deficiency to provide more rapid and effective protection against bleeding episodes, compared to formerly available methods, or to provide more effective protection to such patients during non-bleeding periods. This invention is based on the discovery that the recombinant B-domainless porcine fVIII, termed OBI-1, has greater bioavailability compared to the natural porcine fVIII partially purified from porcine plasma, termed HYATE:C. Therefore, the inventive method employs lower unit doses of OBI-1, including, alternatively, omission of antibody-neutralizing dosage, or has longer intervals between the administration, compared to HYATE:C, to provide equivalent protection in patients having fVIII deficiency. The invention further provides pharmaceutical compositions and kits containing OBI-1 in combination with a pharmaceutically acceptable carrier, that are useful for treating patients in need of fVIII more effectively.

Owner:EMORY UNIVERSITY +1

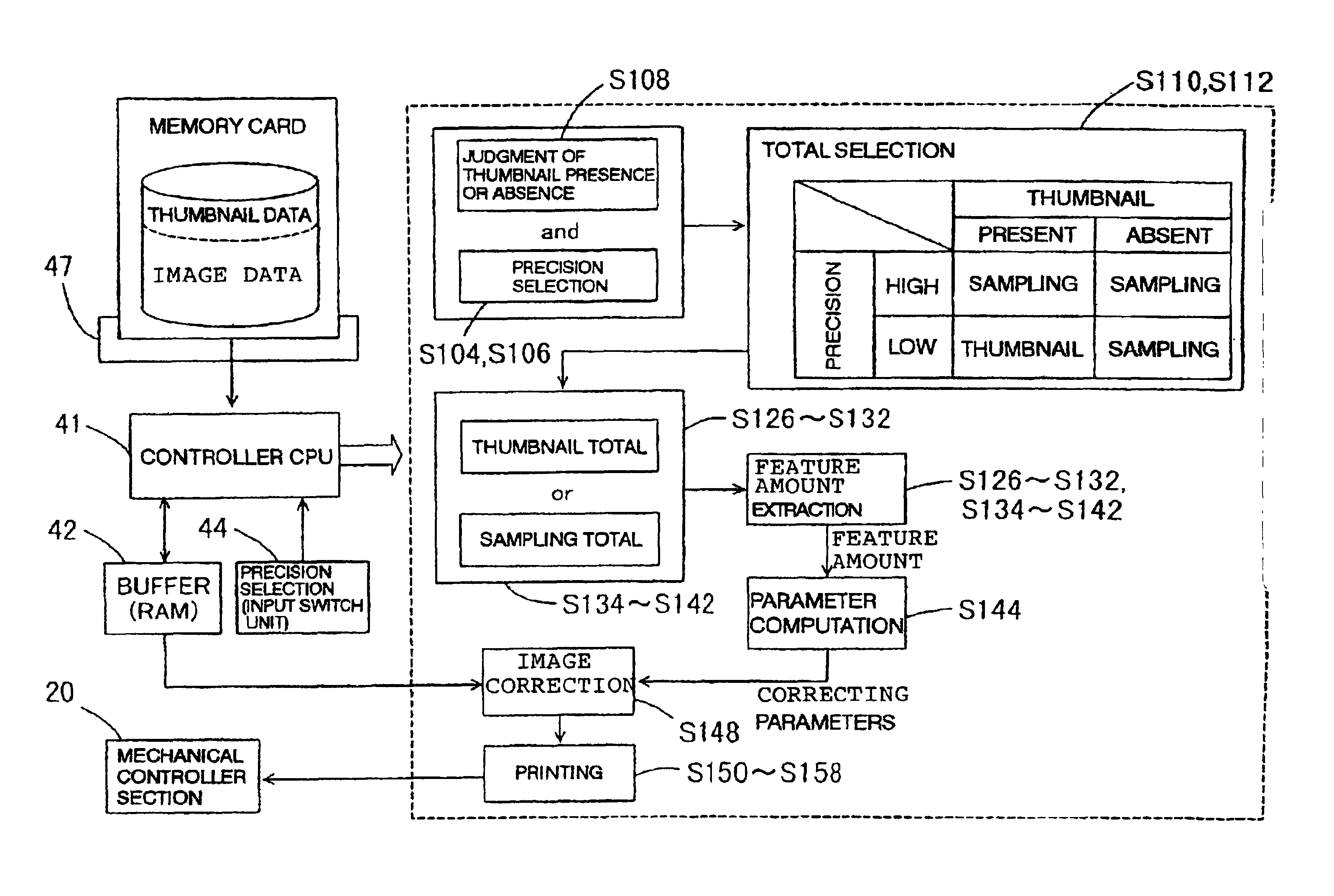

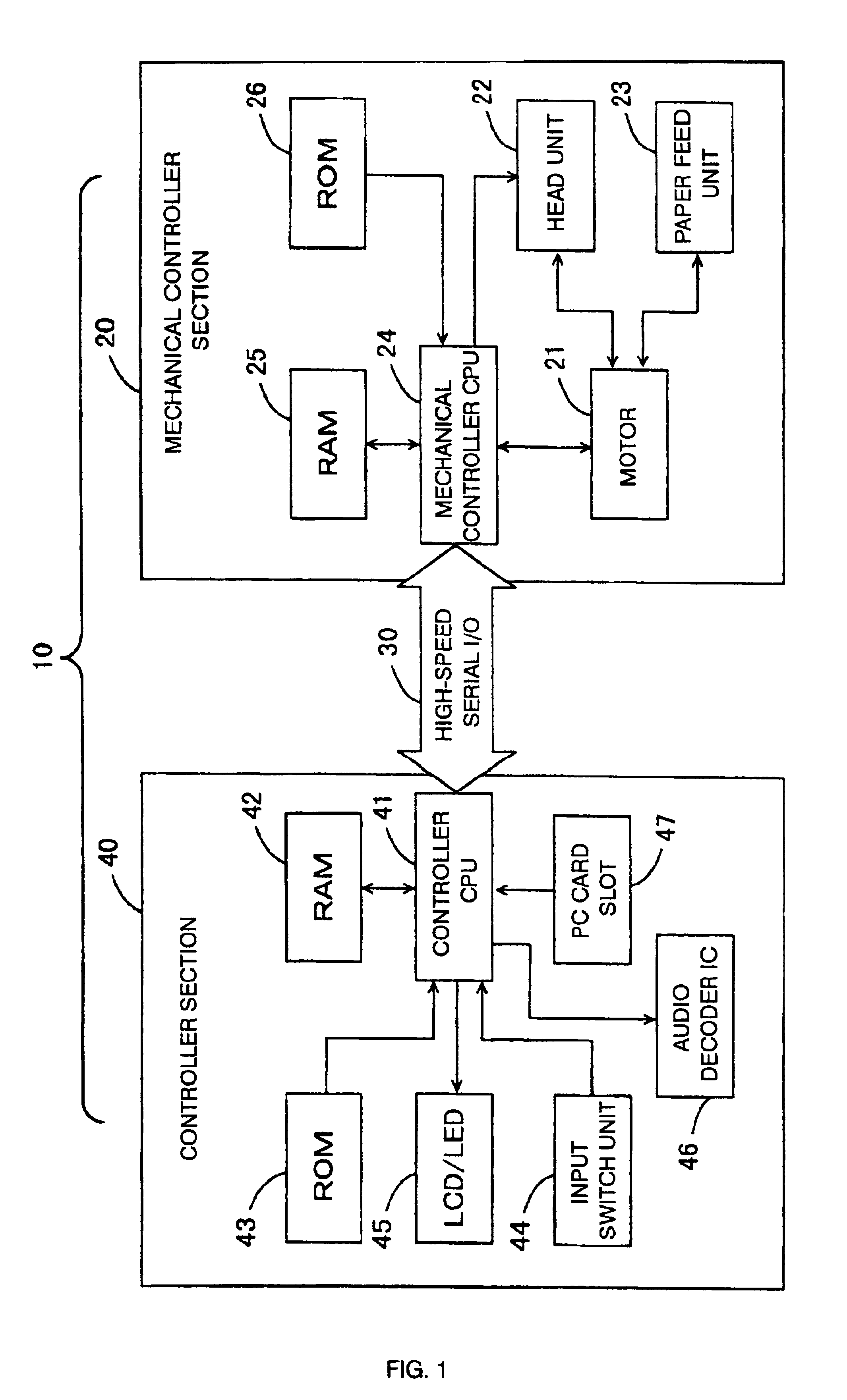

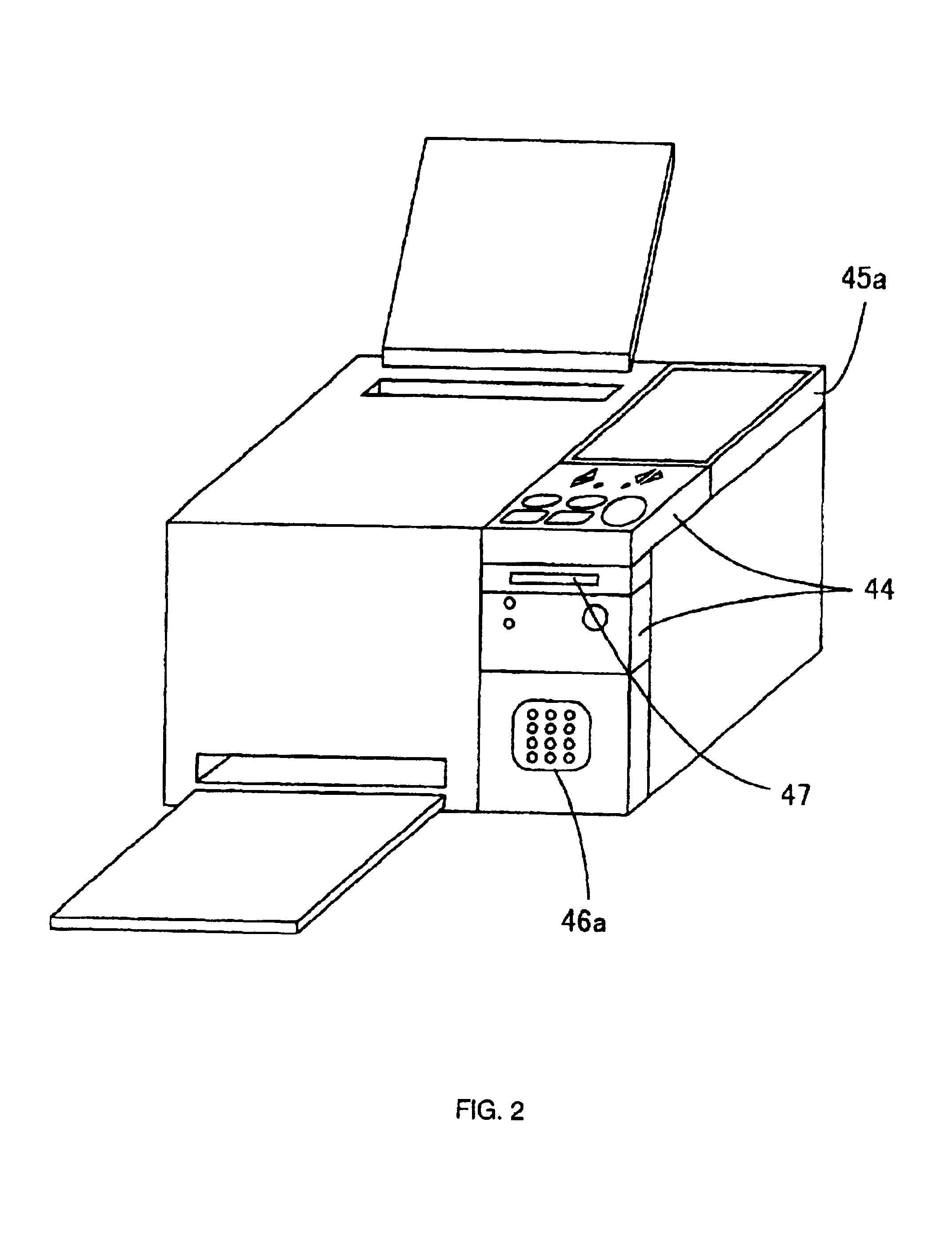

Apparatus and method for image feature amount acquisition and medium recording image feature amount acquisition program, apparatus and method for image correction and medium recording image correcting program, and printing apparatus and method and medium recording printing program

InactiveUS6947169B2Volume of thumbnail data to be readShorten the timeDigitally marking record carriersDigital computer detailsPattern recognitionImage correction

As image data have come to be used in large volumes in recent years, statistical calculation processing of restored and sampled image data often suffers a shortage of memory capacity. In acquiring a feature amount of an image to automatically correct image data, where high-speed processing is preferred, it is judged whether the image data contain thumbnail data (step 108) and, when there are thumbnail data, “thumbnail” is set on a sampling flag (step 110) to secure a buffer for developing the thumbnail data (step 116 and step 120), the thumbnail data are developed in the buffer, and all the pixels are subjected to statistical calculation (step 126 through step 132), resulting in faster processing than where the original image data are developed and sampled.

Owner:SEIKO EPSON CORP

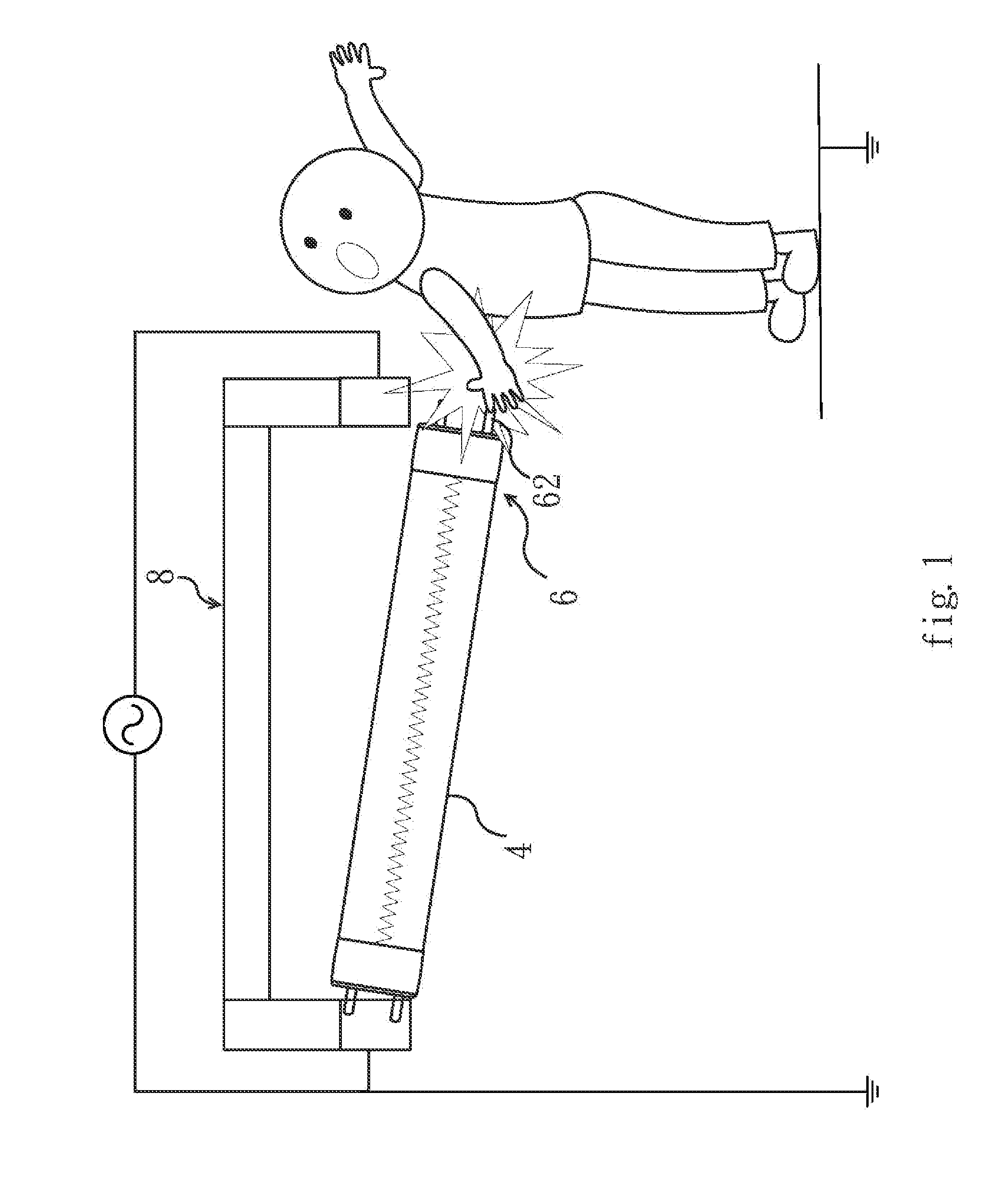

Safety lamp

InactiveUS20120235556A1Eliminate security concernsEasy to useCoupling device connectionsDischarge tube luminescnet screensElectricityEngineering

Owner:ADVANCED CONNECTEK INC

Recovery of benzene and benzene derivatives from gasoline fractions and refinery streams

InactiveUS20130345486A1Improved propertyAdequate shiftingDistillation purification/separationHydrocarbonsAlkaneExtractive distillation

A process for the separation of the aromatic compounds benzene, toluene and xylene from an aromatics-containing reformate gasoline and pyrolysis gasoline or a coke-oven light oil or an aromatics-containing refinery stream, in which the aromatics are separated by an extractive distillation uses a novel solvent combination made up of the compounds n,n′-diformyl piperazine or 2,2-bis-(cyanoethyl)ether in a combination with n-formyl morpholine as a second solvent for extractive distillation so that the solvent combination obtained shows a higher selectivity with regard to the aromatics to be extracted so that a lower solvent load is required. The aromatics-containing feed mixture is first submitted to a pre-distillation so that the obtained fraction has a narrow boiling point range. This fraction is then submitted to an extractive distillation in a first column, in which an aromatics-lean head product of predominantly paraffinic hydrocarbons is obtained as well as an aromatics-enriched bottom product. The bottom product is passed to a second column in which an aromatics-rich raffinate is obtained by reducing the pressure or increasing the temperature so that the extracting solvent combination obtained as bottom product can be recycled into the process.

