Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Guaranteed polishing accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

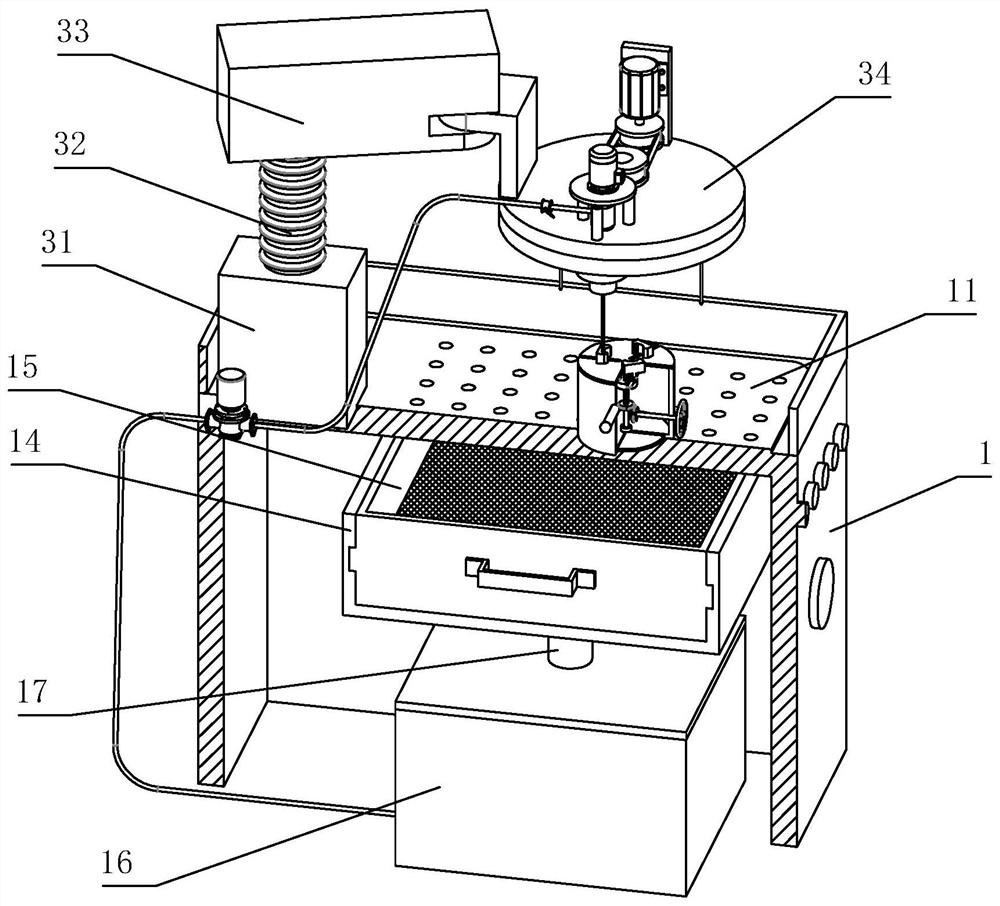

Super-fine polishing process for metal products

The invention provides a super-fine polishing process for metal products. The super-fine polishing process comprises the following steps of (1) cleaning the surfaces of the metal products with cleaning liquid; (2) performing first-time polishing on the surfaces of the metal products, and spraying the metal products with polishing liquid A in the first-time polishing process; (3) performing first-time washing on the metal products with deionized water after first-time polishing is completed; (4) performing second-time polishing on the surfaces of the metal products after first-time washing is completed, and spraying the surfaces of the metal product with polishing liquid B in the second-time polishing process; (5) performing second-time washing on the metal products with deionized water after the second-time polishing is completed; and (6) after second-time washing is completed, stoving and drying the surfaces of the metal products with hot air at 45 DEG C to 55 DEG C. The super-fine polishing process is specially used for polishing the side walls of the metal products of cylindrical structures, the polishing effect is improved, the polishing precision is ensured, dust avoiding andenvironment protection are achieved, and personal safety of an operator is guaranteed.

