Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "High yield in mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

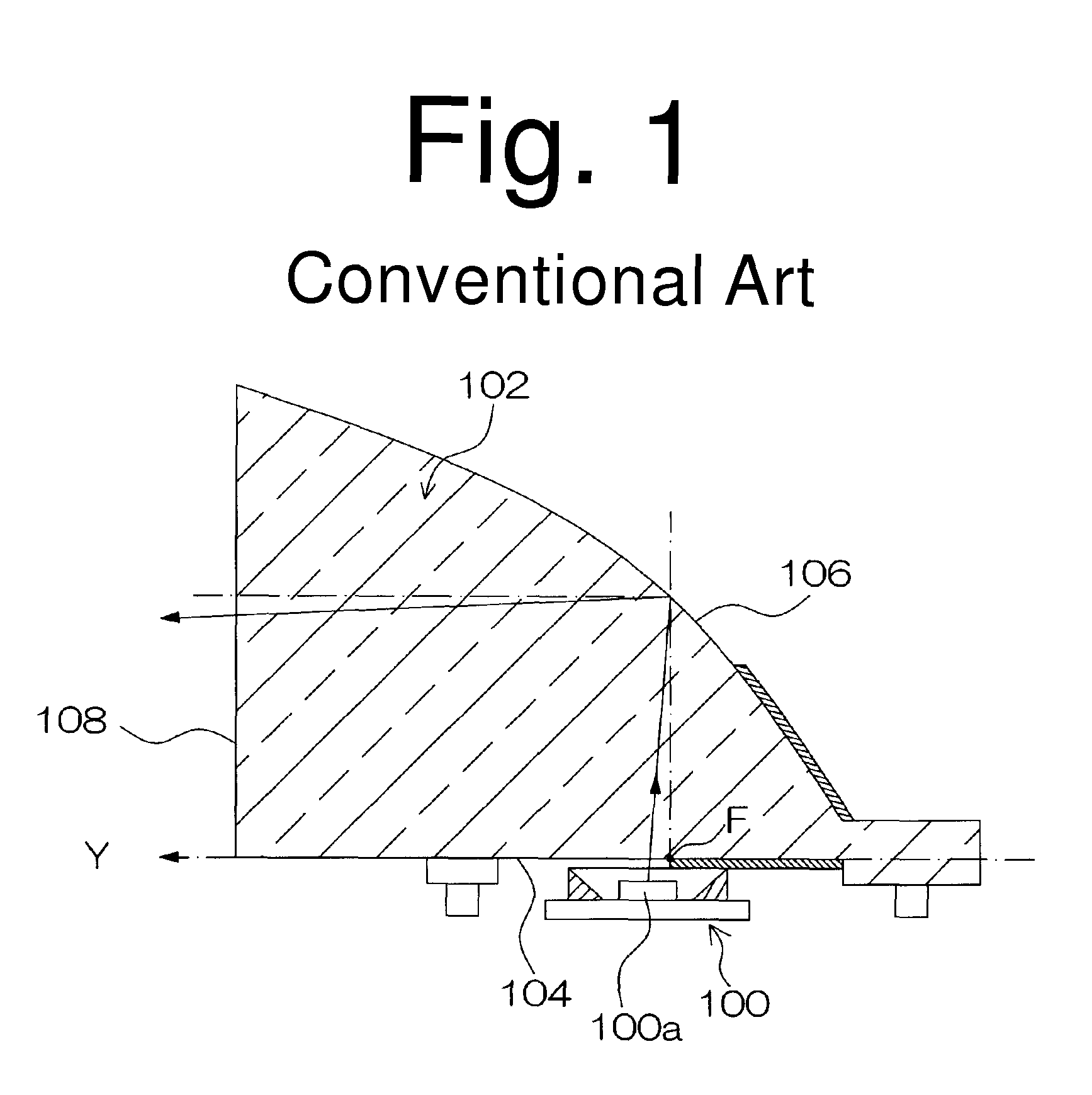

Vehicle light

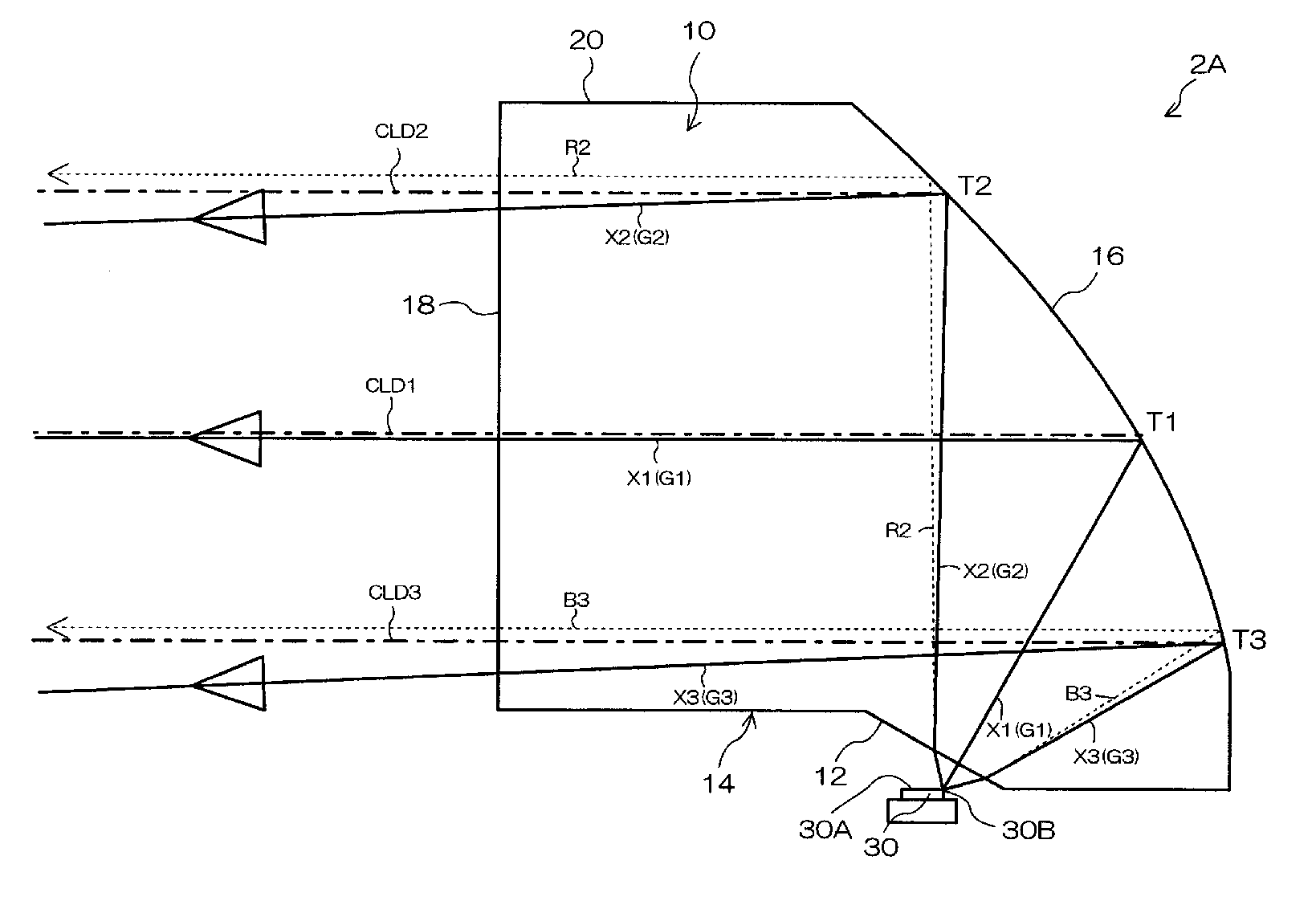

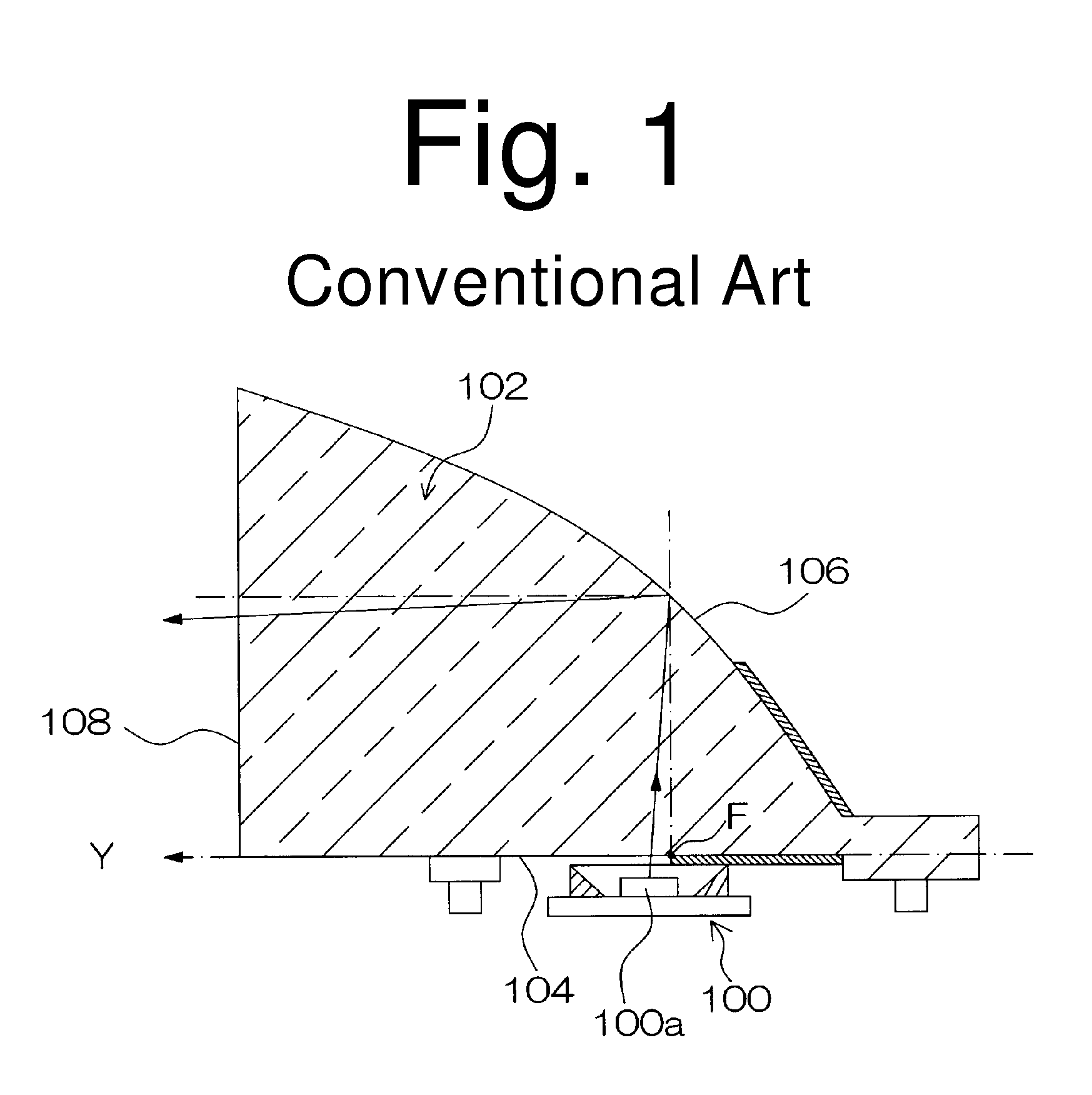

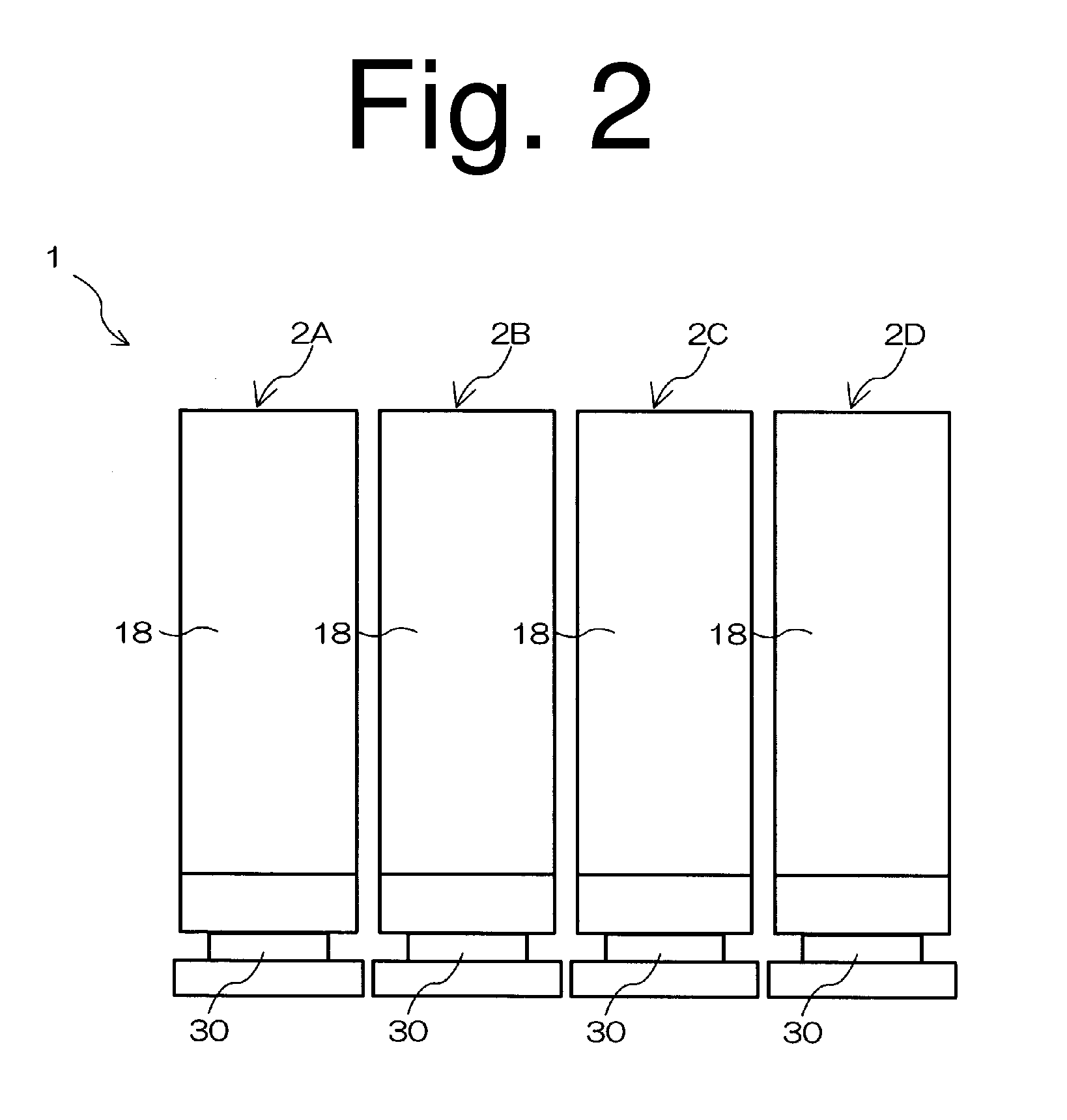

ActiveUS20110085343A1InhibitionLess coloringVehicle headlampsPoint-like light sourceLight guideLight beam

A vehicle light can include a light emitting diode (LED) serving as a light source and an optical system for controlling a light distribution pattern of the light beams from the LED light source utilizing a light guide (such as a lens body having an inner reflecting surface). The vehicle light can project illumination light with a low beam light distribution pattern. The vehicle light can include an LED light source and a lens body serving as a light guide. The lens body can include a light incident surface, a reflecting surface, and a light exiting surface. The LED light source can have a rearmost end light emitting point from which light beams are emitted to form a bright-dark boundary line. Among the light beams, perpendicularly incident light beams not subjected to refraction can be projected toward the bright-dark boundary line while obliquely incident light beams that are subjected to refraction can be corrected to be directed in a lower angular direction than the bright-dark boundary line and to be mixed with the other light beams, thereby preventing color shading of illumination light from the vehicle light.