Owner:UHDE GMBH

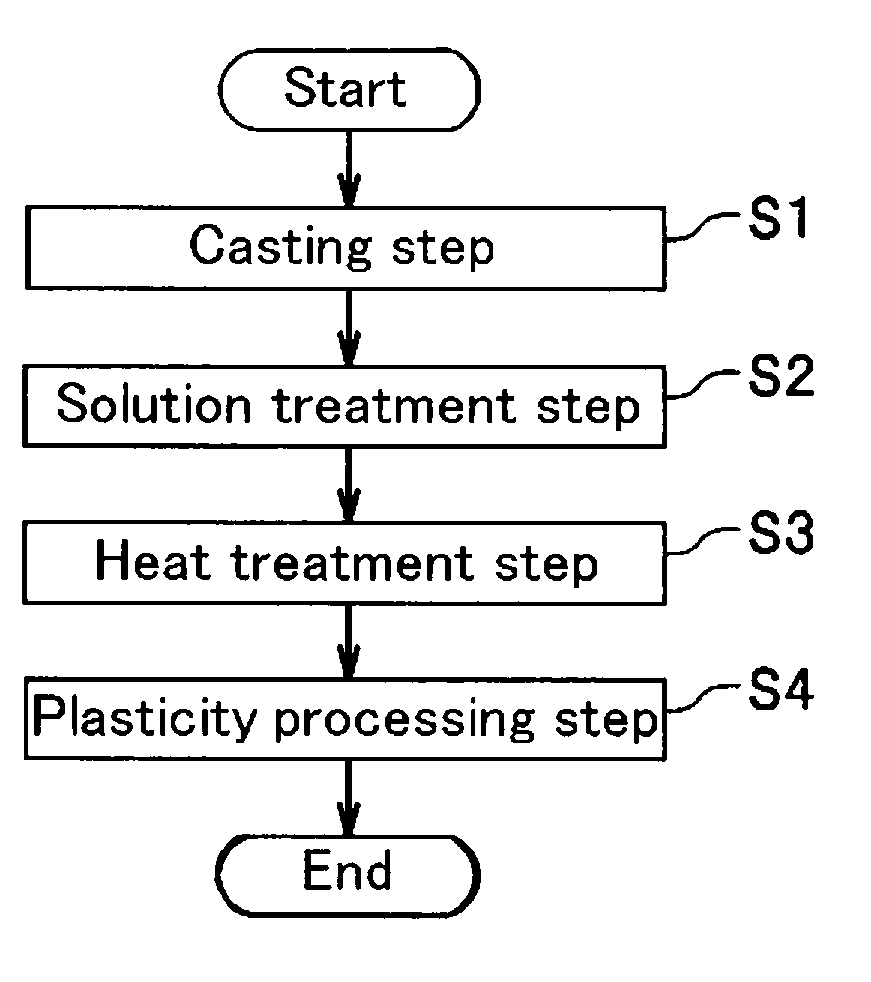

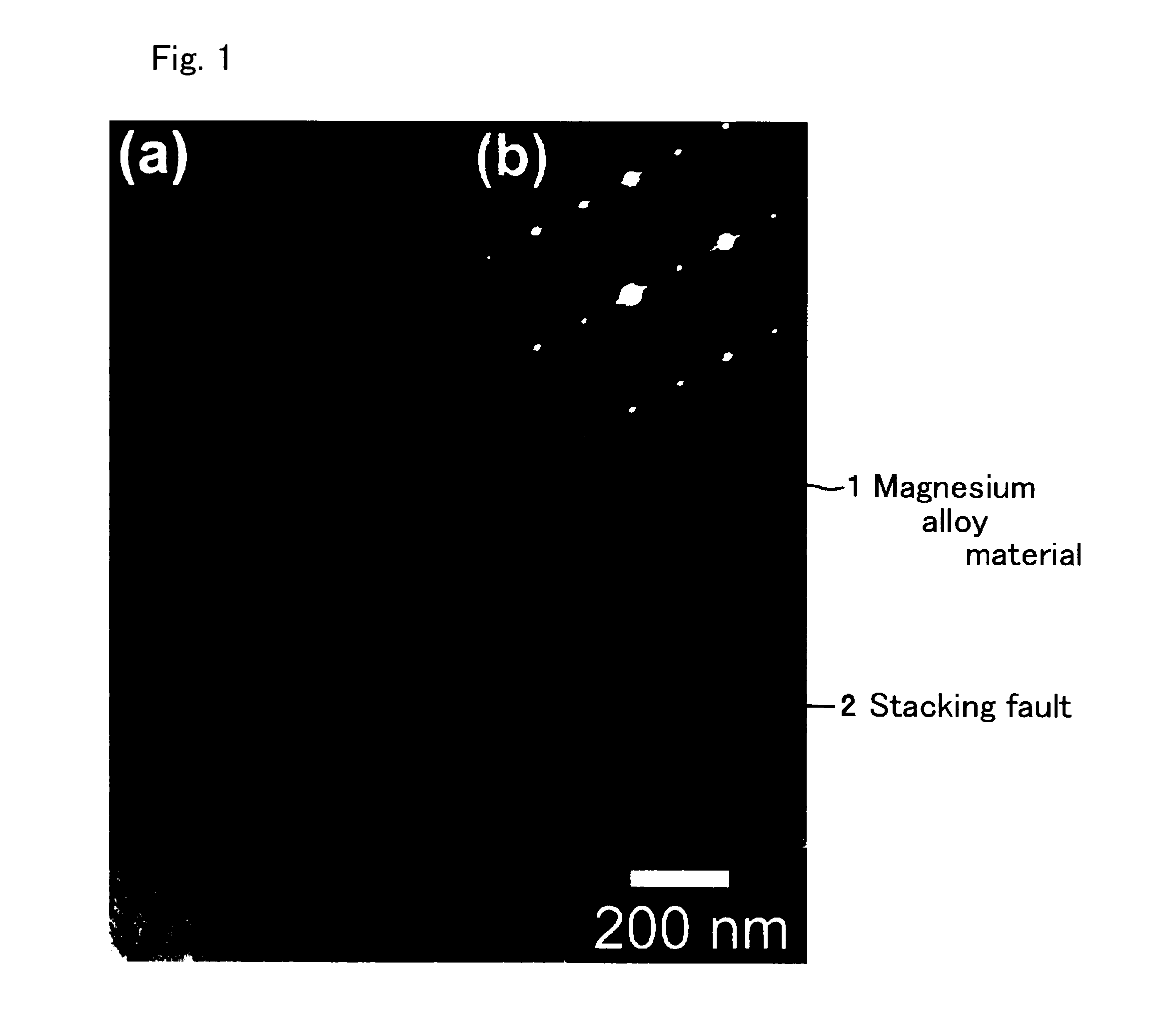

Magnesium alloy material and method for manufacturing the same

InactiveUS20100206438A1Good effectImprove featuresHeat treatment process controlSolution treatmentStacking fault

The present invention provides a magnesium alloy material excellent in mechanical properties without using specific manufacturing facilities and processes and a method of manufacturing the same. The magnesium alloy material is an Mg—Zn—RE alloy containing, as an essential component, Zn and at least one of Gd, Tb, and Tm as RE, and of the rest including Mg and unavoidable impurities, and has stacking faults of a thickened two-atomic layer of Zn and RE in the alloy structure of the Mg—Zn—RE alloy. A method of manufacturing a magnesium alloy material involves a casting step, a solution treatment step, and a heat treatment step and the heat treatment step is carried out in a condition satisfying −14.58 [ln(x)]+532.32<y<−54.164 [ln(x)]+674.05 and 0<x≦2, wherein y denotes the heat treatment temperature (K) and x denotes the heat treatment time (h).

Owner:KOBE STEEL LTD +2

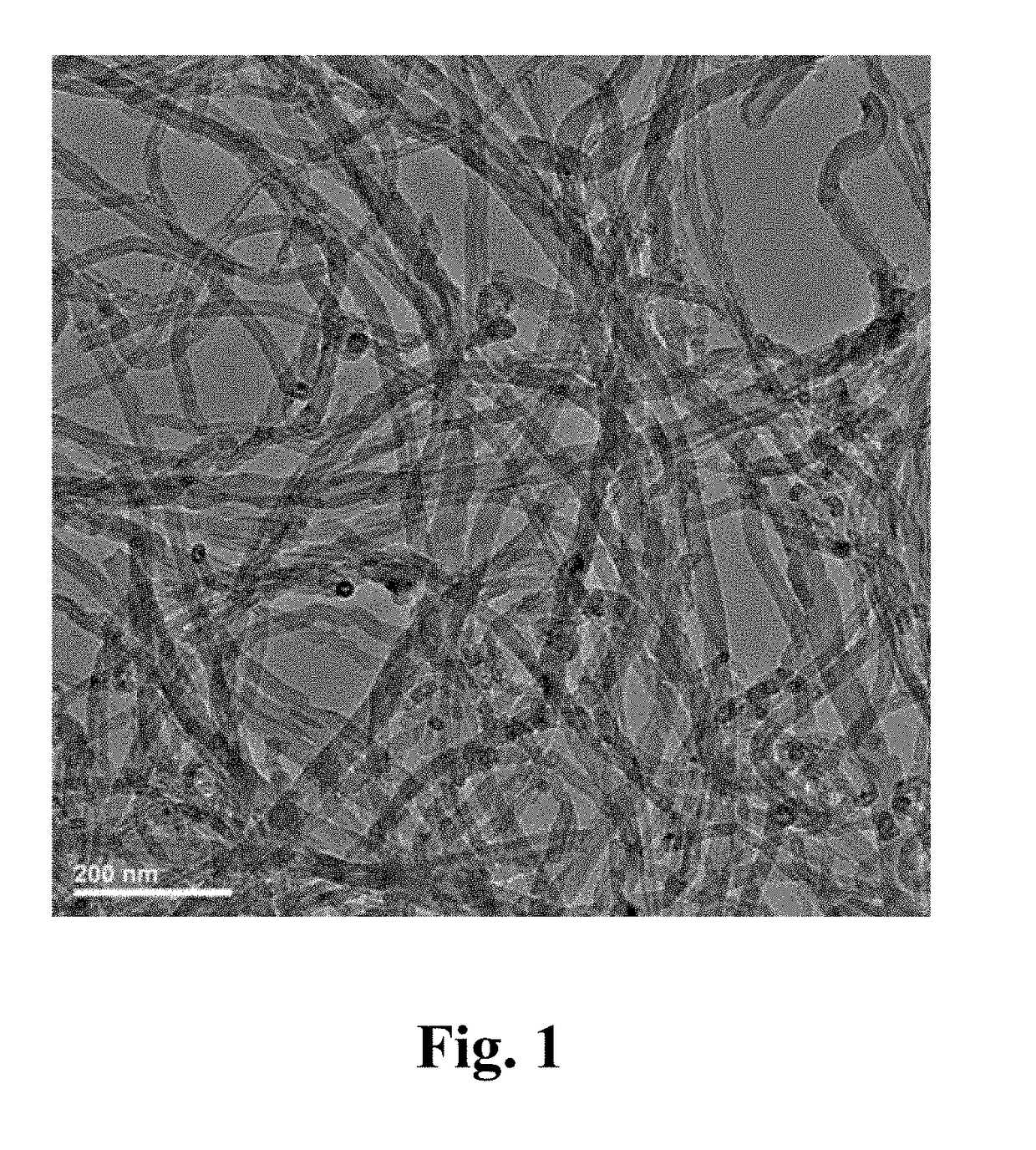

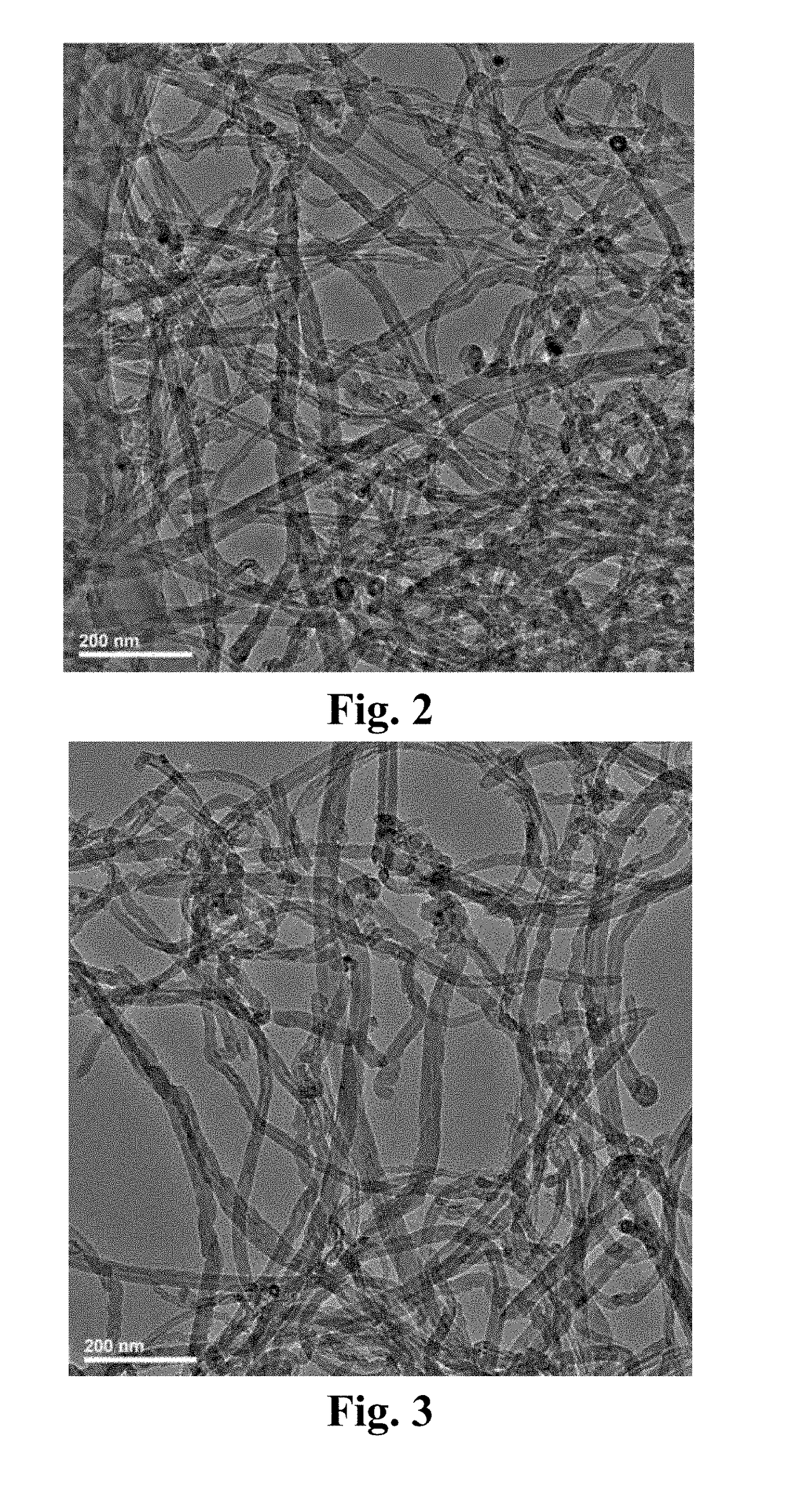

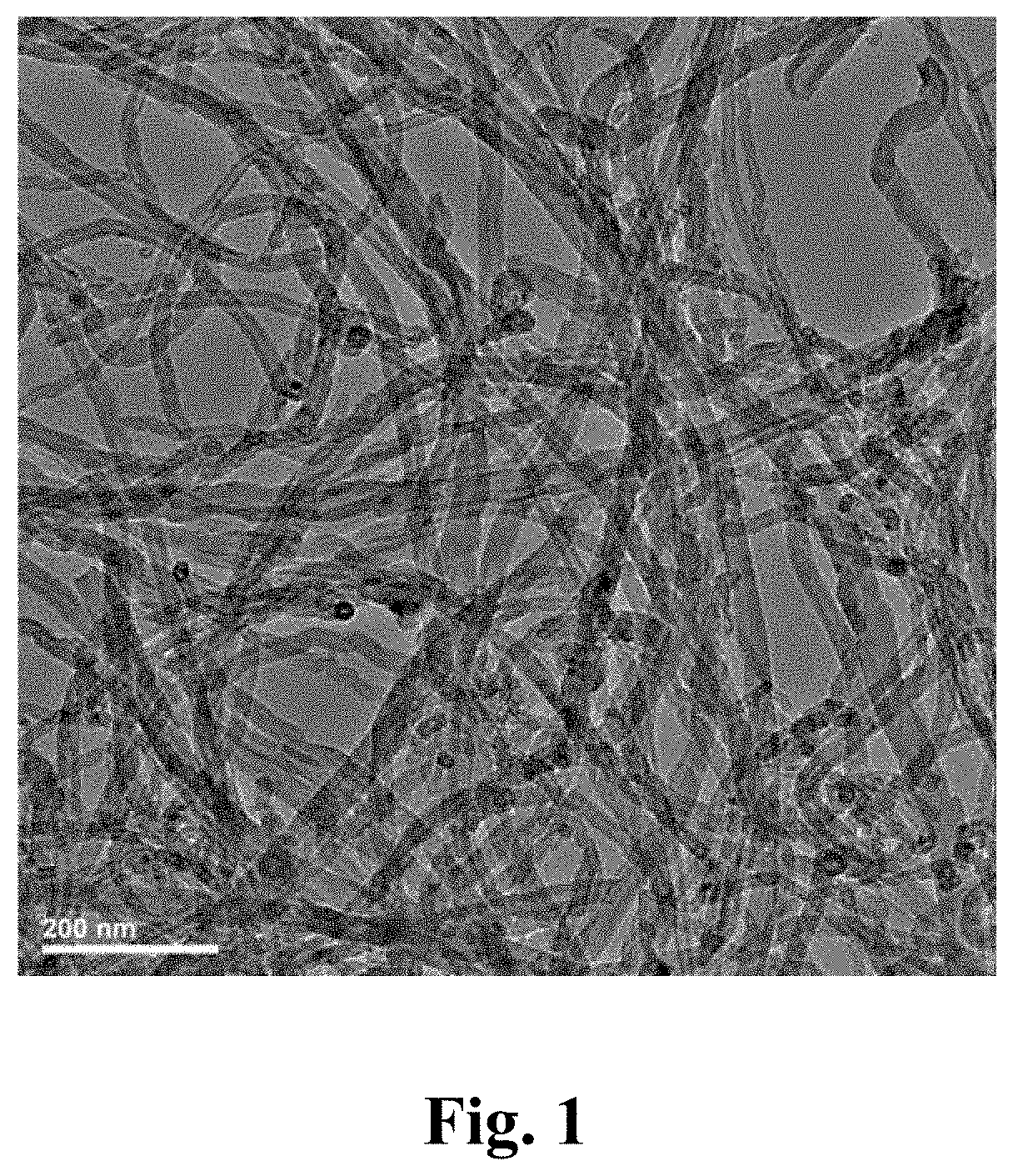

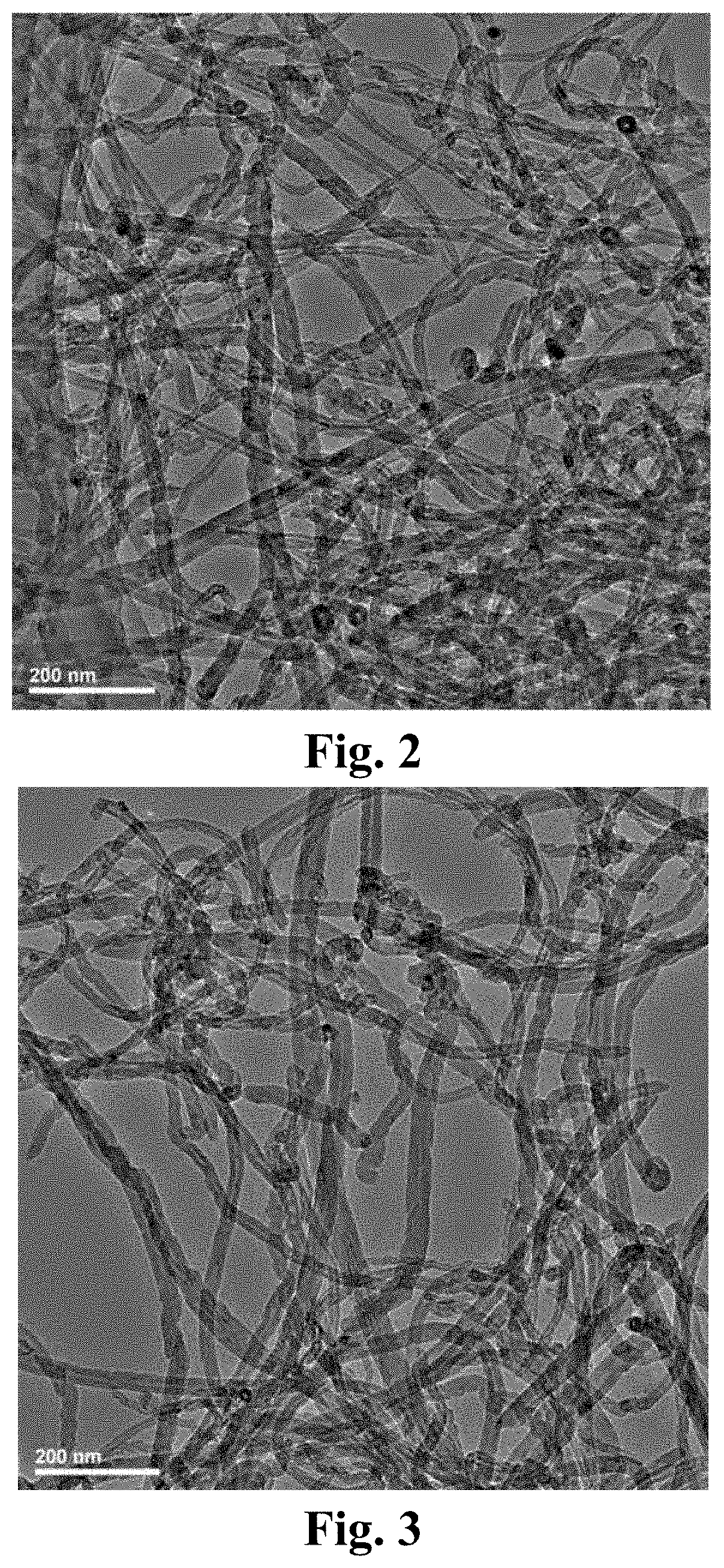

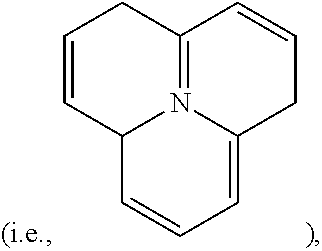

Heteroatom-containing nanocarbon material, preparation method and use thereof, and method for dehydrogenation reaction of hydrocarbons

ActiveUS20180015445A1Stable propertyLittle influenceCatalystsHydrocarbon preparation catalystsHydrocarbonPhotochemistry

A heteroatom-containing nano-carbon material, based on the total weight of said heteroatom-containing nano-carbon material and calculated as the elements, has an oxygen content of 1-6 wt %, a nitrogen content of 0-2 wt %, a carbon content of 92-99 wt %. In its XPS, the ratio of the oxygen content as determined with the peak(s) in the range of 531.0-532.5 eV to the oxygen content as determined with the peak(s) in the range of 532.6-533.5 eV is 0.2-0.8; the ratio of the carbon content as determined with the peak(s) in the range of 288.6-288.8 eV to the carbon content as determined with the peak(s) in the range of 286.0-286.2 eV is 0.2-1; the ratio of the nitrogen content as determined with the peak(s) in the range of 398.5-400.1 eV to the total nitrogen content is 0.7-1. The heteroatom-containing nano-carbon material shows a good catalytic capability in dehydrogenation of hydrocarbons.