Owner:杭州临安恒达精密仪表元件厂

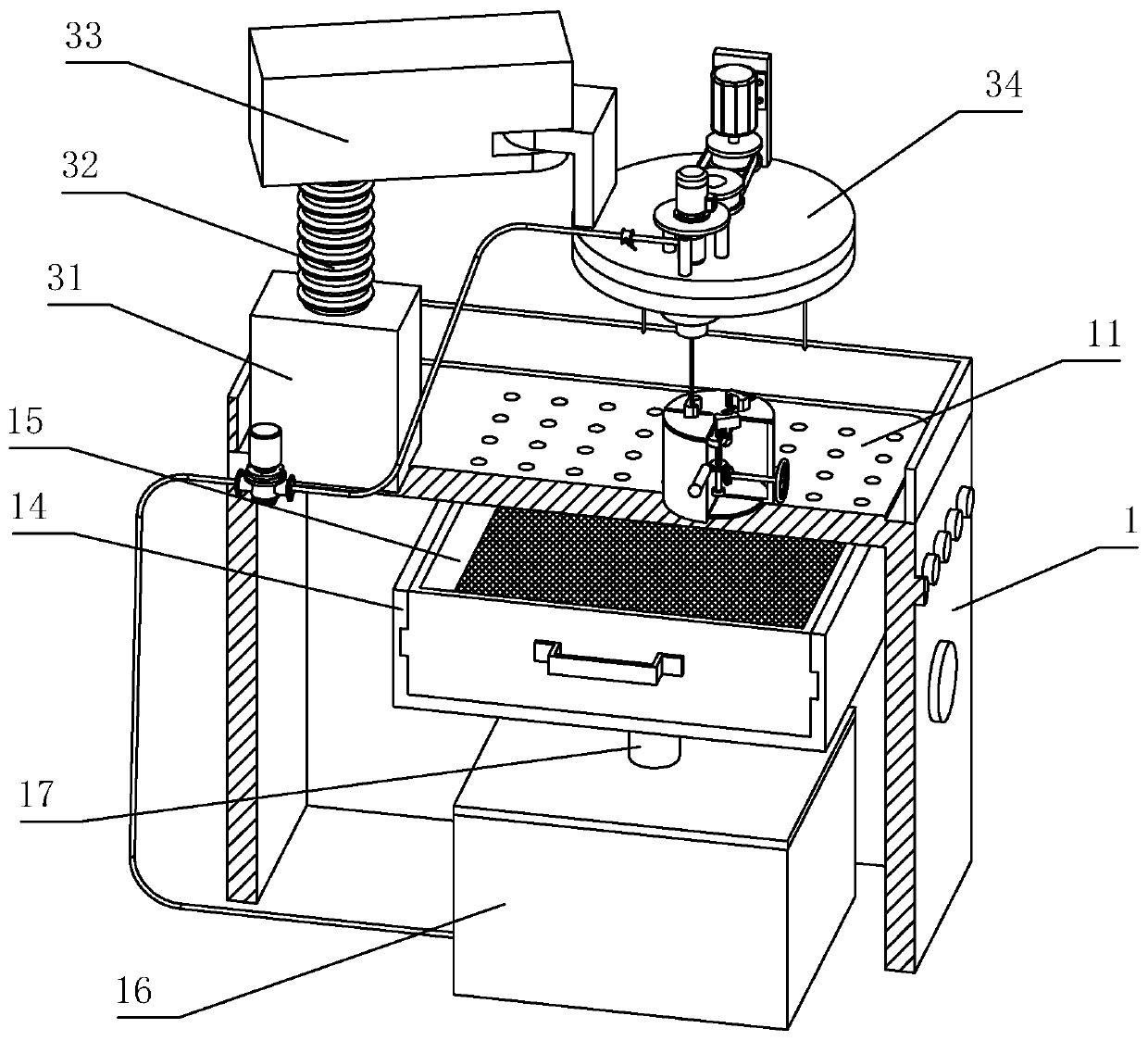

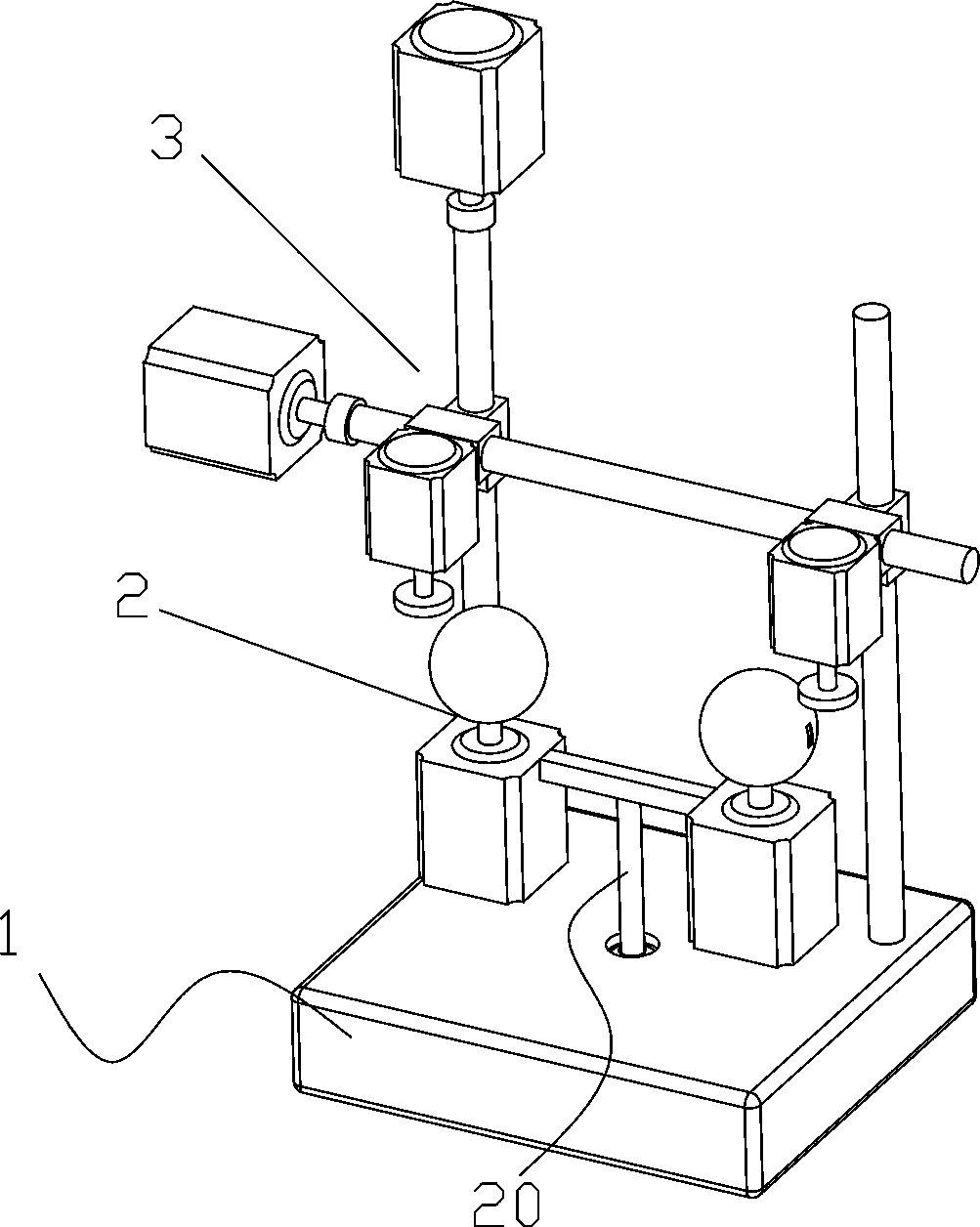

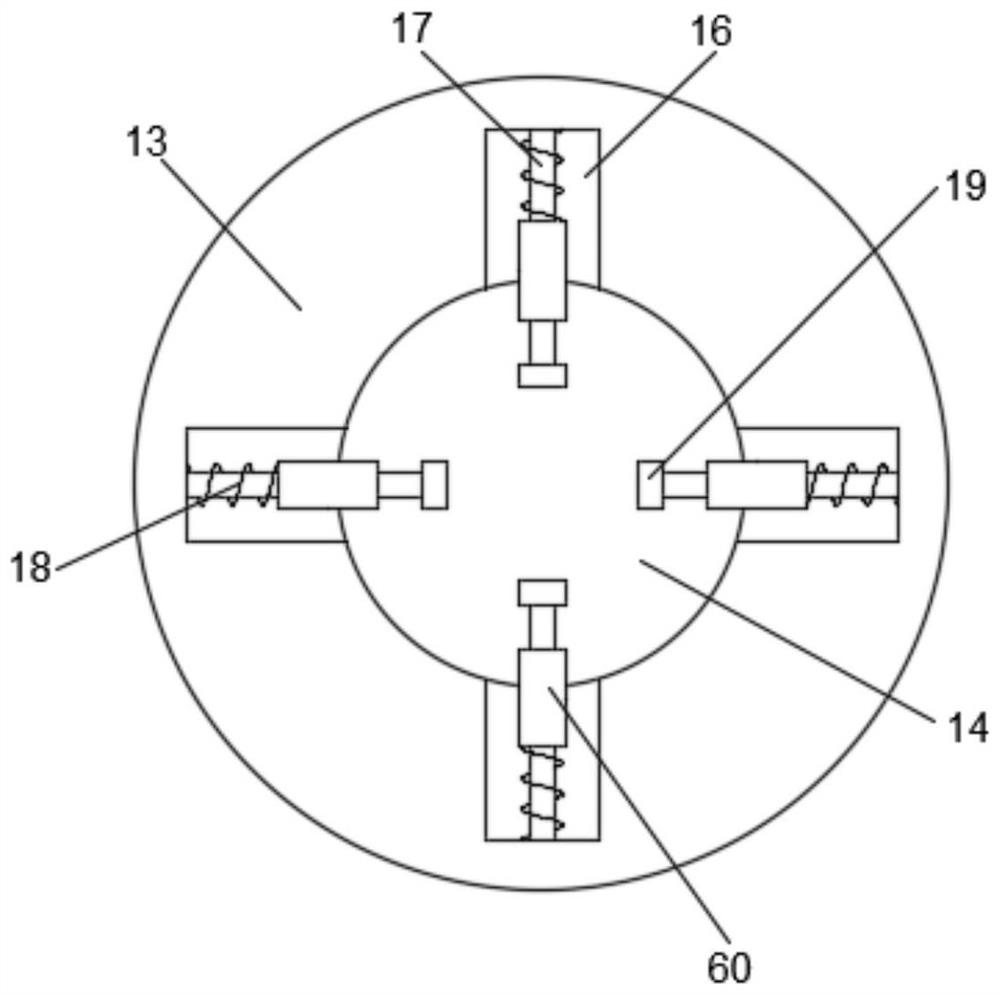

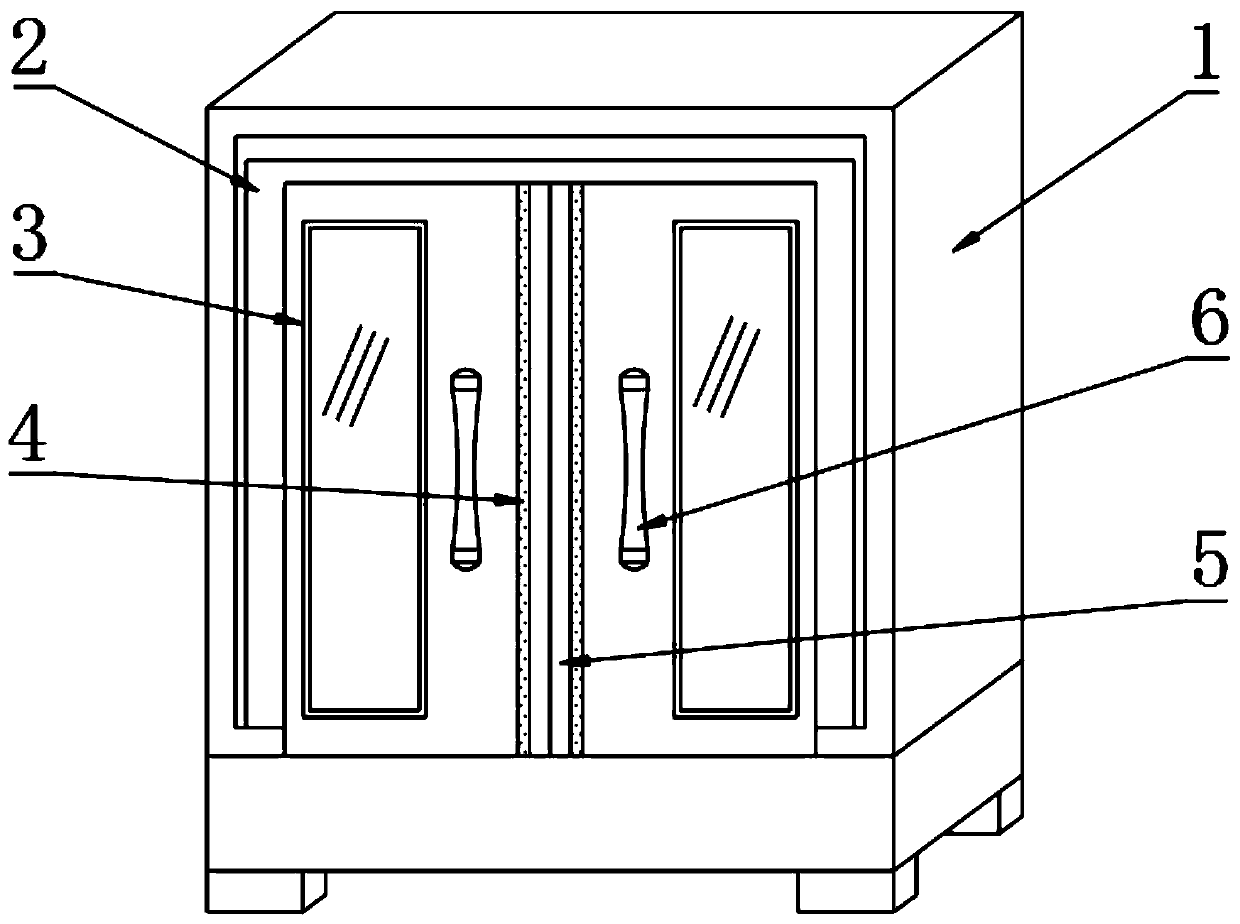

Polishing device and technology for false tooth machining

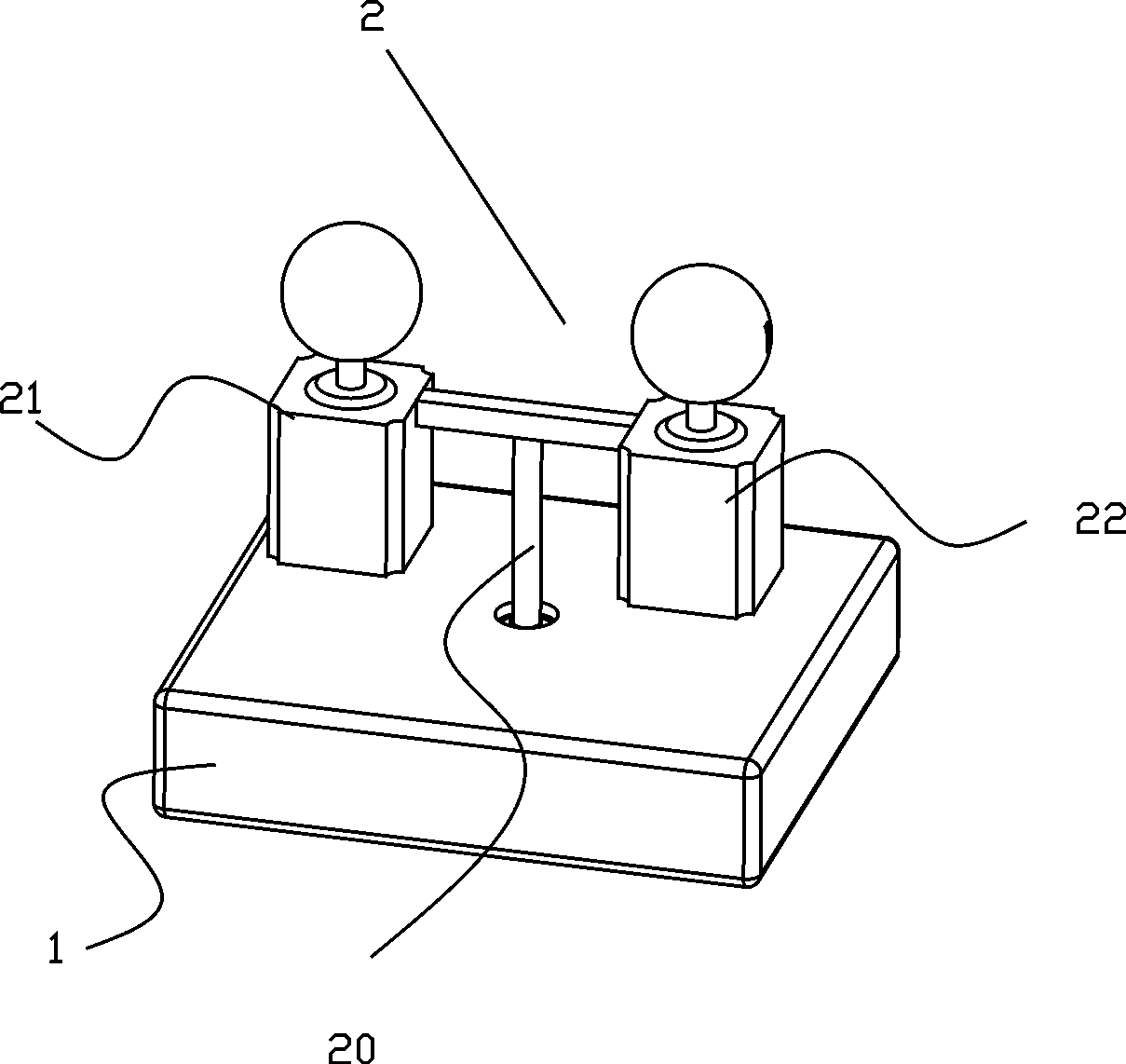

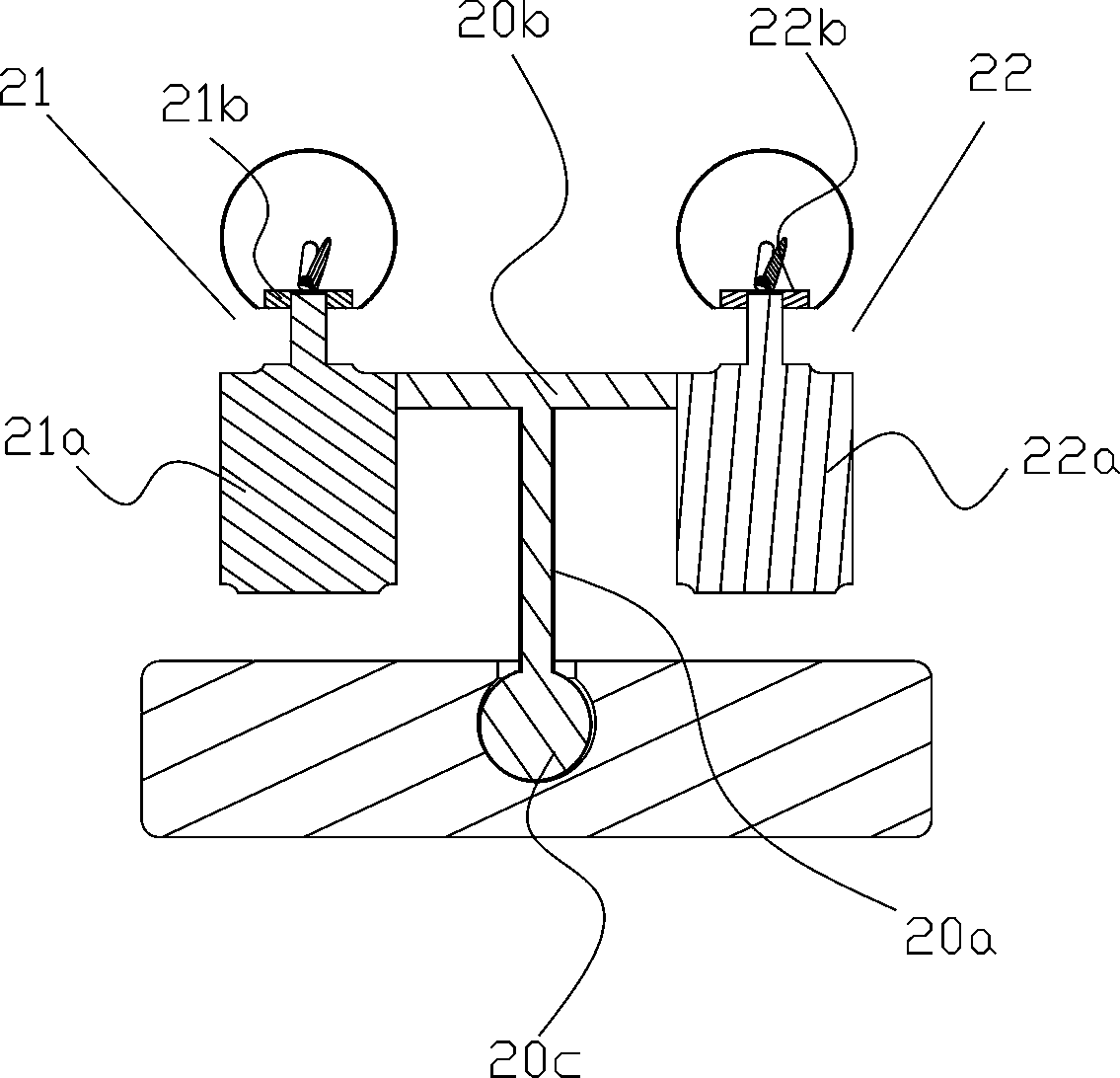

ActiveCN111251143APrevent overthrowUndershootGrinding drivesLapping machinesPolishingFixed prosthodontic

The invention relates to a polishing device for false tooth machining. The polishing device comprises a base, an installation seat which is placed on the base and is used for fixing a false tooth in the polishing process, a support fixed to the base and a grinding tool which is installed at the end, away from the base, of the support and is used for grinding the false tooth. The polishing device is characterized in that a magnetic worktable is arranged on the upper end face of the base; multiple concentric ring-shaped grooves are formed in the lower end face of the installation seat; magnets are arranged in the ring-shaped grooves; and a clamping mechanism used for clamping and fixing the false tooth is arranged on the installation seat. The polishing device has the effects that the relative position between the installation seat and the base is conveniently adjusted, and therefore the grinding process is more convenient.

