A kind of stamping forming method of crankshaft speed signal disc

A technology of crankshaft speed and stamping forming, which is applied in transportation, packaging, vehicle parts, etc., can solve the problems of gas turbulence, unfavorable rapid production, long working hours, etc., and achieve the goal of simplifying the manufacturing method, reducing the cost of abrasive tools, and reducing the production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] A stamping forming method of a crankshaft speed signal disc, comprising the following steps:

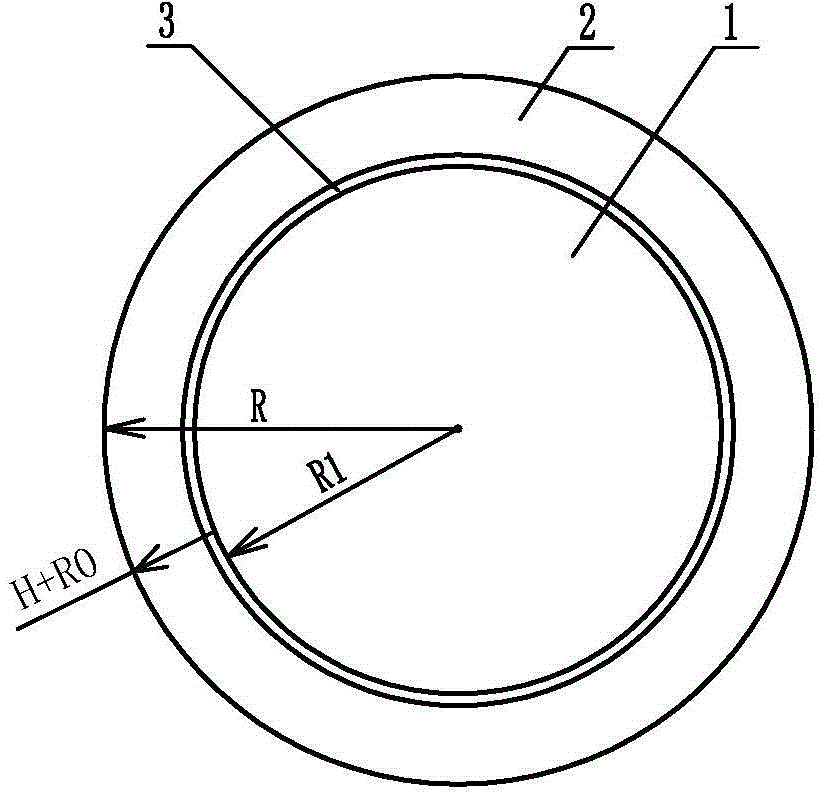

[0045] (1) Blanking: Punch the whole thin steel plate into a circular blank with dimensions including the height of the side ring and the width of the groove, that is, the radius of the circular blank is R=R1+R0+H, where R1 is the radius of the chassis 1 of the crankshaft speed signal disk, H is the height of the side ring 2 of the crankshaft speed signal disk, and R0 is the stamping allowance of the curved transition groove;

[0046] (2) Pressure groove: install the pressure groove composite mold on the vertical punching machine, and punch a curved transition groove 3 on the circumference of the chassis corresponding to the radius R1, that is, the joint between the chassis and the side ring of the signal plate;

[0047] (3) Deep drawing: use the drawing die to carry out bending and deep drawing, so that the side ring of the signal plate is flanged 90° along the curved transit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com