Owner:SEOUL SEMICONDUCTOR +1

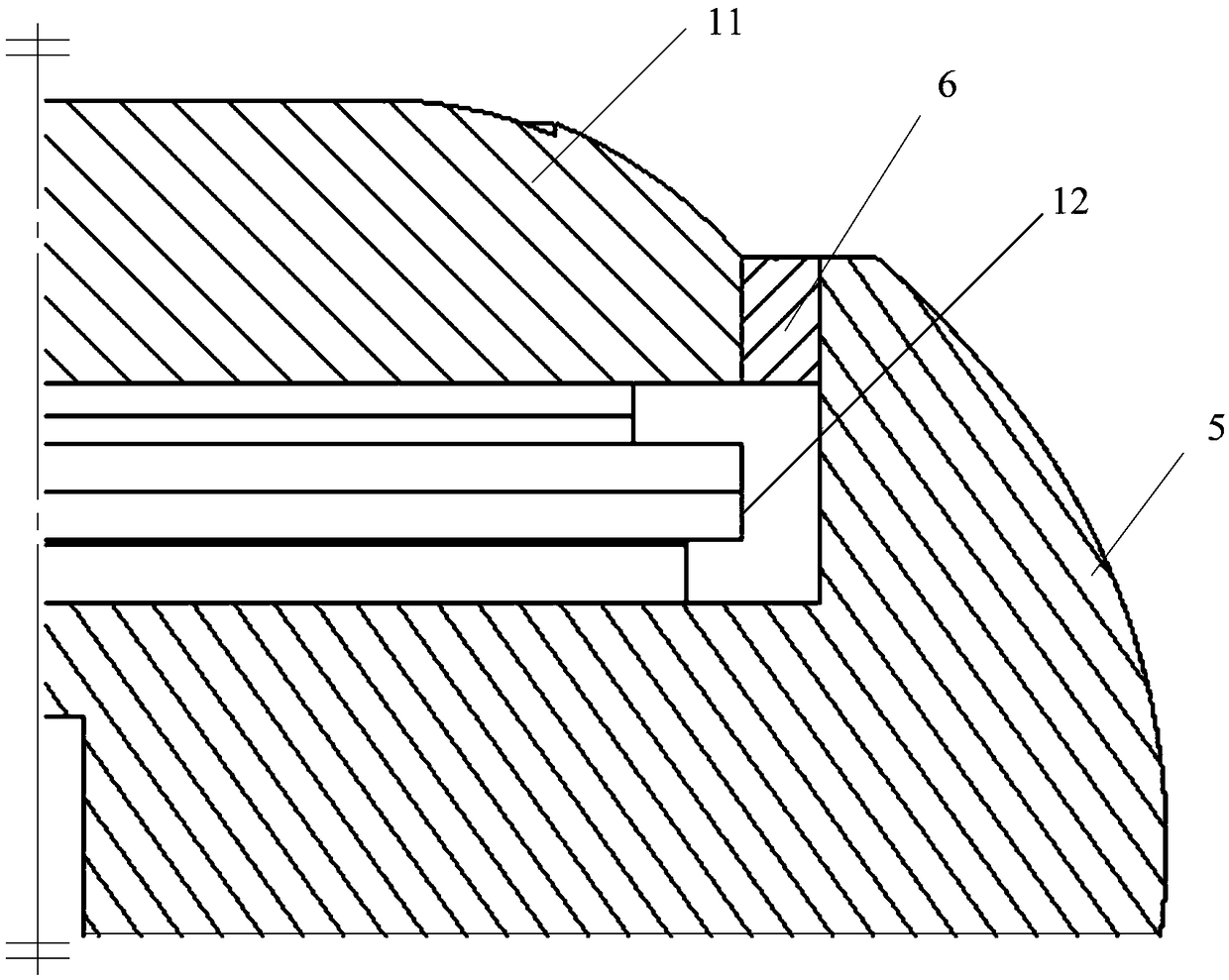

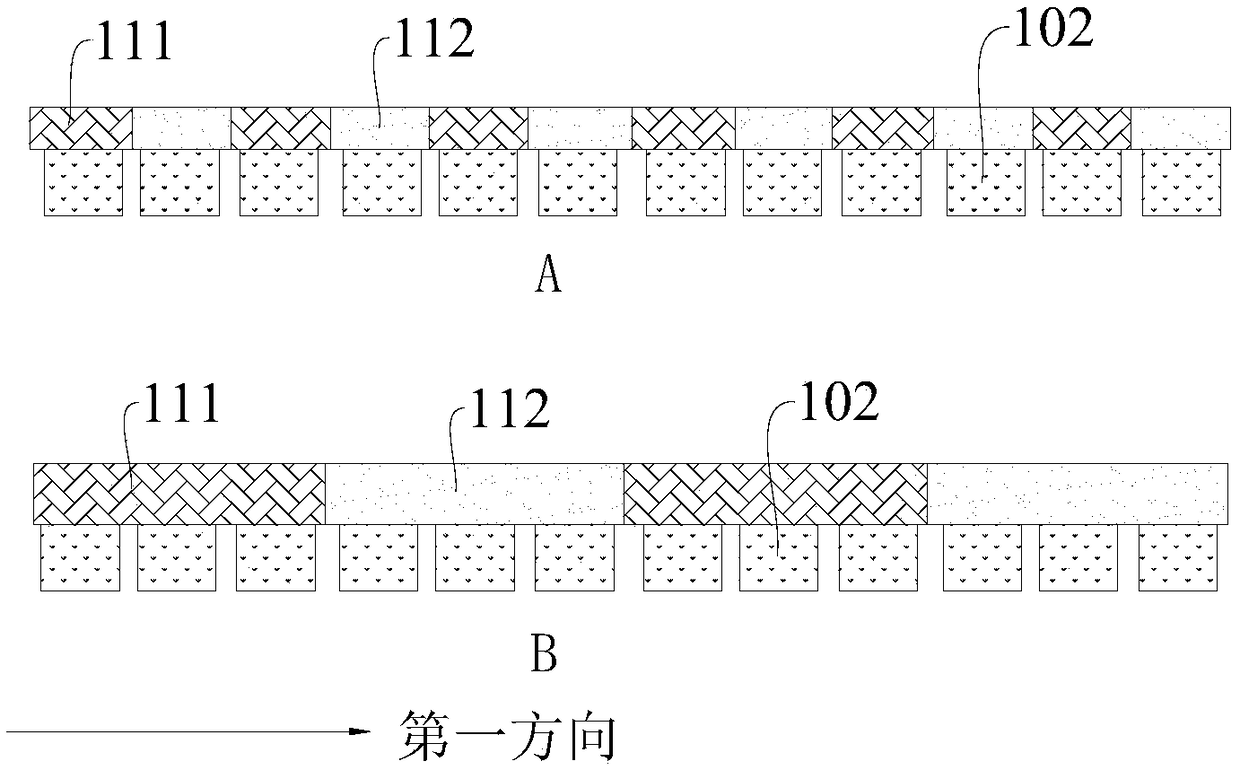

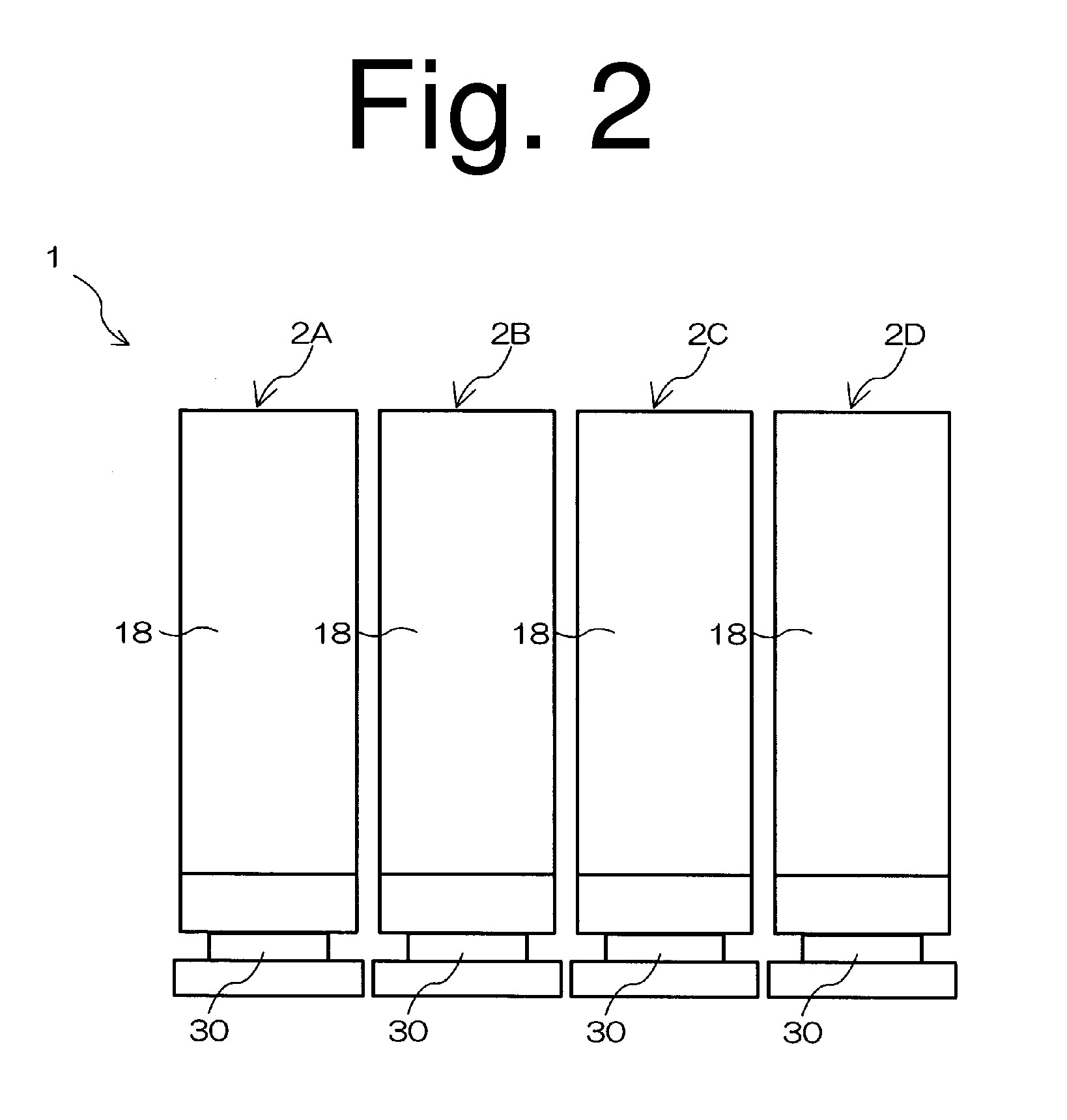

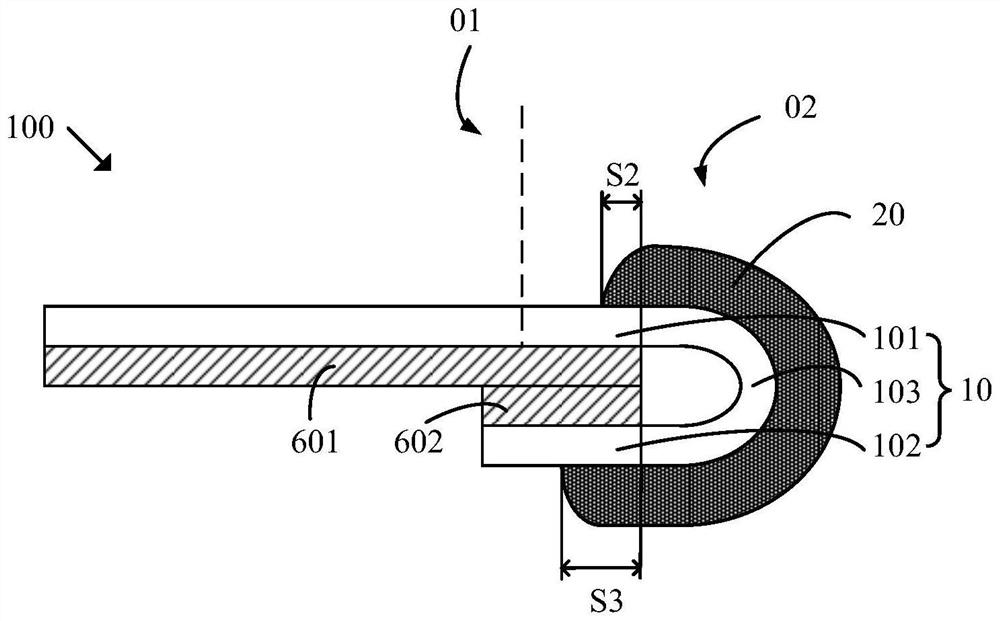

Display backplane

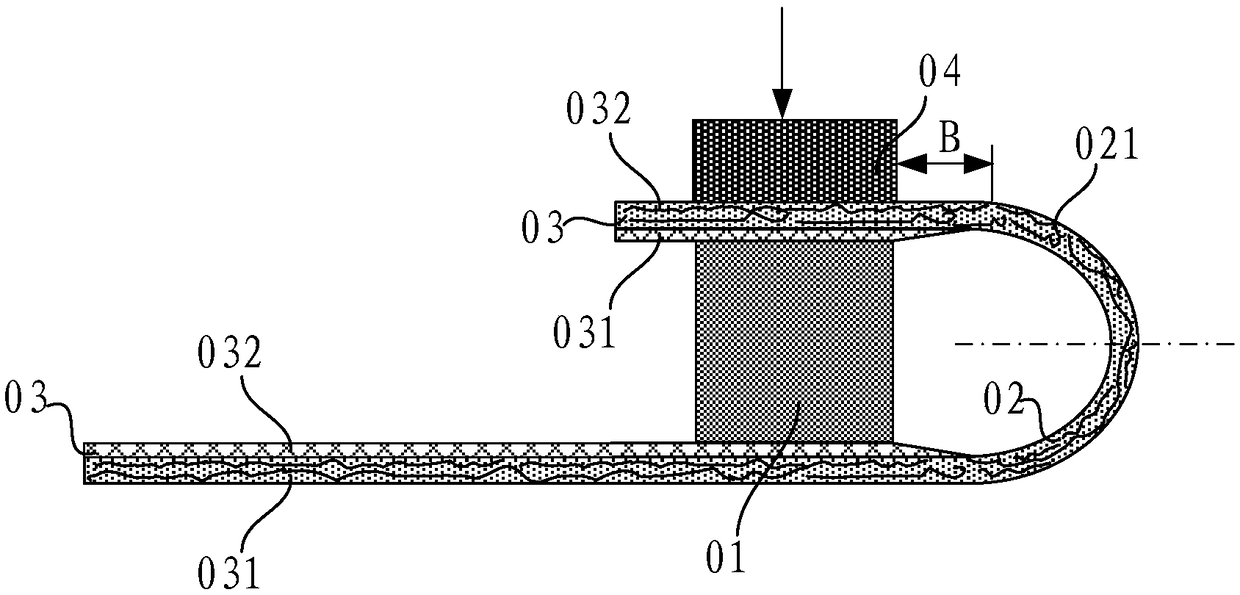

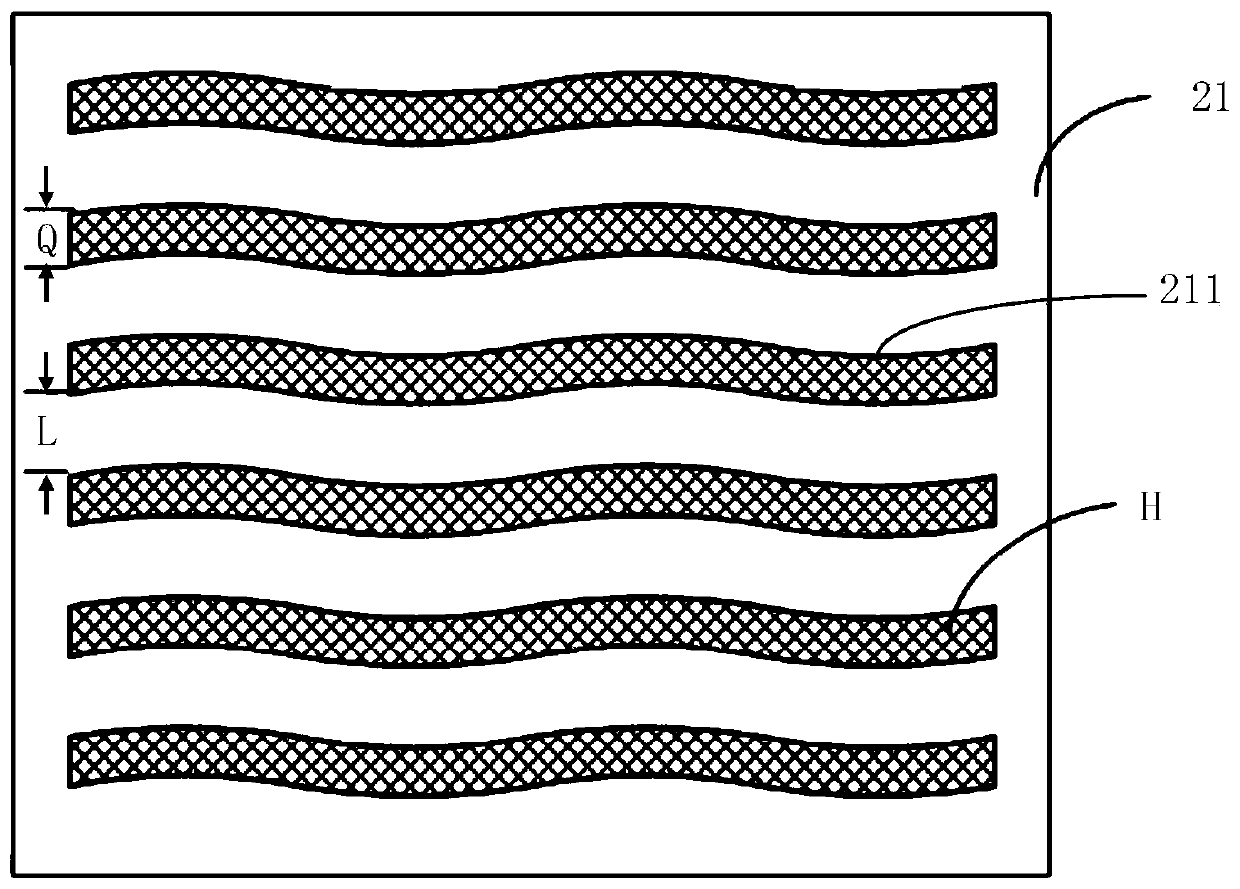

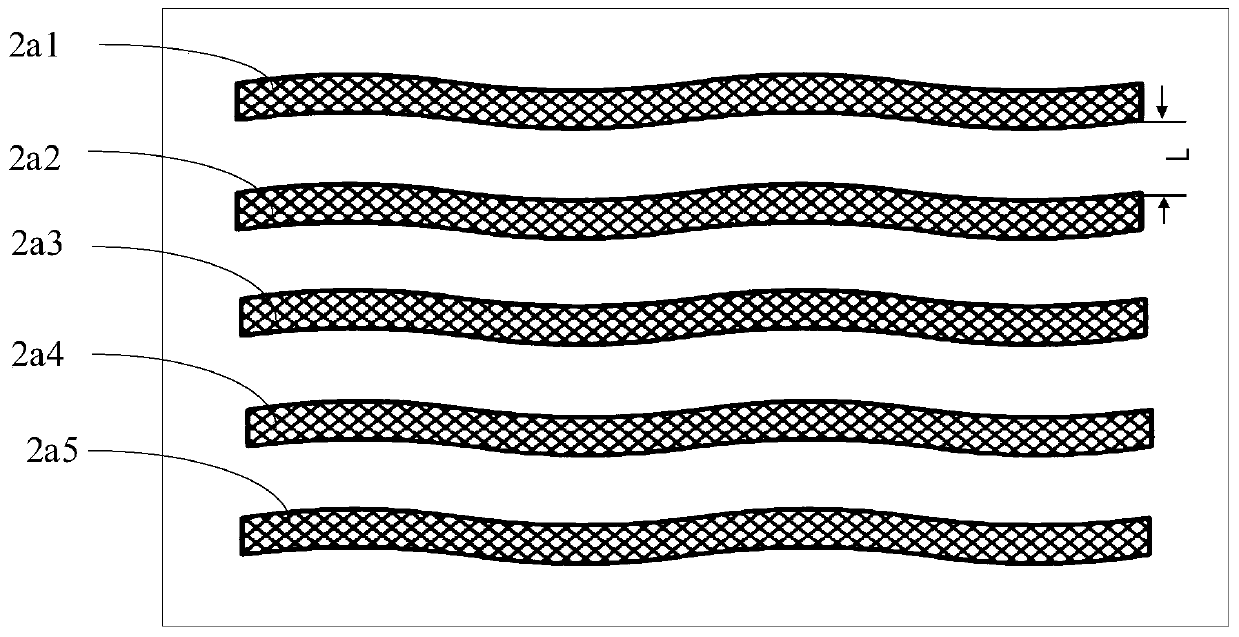

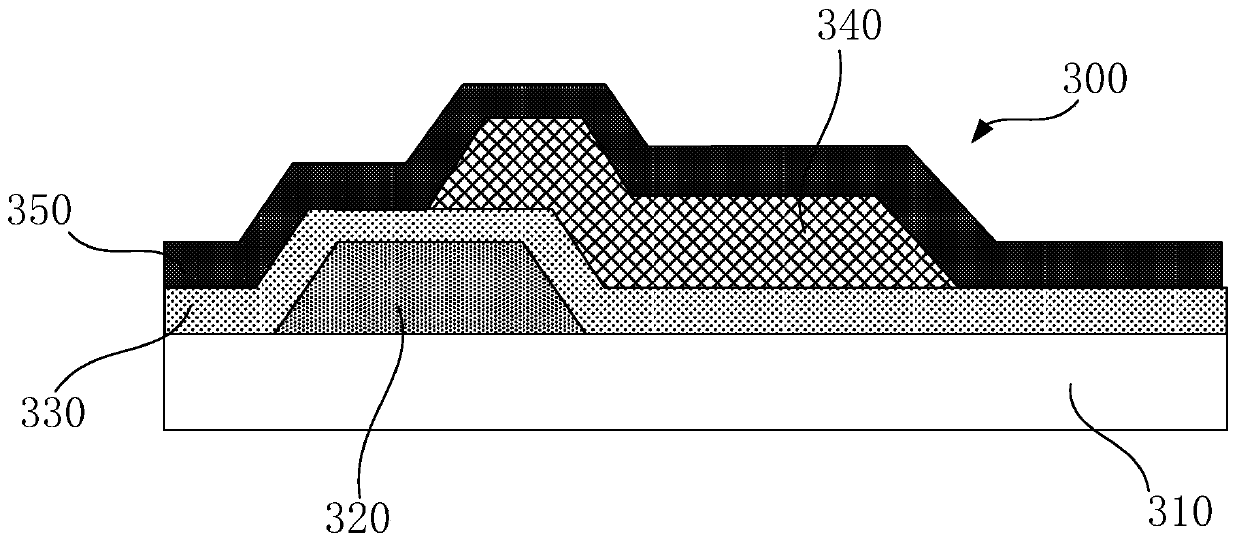

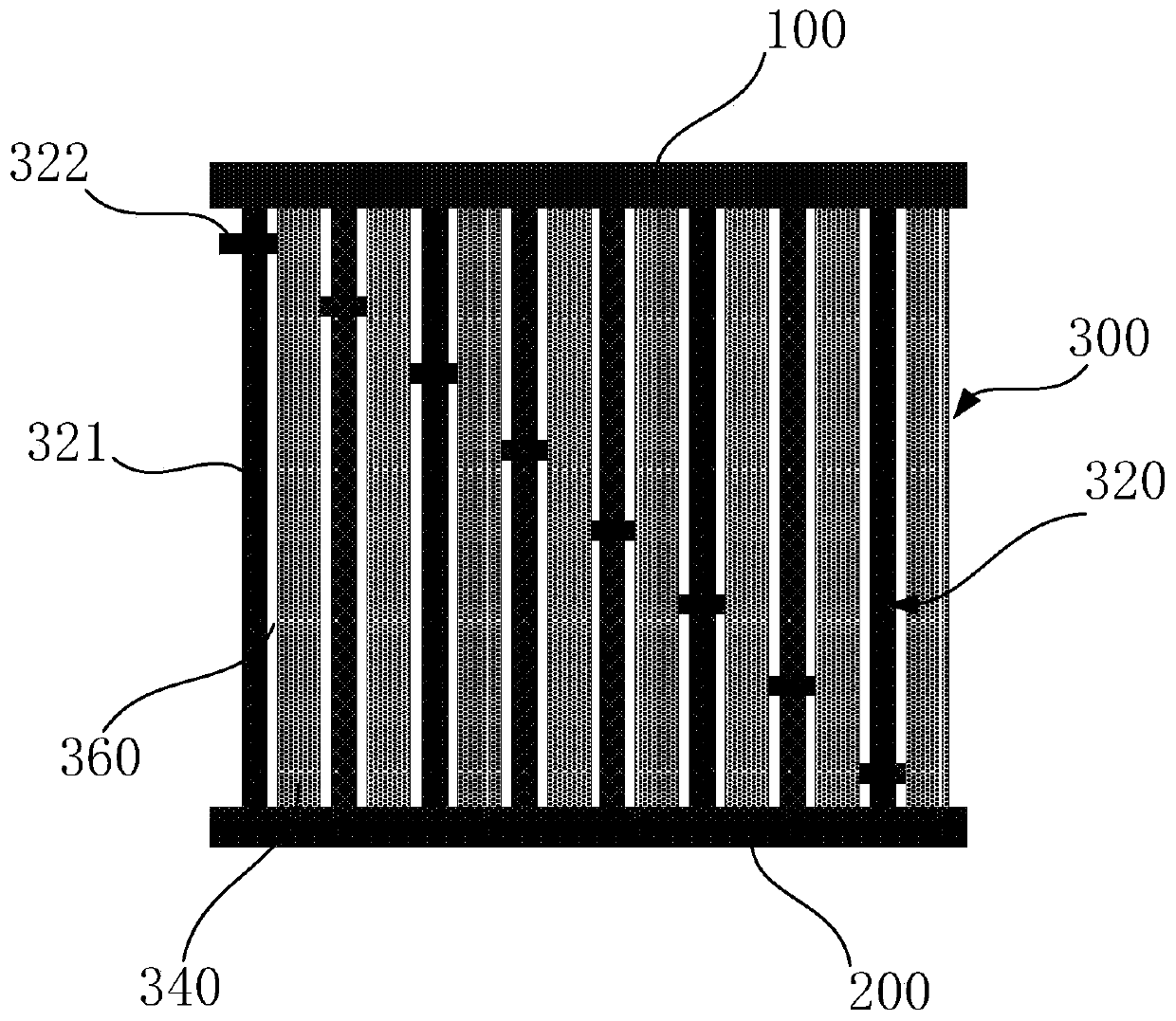

ActiveCN108735103AImprove the success rate of bendingReduce wrinklesIdentification meansEngineeringCushion

The invention relates to the technical field of display, and discloses a display backplane which comprises a bent region, non-bent regions and a connection layer. The non-bent regions include a firstnon-bent region and a second non-bent region, the first non-bent region and the second non-bent region are connected with each other by the bent region, the connection layer is arranged between the first non-bent region and the second non-bent region and is close to the bent region, and the first non-bent region and the second non-bent region can be supported by the connection layer and can be adhered with the connection layer. The display backplane has the advantages that cushion structures for cushioning squeezing effects of the edges of the connection layer on the non-bent regions are formed at the edges, which are close to the bent region, of the connection layer, cushion effects can be realized by the cushion structures when bending processes are carried out on the bent region of thedisplay backplane, accordingly, back films of the non-bent regions and metal in source and drain electrode metal layers of the non-bent regions can be prevented from being directly squeezed by the edges of the connection layer, squeezing acting force which is applied by the edges of the connection layer on metal routing in the bent region can be reduced, breakage of an internal metal wire can be reduced when the bent region is bent, the bending success rate of the display backplane can be increased, and the mass production yield of products can be increased.