Owner:泉州市超维医疗科技有限公司

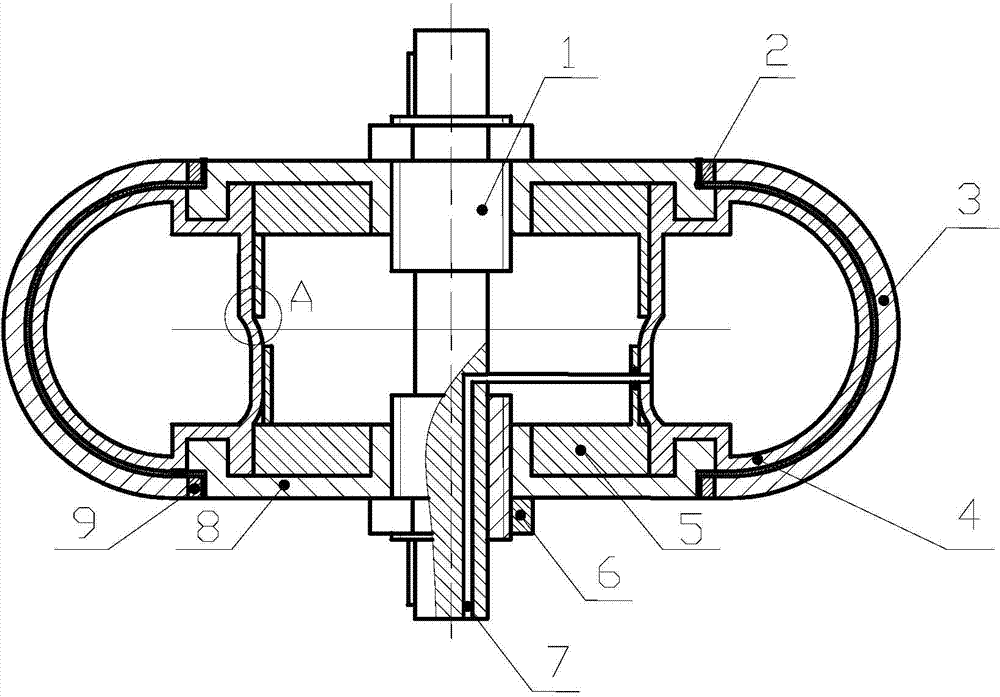

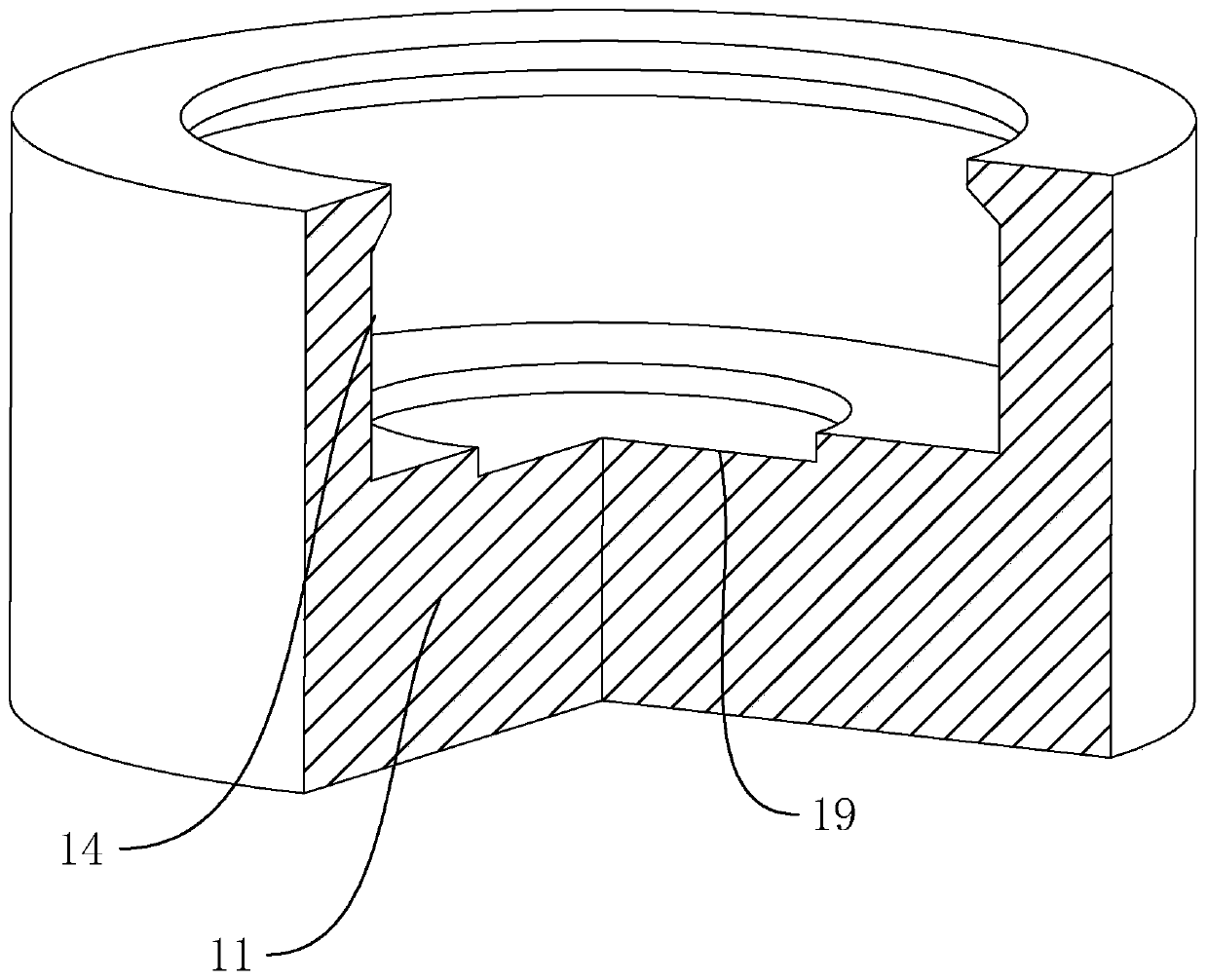

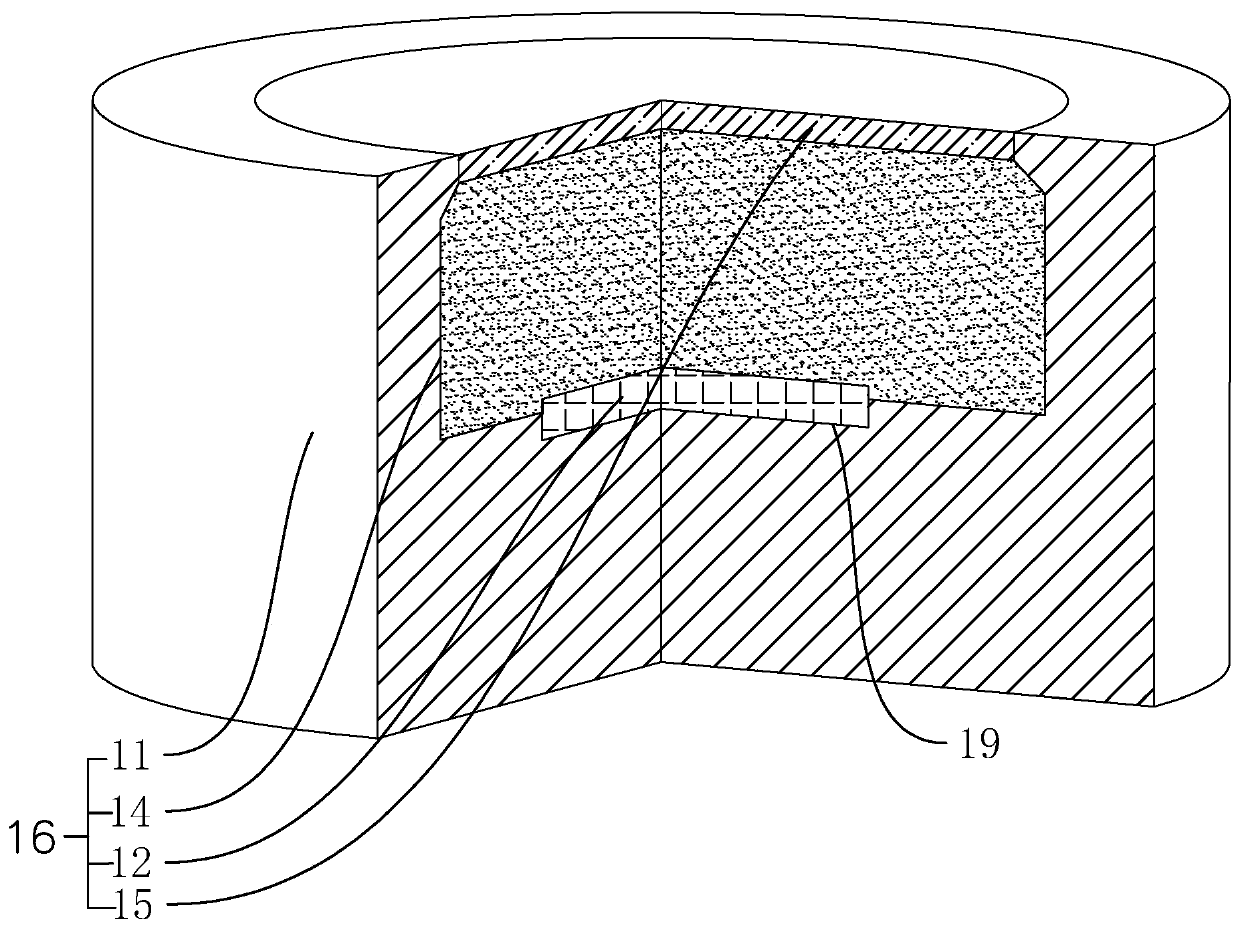

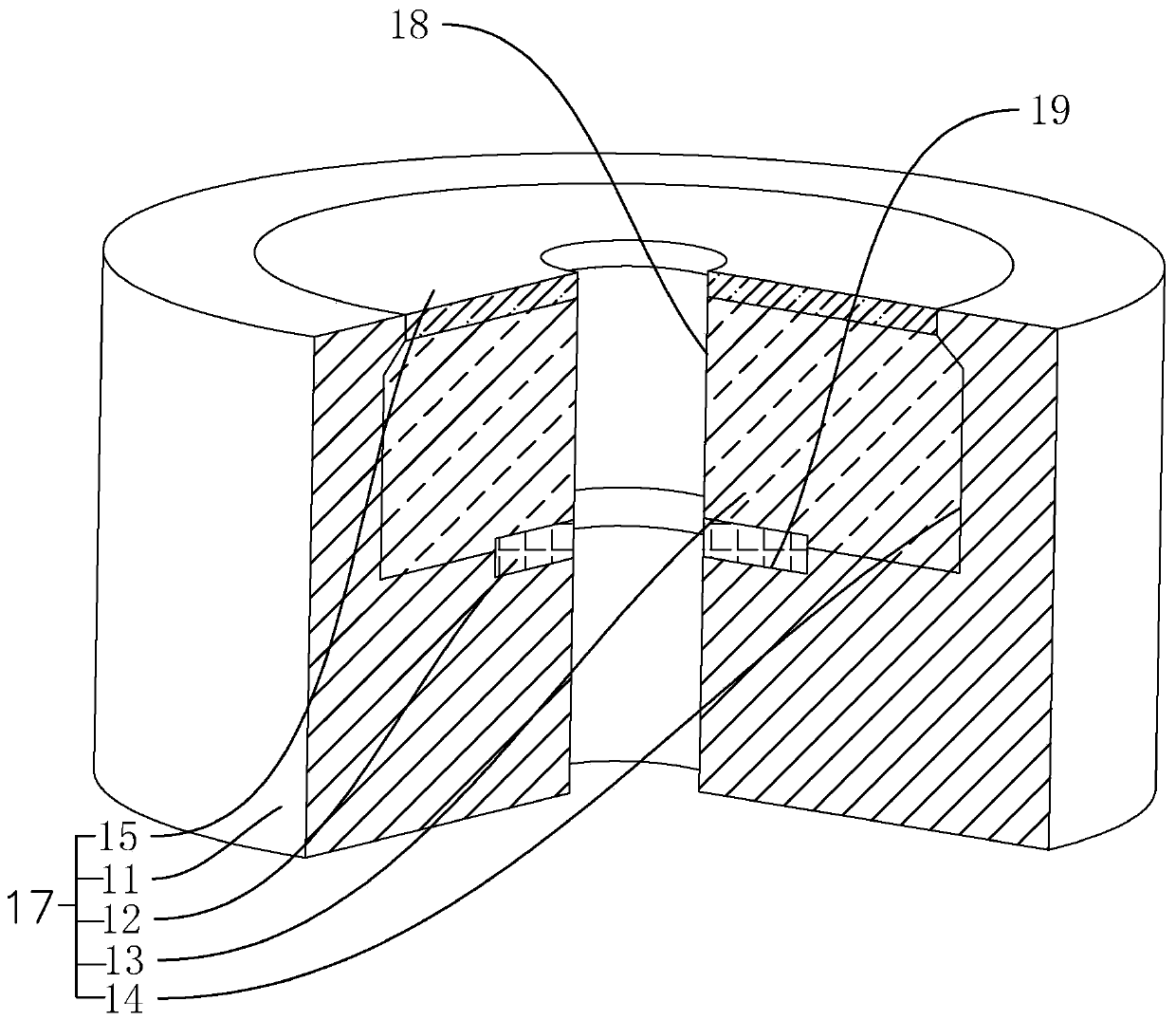

Circular arc radius adjustable disc type air bag polishing head

The invention discloses a circular arc radius adjustable disc type air bag polishing head, and relates to air bag polishing tools. The disc type air bag polishing head is provided with adjusting screw rods, an annular air bag support, an annular elastic outer layer, an annular elastic inner layer, an elastic inner layer fixing sleeve, adjusting flanges, an air bag support fixing sleeve and a polishing material layer. The adjusting screw rods are provided with adjusting threaded sleeves and spindle connecting rods. The annular elastic inner layer is bonded with the elastic inner layer fixing sleeve, the elastic inner layer fixing sleeve is provided with a supporting plate, and the supporting plate is provided with a slotted hole. The elastic inner layer fixing sleeve and the annular elastic outer layer are integrally placed into a clamping groove of the adjusting flanges. The air bag support fixing sleeve enables the annular air bag support to be fixed on the adjusting flanges and to be closely matched with the adjusting flanges, and the annular elastic outer layer is directly arranged on the annular air bag support in an injection molding mode. The adjusting threaded sleeves are screwed into the two screw rods respectively, the spindle connecting rods are placed into the adjusting threaded sleeves, and the polishing material layer is bonded on the surface of the annular elastic outer layer. The air bag circular arc radius is adjustable, dynamic balance performance is good, and positioning accuracy and machining accuracy are improved obviously.