Owner:CHINA PETROCHEMICAL CORP +1

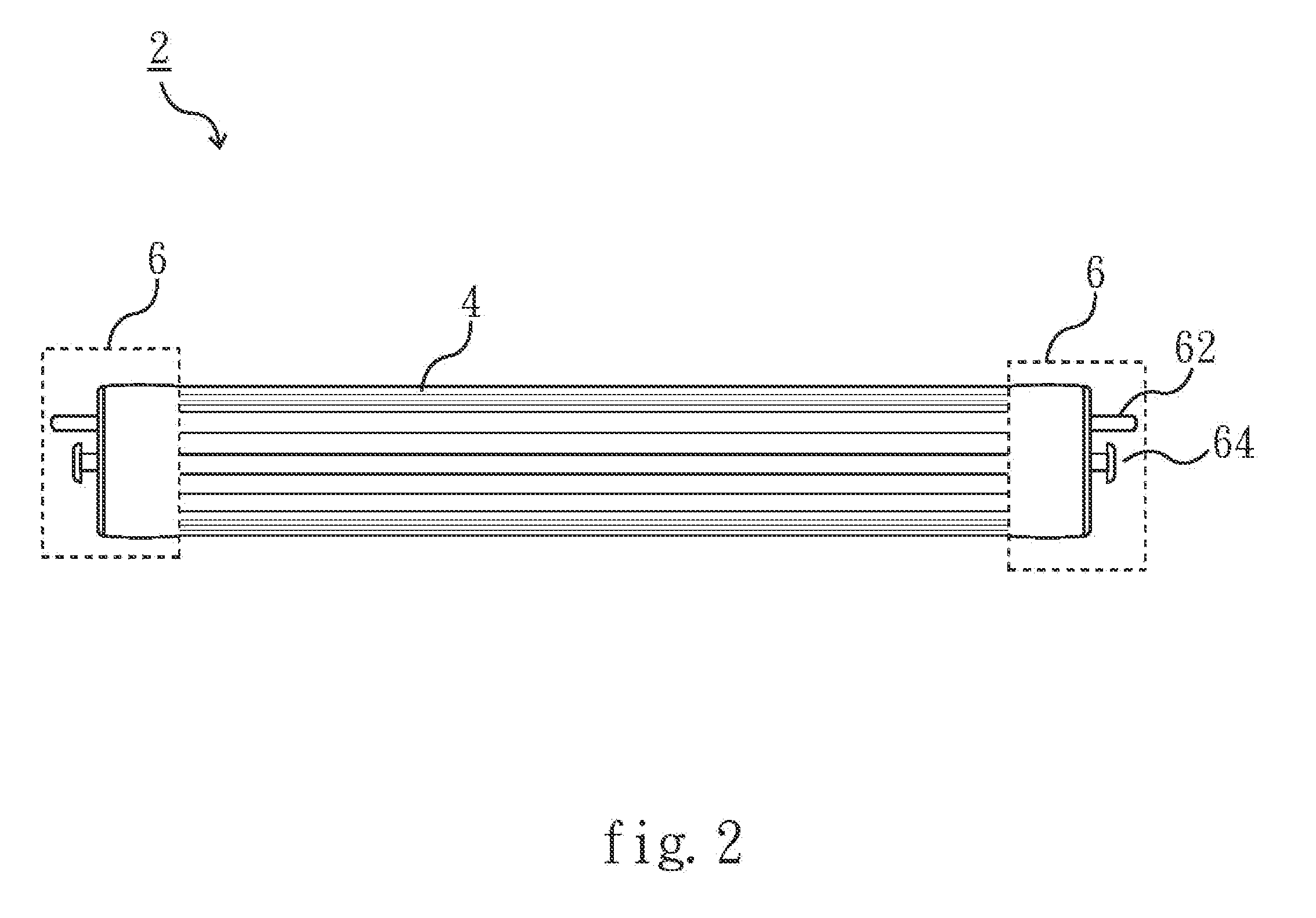

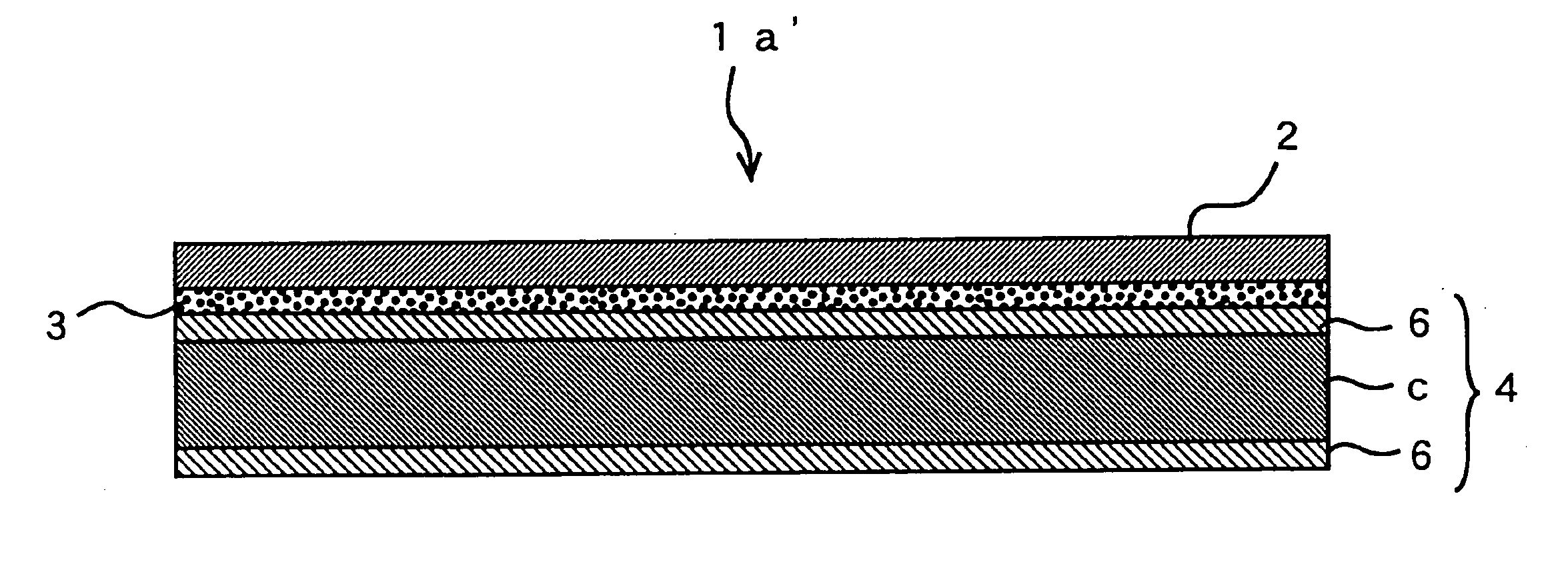

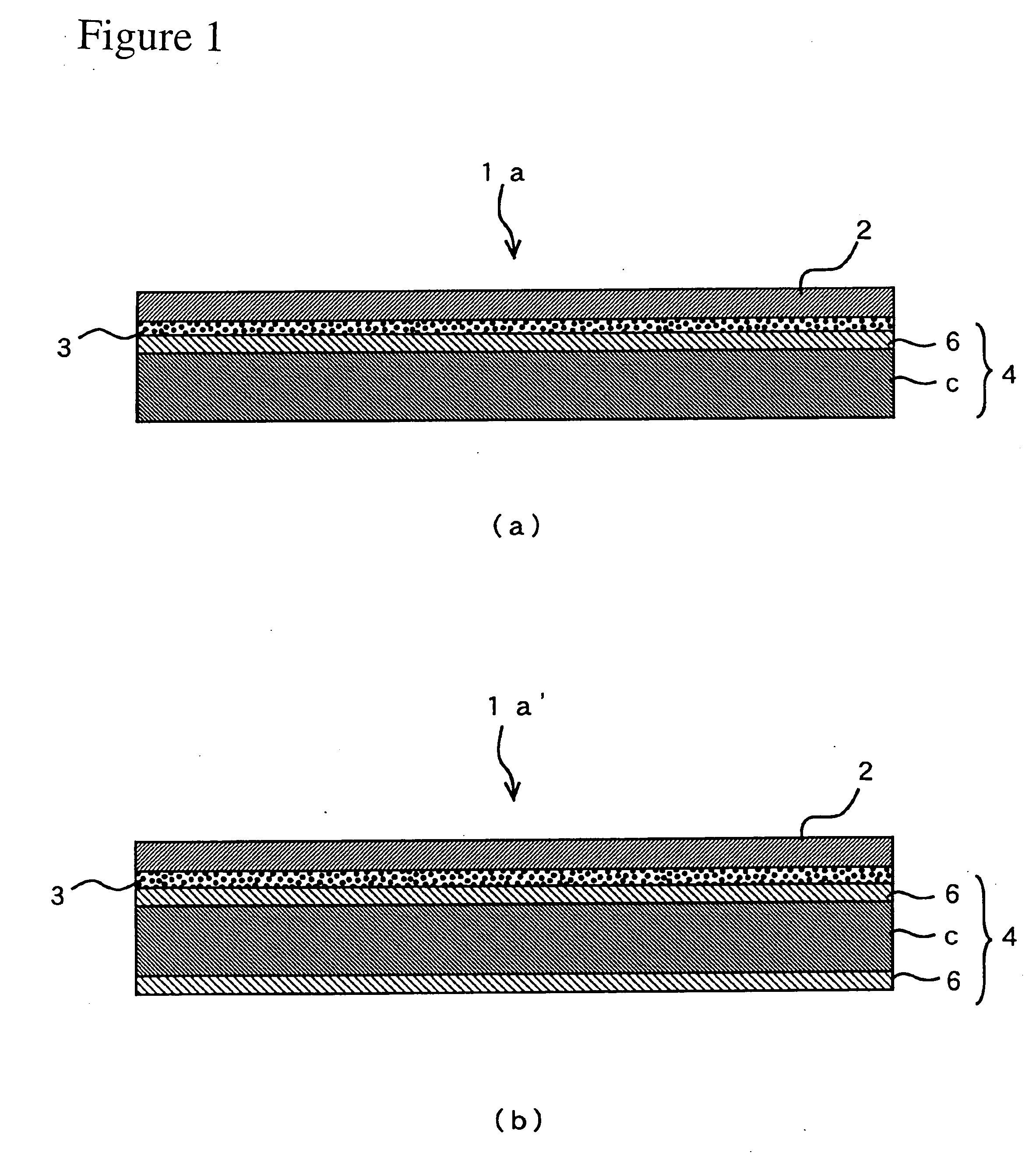

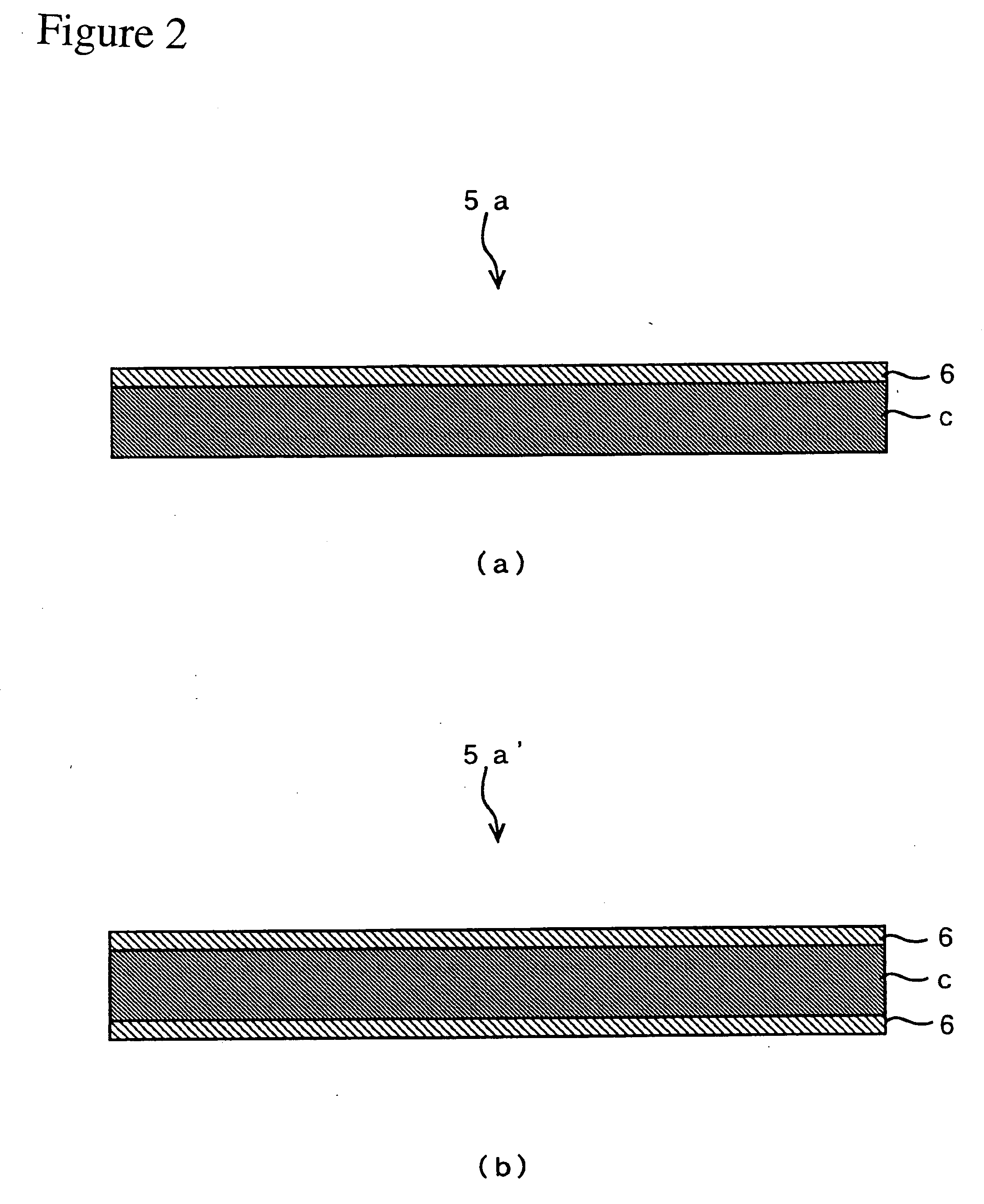

Capacitor layer forming material, method of manufacturing a composite foil used where manufacturing the same, and print wiring board having a circuit where a capacitor is embedded, obtained by using the same

InactiveUS20060087794A1Withstand expansionHighly achievedFixed capacitor electrodesPrinted circuit aspectsCopperDielectric layer

It is an object to provide a capacitor layer forming material useful for a printed wiring board with a substrate of fluorine resin, liquid-crystal polymer or the like, which is fabricated by hot-pressing at 300 to 400° C., and showing no deterioration in strength after the hot-pressing. In order to achieve the object, the capacitor layer forming material, comprising a first electroconductive layer used for forming an upper electrode and second electroconductive layer used for forming a lower electrode with a dielectric layer in-between for a printed wiring board, has the second electroconductive layer made of a composite foil comprising a copper layer coated with one or more layers of, plated hard nickel, plated cobalt and plated nickel / cobalt alloy.