Owner:BOE TECH GRP CO LTD +1

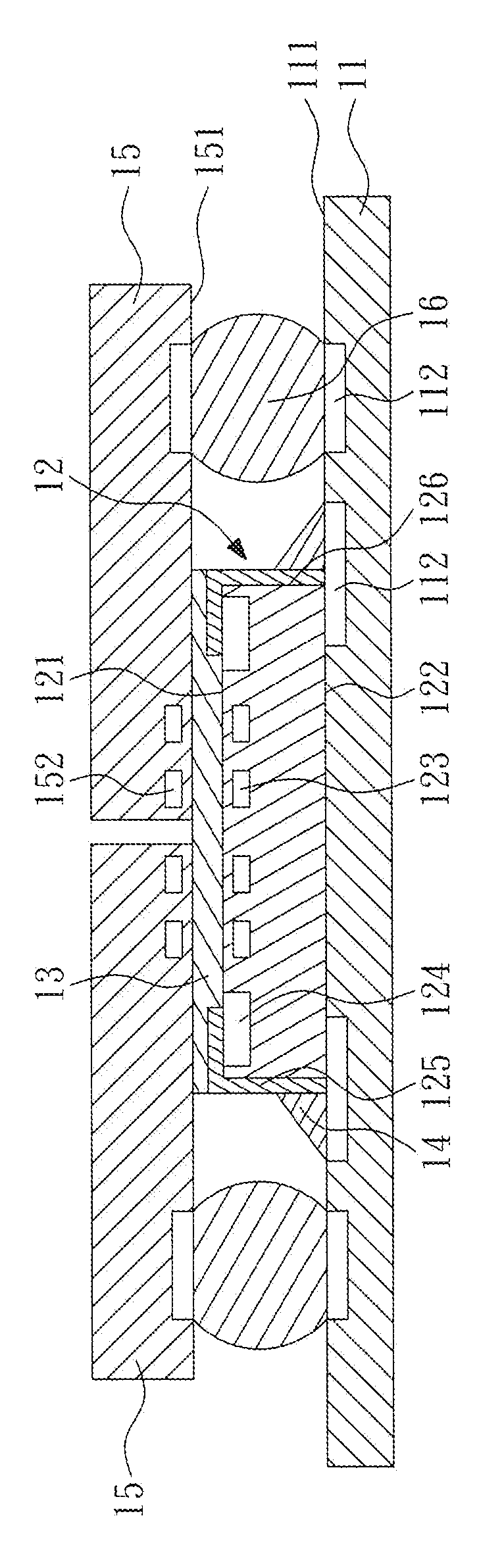

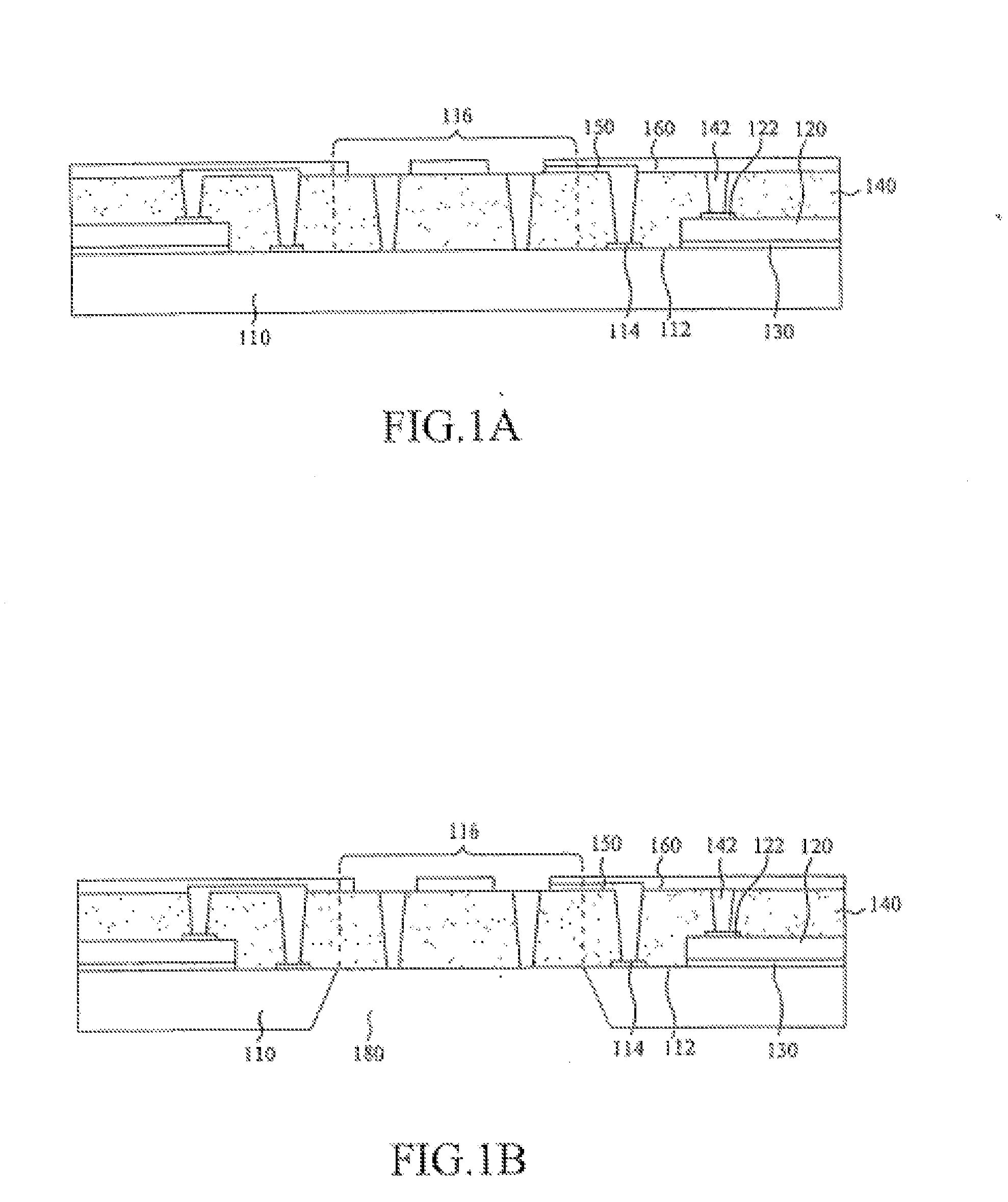

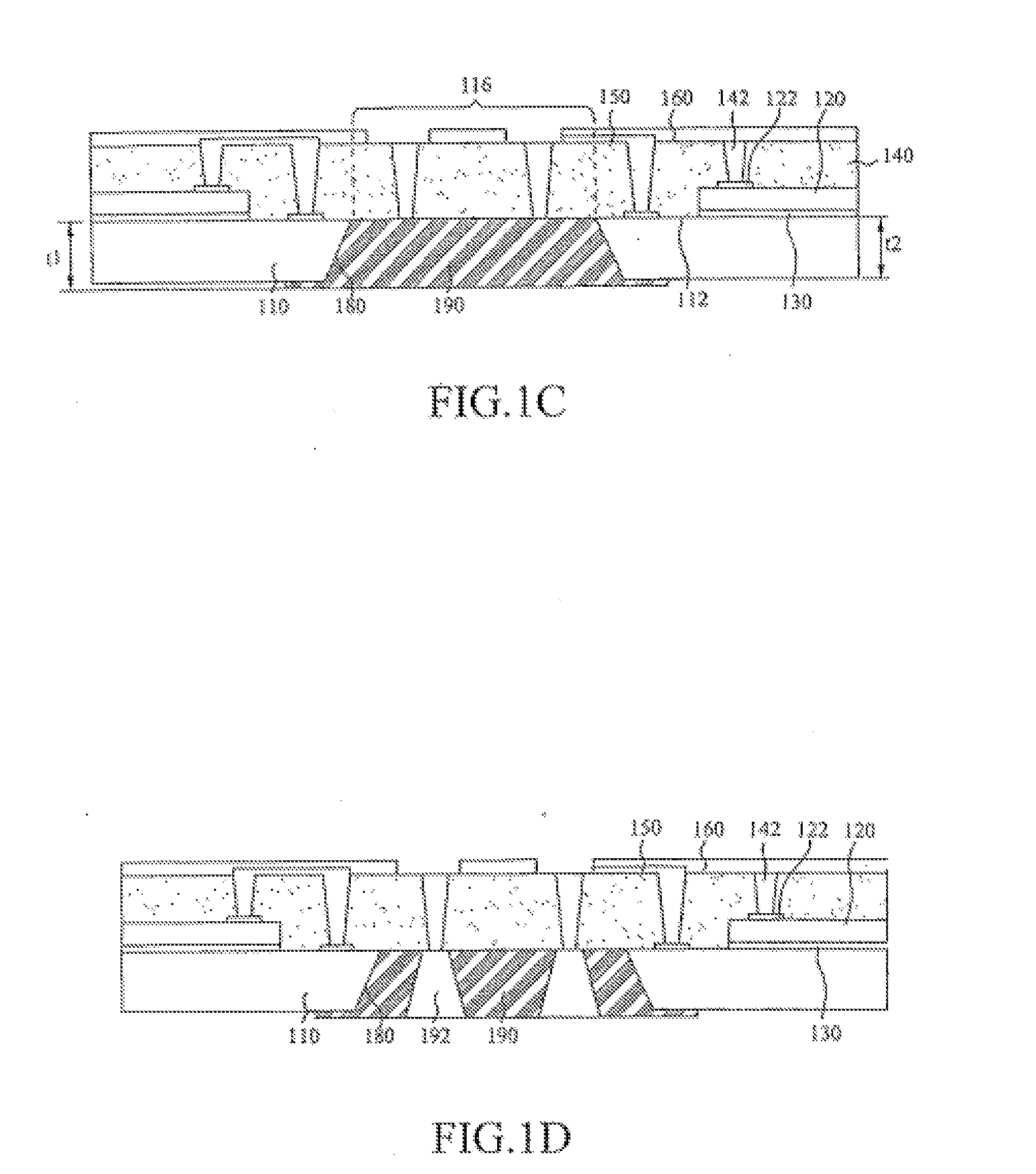

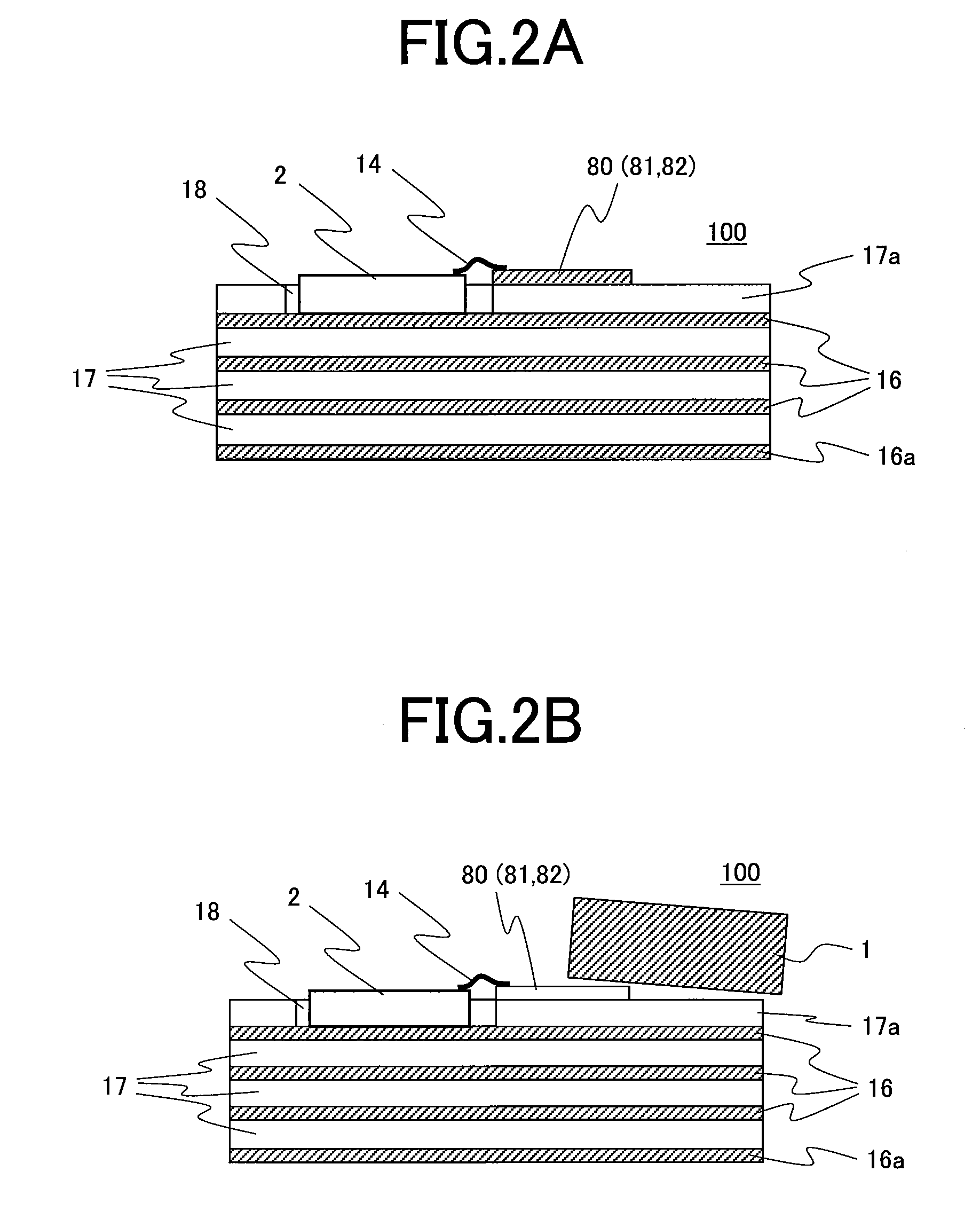

Semiconductor Package And Method For Making The Same

InactiveUS20120091575A1Mass-production yield is increasedHigh yield in mass productionSemiconductor/solid-state device detailsSolid-state devicesCapacitive couplingProximity communication

The present invention relates to a semiconductor package and a method for making the same. The semiconductor package includes a substrate, at least one first chip, a dielectric layer and at least one second chip. The first chip is attached and electrically connected to the substrate. The first chip includes a first active surface and a plurality of first signal coupling pads. The first signal coupling pads are disposed adjacent to the first active surface. The dielectric layer is disposed on the first active surface. The second chip is attached and electrically connected to the substrate by metal bumps. The second chip includes a second active surface and a plurality of second signal coupling pads. The second active surface contacts the dielectric layer. The second signal coupling pads are disposed adjacent to the second active surface, and capacitively coupled to the first signal coupling pads of the first chip, so as to provide proximity communication between the first chip and the second chip. Whereby, the gap between the first signal coupling pads of the first chip and the second signal coupling pads of the second chip is controlled by the thickness of the dielectric layer. Therefore, the mass-production yield of the semiconductor package is increased.

