Magnesium alloy material and method for manufacturing the same

a technology of alloy materials and alloy materials, applied in the direction of manufacturing tools, heat treatment process control, heat treatment apparatus, etc., can solve the problems of low productivity and limited application of further parts, and achieve the effect of improving tensile strength, elongation, and proof strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

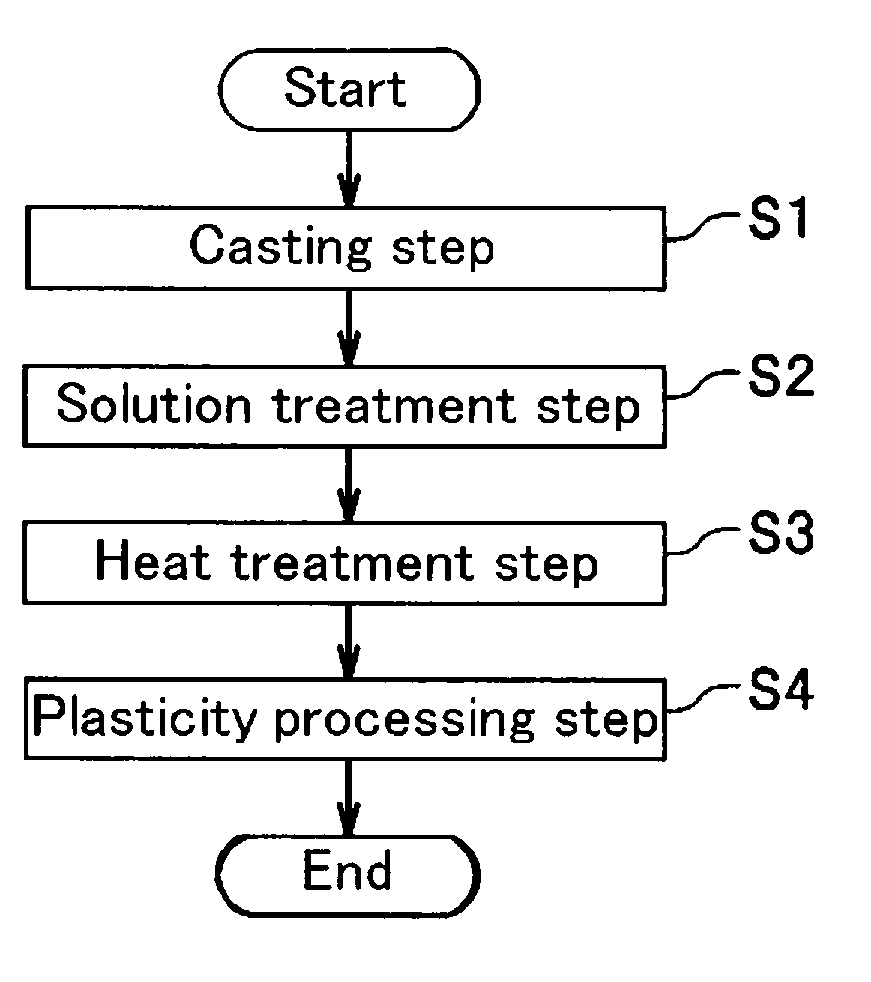

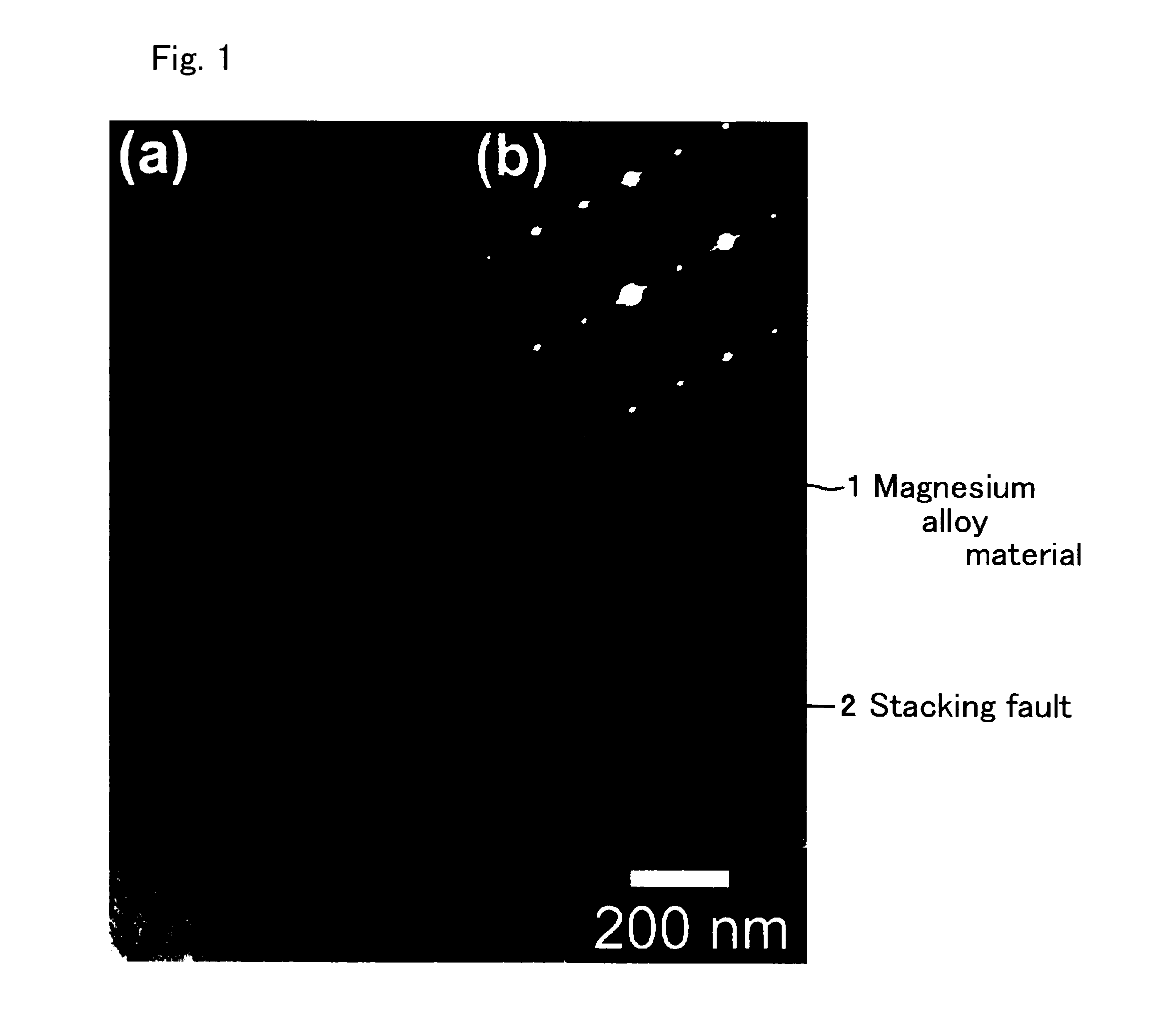

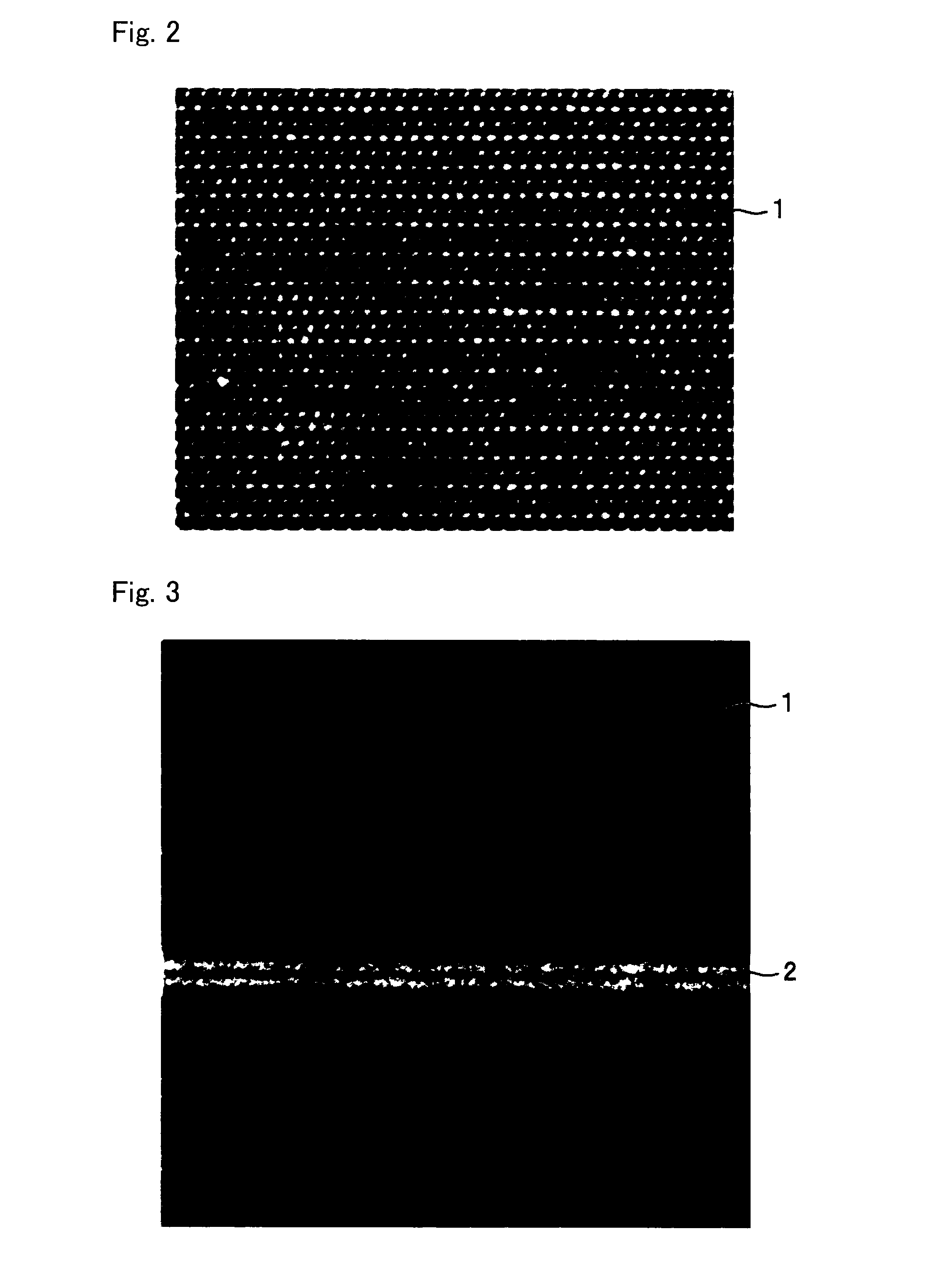

[0077]Next, Examples of the invention will be described. Herein, Examples merely exemplify the invention and do not at all limit the invention. FIG. 17 is a graph showing the relation of heat treatment temperature and the heat treatment time. FIG. 18 is a block chart showing the respective steps for evaluating mechanical properties. FIGS. 19(a) to 19(d) are TEM photographs in the case where each cast ingot is subjected to heat treatment at the respective temperatures for the respective times. FIGS. 12(a) to 20(c) are TEM photographs in the case where each cast ingot is subjected to heat treatment at a temperature of 673K for the respective times.

[0078]An Mg—Zn—Gd alloy containing 1 at. % of Zn, 2 at. % of Gd, and the rest including Mg and unavoidable impurities as a magnesium alloy material was loaded to a melting furnace and melted by a flux refining. Successively, the thermally melted material was cast by a casting die as shown in FIG. 18 to produce an ingot of a size of φ29 mm×L6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| average crystal grain diameter | aaaaa | aaaaa |

| elongation ratio | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com