Owner:MITSUI MINING & SMELTING CO LTD

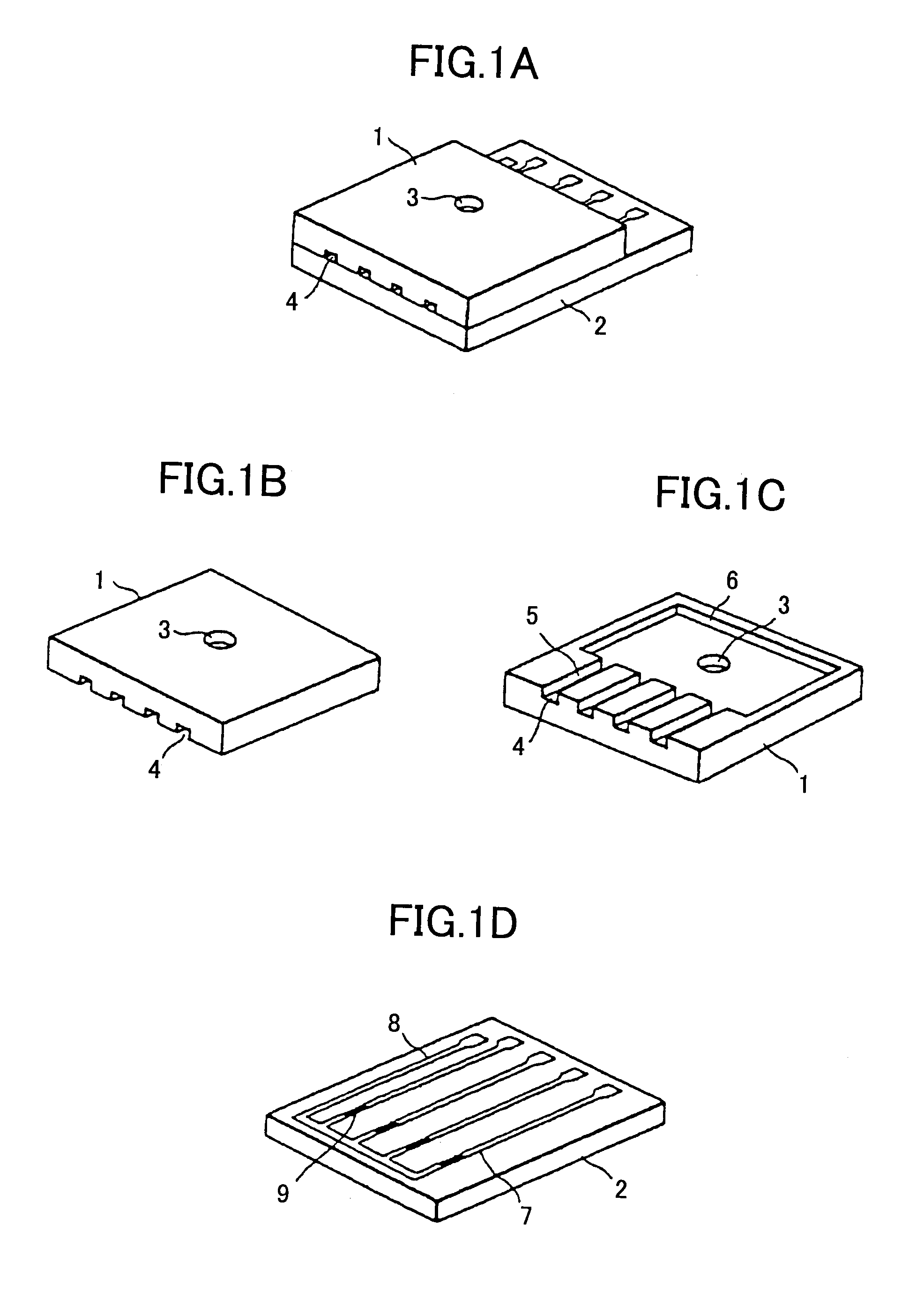

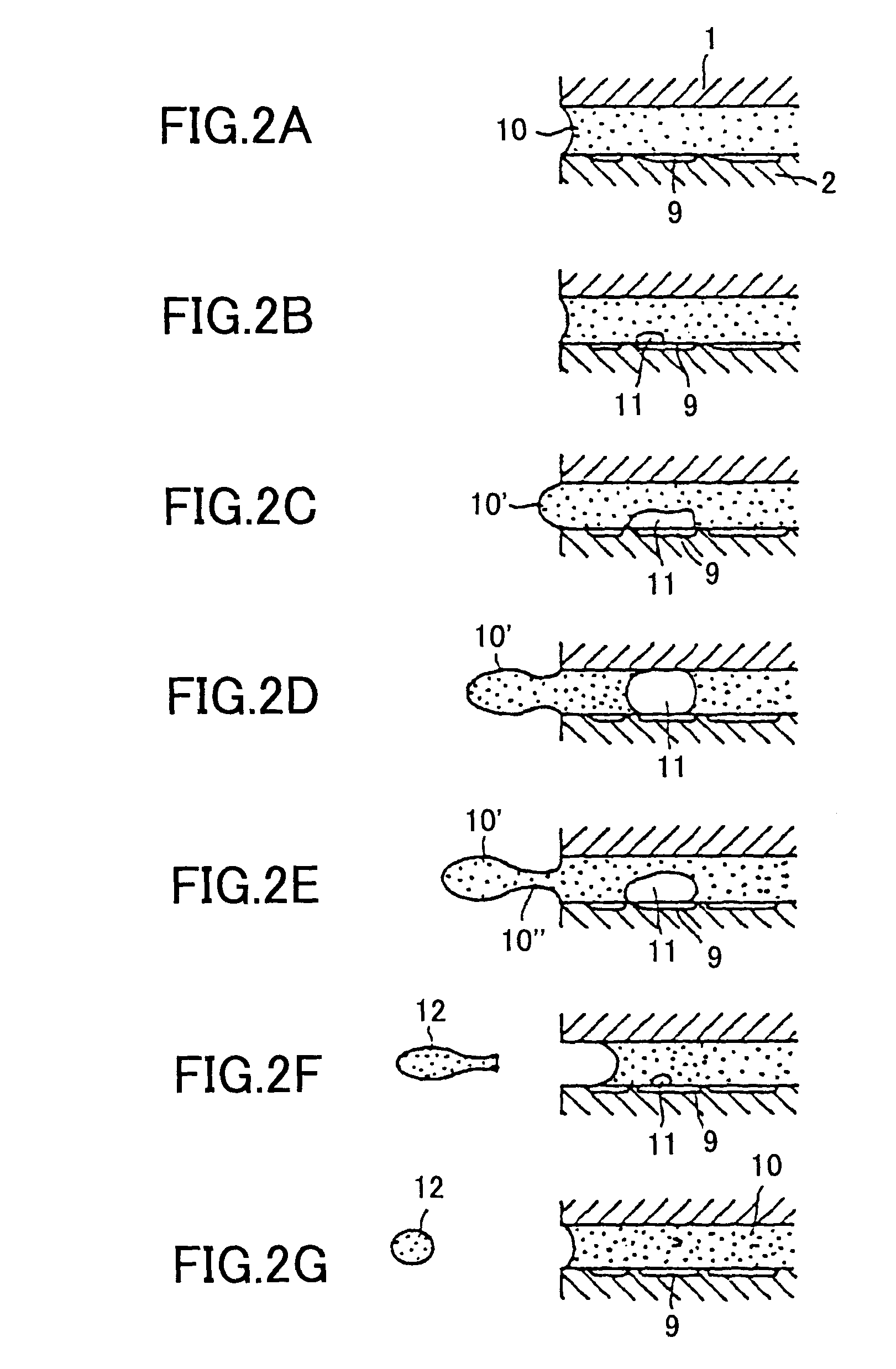

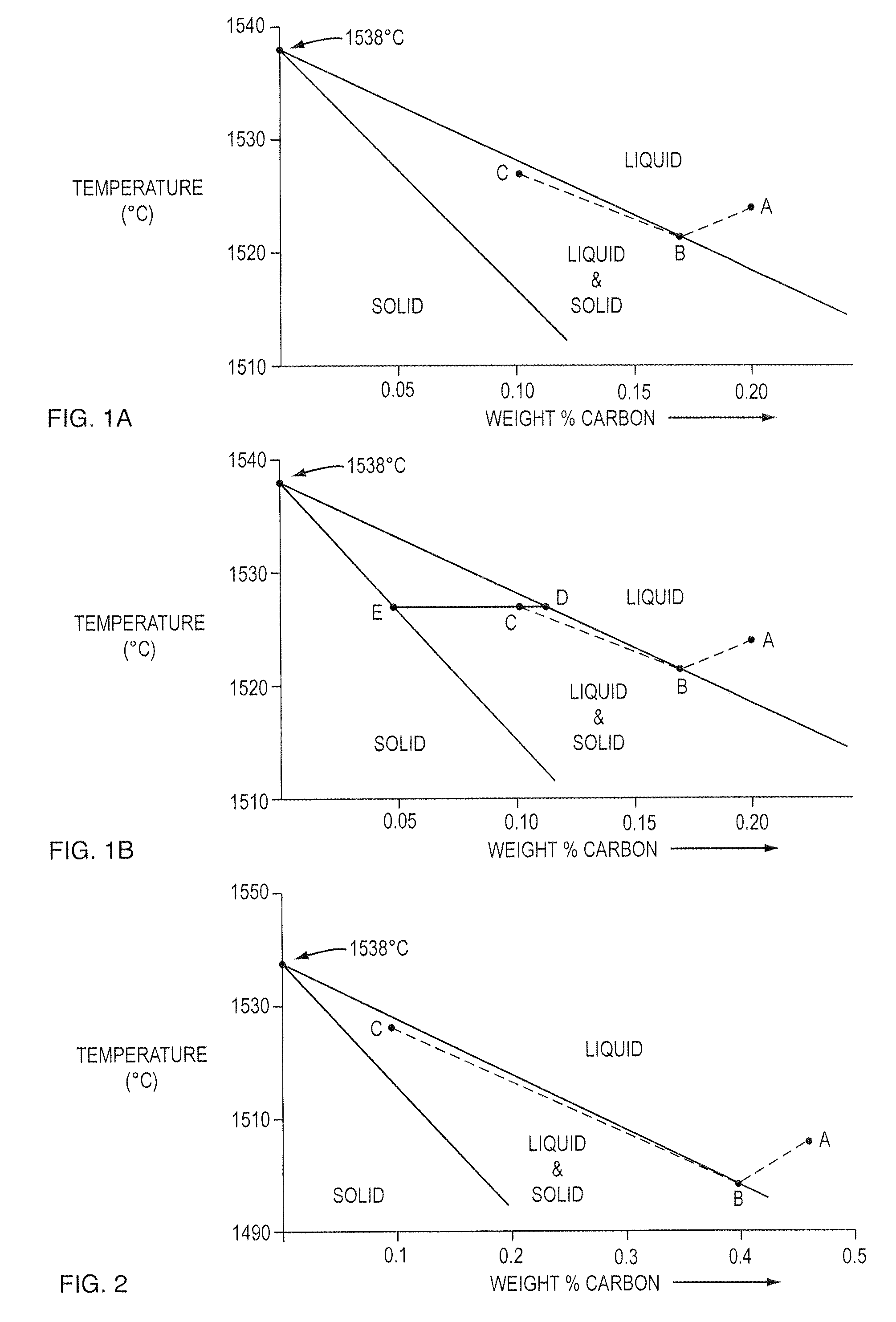

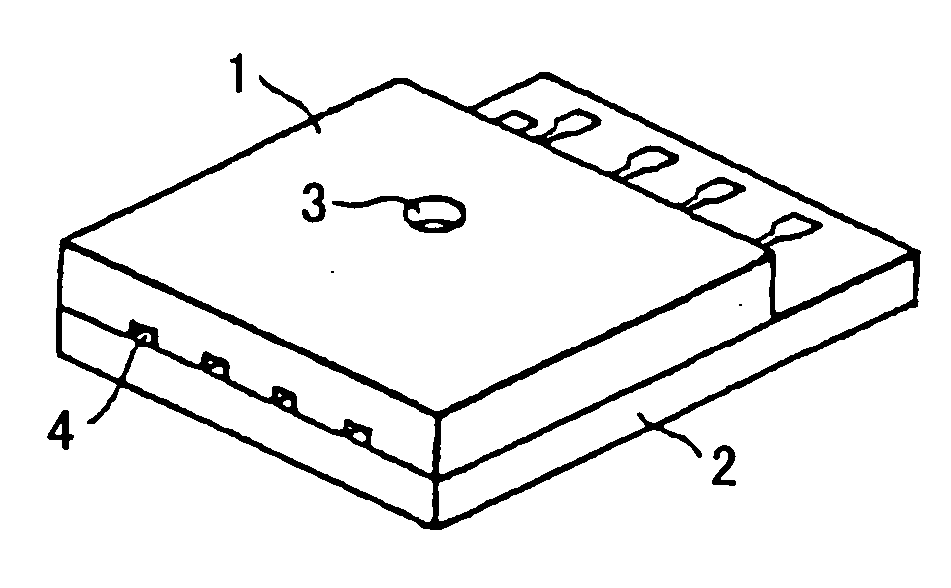

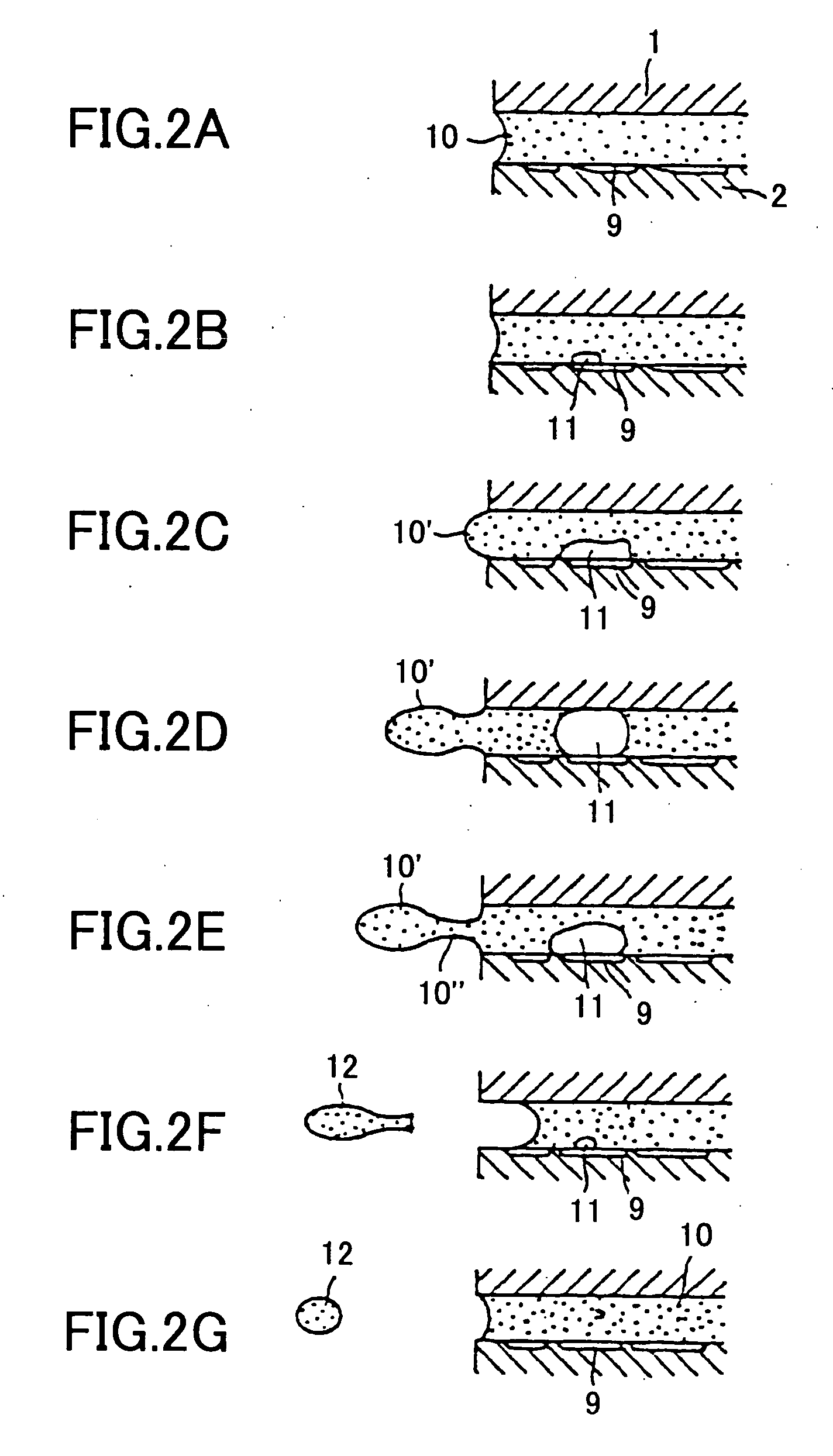

Liquid jet recording apparatus, liquid jet head, and recording liquid

InactiveUS7150521B2Good body shapePrevent nozzle cloggingInking apparatusMeasurement apparatus componentsLiquid jetFiber

A liquid jet head includes a nozzle element having nozzles from which a recording liquid is ejected to a recording medium, wherein the recording liquid contains fine particles of a pigment, wherein the fine particles of the pigment contained in the recording liquid are no less than 1% by weight, wherein each of the nozzles has an area that is less than 500 μm, wherein each of the fine particles of the pigment has a diameter satisfying a relation of 0.0005≦Dp / Do≦0.02, wherein “Dp” represents the diameter of each of the fine particles of the pigment and “Do” represents a size of each of the nozzles, wherein when the nozzle element ejects the recording liquid onto the recording medium, a contact angle of the recording liquid stops changing when 100 ms or less elapses after the recording liquid contacts the recording medium, wherein the fine particles of the pigment are smaller than fibers of the recording medium, wherein the fine particles of the pigment are smaller than spaces between the fibers of the recording medium.

Owner:RICOH KK

Display device, method for driving the same, and electronic device using the display device and the method

InactiveUS8446397B2Quality improvementHighly achievedElectrical apparatusElectroluminescent light sourcesElectrical resistance and conductanceElectricity

An object is to reduce degradation of display quality due to variation in luminance of light-emitting elements, which is caused by variation in voltage because of wiring resistance of current supply lines, and to improve the display quality. In a voltage program period, a terminal serving as a source of a transistor for driving an EL element is electrically connected to a first wiring to which a first potential is supplied. In a light-emitting period, the terminal serving as the source of the driving transistor is electrically connected to a second wiring to which a second potential is supplied. Accordingly, voltage between a gate terminal and the source terminal of the driving transistor can be held without being adversely affected by wiring resistance of the current supply lines.