Owner:ADVANCED SEMICON ENG INC

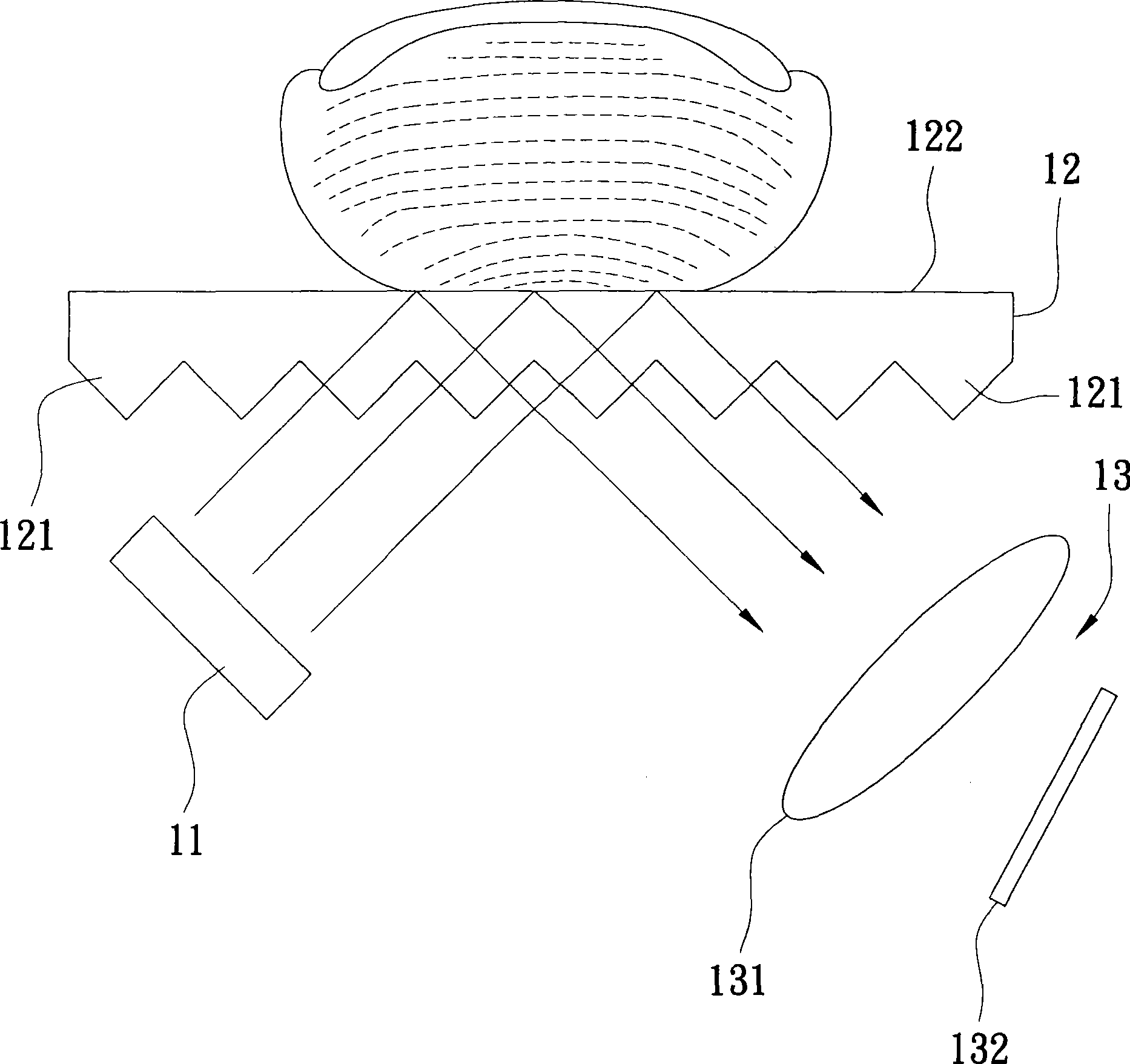

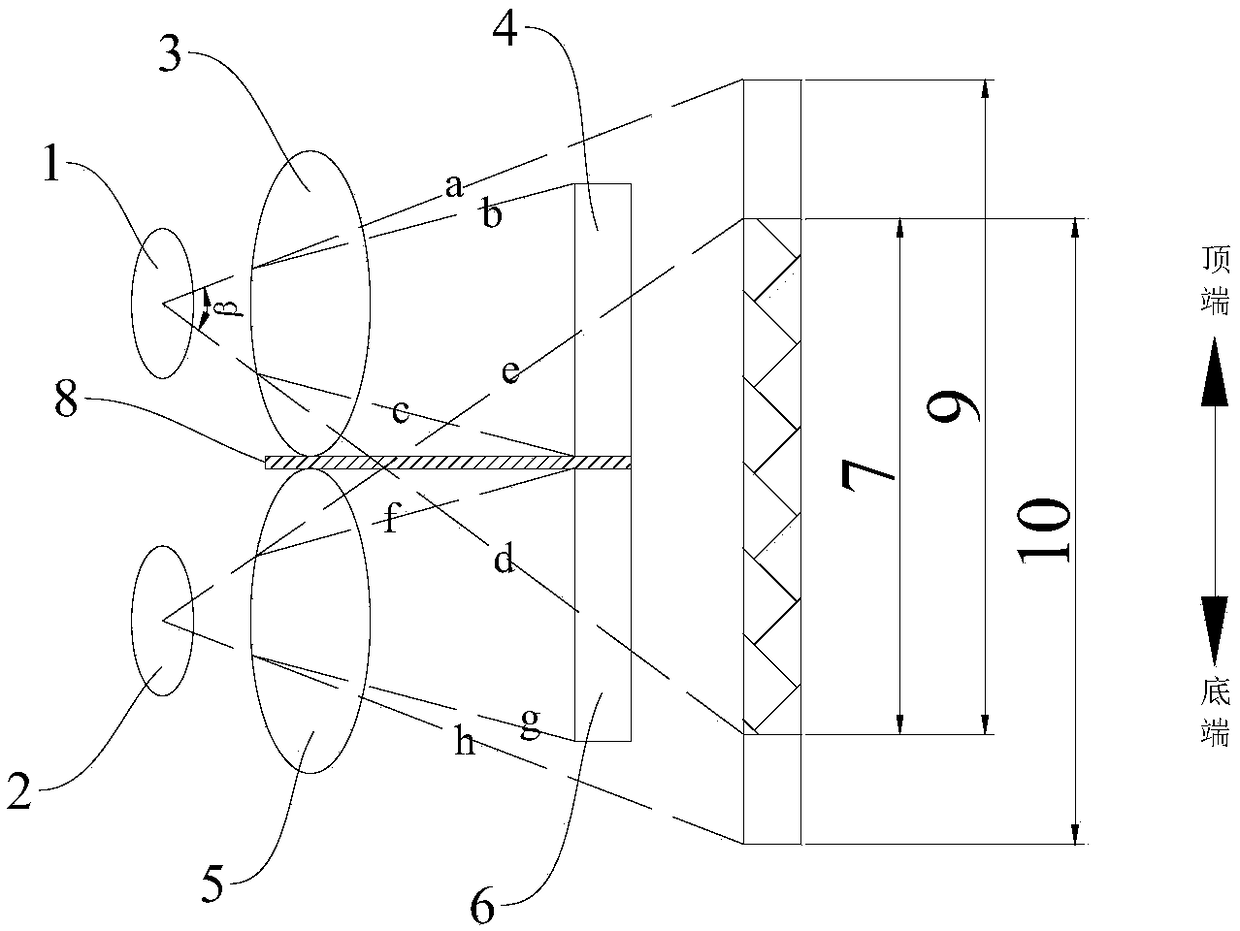

Finger print input module

InactiveCN101419662AReduced installation accuracyHigh yield in mass productionCharacter and pattern recognitionPrismImage signal

The invention discloses a fingerprint input module group which comprises a light emitting unit, an imaging unit and an image sampling unit. The light emitting unit comprises a plane light source for emitting lights and a light harvesting punch hole. The imaging unit comprises a transparent substrate which is septal to the plane light source and at least one micro-prism element which is arranged on the substrate; the image sampling unit and the imaging unit are respectively arranged at the two opposite sides of the emitting unit. Lights are collected by the light harvesting punch hole and are converted into an image signal. By the septal between the plane light source and the substrate and due to the fact that the image sampling unit and the imaging unit are respectively arranged at the two opposite sides of the emitting unit, the image sampling unit can obtain clearly demarcated bright and dark fingerprint images. Therefore, the required installation precision of the units which are mutually overlapped can be lowered greatly, and the yield rate can be improved.

Owner:巫仁杰

Wafer Leveled Chip Packaging Structure and Method Thereof

ActiveUS20150364457A1Reduce manufacturing costHigh yield in mass productionSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical and Electronics engineering

A wafer-leveled chip packaging method, comprising the steps of: providing a wafer; attaching at least one first chip to the wafer; forming a first insulating layer on the wafer; forming a plurality of first conductive vias penetrating the first insulating layer, wherein parts of the first conductive vias are electrically connected with the first chip; forming a conductive pattern layer on the surface of the first insulating layer wherein the conductive pattern layer is electrically connected with the first conductive vias; forming a plurality of through holes penetrating the wafer; filling a second insulating layer in the through holes; and forming a plurality of second conductive vias in the second insulating layer, wherein the second conductive vias are electrically connected with the first conductive vias.

Owner:INVENSAS CORP

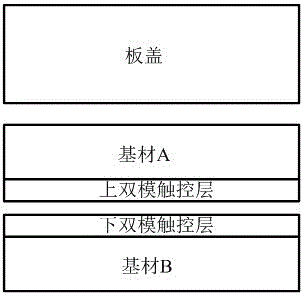

Electromagnetic and capacitive dual-mode touch screen

InactiveCN105867708ASimple structureLow costInput/output processes for data processingCapacitanceDual mode

The invention discloses an electromagnetic and capacitive dual-mode touch screen which comprises a base material A and a base material B. One surface of the base material A and one surface of the base material B are both provided with a dual-mode touch layer, and the base material A provided with one dual-mode touch layer and the base material B provided with one dual-mode touch layer are assembled to form the dual-mode touch screen. Each dual-mode touch layer is internally provided with a capacitance inductor and an electromagnetic inductive loop, wherein the capacitance inductor and the electromagnetic inductive loop are located on the same horizontal plane. Inductive devices, namely the dual-mode touch layers, are arranged on the two base materials respectively, the placed inductive devices do not need to be processed on two sides, scratches are reduced, and the yield is increased. Compared with glass base materials, film materials are used in the base materials in the screen, so that the problem that films are likely to be broken and scratched during cutting does not exist. Besides, the base materials made of the film materials can well meet the requirement for light products.

Owner:钟新宇

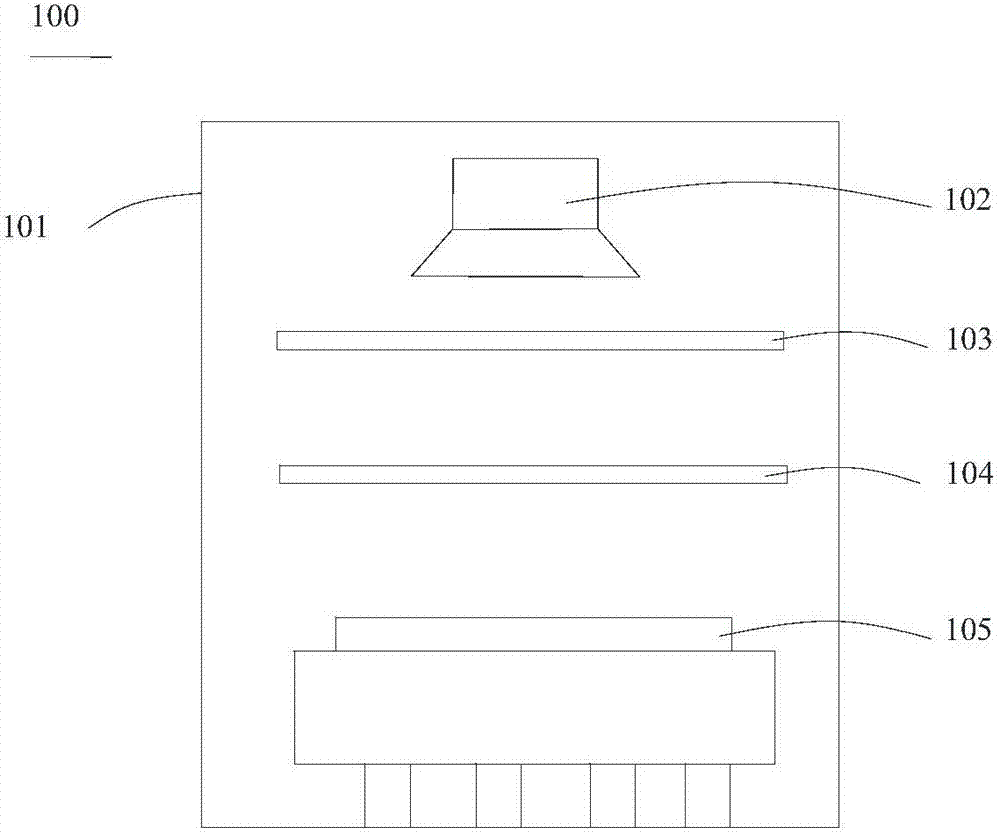

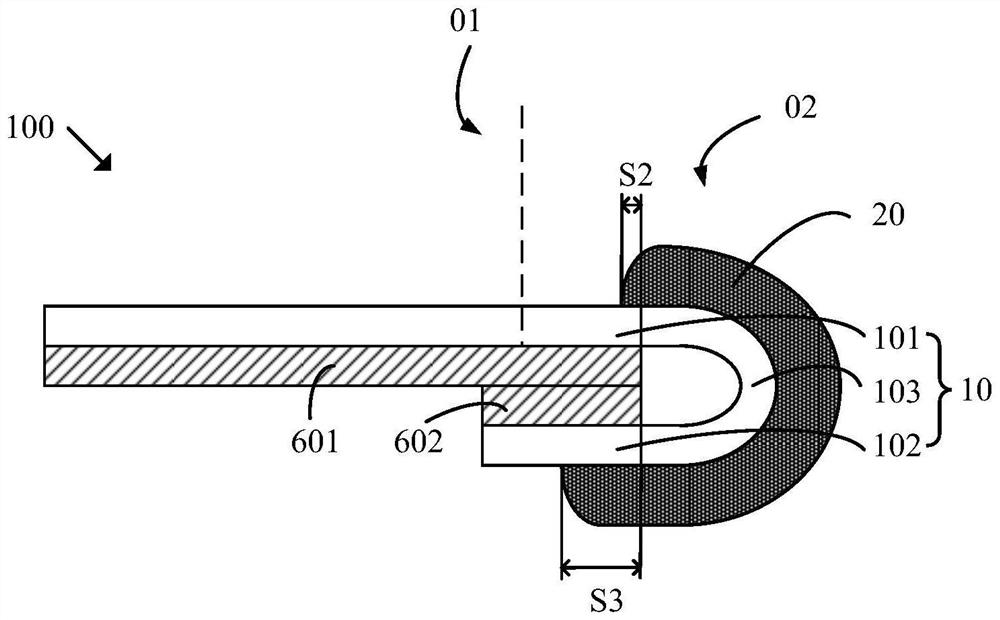

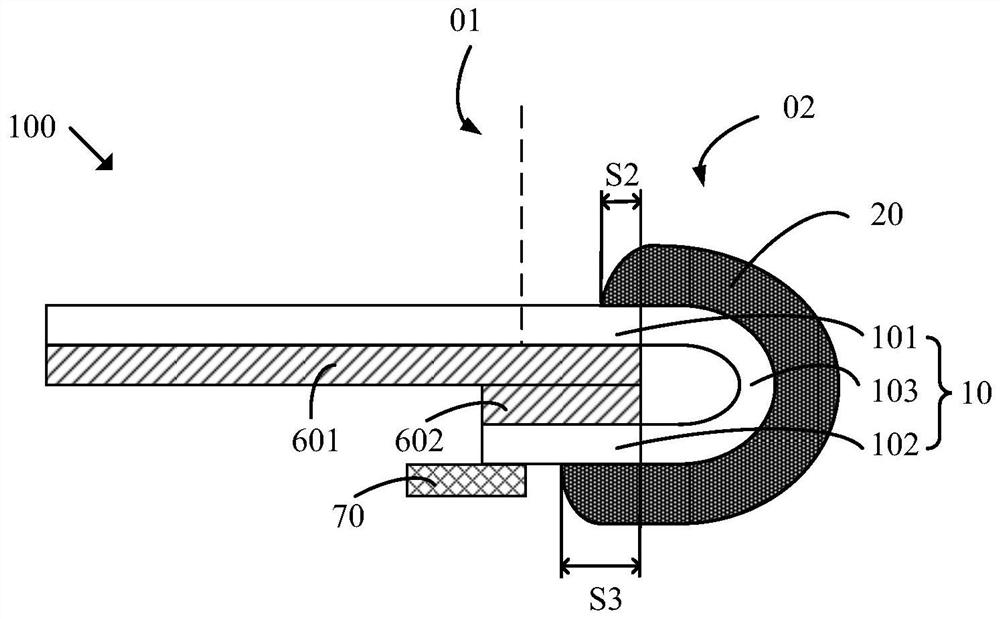

Display screen and mobile terminal

InactiveCN108494912AGuaranteed reliabilityAvoid side dispensing processTelephone set constructionsEngineeringComputer engineering