Owner:SEMICON ENERGY LAB CO LTD

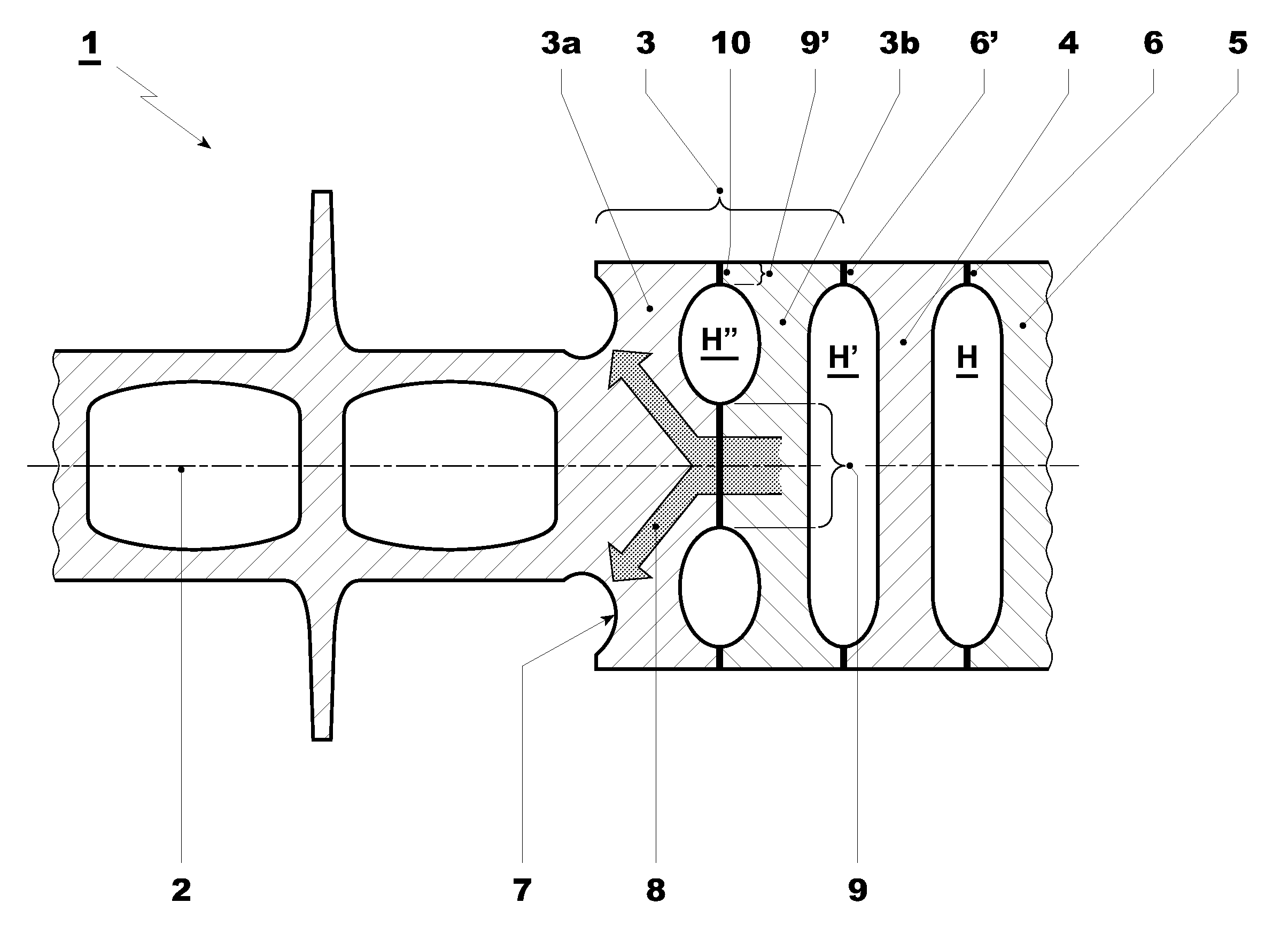

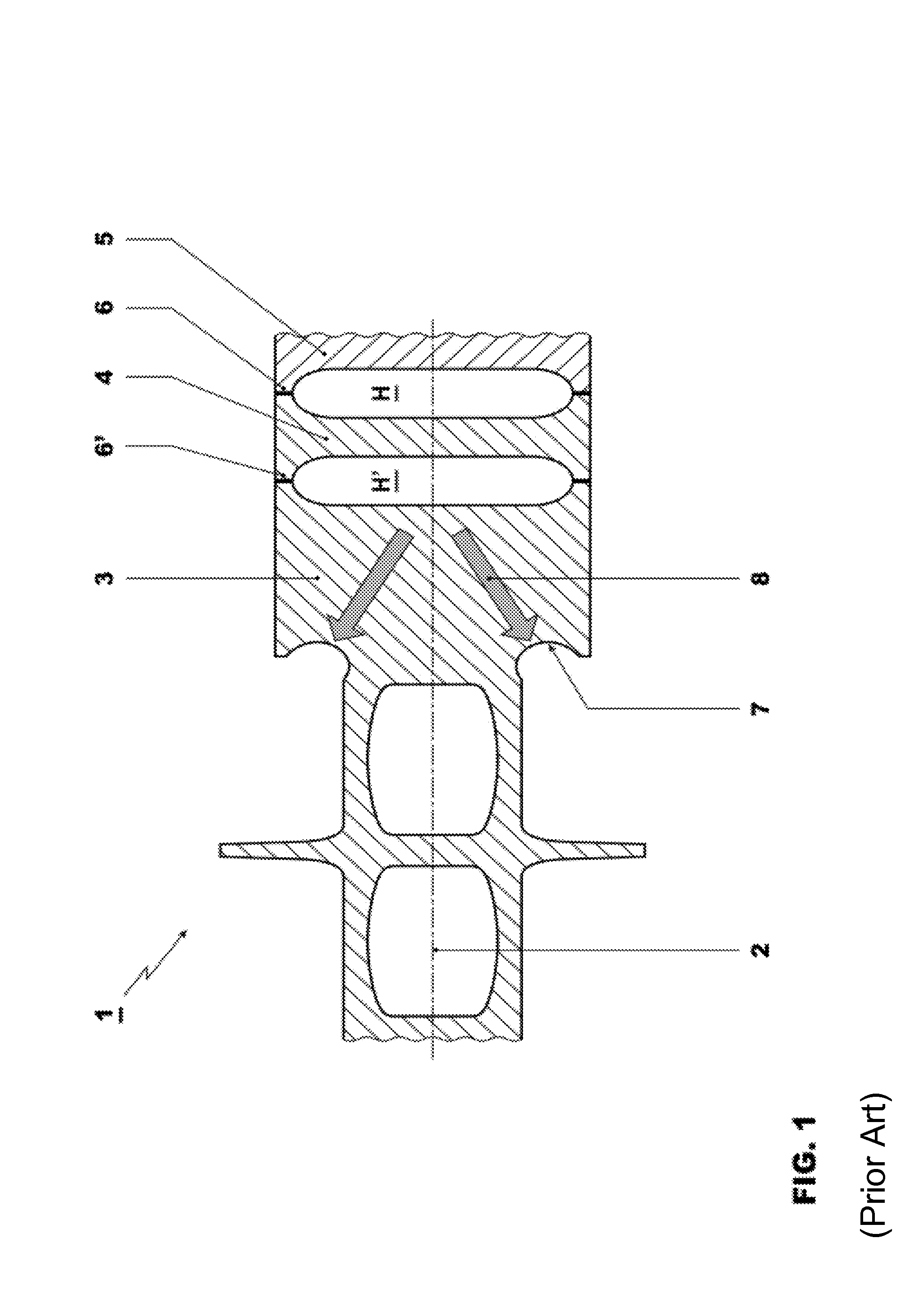

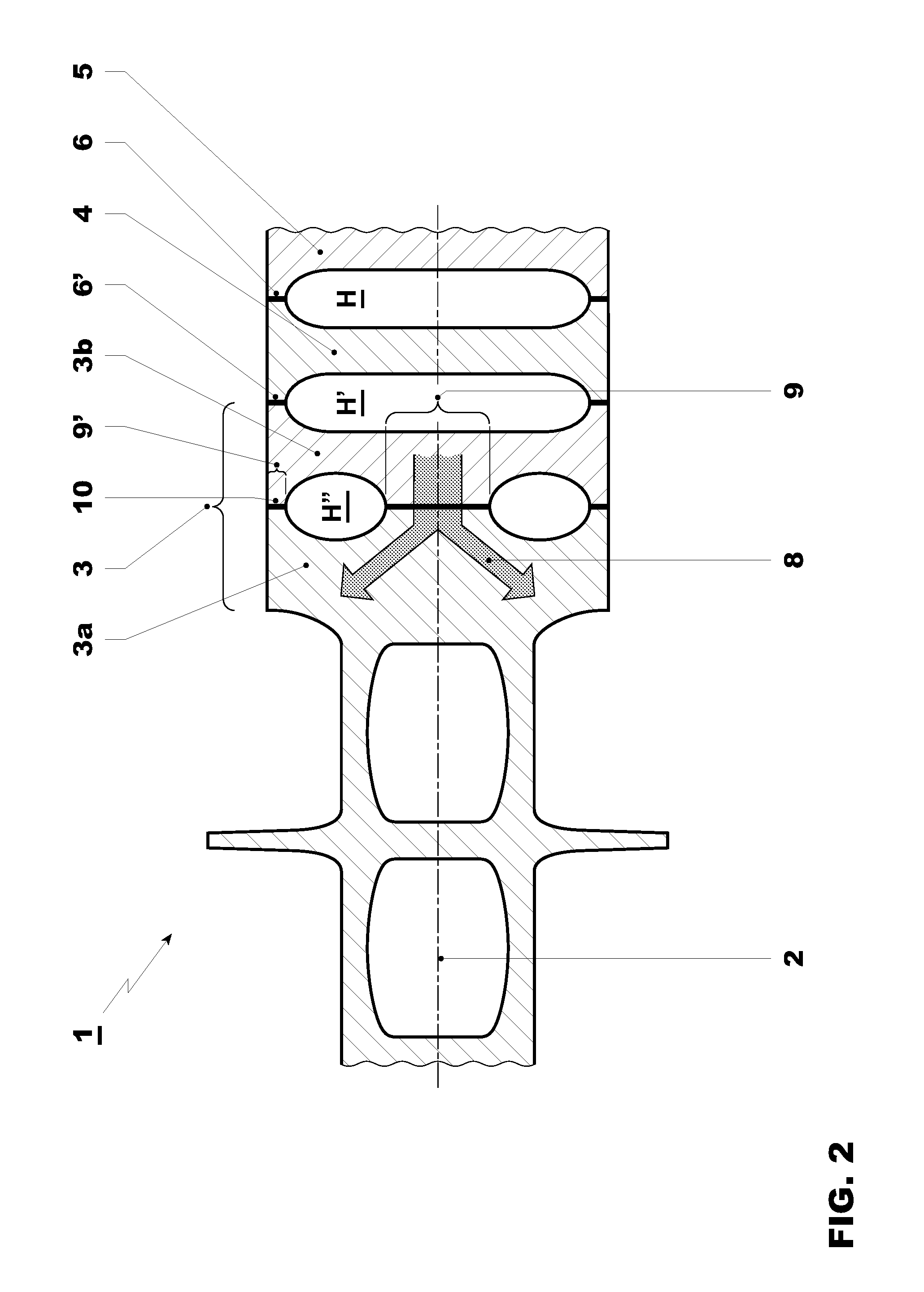

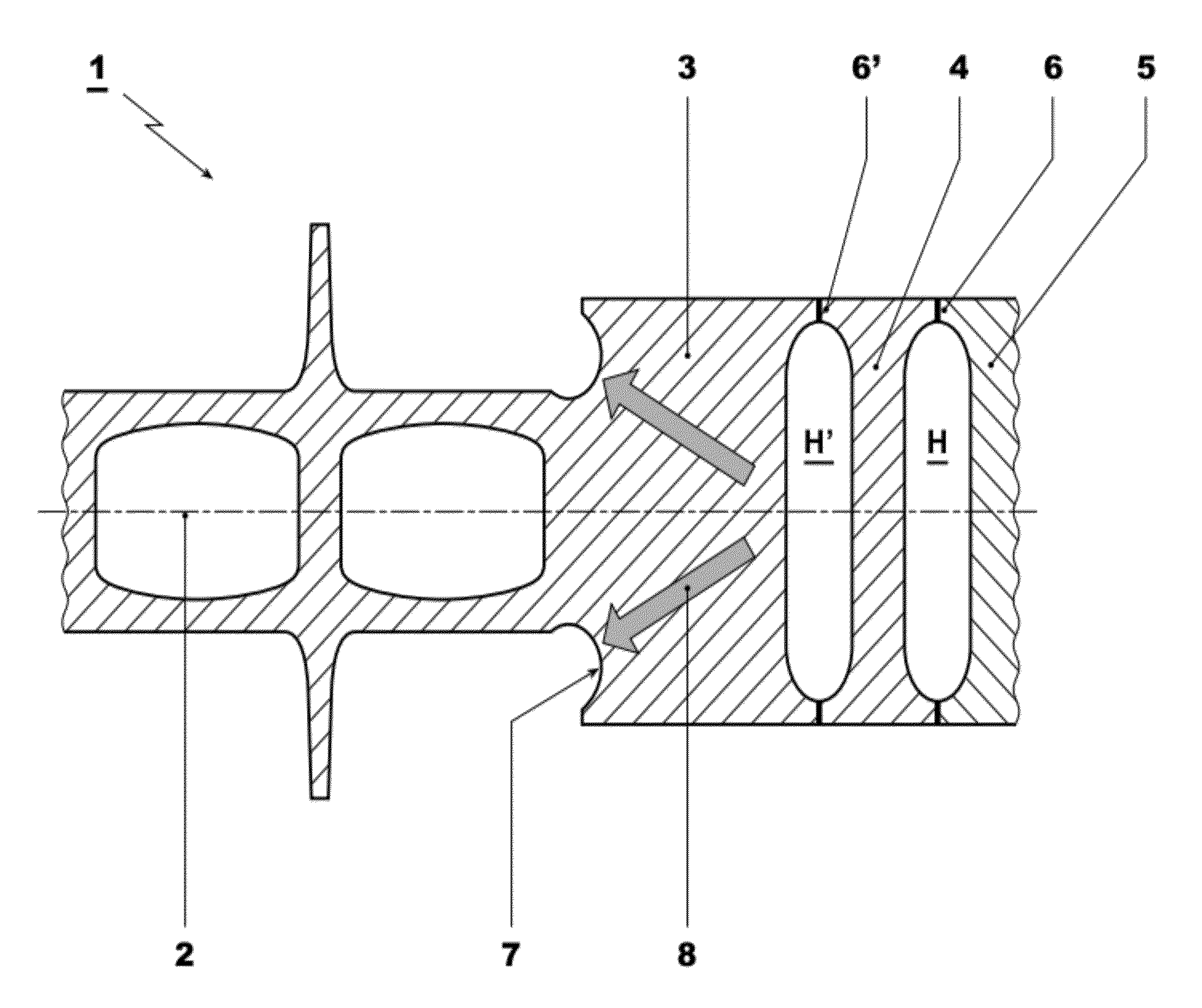

Welded rotor of a gas turbine engine compressor

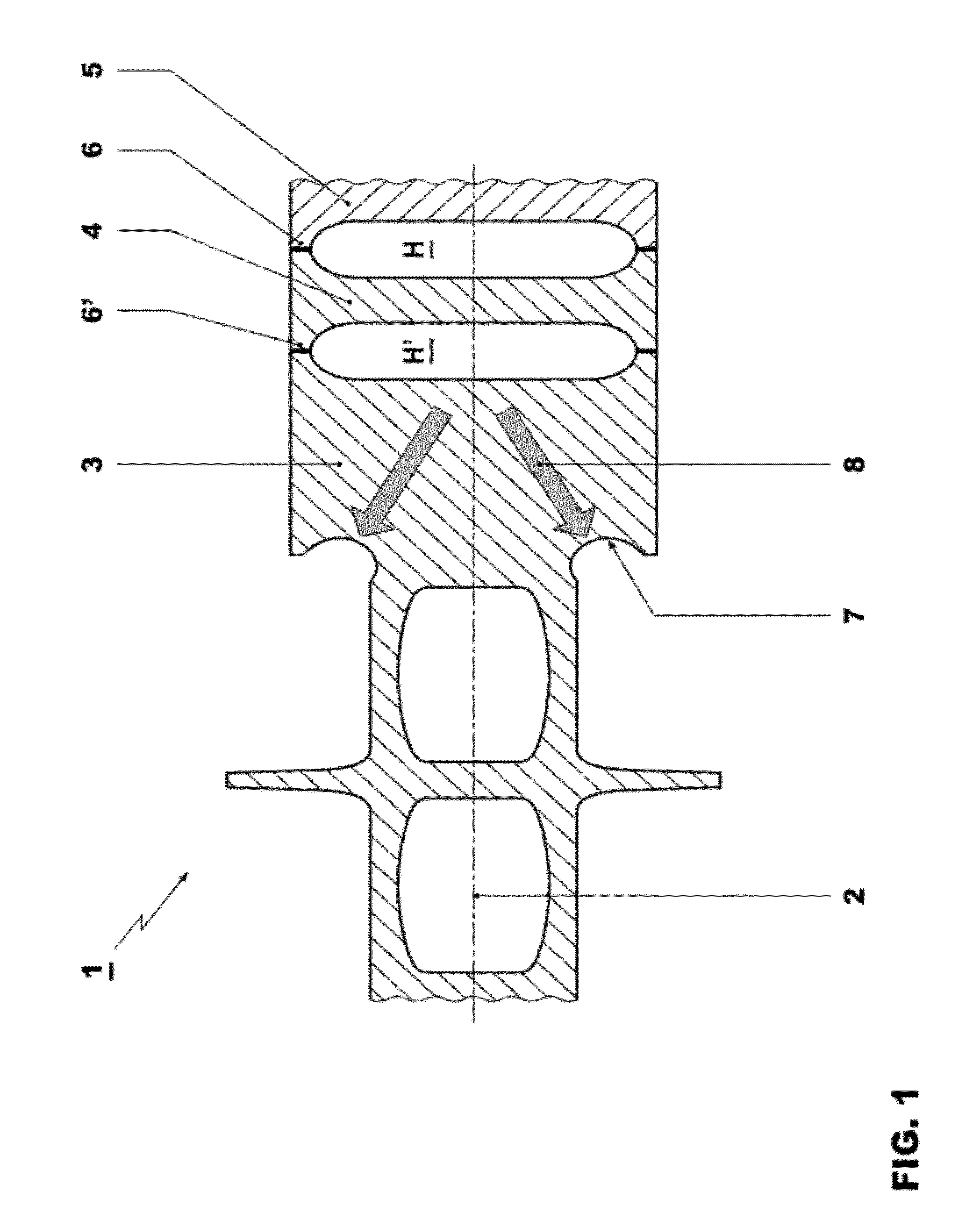

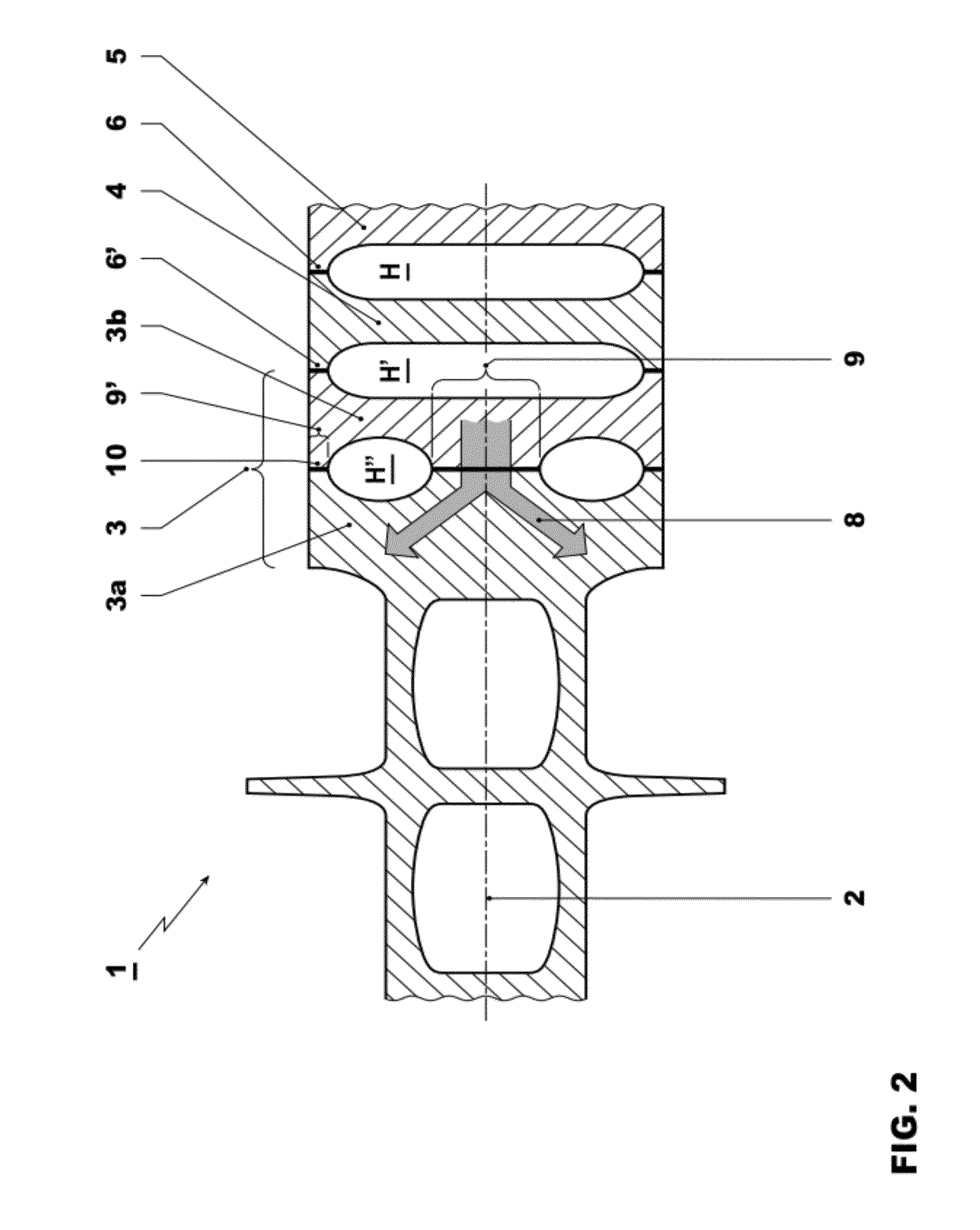

A rotor (1) of a gas turbine compressor comprises a multiplicity of welded-together rotor disks (3a, 3b, 4, 5), of which two or more rotor disks (3a, 3b), in a radially outer region (9′), are welded together, and, in a radially inner central region (9), are abutment-joined together. Via the abutment-joining of two rotor disks (3a, 3b), a heat flow (8) radially outward from the center of the rotor (1) is achieved so that the material temperature of the rotor (1) can be kept below a predetermined level during operation. As a result, the service life of the rotor (1) can be increased. In one embodiment, one rotor disk (3a), on its surface, additionally has a recess (7) which can be cooled from outside. The rotor disks (3a, 3b) according to the invention, which are welded and abutment-joined together, can especially be used at the last point in the flow direction of the compressor.