Owner:VIVO MOBILE COMM CO LTD

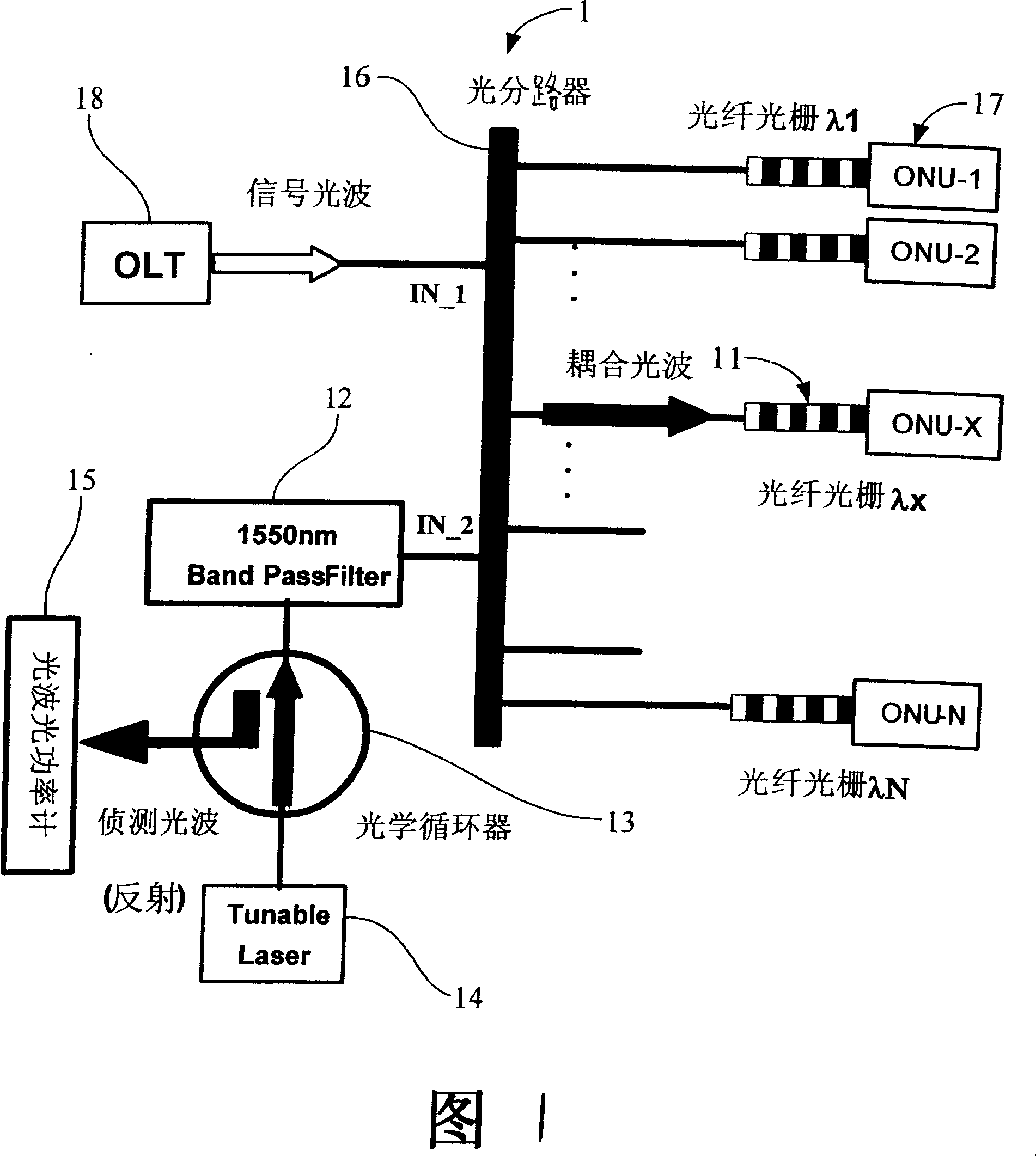

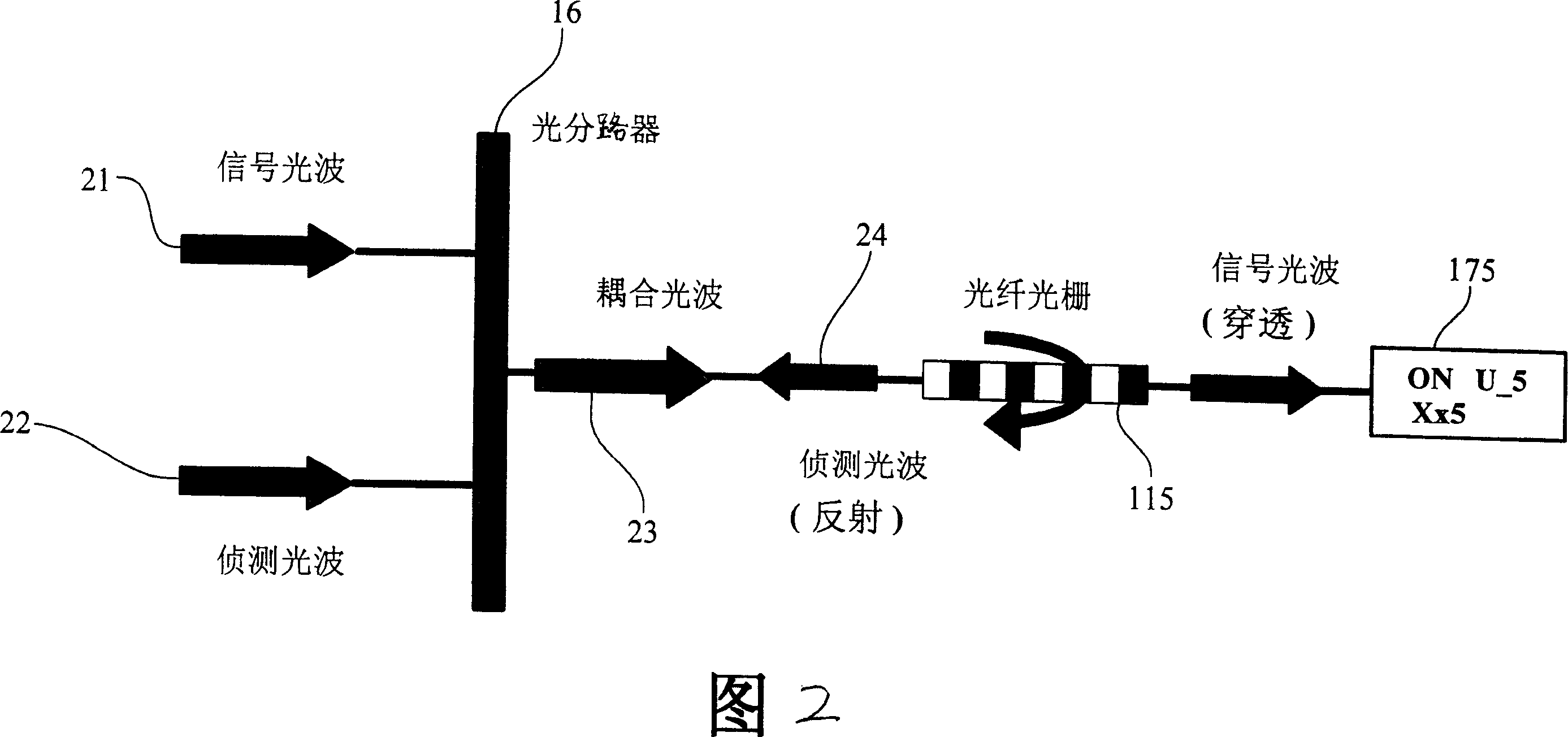

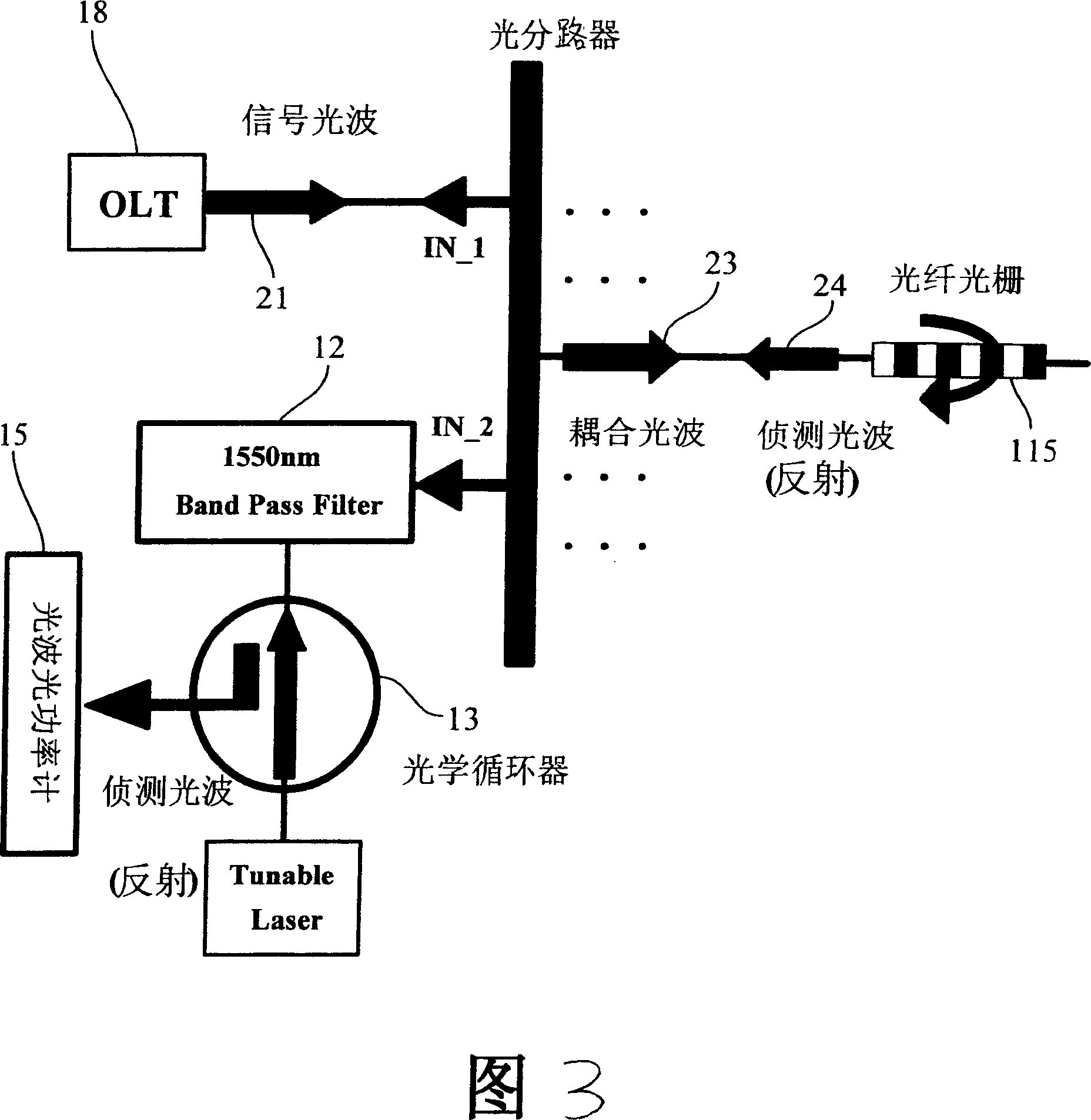

Detecting device for optical-fiber circuit breakage of passive light network PON system

InactiveCN1980094AReliableIntegrityWavelength-division multiplex systemsElectromagnetic transmissionOptical power meterGrating

Using intensity of reflected light of sensing light wave from fiber grating, the invention determines whether there is disconnection in fiber loop, or light loss of fiber loop is too high in order to distinguish whether electric system control or fiber loop goes wrong decidedly. Using 1550nm fiber Bragg grating as main module, the device includes 1550nm light band-pass filter, optical circulator, tunable laser light source, and optical power meter of light wave. The invention is the technique for detecting disconnection of fiber loops in low cost, and replicated assembling and repeatedly uses so as to reduce maintenance cost outdoors.

Owner:CHUNGHWA TELECOM CO LTD

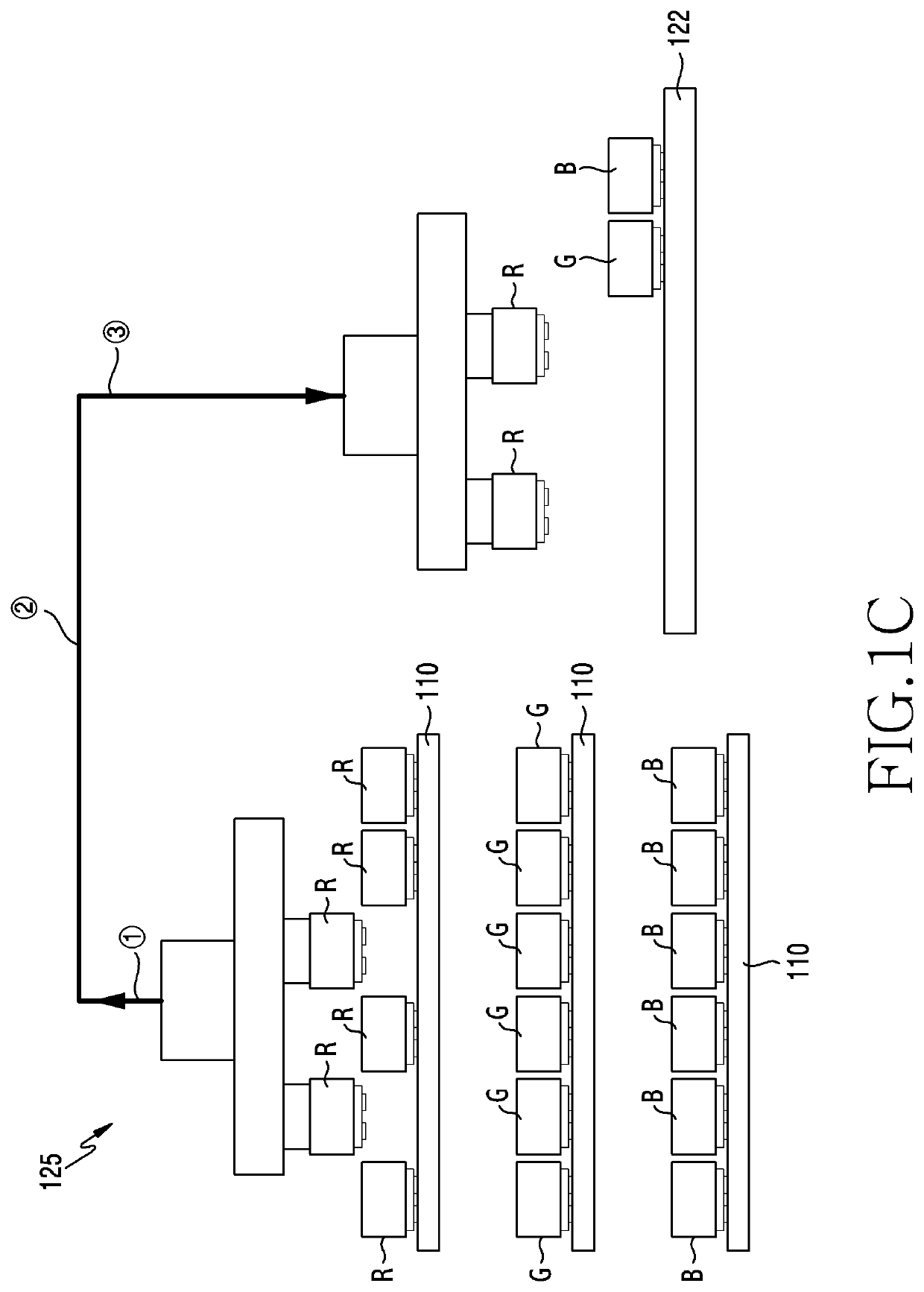

Micro-led display and manufacturing method therefor

ActiveUS20210375833A1Highly integratedIncrease productionSolid-state devicesSemiconductor/solid-state device manufacturingLED displayDisplay device

The disclosure describes a micro Light Emitting Diode (LED) display. The display may include a Printed Circuit Board (PCB) including a plurality of solder pads, a micro LED package including a plurality of micro LED chips, and a plurality of solder electrodes which bond the micro LED chips onto the solder pads of the PCB. The micro LED package may be re-arranged in an Red Green Blue (RGB) state on a temporary fixing film by using a pickup device in accordance with a display pixel configuration, after the micro LED chips are attached to a carrier film.

Owner:SAMSUNG ELECTRONICS CO LTD

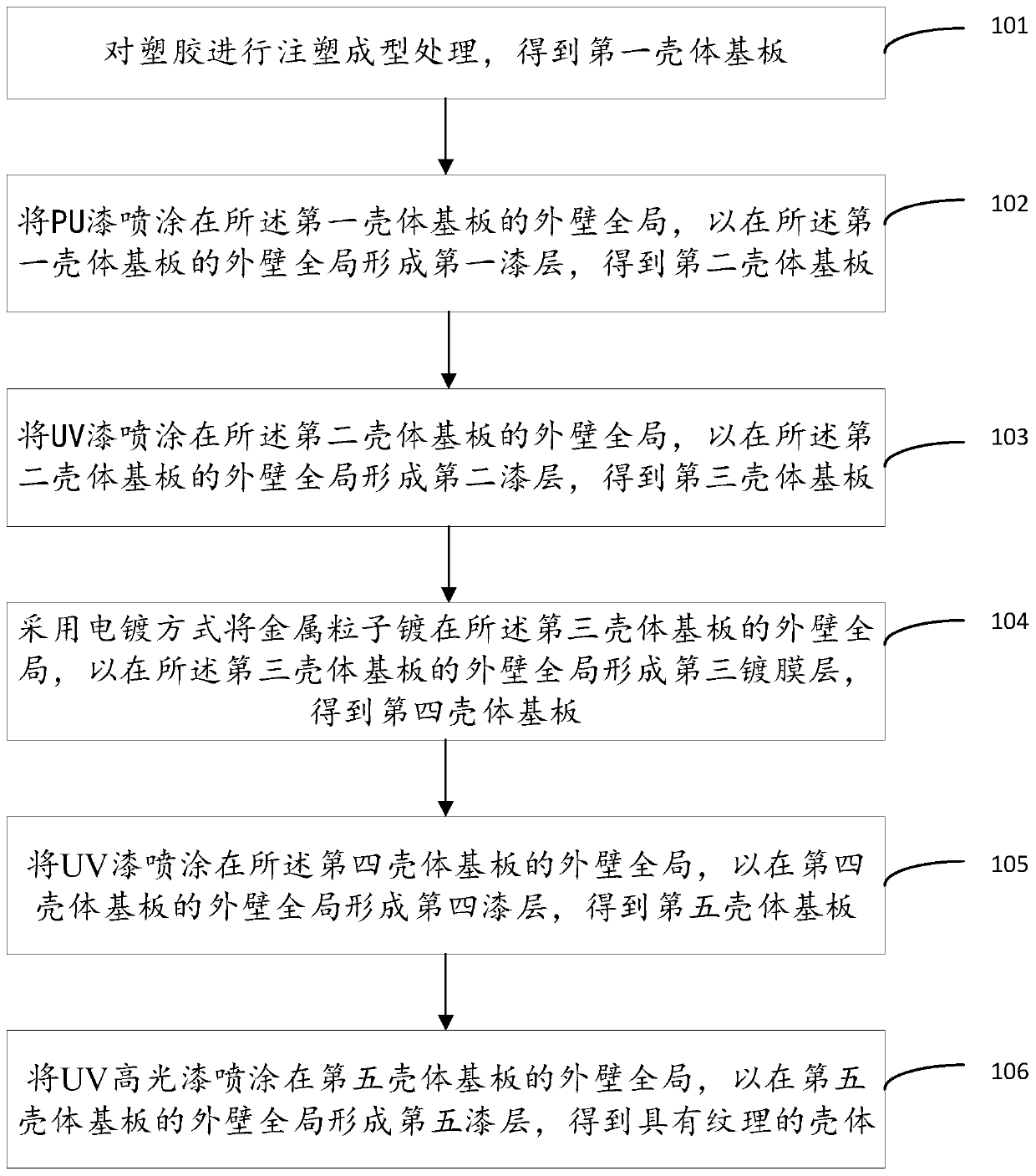

Shell machining method, shell and mobile terminal

ActiveCN110933887AWith glare visual effectSimple preparation processCasings/cabinets/drawers detailsMetal particleInjection moulding

The embodiment of the invention discloses a shell processing method, a shell and a mobile terminal. The method comprises the steps of carrying out injection molding on the plastic to obtain a first shell substrate, and setting a texture on the outer wall of the first shell substrate; spraying a PU paint on the outer wall of the first shell substrate globally to form a first paint layer to obtain asecond shell substrate; spraying the UV paint on the outer wall of the second shell substrate globally to form a second paint layer to obtain a third shell substrate; plating the metal particles on the outer wall of the third shell substrate globally in an electroplating mode to form a third coating layer to obtain a fourth shell substrate; spraying the UV paint on the outer wall of the fourth shell substrate globally to form a fourth paint layer to obtain a fifth shell substrate; spraying the UV highlight paint on the outer wall of the fifth shell substrate globally to form a fifth paint layer to obtain the shell with textures, wherein the textures are blind holes which are parallel to one another and distributed at intervals. By the adoption of the scheme, the damage to the shell duringproduction can be reduced, then the mass production yield of the shell production is increased, and the production cost is reduced.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

Display panel and display device

ActiveCN110379841AImprove stabilityAvoid short circuit conditionsSolid-state devicesSemiconductor devicesDisplay deviceEngineering

The invention provides a display panel and a display device. The display panel comprises a display area, a driver and a fan-out area connecting the display area and the driver, wherein the fan-out area includes a substrate, a plurality of first metal wires, an insulating layer, a plurality of second metal wires and an interlayer dielectric layer; the plurality of first metal wires are arranged onthe substrate in parallel at intervals; the insulating layer covers the plurality of first metal wires; the plurality of second metal wires are arranged on the insulating layer in parallel at intervals, each second metal wire is positioned between two adjacent first metal wires, and the interlayer dielectric layer covers the plurality of second metal wires. In the adjacent first metal wire and thesecond metal wire, one part of the second metal wire is overlapped on the insulating layer right above the first metal wire, the other parts of the second metal wire form a slit with the first metalwire when the fan-out area becomes narrow, the overlapping part forms a bulge to prevent the slit from connecting the display area and the driver, thereby preventing the residue of other metal layersfrom resulting in a short circuit between the display area and the driver.

Owner:YUNGU GUAN TECH CO LTD

Virtual reality display screen, head display device and virtual reality head display system

The invention provides a virtual reality display screen, a head display device and a virtual reality head display system. The display screen comprises a display panel and a first polaroid, wherein thefirst polaroid is arranged on a first surface of the display panel, the first polaroid comprises multiple first regions and multiple second regions, the multiple first regions and the multiple secondregions are alternately distributed in the first direction, and polarization directions of the first regions and the second regions are perpendicular to each other. The display screen is advantaged in that the whole display screen can be seen by two eyes of a user, the visual view field and the double-eye overlapped region of the virtual reality head display system can be greatly improved, the virtual world immersion effect of the user is enhanced, compared with the prior art, the use of one display screen can eliminate restriction of the strict alignment relationship in the dual display screen mounting process, and the production yield is improved.

Owner:BOE TECH GRP CO LTD +1

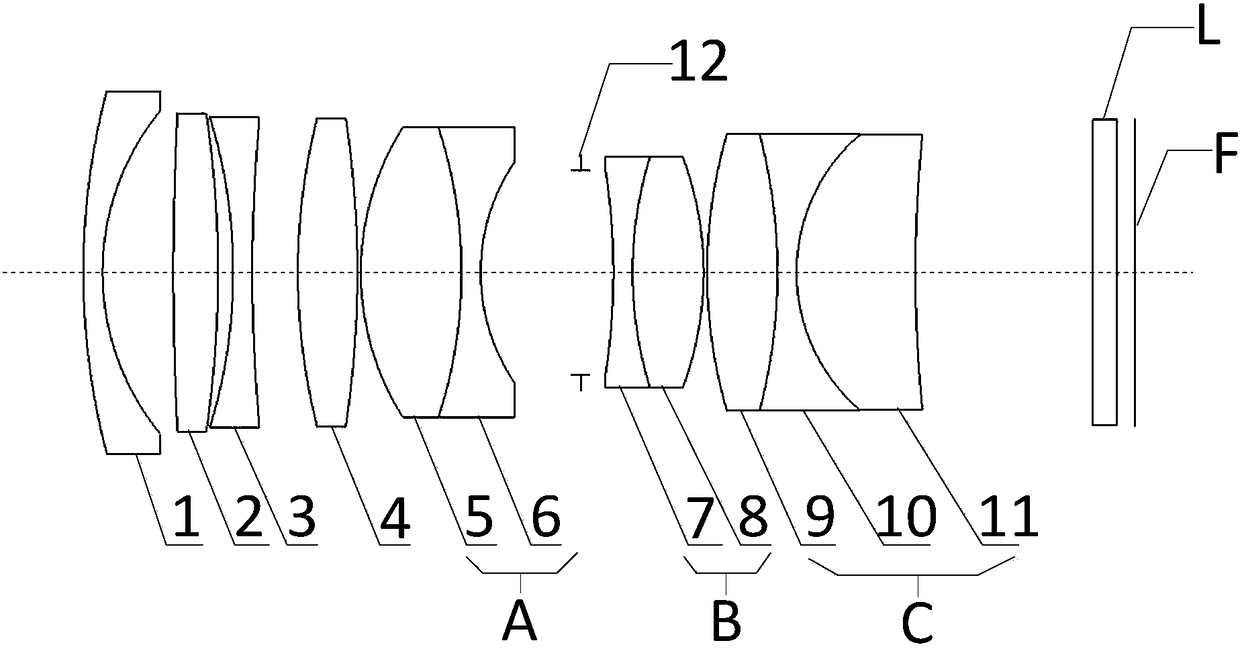

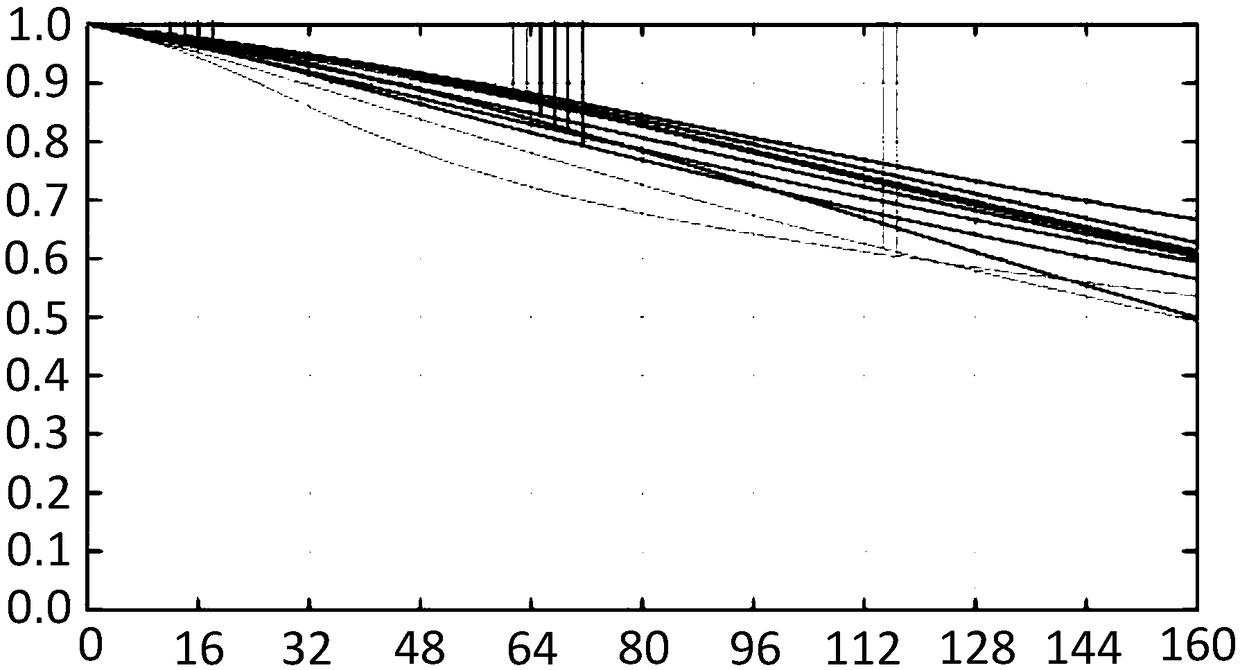

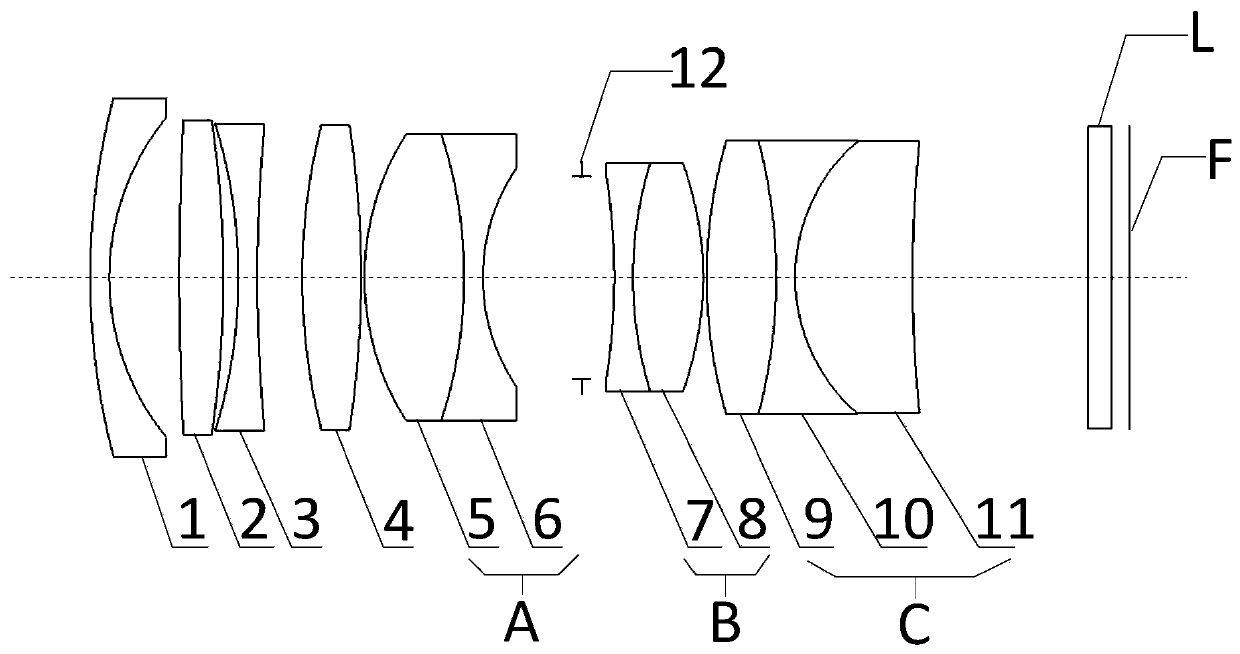

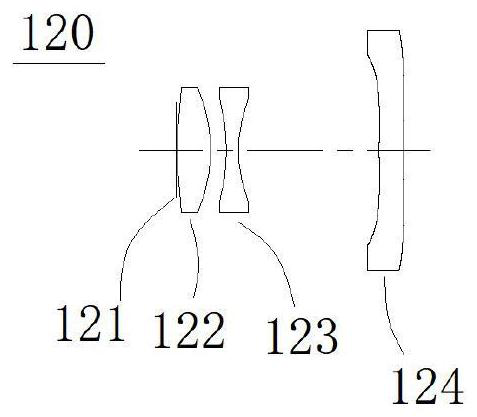

Optical lens

The invention discloses an optical lens. The optical lens is distributed by adopting reasonable focal power and has a specific structure shape; the ten million level pixel grade resolution can be reached under a relatively compact framework. Besides, for the framework is simple, the optical lens of the embodiment has low cost. By adopting the structure shape of the optical lens system provided bythe invention, abbe coefficients and other parameters of an optical glass material are well matched with the imaging condition, thus the spherical aberration, coma, astigmatism, field curvature, chromatic difference of magnification, and chromatism of position of the lens system are well corrected; the uniform imaging of the whole pixel face is guaranteed while the dual-purpose function in daytimeand nighttime is also realized; the optical lens meets the using requirement of a 4K camera and is compact structure and small in outside dimension; besides, all optical lenses adopt spherical surface design, the cold processing technical performance of the lens is good; the glass material and the finished product lens are low in cost, massive in output, and high in yield; the optical lens can bewidely applied to the security defense monitoring field.

Owner:ZHEJIANG DAHUA TECH CO LTD

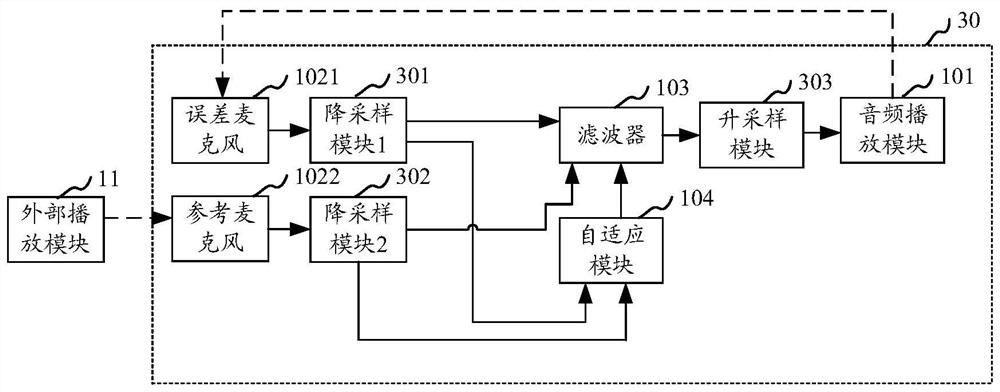

Calibration method and device of active noise reduction system of wearable equipment, storage medium and terminal

PendingCN113345400ALower Consistency RequirementsEliminate or reduce compliance testing requirementsHearing device active noise cancellationSound producing devicesEnvironmental noiseNoise

The invention discloses a calibration method and device of an active noise reduction system of wearable equipment, a storage medium and a terminal. The method comprises the steps: starting the active noise reduction system, enabling an audio playing module to play a noise test signal, and collecting the noise test signal through a sound collection module; calculating secondary path estimation of the active noise reduction system; stopping playing the noise test signal, playing an environment noise through an external playing module, and configuring an initial parameter of the active noise reduction system and a preset calibration coefficient of a filter, wherein the initial parameter comprises the secondary path estimation; and enabling the audio playing module to play the noise reduction signal, and acquiring the target coefficient of the filter, wherein the target coefficient is used for calibrating the filter. According to the scheme, the mass production yield of the wearable equipment can be improved, and the noise reduction performance is increased.

Owner:RDA MICROELECTRONICS SHANGHAICO LTD

Dielectric resonator oscillator and radar system using the same

InactiveUS20090051449A1High yield in mass productionLow production costOscillations generatorsRadio wave reradiation/reflectionPhysicsDielectric substrate

In the mass production of dielectric resonator oscillators (DROs), it is necessary to regulate the position where a dielectric resonator is placed with a high degree of accuracy and thus time required for the assembly work increases undesirably. Further, a terminating resistor and earthing means are formed at an end of a transmission line that is electromagnetically coupled to the dielectric resonator and constitutes the resonator on a dielectric substrate, and as a result the production cost increases. The present invention is characterized in that, in the components of a DOR, only a transmission line is formed on a dielectric substrate, and an oscillating active element and a terminating resistor and the earthing means on an MMIC chip are connected to the transmission line with metallic wires, metallic ribbons, or the like. Further, an open stub is formed in the middle of the transmission line on the side close to the oscillating active element when it is viewed from the dielectric resonator.

Owner:HITACHI LTD

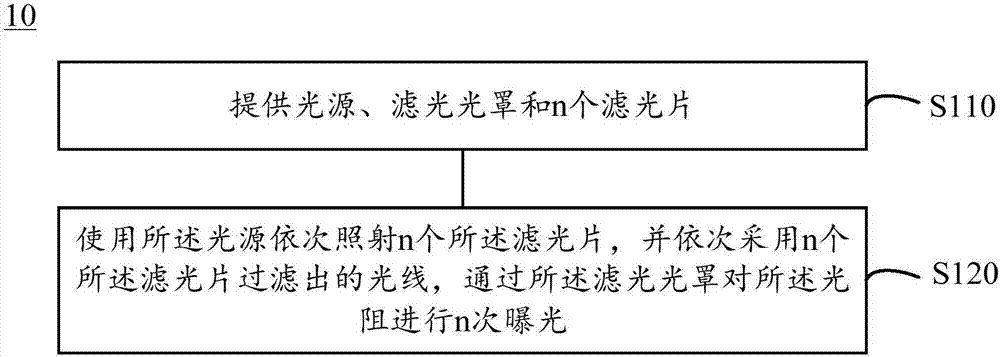

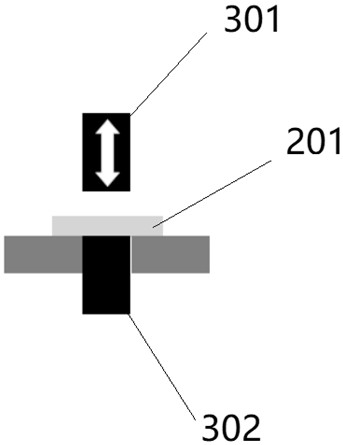

Exposure method and exposure device

ActiveCN107300836AReduce mistakesEasy to debugPhotomechanical exposure apparatusMicrolithography exposure apparatusOptoelectronicsProcess window

The invention provides an exposure method. The exposure method is used for exposing a photoresist on a substrate to form a layer structure with a segment difference. The exposure method comprises the following steps: providing a light source, a light filtering hood and n light filters, wherein a light-impermeable area and a light filtering area are arranged on the light filtering hood, the light filtering area is used for transmitting at least two types of light rays, each light filter is used for transmitting one type of light rays, the types of the light rays transmitted by the n light filters are different from one another, and n is greater than or equal to 2; using the light source for sequentially irradiating the n light filters; sequentially using the n light filters for transmitting the light rays; performing n times exposure on the photoresist through the light filtering hood. The invention further provides an exposure device. Through the exposure method and the exposure device, film thickness control can be refined, reduction in a film thickness error is facilitated, debugging of an exposure process is facilitated, a process window is increased, and the yield rate during batch production is increased.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