Owner:ANSALDO ENERGIA SWITZERLAND AG

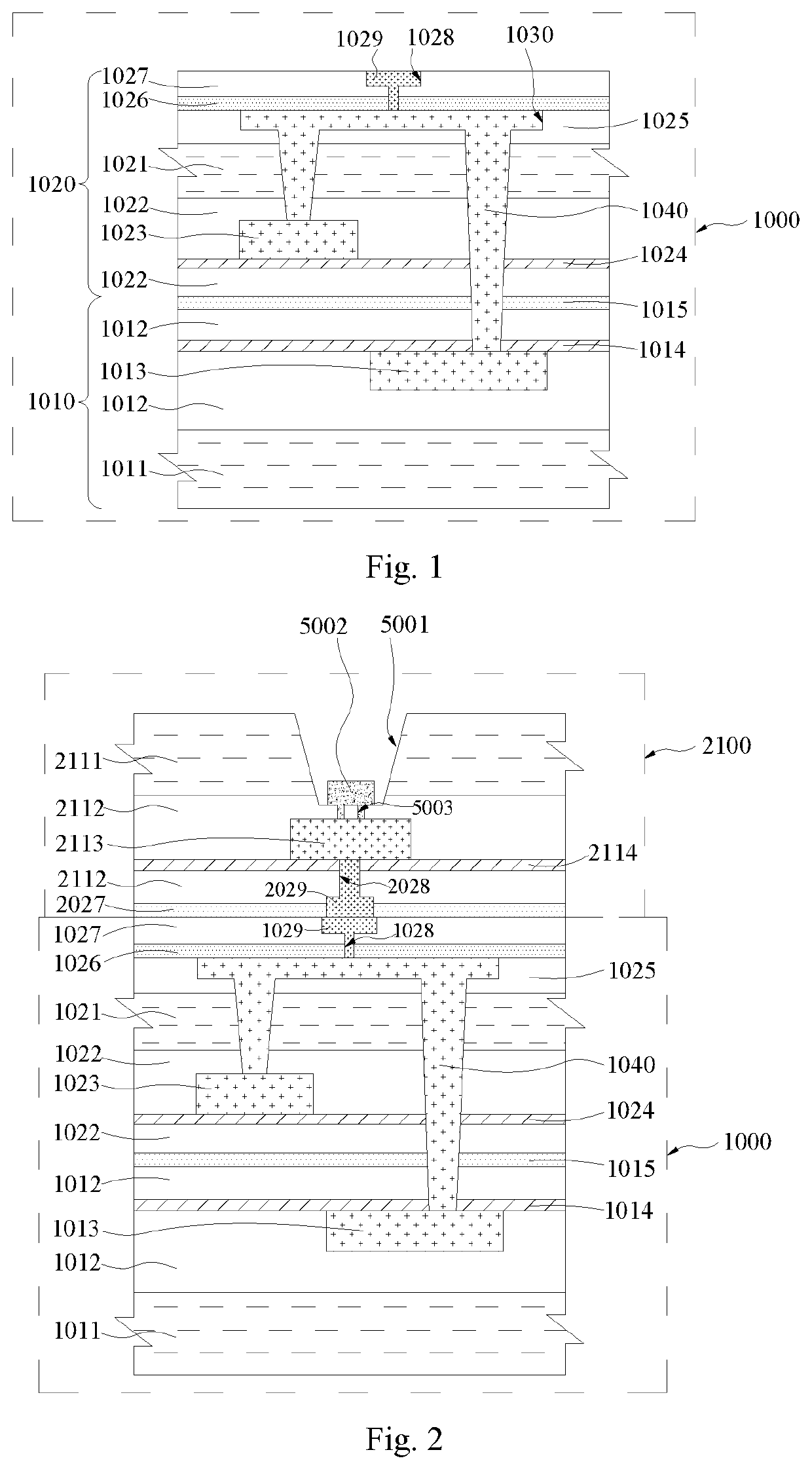

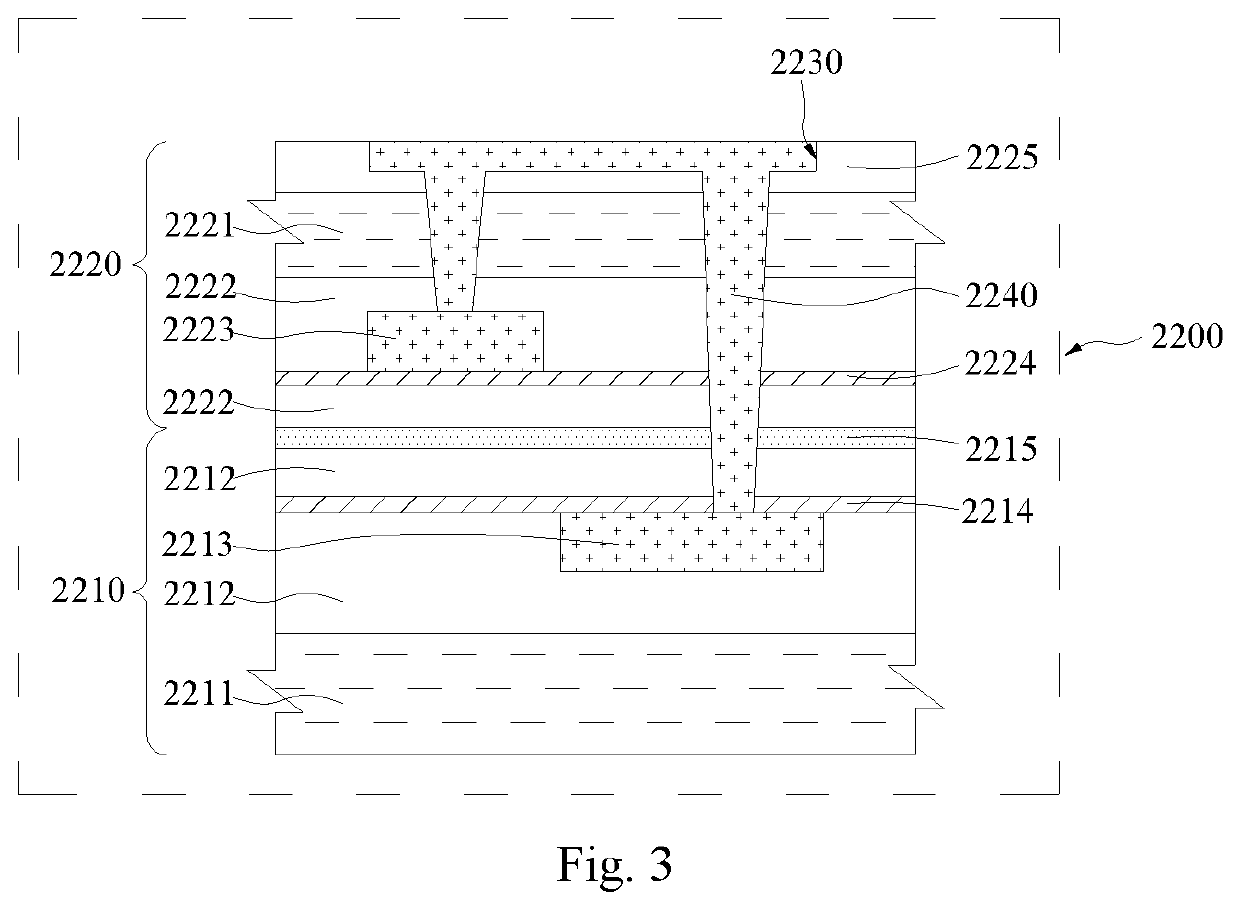

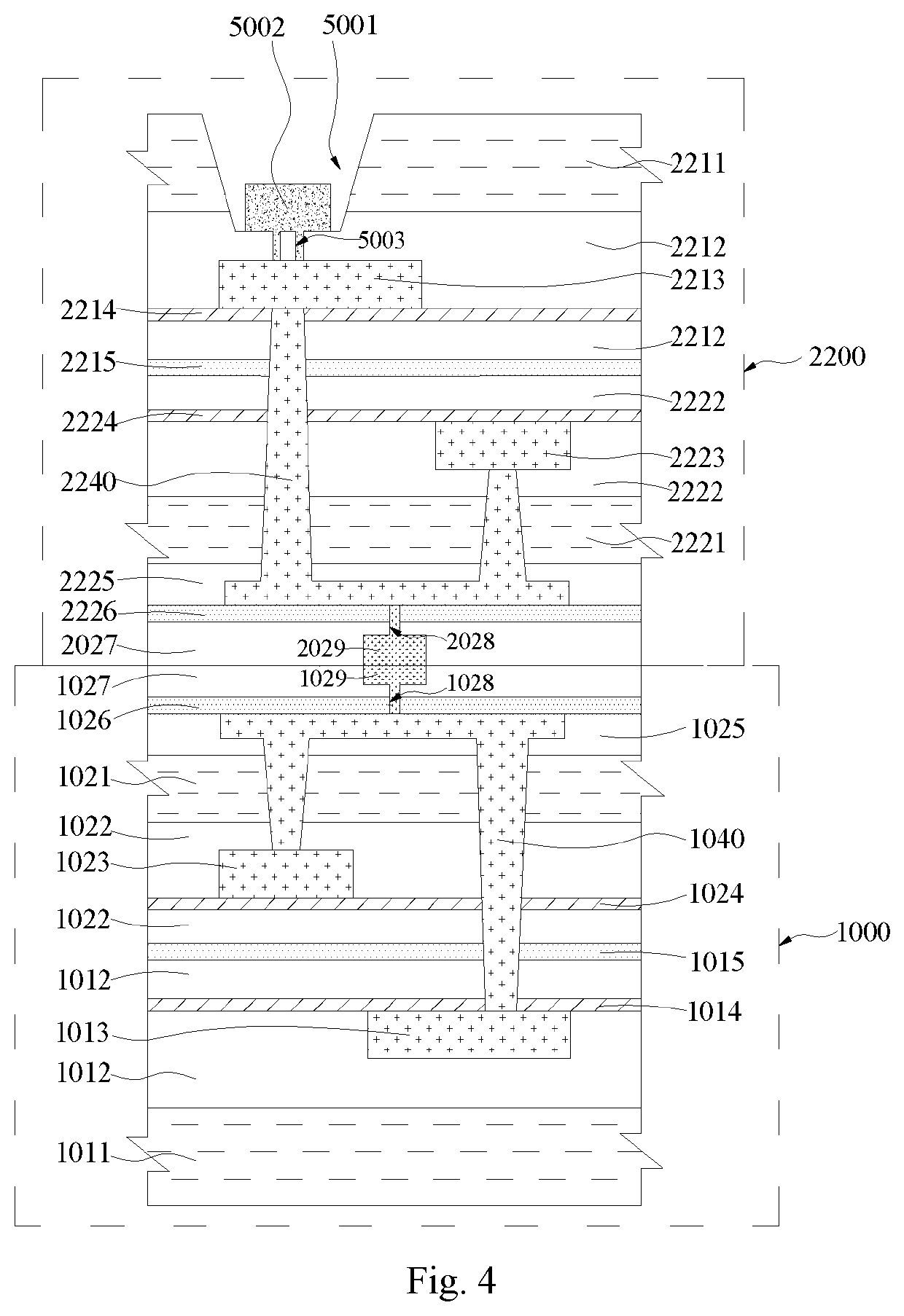

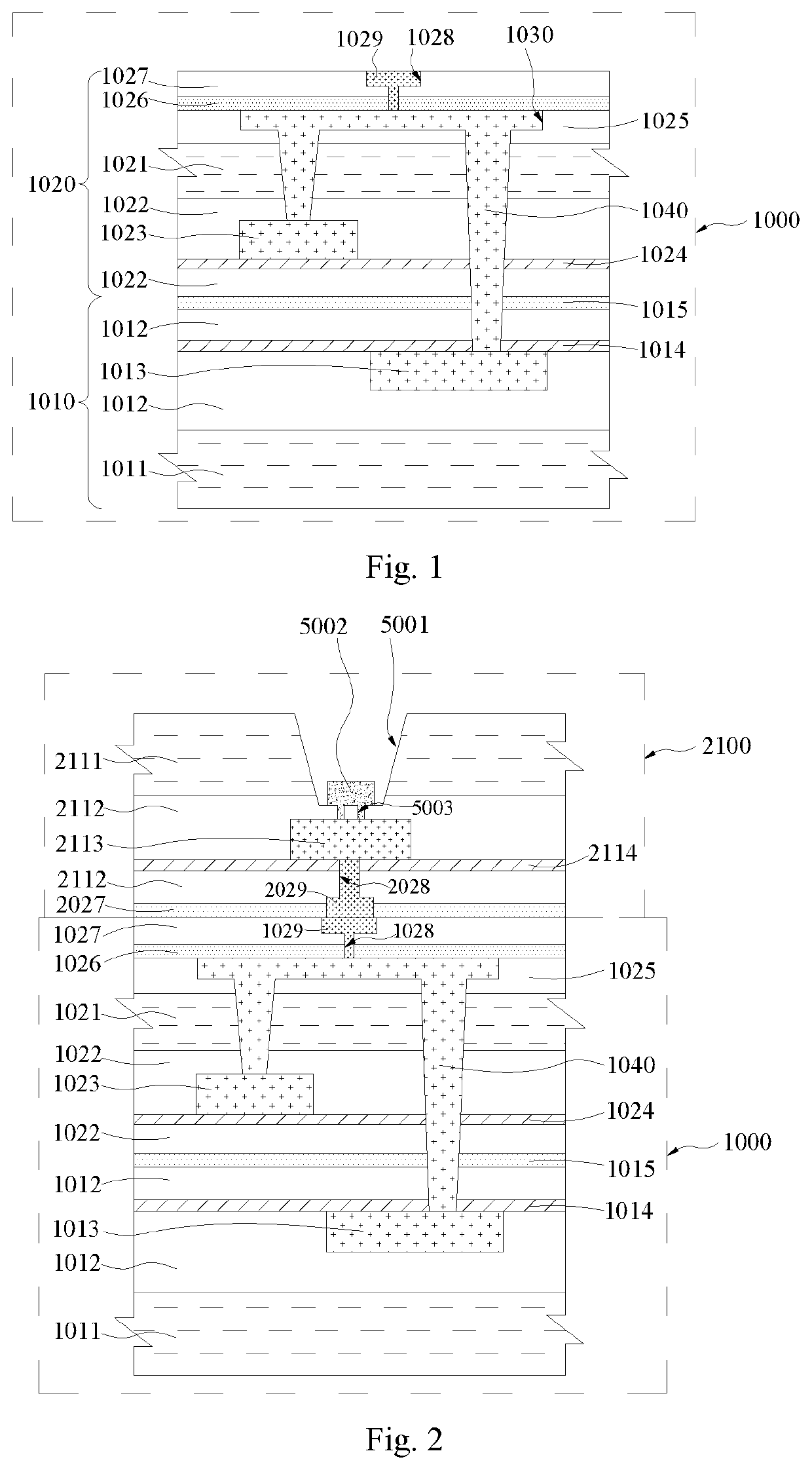

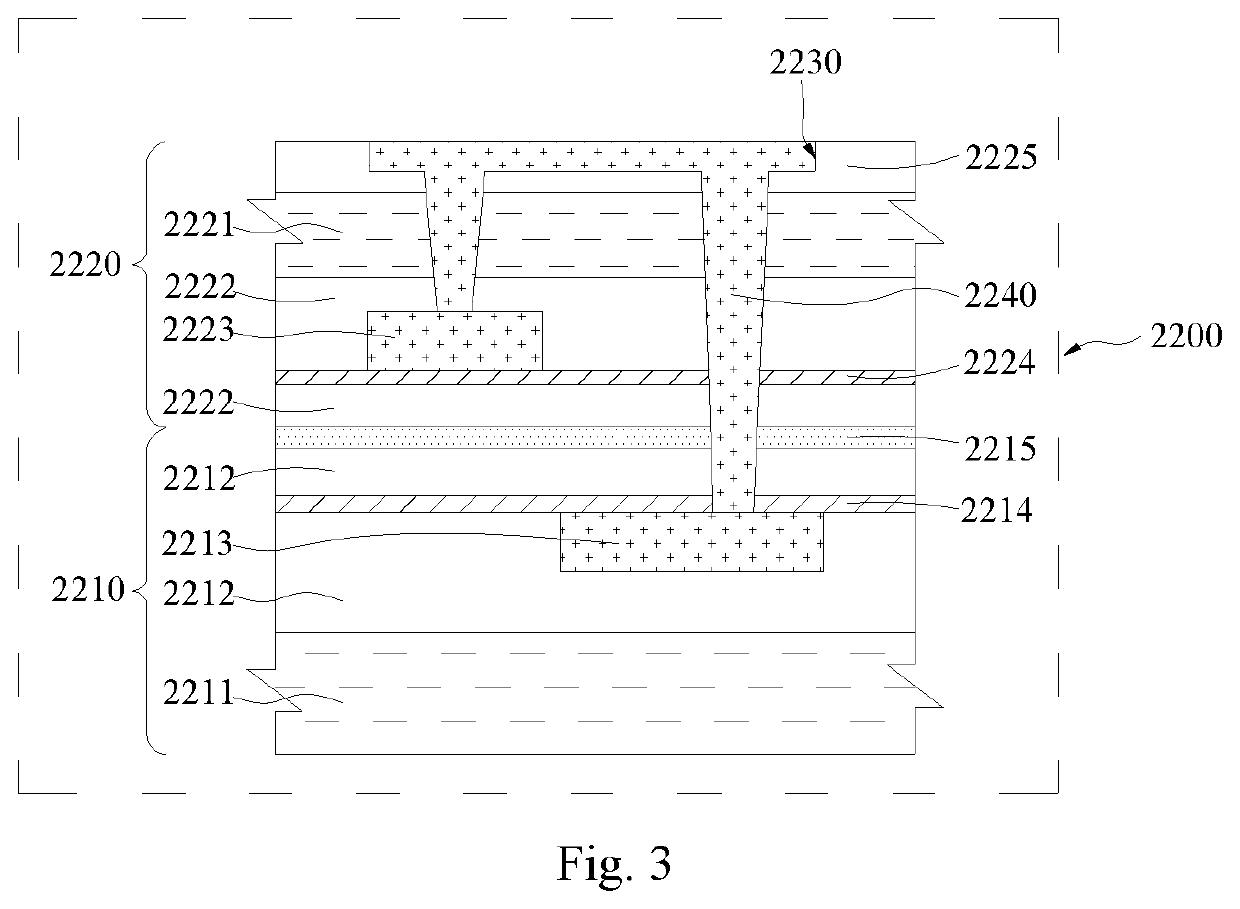

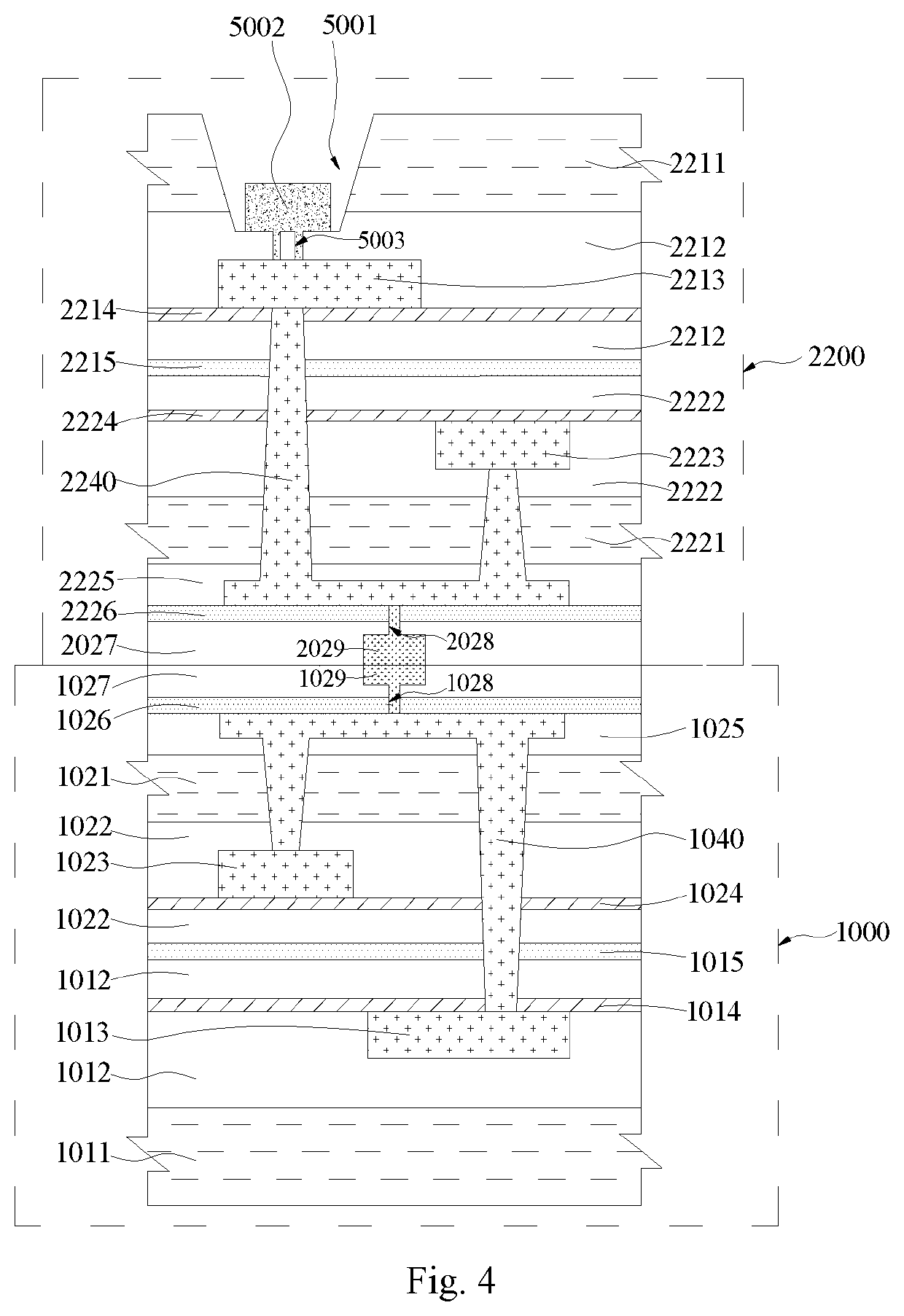

Multi-wafer bonding structure and bonding method

ActiveUS10930619B2Shorten the interconnection distanceIncrease transfer speedSemiconductor/solid-state device detailsSolid-state devicesWaferingElectrical connection

A multi-wafer bonding structure and bonding method are disclosed. The multi-wafer bonding structure includes a first unit and a second unit, a metal layer of each wafer in the first unit electrically connected to an interconnection layer of the first unit, a first bonding layer in the first unit electrically connected to the interconnection layer of the first unit, a second bonding layer in the second unit electrically connected to a metal layer of the second unit, and the first bonding layer being in contact with the second bonding layer to achieve an electrical connection, thereby achieving the electrical connection among the interconnection layer of the first unit, the first bonding layer, the second bonding layer and the metal layer of each wafer.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

Welded rotor of a gas turbine engine compressor

InactiveUS20120275926A1Improve cooling effectSmall sizePump componentsReaction enginesHeat flowEngineering

A rotor (1) of a gas turbine compressor comprises a multiplicity of welded-together rotor disks (3a, 3b, 4, 5), of which two or more rotor disks (3a, 3b), in a radially outer region (9′), are welded together, and, in a radially inner central region (9), are abutment-joined together. Via the abutment-joining of two rotor disks (3a, 3b), a heat flow (8) radially outward from the center of the rotor (1) is achieved so that the material temperature of the rotor (1) can be kept below a predetermined level during operation. As a result, the service life of the rotor (1) can be increased. In one embodiment, one rotor disk (3a), on its surface, additionally has a recess (7) which can be cooled from outside. The rotor disks (3a, 3b) according to the invention, which are welded and abutment-joined together, can especially be used at the last point in the flow direction of the compressor.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Low energy, high substrate efficiency, anaerobic, deep, bubble column fermentation processes

ActiveUS8771999B2Speed up the conversion processRisk minimizationBiofuelsChemical recyclingSimple Organic CompoundsHydrogen

Bioconversion processes are disclosed that enable high conversion efficiencies of gas substrate containing both carbon monoxide and hydrogen to oxygenated organic compounds via the carbon monoxide and hydrogen pathways using anaerobic, deep, bubble column fermentation in a cost effective manner. The high conversion efficiency processes of this invention comprise the combination of using at least two deep, bubble column reactors in flow series and using certain feed gas compositions and microbubbles while avoiding carbon monoxide inhibition.

Owner:SYNATA BIO INC

Fiber base material for wet friction material

InactiveUS7309725B2Increased durabilityKeeps a certain modulus of elasticityPaper/cardboardFriction clutchesDecompositionIndustrial machine

A fibrous base material giving a wet frictional material used for clutch, differential gear, brake, etc. of cars, industrial machines, etc. having an excellent durability where plastic deformation of fiber and deterioration by acidic decomposition products of lubricant additives do not take place is provided. A fibrous base material for wet frictional materials which comprises a fiber component, a friction adjusting material and a filler, said fiber component containing 5 to 50% by weight of a homoacrylonitrile fiber where modulus of elasticity at 180° C. is not less than 10 cN / dtex and shrinking rate at 200° C. is within 5% and / or a homoacrylonitrile fiber in a pulp form prepared by fibrillation of said homoacrylonitrile fiber.

Owner:JAPAN EXLAN CO LTD

Multi-wafer bonding structure and bonding method

ActiveUS20200075550A1Short interconnection distanceHigh signal transmission rateSemiconductor/solid-state device detailsSolid-state devicesWaferingElectrical connection

A multi-wafer bonding structure and bonding method are disclosed. The multi-wafer bonding structure includes a first unit and a second unit, a metal layer of each wafer in the first unit electrically connected to an interconnection layer of the first unit, a first bonding layer in the first unit electrically connected to the interconnection layer of the first unit, a second bonding layer in the second unit electrically connected to a metal layer of the second unit, and the first bonding layer being in contact with the second bonding layer to achieve an electrical connection, thereby achieving the electrical connection among the interconnection layer of the first unit, the first bonding layer, the second bonding layer and the metal layer of each wafer.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

Heteroatom-containing nanocarbon material, preparation method and use thereof, and method for dehydrogenation reaction of hydrocarbons

A heteroatom-containing nano-carbon material, based on the total weight of said heteroatom-containing nano-carbon material and calculated as the elements, has an oxygen content of 1-6 wt %, a nitrogen content of 0-2 wt %, a carbon content of 92-99 wt %. In its XPS, the ratio of the oxygen content as determined with the peak(s) in the range of 531.0-532.5 eV to the oxygen content as determined with the peak(s) in the range of 532.6-533.5 eV is 0.2-0.8; the ratio of the carbon content as determined with the peak(s) in the range of 288.6-288.8 eV to the carbon content as determined with the peak(s) in the range of 286.0-286.2 eV is 0.2-1; the ratio of the nitrogen content as determined with the peak(s) in the range of 398.5-400.1 eV to the total nitrogen content is 0.7-1. The heteroatom-containing nano-carbon material shows a good catalytic capability in dehydrogenation of hydrocarbons.

Owner:CHINA PETROCHEMICAL CORP +1

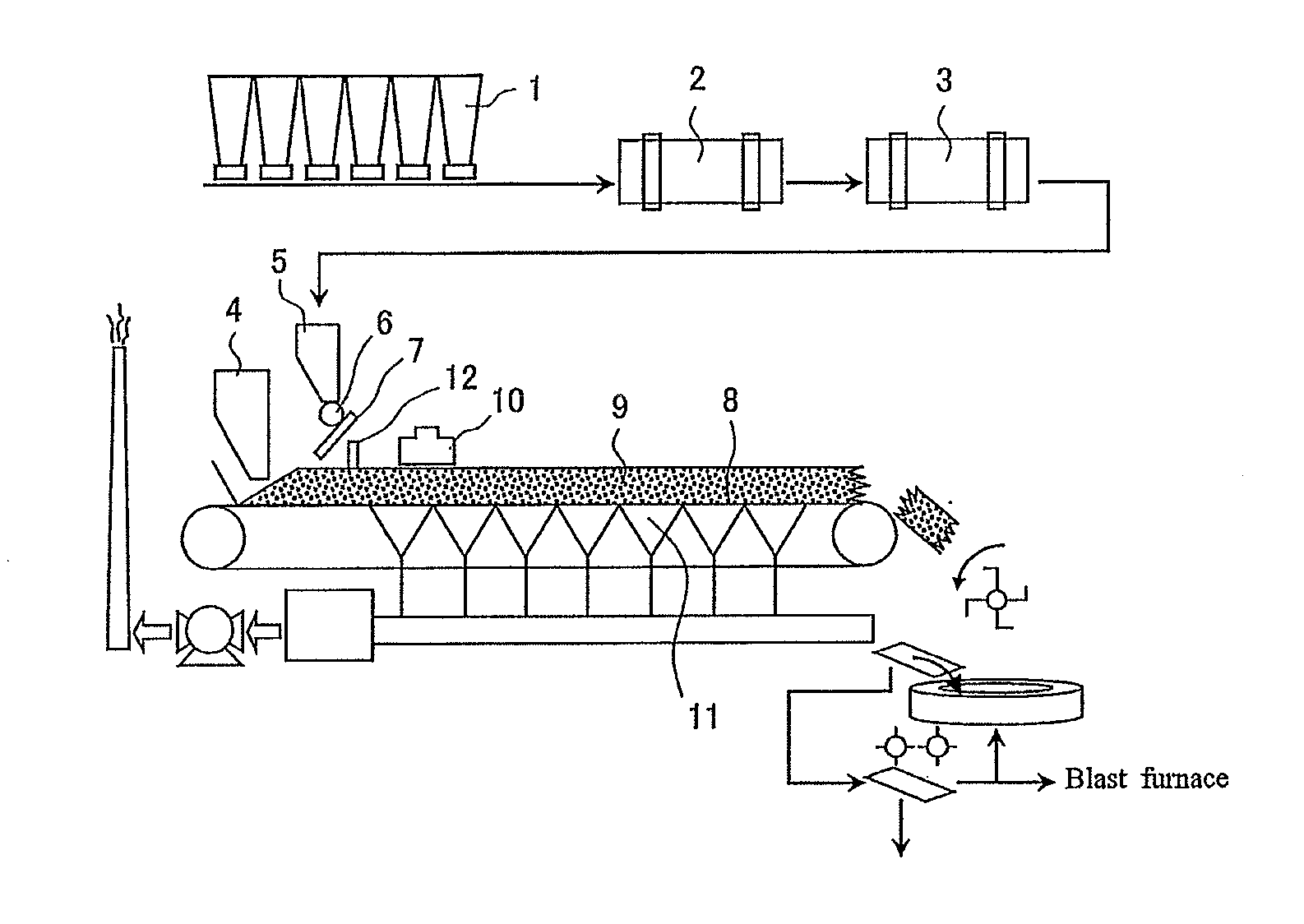

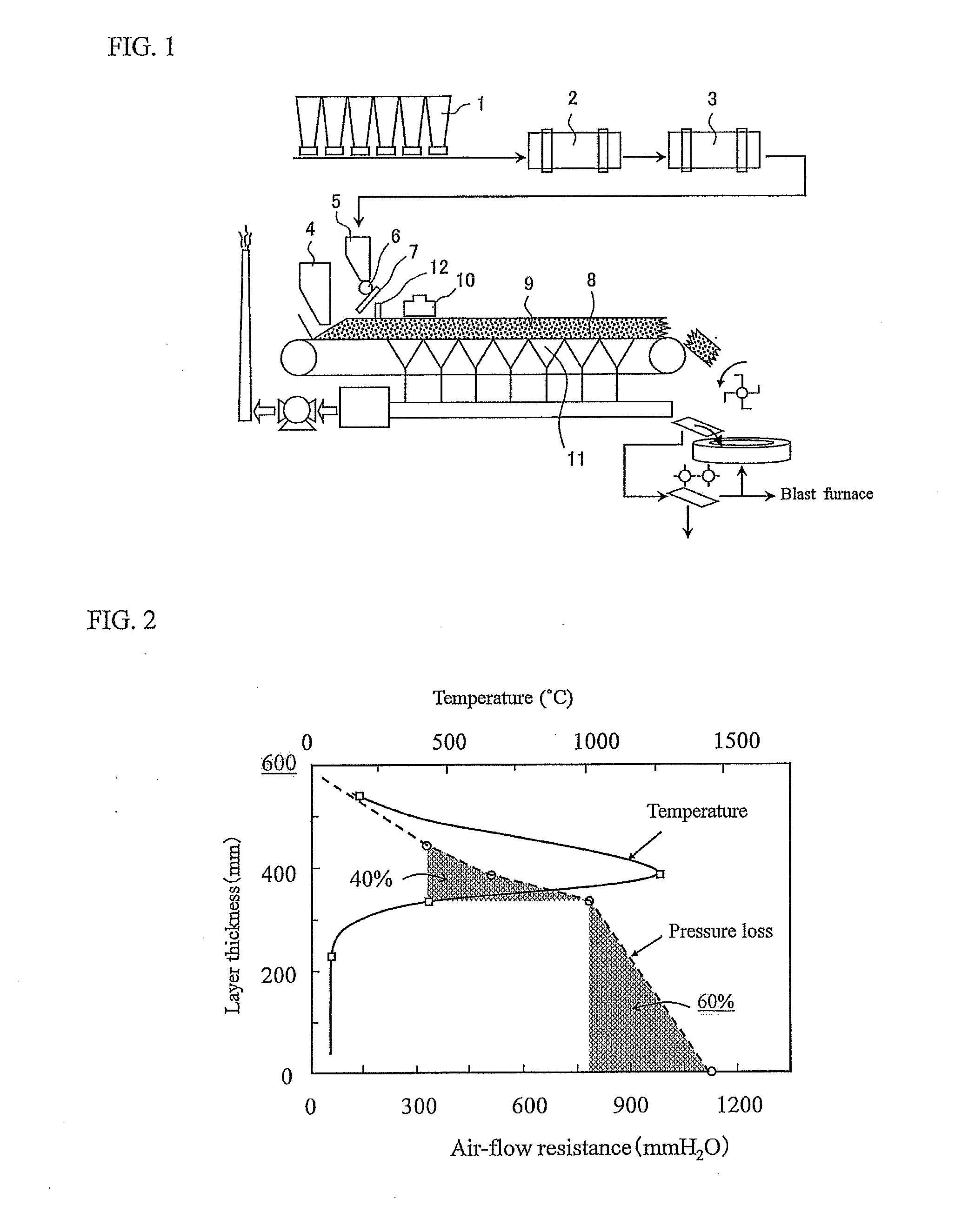

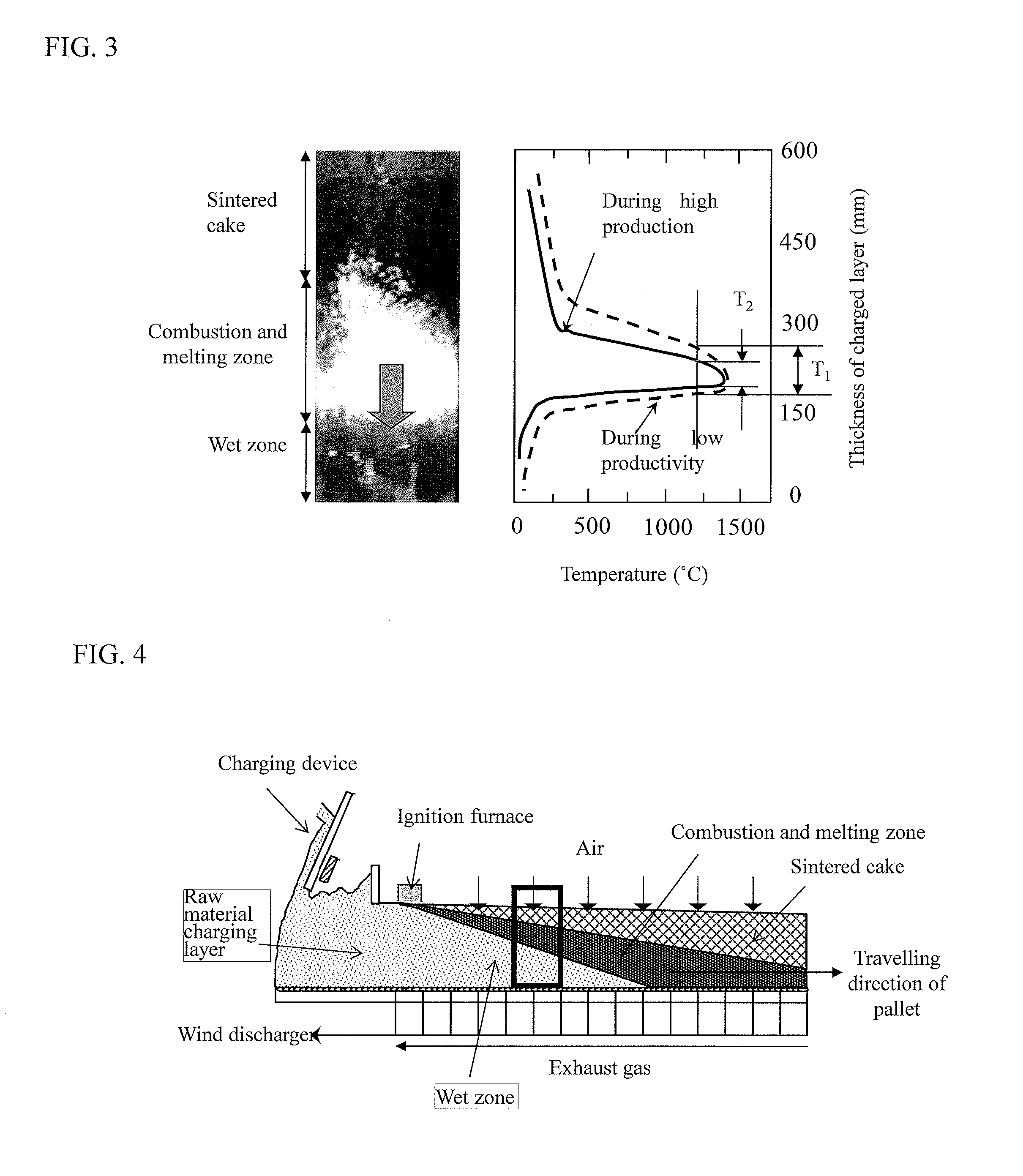

Method for producing sintered ore

Method for producing sintered ore in which air above a charged layer containing a gaseous fuel supplied from a plurality of gaseous fuel supplying devices installed in a machine length direction on a downstream of an ignition furnace of a sintering machine is sucked by a wind box disposed below a pallet and is introduced into the charged layer, and the gaseous fuel and the carbon material are combusted inside the charged layer to produce the sintered ore, wherein a total amount of supply of the gaseous fuel supplied from the gaseous fuel supplying devices is set to be constant, the amount of supply of the gaseous fuel supplied from each gaseous fuel supplying devices is increased or decreased depending on an amount of air sucked into the charged layer in a region which each gaseous fuel supplying device is installed, thereby optimizing a supply ratio of the gaseous fuel.