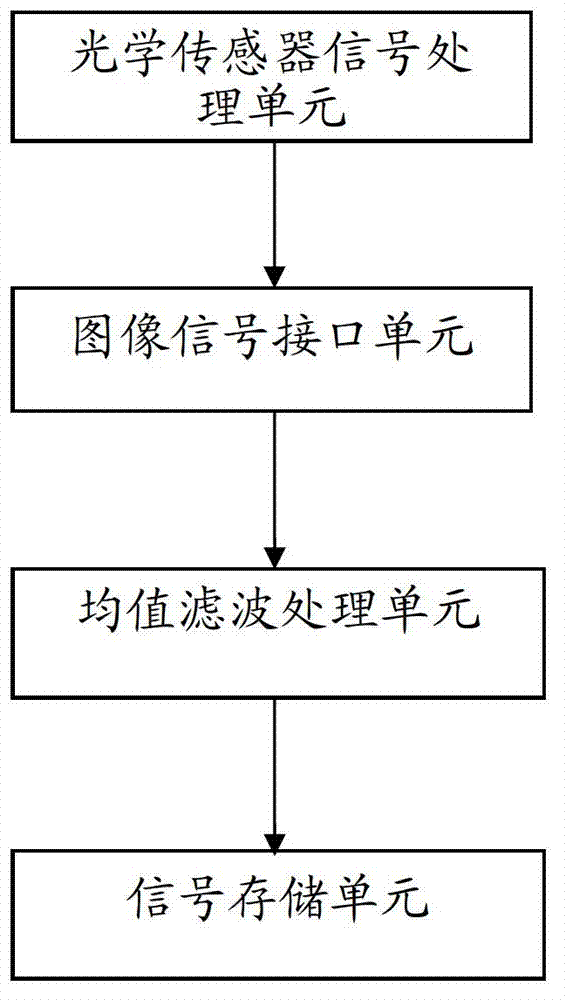

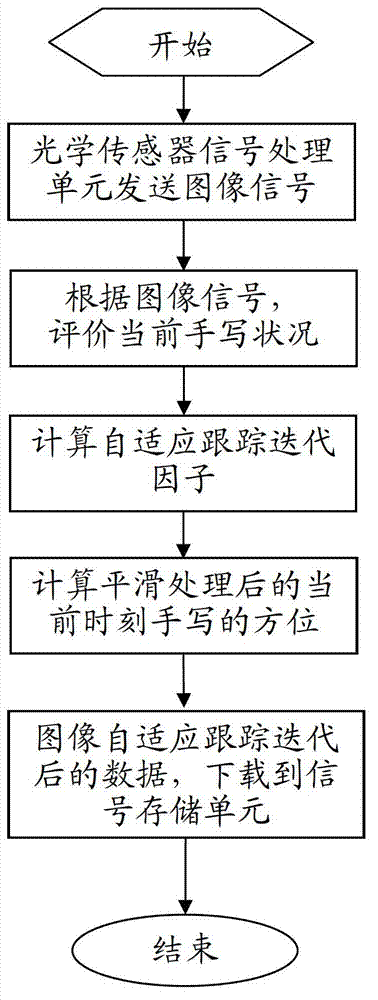

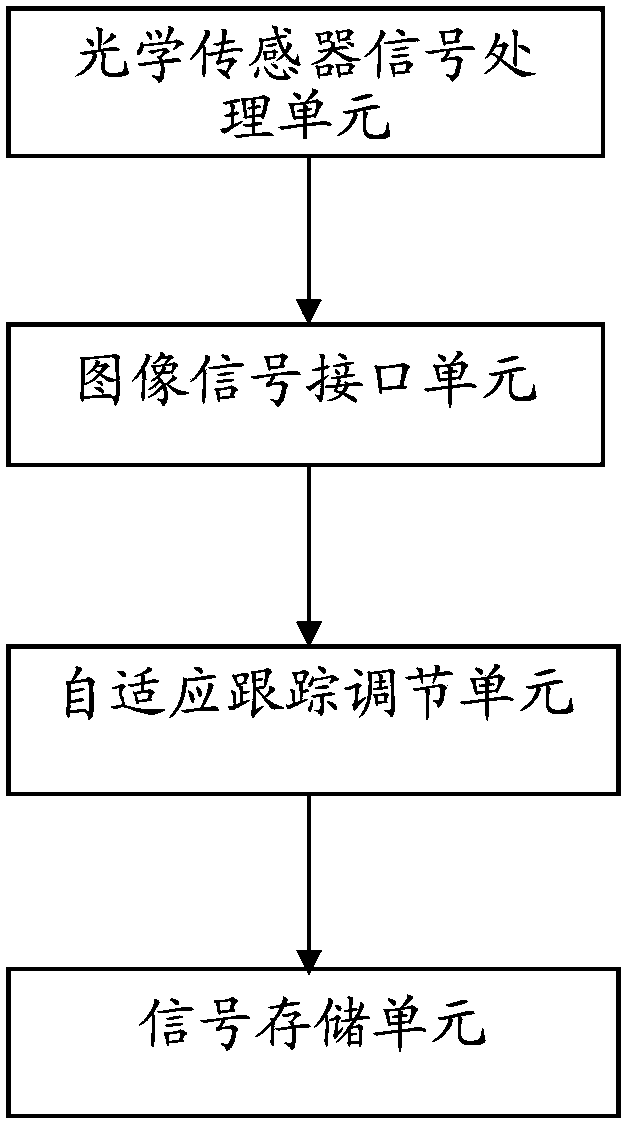

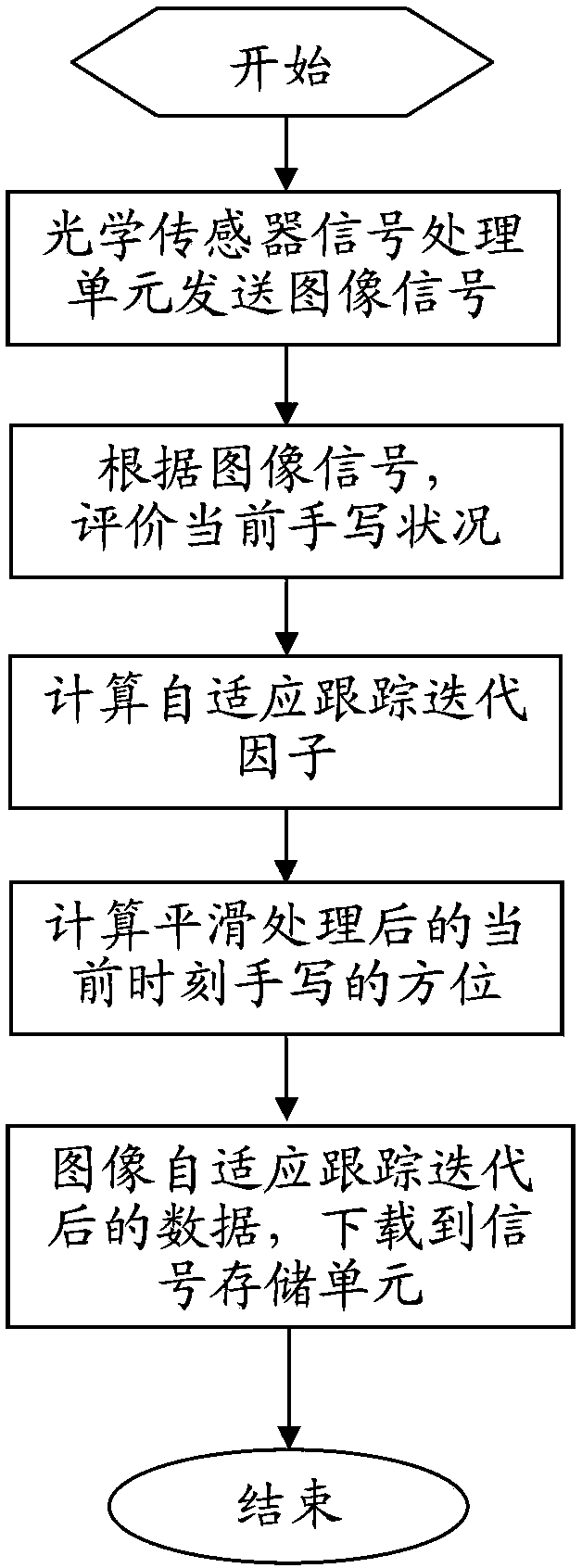

Method for smooth processing of optical touch handwritten fonts

ActiveCN103034374AOptical touch handwriting smoothingReal-time computingInput/output processes for data processingHandwritingTouchscreen

The invention relates to a method for smooth processing of optical touch handwritten fonts. Function modules comprise an optical sensor signal processing unit, an image signal interface unit, a self-adaptive tracking and adjusting unit, and a signal storage unit. The method for smooth processing comprises the following steps of enabling the optical sensor signal processing unit to collect and process image signals displayed on a touch screen; enabling the image signal interface unit to transmit the received perceptual image signals of the optical sensor signal processing unit into the self-adaptive tracking and adjusting unit; enabling the self-adaptive tracking and adjusting unit to carry out self-adaptive iterative computation and processing on the transmitted perceptual image signals, and correcting the touch positions of the current points of the images; and transmitting the image data after being subjected to the self-adaptive tracking and iteration into the signal storage unit for storing. The method has the advantages that the robustness is obviously improved, the optical touch handwriting is smoother, and higher timeliness, accuracy and stability are realized. In the industrial mass production mode, the easy implementation is realized, and the qualified rate of the mass production is high.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

A kind of stamping forming method of crankshaft speed signal disc

InactiveCN103769469BSimple manufacturing methodReduce processVehicle componentsHigh volume manufacturingPunching

The invention provides a stamping forming method of an automobile crankshaft signal panel. The stamping forming method comprises a blanking process, a groove rolling process, a punching process, a deep drawing and flanging process, a large and small signal hole punching process, a reshaping process and the like. By applying the stamping forming method for a crankshaft rotating speed signal panel, a complicated porous-structure panel body and a cover body part can be manufactured by virtue of a stamping forming process, and the method has the advantages of fewer processes, simple operation and control, high material utilization, short production period, less environmental pollution and the like, is beneficial to realization of automatic large-batch production and can be used for improving the production efficiency and lowering the production cost; signal hole processing is performed after metallic material plastic deformation, hole processing is more accurate, and the method can be used for solving the problems such as irregular shape of deep-drawn rectangular teeth, deformation of deep-drawn holes of a complicated-structure piece and high cracking, wrinkling and deformation possibility of a panel body due to uneven stress strain in a rectangular tooth primary stamping forming method, and can be applied to large-batch production of automobile parts.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Technical preparation method of IBC battery

PendingCN107331714AQuick identificationPrecise alignmentPhotovoltaic energy generationSemiconductor devicesCcd cameraReflectivity

The invention discloses a technical preparation method of an IBC battery, which comprises the steps of A, performing front texturing and back polishing on an n-type original silicon wafer, the front textured surface ranges between 1 micron and 10 microns in size, the reflectivity of the textured surface is 9%-13%, and the back polishing reflectivity is 30%-45%; B, forming a first doped region at the back, and then performing back selective partition to remove an oxide layer; C, performing partition texturing and etching by using KOH with the mass ratio being 1%-3%, an additive with the mass ratio being 3%-5% and an etching solution with the temperature ranging between 75 DEG C and 85 DEG C, wherein the reflectivity of an etched area is 20%-28%; and then D, forming a second doped region at the back, forming FSF at the front, depositing a passivation layer at the front and the back, and finally selectively forming metal electrodes of a p-region and an n-region at the back. After adopting the method, in the back metal printing process, the p-region and the n-region are distinguished by using the textured surface / polished surface to form surface state contrast, a CCD camera has different spectral responses at different surface states in metal printing, and thus quick and accurate alignment of metal printing is achieved.

Owner:JINENG CLEAN ENERGY TECH LTD

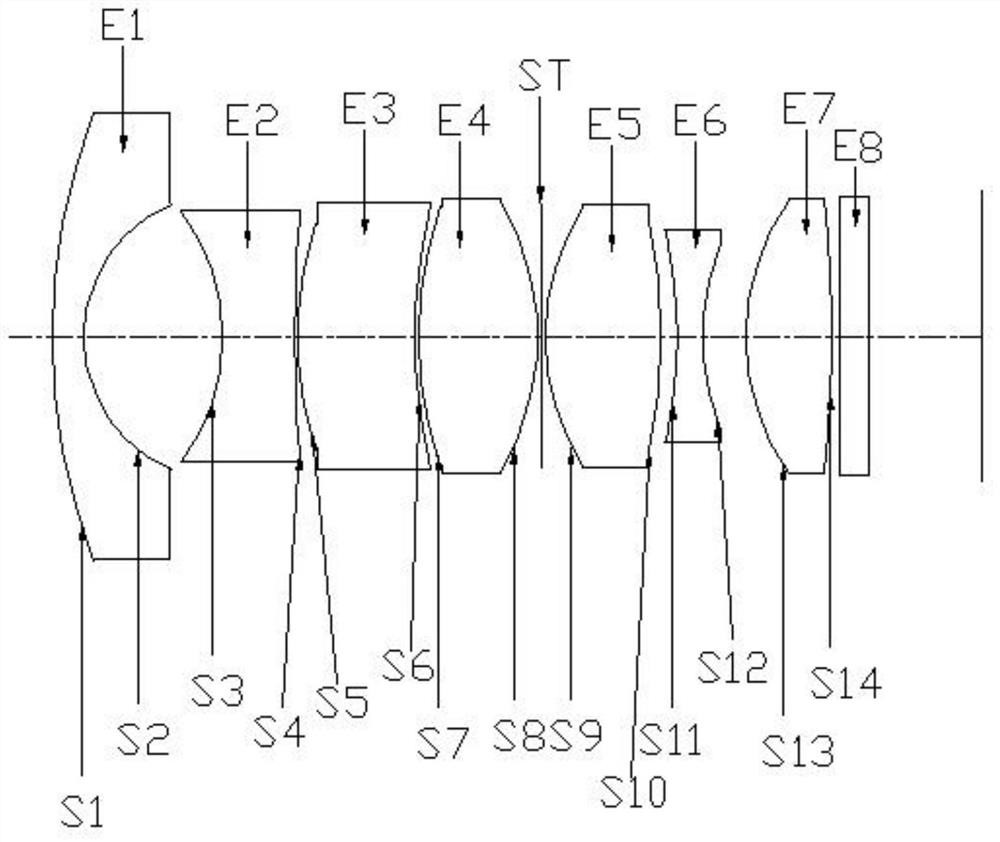

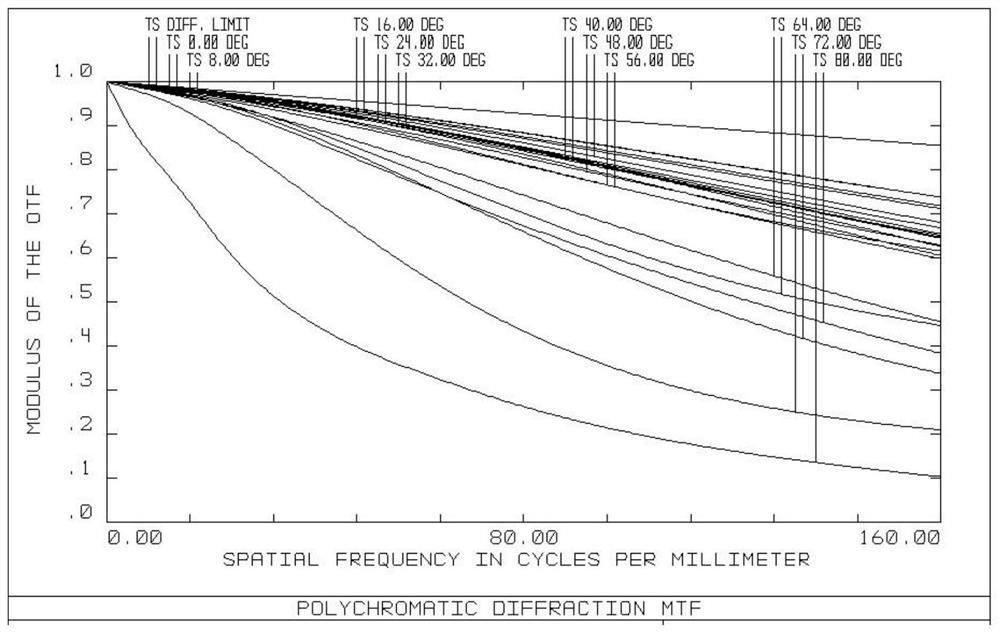

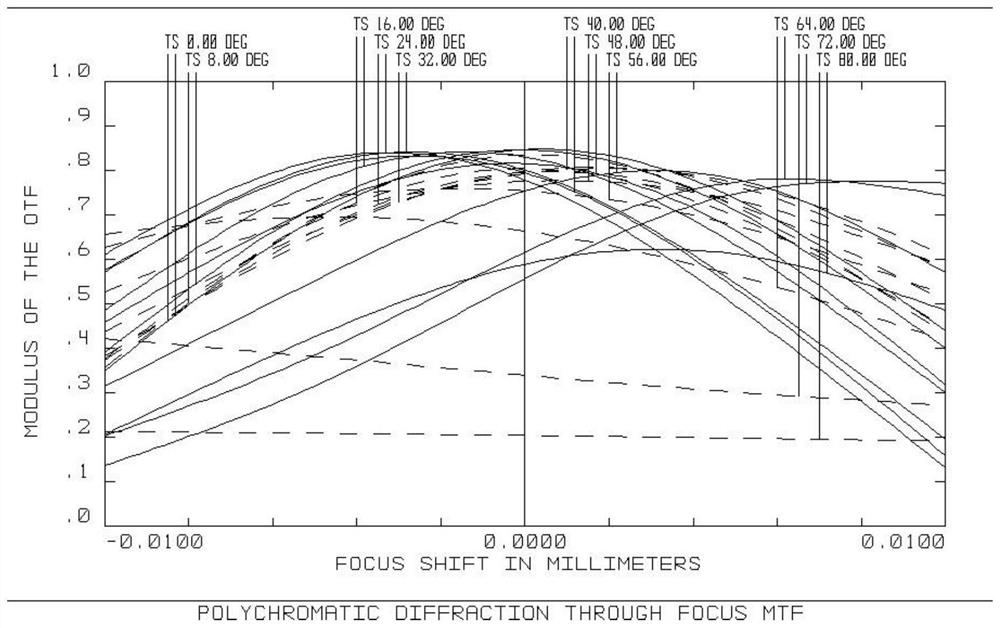

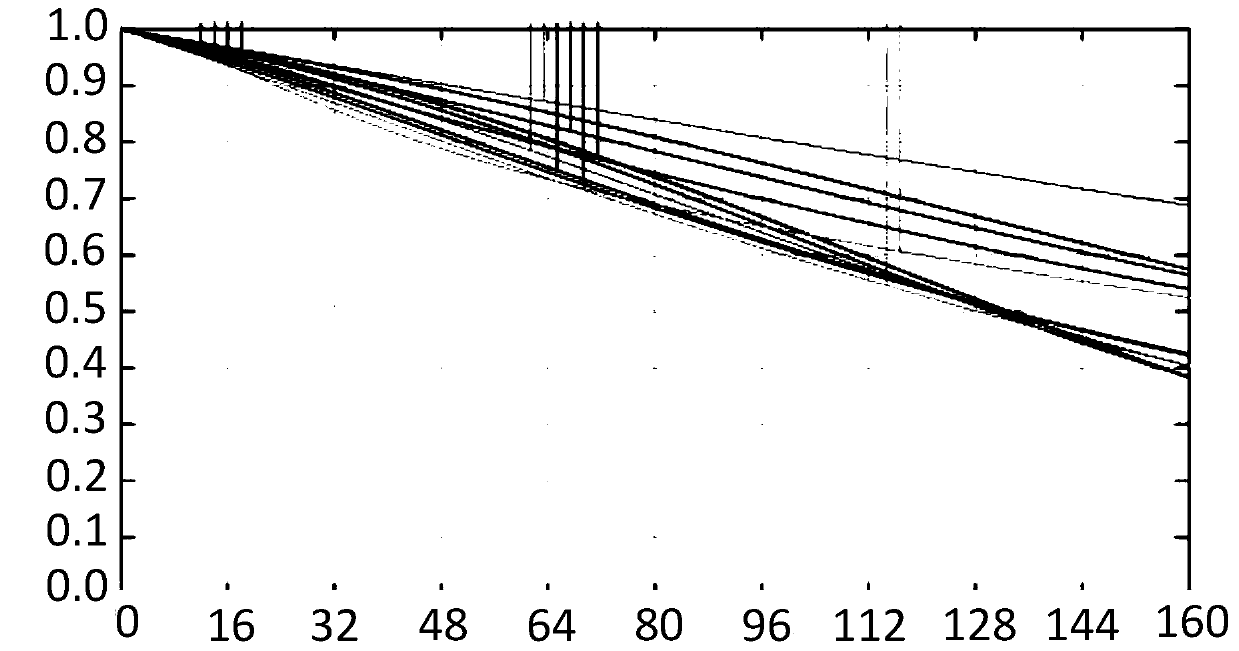

Large-aperture ultra-wide-angle high-definition lens and camera device comprising same

The invention discloses a large-aperture ultra-wide-angle high-definition lens and camera equipment comprising the same. The large-aperture ultra-wide-angle high-definition lens sequentially comprisesa first lens, a second lens, a third lens, a fourth lens, a fifth lens, a sixth lens, a seventh lens and an optical filter from an object plane to an image plane along the optical axis. The lens is compact in structure and small in boundary dimension, the weight of the lens is greatly reduced, the cost is reduced, and the research and development period is shortened. According to the invention, the aberration of the lens system is corrected to a large extent, the MTF resolution is high, it is guaranteed that high definition is achieved on the whole image plane, even imaging can be achieved, the lens can be matched with 1 / 2.5 chips (eight million pixels or above), the field angle of the lens reaches 160 degrees or above, the FNO reaches 1.2, the luminous flux is large, and the camera shooting effect at night is better.