Owner:JFE STEEL CORP

Robot joint space point-to-point movement trajectory planning method

ActiveUS11103996B2Smooth movementEasy to operateProgramme-controlled manipulatorNumerical controlControl systemSimulation

A robot joint space point-to-point movement trajectory planning method. Joint space trajectory planning is performed according to the displacement of a robot from a start point to a target point during PTP movement and a limitation condition of a preset movement parameter physical quantity of each axis in a robot control system. An n-dimensional space is constructed by taking each axis of the robot as a vector, wherein n≥2, and the movement parameter physical quantity of each axis of the robot is verified according to a vector relationship between the n axes of the robot, so that a trajectory planning curve of each axis of the robot satisfies the limitation condition of the preset movement parameter physical quantity. The method has a small amount of calculations and strong real-time performance, the movement curves are mild, the control time is optimal, and the algorithm execution effect is good.

Owner:NANJING ESTUN ROBOTICS CO LTD

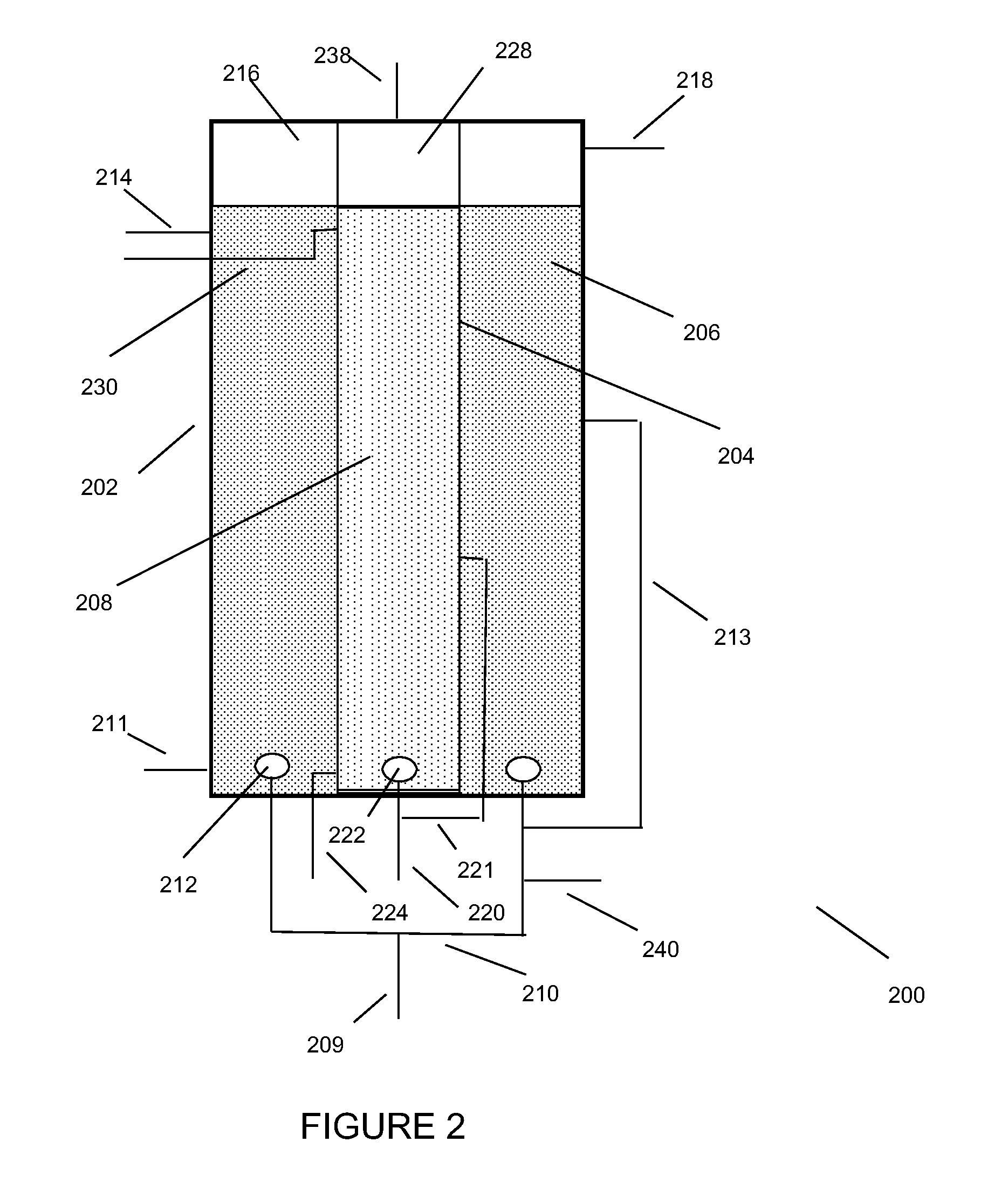

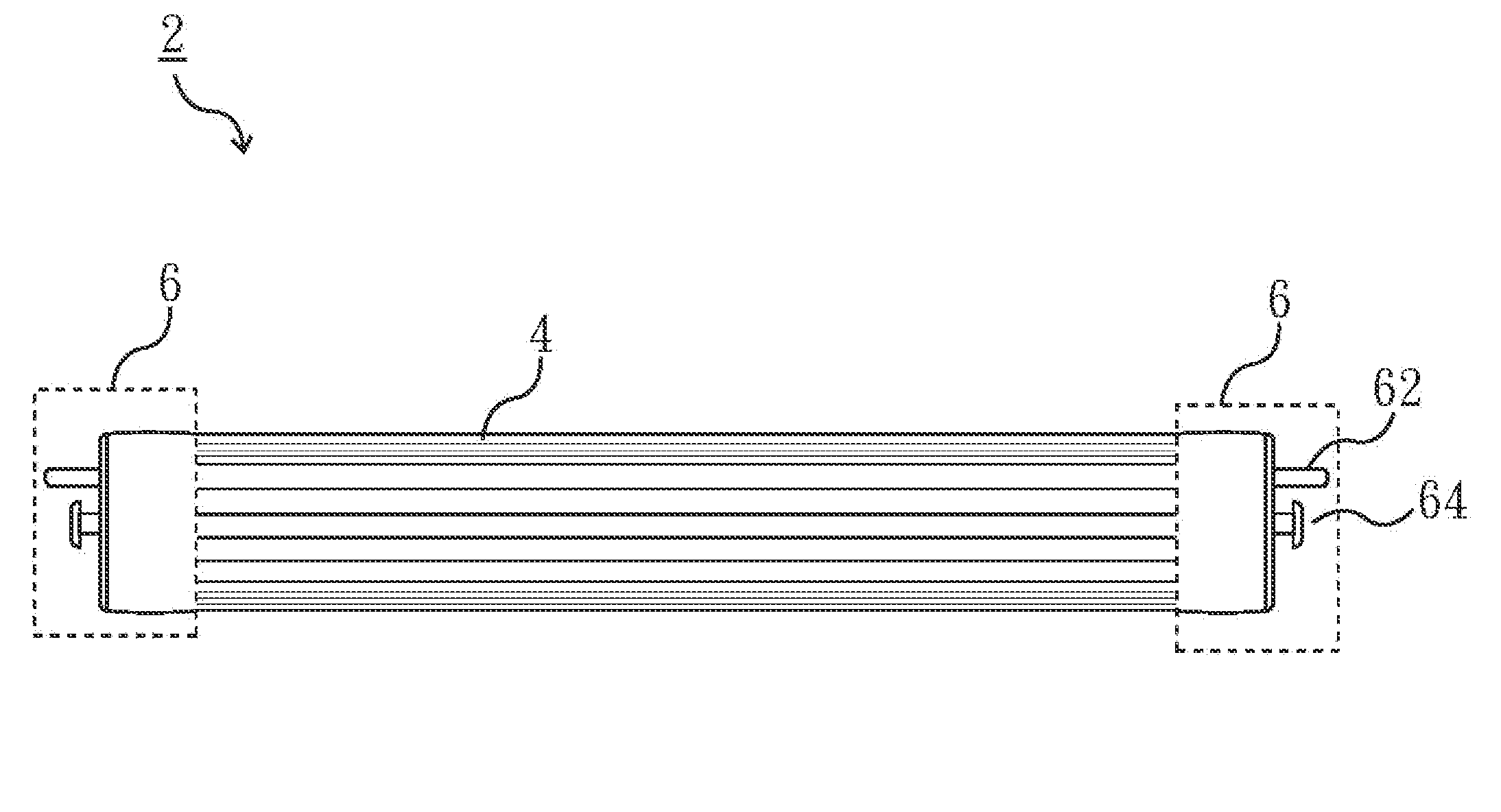

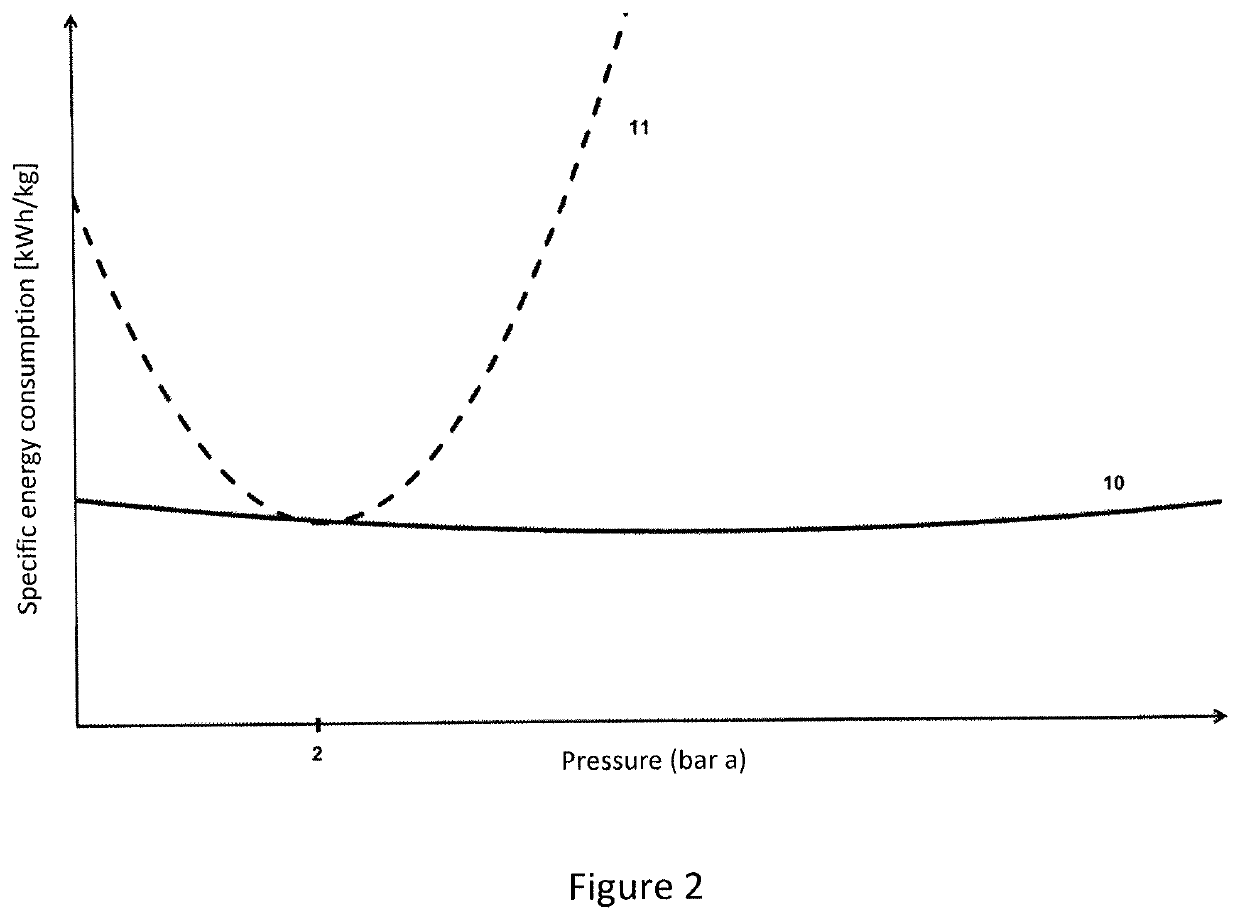

Ozone generation at high pressures

ActiveUS10829373B2High ozone concentrationHighly achievedElectrical discharge ozone preparationDielectricEnvironmental engineering

A method for producing ozone at elevated pressure with a capacity of at least 1 kg ozone / hour by an ozone generator having a high voltage electrode and a counter electrode. The electrodes delimit a gap in which a dielectric is arranged and through which a gas containing oxygen and having a gas pressure of pgas flows. The high voltage electrode and the counter electrode with a connection for an electric power supply to generate discharges are provided in at least one discharge gap. The power supply provides a voltage in a range from 1 kV to 50 kV and wherein stroke widths di of the discharge are distributed between a minimum stroke width dmin and a maximum stroke width dmax. The gas pressure pgas of the gas containing oxygen at the outlet of the ozone generator is at least 3 bar.

Owner:XYLEM IP MANAGEMENT SARL

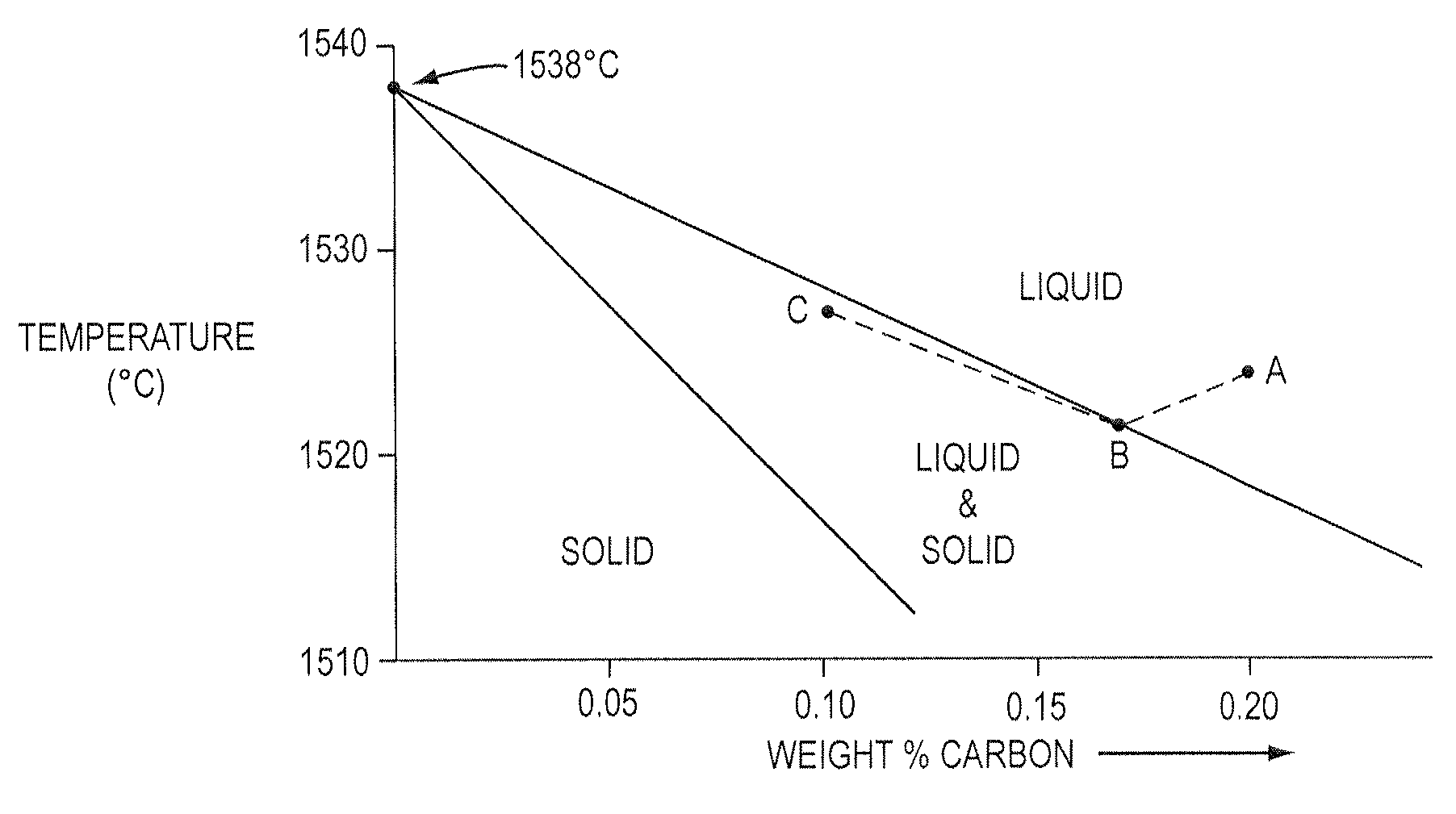

Method of refining the grain structure of alloys

The invention is directed to a method of making liquid metal compositions containing a large number of solid particles per unit volume, without external heat removal, which solid particles act as nuclei for grains when the metal is solidified. A method of forming a metal solid includes the step of partially removing a solute of a liquid metallic solution which is at its liquidus temperature to partially solidify a metal solvent component, thereby forming a solid fraction, wherein there is essentially no reduction in temperature of the liquid metallic solution and solid fraction. The method further includes the step of subsequently lowering the temperature of the liquid metallic solution and solid fraction to solidify the remaining liquid metallic solution and thereby form a solid that includes the solid fraction formed during the step of partial solute removal. In an embodiment, the method further includes turbulence from gas evolution which aids in solid particle formation and grain refinement.

Owner:MASSACHUSETTS INST OF TECH

Liquid jet recording apparatus, liquid jet head and recording liquid

InactiveUS20060203060A1Prevent nozzle cloggingAvoid cloggingInking apparatusMeasurement apparatus componentsLiquid jetFiber

A liquid jet head includes a nozzle element having nozzles from which a recording liquid is ejected to a recording medium, wherein the recording liquid contains fine particles of a pigment, wherein the fine particles of the pigment contained in the recording liquid are no less than 1% by weight, wherein each of the nozzles has an area that is less than 500 μm2, wherein each of the fine particles of the pigment has a diameter satisfying a relation of 0.0005≦Dp / Do≦0.02, wherein “Dp” represents the diameter of each of the fine particles of the pigment and “Do” represents a size of each of the nozzles, wherein when the nozzle element ejects the recording liquid onto the recording medium, a contact angle of the recording liquid stops changing when 100 ms or less elapses after the recording liquid contacts the recording medium, wherein the fine particles of the pigment are smaller than fibers of the recording medium, wherein the fine particles of the pigment are smaller than spaces between the fibers of the recording medium.

Owner:RICOH KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com