Owner:江西特莱斯光学有限公司

Method for improving mass-production yield of large-area organic solar cells

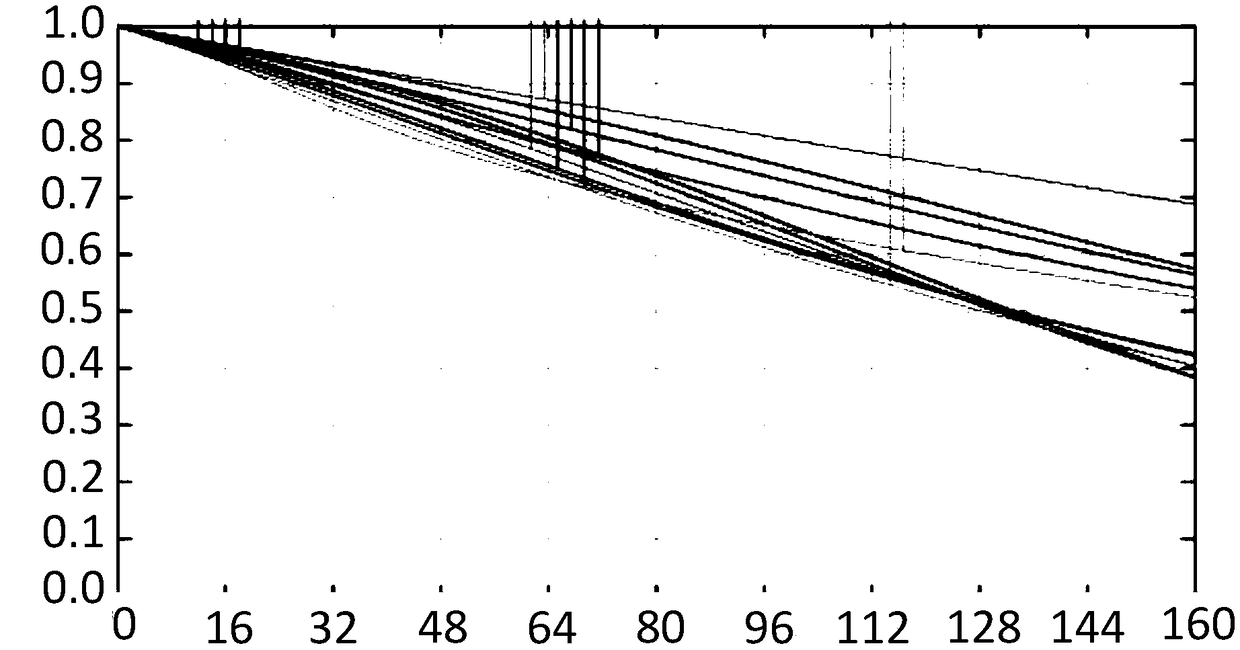

ActiveUS20170170397A1High yield in mass productionImprove quality stabilityFinal product manufactureSolid-state devicesProduction rateOrganic solar cell

The present invention discloses a method for improving mass-production yield of large-area organic solar cells for forming the active layer using the roll-to-roll process. The active layer includes low-bandgap high-polymer PTB7, Fullerenes derivative PC71BM, and high-boiling-point additives. The addition of the high-boiling-point additives can enhance the efficiency of organic solar cells effectively. In the roll-to-roll process according to the present invention, the drying temperature for the wet film is controlled for controlling the content of additives in the dry film. Thereby, the stability of the overall mass production and the device yield can be both improved.

Owner:INST NUCLEAR ENERGY RES ROCAEC

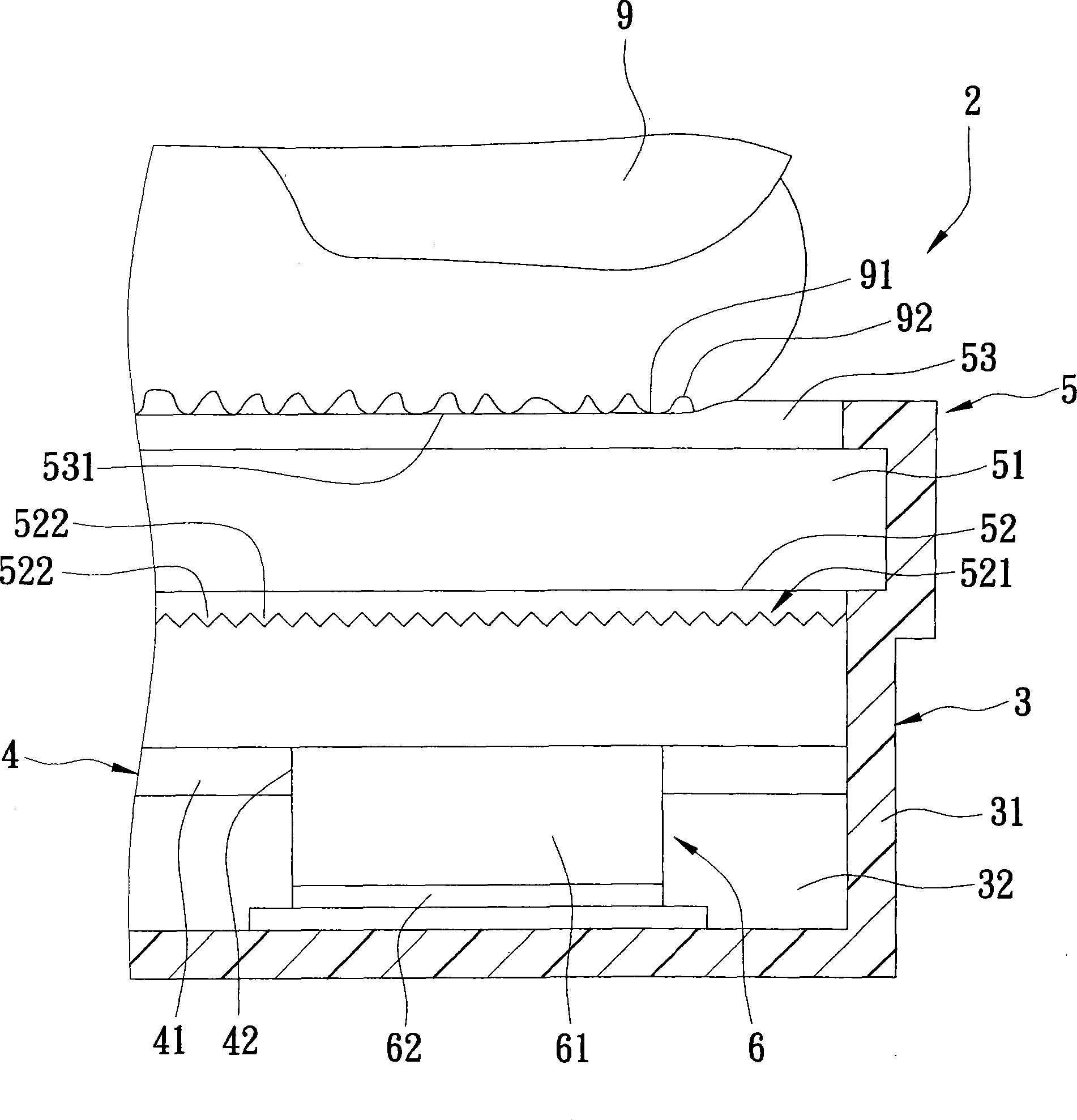

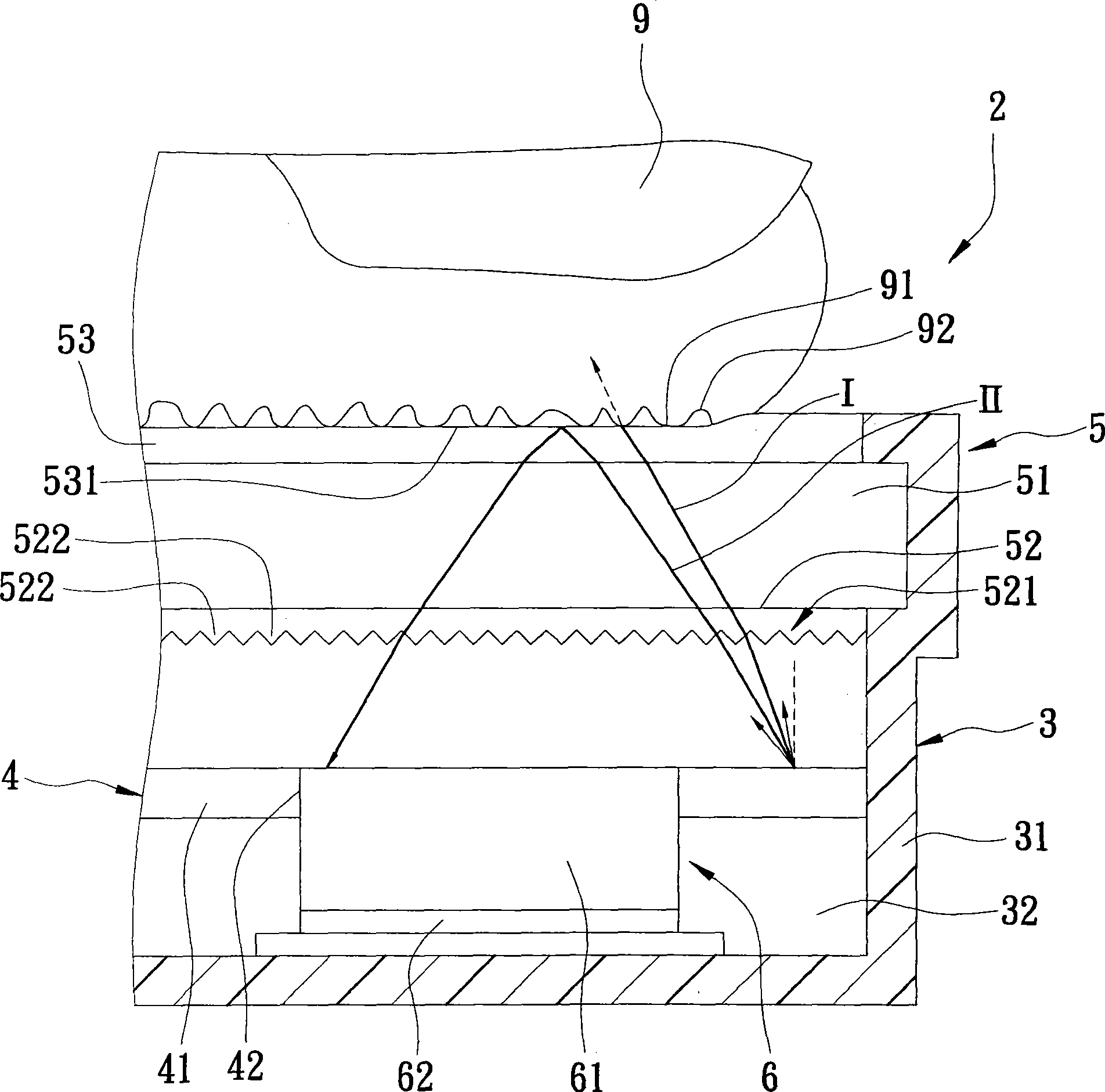

Vehicle light

ActiveUS8550676B2Reduce overall chromatic aberrationLess color shadingVehicle headlampsPoint-like light sourceLight guideDistribution pattern

A vehicle light can include a light emitting diode (LED) serving as a light source and an optical system for controlling a light distribution pattern of the light beams from the LED light source utilizing a light guide (such as a lens body having an inner reflecting surface). The vehicle light can project illumination light with a low beam light distribution pattern. The vehicle light can include an LED light source and a lens body serving as a light guide. The lens body can include a light incident surface, a reflecting surface, and a light exiting surface. The LED light source can have a rearmost end light emitting point from which light beams are emitted to form a bright-dark boundary line. Among the light beams, perpendicularly incident light beams not subjected to refraction can be projected toward the bright-dark boundary line while obliquely incident light beams that are subjected to refraction can be corrected to be directed in a lower angular direction than the bright-dark boundary line and to be mixed with the other light beams, thereby preventing color shading of illumination light from the vehicle light.

Owner:SEOUL SEMICONDUCTOR +1

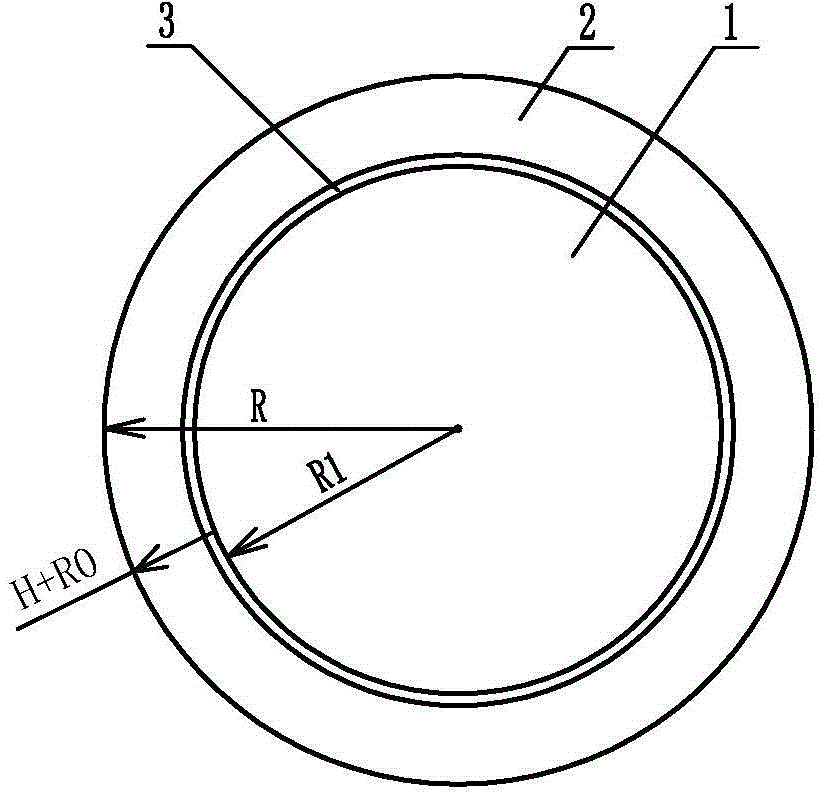

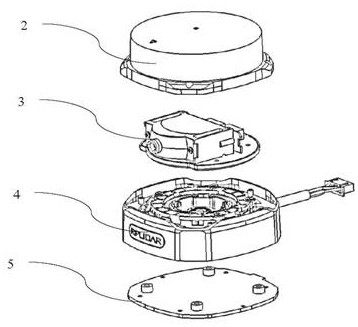

Narrow-window coaxial single-line laser scanning range finder

PendingCN113281767AReduce processing difficultyHigh yield in mass productionElectromagnetic wave reradiationInformation processingLaser ranging

The invention discloses a narrow-window coaxial single-line laser scanning range finder, and the range finder comprises: a range finding core part which is used for obtaining range finding data; a control module which is movably connected with the range finding core part; and a ranging core part which comprises an optical module and an information processing module, wherein the information processing module is used for processing a laser ranging signal obtained by the optical module and converting the laser ranging signal into distance data. The optical module comprises a laser emitting unit, a focusing lens and a photosensitive receiving unit. The laser emitting unit is used for generating pulse emitting laser and generating a start signal used for flight time timing. The focusing lens is used for converging the light beams reflected by the measured object and focusing the light beams to the photosensitive receiving unit; and the photosensitive receiving unit is used for generating a photoelectric signal and generating a stop signal for timing in flight according to the photoelectric signal. According to the invention, the ranging core member is rotatably arranged on the control module, 360-degree scanning ranging can be realized, a reflector device is omitted, the process difficulty of assembly is reduced, and the yield of mass production can be effectively improved.

Owner:SHANGHAI SLAMTEC

an optical lens

Owner:ZHEJIANG DAHUA TECH CO LTD

A wax spray method for reducing the corrosion dispersion of quartz wafer sheets

ActiveCN113463027BAdjust corrosion dispersionThe frequency difference is reducedLiquid surface applicatorsAfter-treatment detailsEtchingPhysical chemistry

Owner:HUBEI TKD ELECTRONICS TECH +1

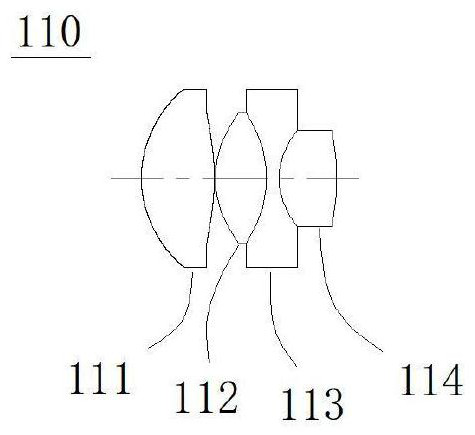

Large-view-field small-size ultra-short-focus projection lens

InactiveCN113050255ALarge projection formatGood workmanshipProjectorsOptical elementsOphthalmologyProjection lens

The invention discloses a large-view-field small-size ultra-short-focus projection lens, which comprises a refractor group and a reflector group. The refractor group comprises a first lens group at least comprising an aspherical lens and at least one balsaming lens, a second lens group comprising a low-focal-power aspherical lens and other spherical lenses, and a refraction lens closest to the reflector group is an aspherical lens in a third lens group; the reflector group comprises an aspheric reflector. The lens has the advantages of large projection breadth, good manufacturability, low cost and no virtual focus at high temperature.

Owner:黄国豹

A method for smoothing handwritten fonts by optical touch

ActiveCN103034374BOptical touch handwriting smoothingReal-time computingInput/output processes for data processingHandwritingTouchscreen

Owner:HUAWEI TEHCHNOLOGIES CO LTD

Display panel and mobile terminal

PendingCN114446174AHigh yield in mass productionGuaranteed preset spacingIdentification meansOptical elementsCapillary actionStructural engineering

The invention provides a display panel and a mobile terminal. The panel layer is composed of but not limited to a first part, a second part and a bent third part connected to the first part and the second part; the protective layer is located on the third part; the first supporting layer is located on the side, away from the protective layer, of the panel layer and is opposite to the first part; the cover plate layer is located on the first part; the thickness of the side, close to the first part, of the protective layer is set to be smaller than that of the middle of the protective layer, the side, close to the first part, of the protective layer is located between the side, close to the third part, of the first part and the inner boundary of the ink layer, the capillary action is combined, and the thickness of the ink layer is smaller than that of the side, close to the third part, of the protective layer. In other words, the final form of the protective layer can ensure that the preset distance is formed between the composition material of the protective layer and the tearable film layer in the process of manufacturing the protective layer, so that the risk that the protective layer is torn when the tearable film layer is torn is reduced, and the yield of mass production of the display panel is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Ultra-wideband phase shifter

InactiveCN105006608AAchieve phase shiftIncrease working frequencyWaveguide type devicesDielectricUltra-wideband

The present invention provides an ultra-wideband phase shifter comprising a first dielectric sheet, a second dielectric sheet, a metal sheet, ferrites and a waveguide. The first dielectric sheet, the second dielectric sheet and the metal sheet are sequentially stacked up and are fixedly bonded together by the conductive adhesive. The surface of the second dielectric sheet, adjacent to the first dielectric sheet, is provided with a groove. A nematic liquid crystal is injected into a cavity enclosed by the groove and the first dielectric sheet. The outer surface of the first dielectric sheet and the outer surface of the metal sheet are sequentially and respectively provided with at least two layers of ferrites. An excitation wire passes through the ferrites. The first dielectric sheet, the second dielectric sheet, the metal sheet and the ferrites are located in the cavity of the waveguide. The two ends of the waveguide are respectively provided with a first matched medium and a second matched medium. The two ends of the first dielectric sheet and the two ends of the second dielectric sheet are in contact with the first matched medium. The two ends of the ferrites are in contact with the second matched medium. The dielectric constant of the first matched medium is larger than the dielectric constant of the second matched medium. The ultra-wideband phase shifter can be used for phase shifting within the range of ultra-wideband microwave frequency band.

Owner:CHENGDU ZHONGWEI ELECTRONICS MICROWAVE TECH

A foldable display panel

ActiveCN110600515BAvoid mass productionHigh yield in mass productionSolid-state devicesIdentification meansEngineeringMechanical engineering

The invention discloses a foldable display panel. The display panel includes an effective area and an ineffective area arranged around the effective area. A deformation layer is arranged in the ineffective area of the display panel; the material of the deformation layer is The force-induced strain material is included, so as to detect the deformation degree and crack defect of the display panel according to the light emission color and brightness of the force-induced strain material, so as to improve the mass production yield.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com