Owner:XIAMEN UNIV

Method for polishing and cleaning optical lens

InactiveCN109702561AEasy to operateImprove efficiencyFlexible article cleaningCleaning using liquidsOrganic solventAlcohol

The invention provides a method for polishing and cleaning an optical lens and relates to the technical field of lens machining. The method for cleaning the optical lens is characterized by comprisingthe following steps of firstly, cleaning with an organic solvent; secondly, cleaning with water; thirdly, cleaning with a basic solution; fourthly, cleaning with water; fifthly, cleaning with an acidic solution; sixthly, cleaning with water; seventhly, ultrasonic cleaning; eighthly, cleaning with alcohol; ninthly, cleaning with water; and tenthly, vacuum drying. The method for polishing and cleaning the optical lens has the beneficial effects that the polishing method is simple in operation and high in efficiency; the facial form and polishing accuracy of the lens can be guaranteed; and the cleaning effect of the optical lens is improved by the cleaning method.

Owner:新野旭润光电科技有限公司

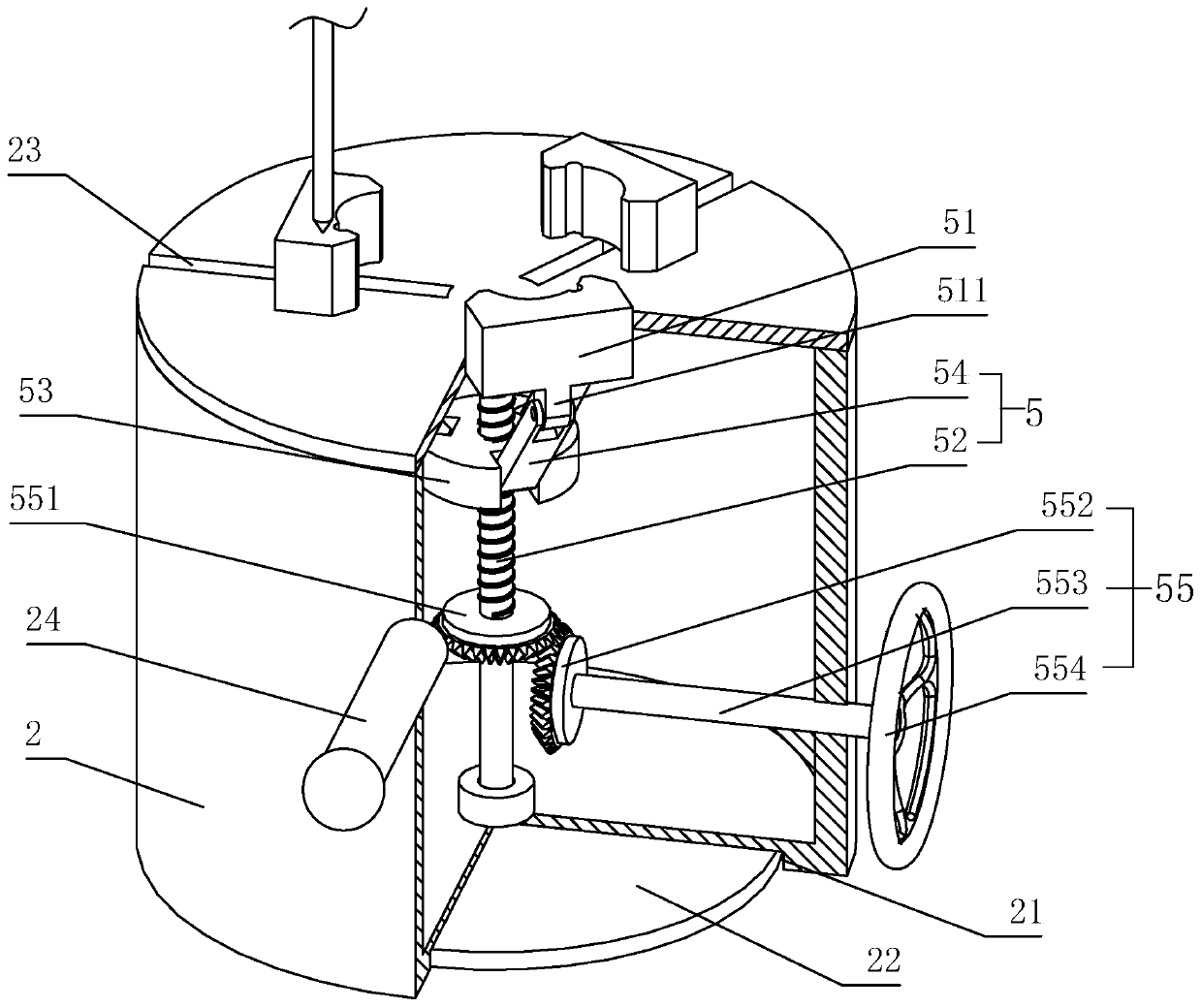

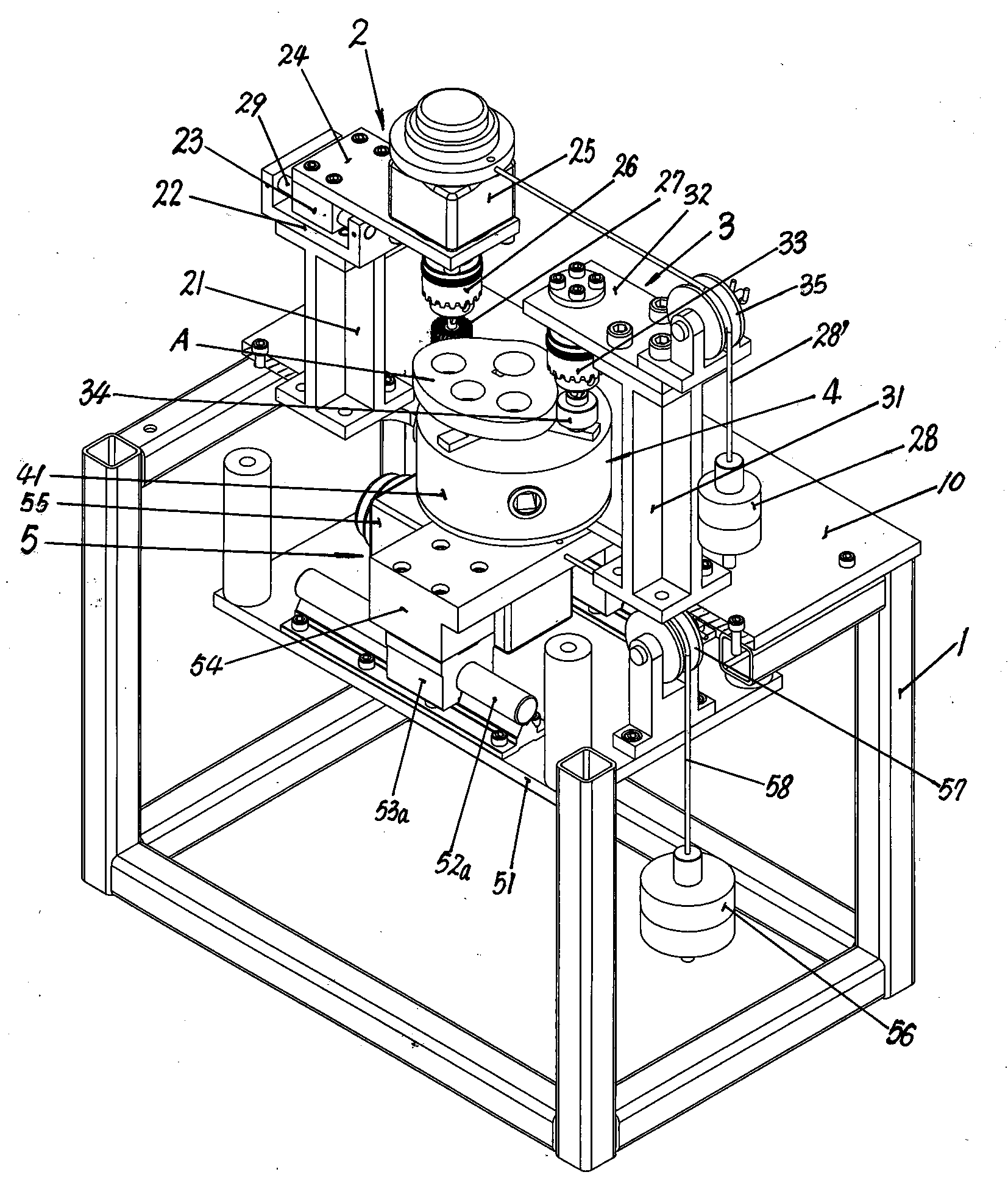

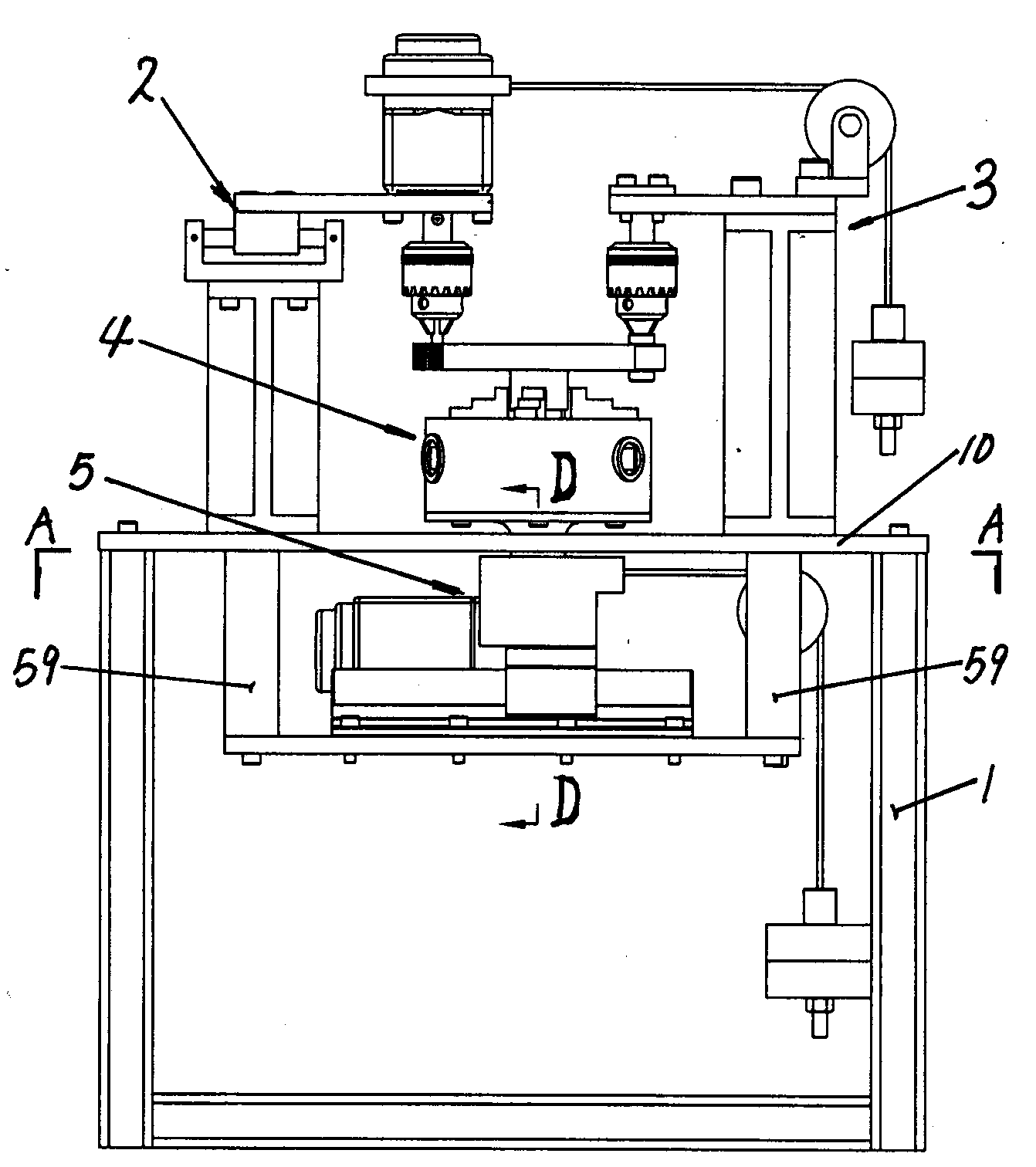

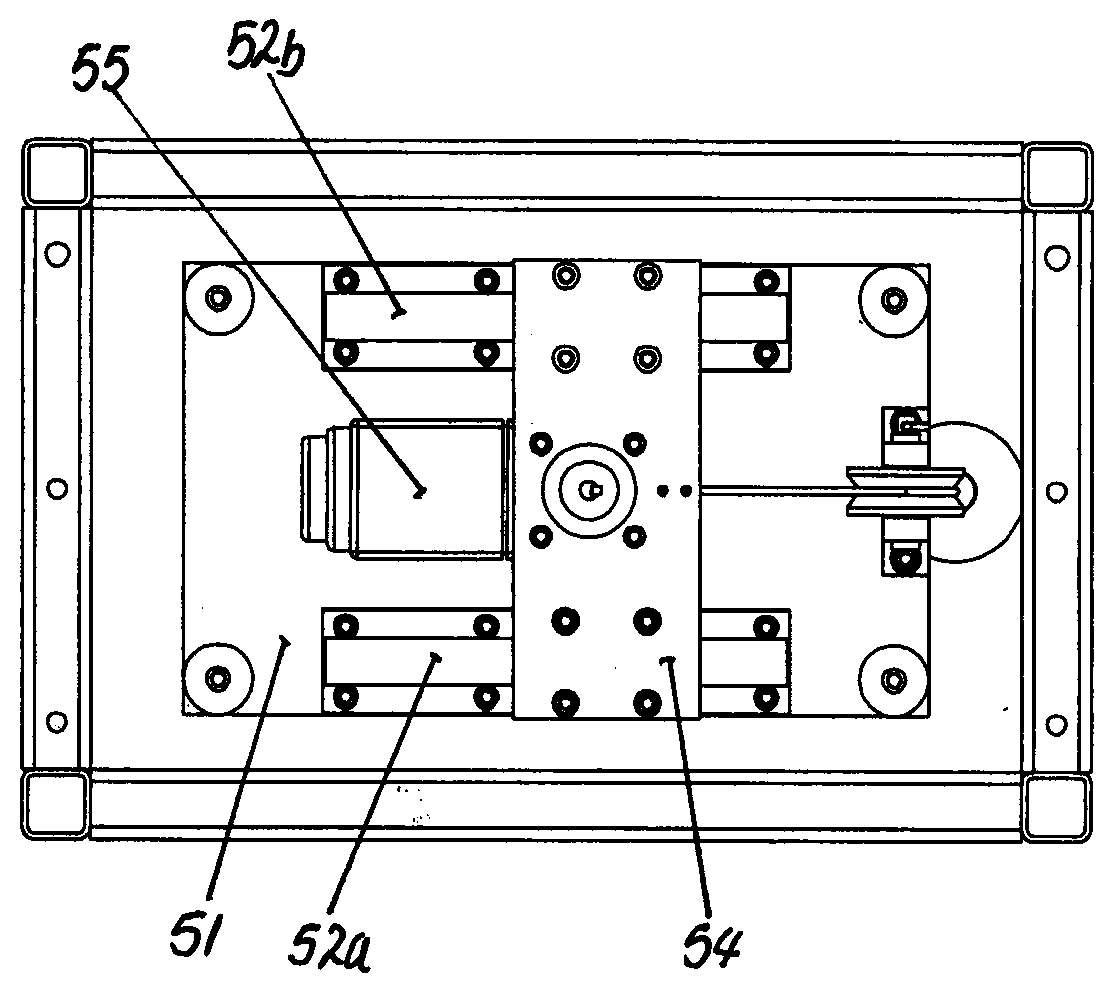

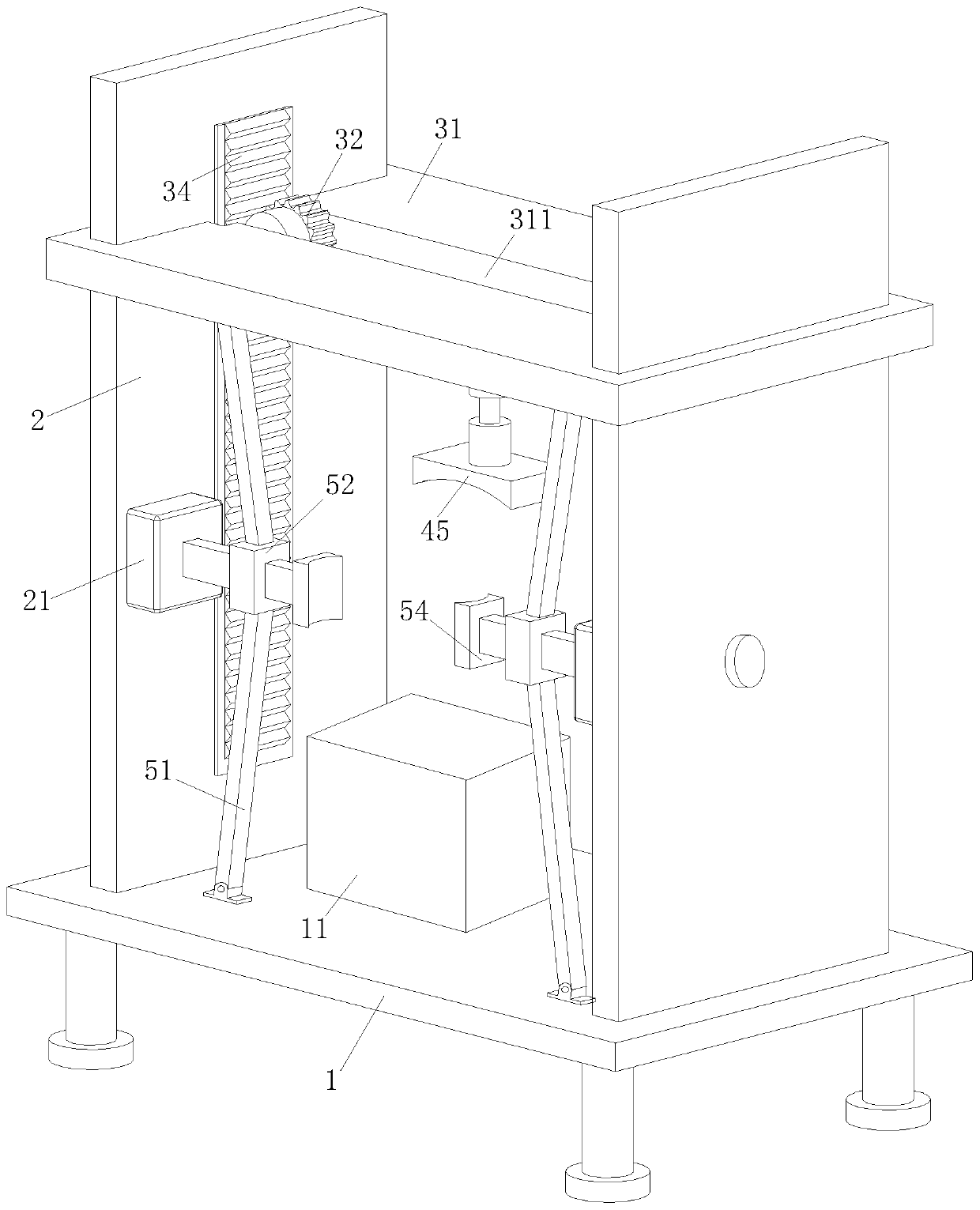

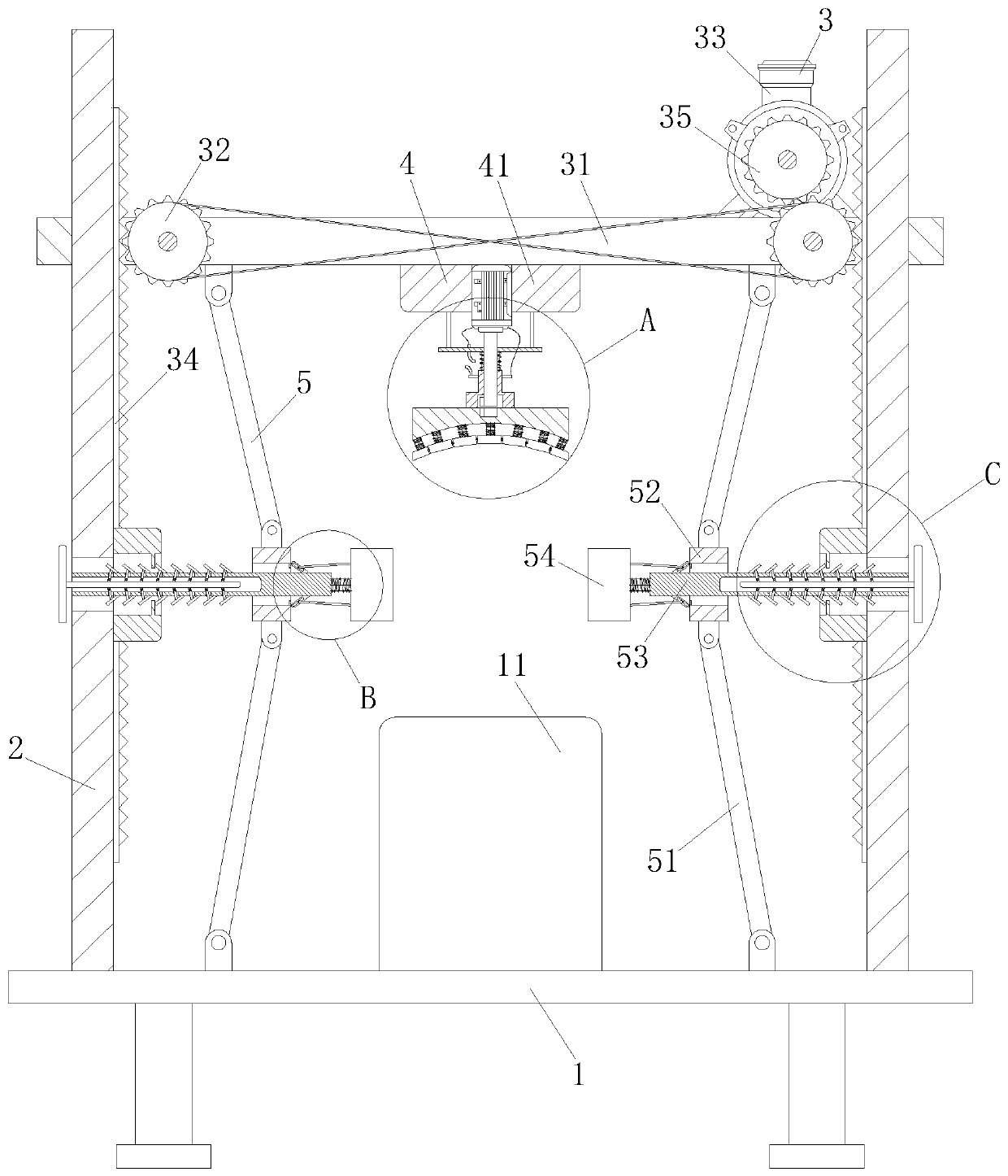

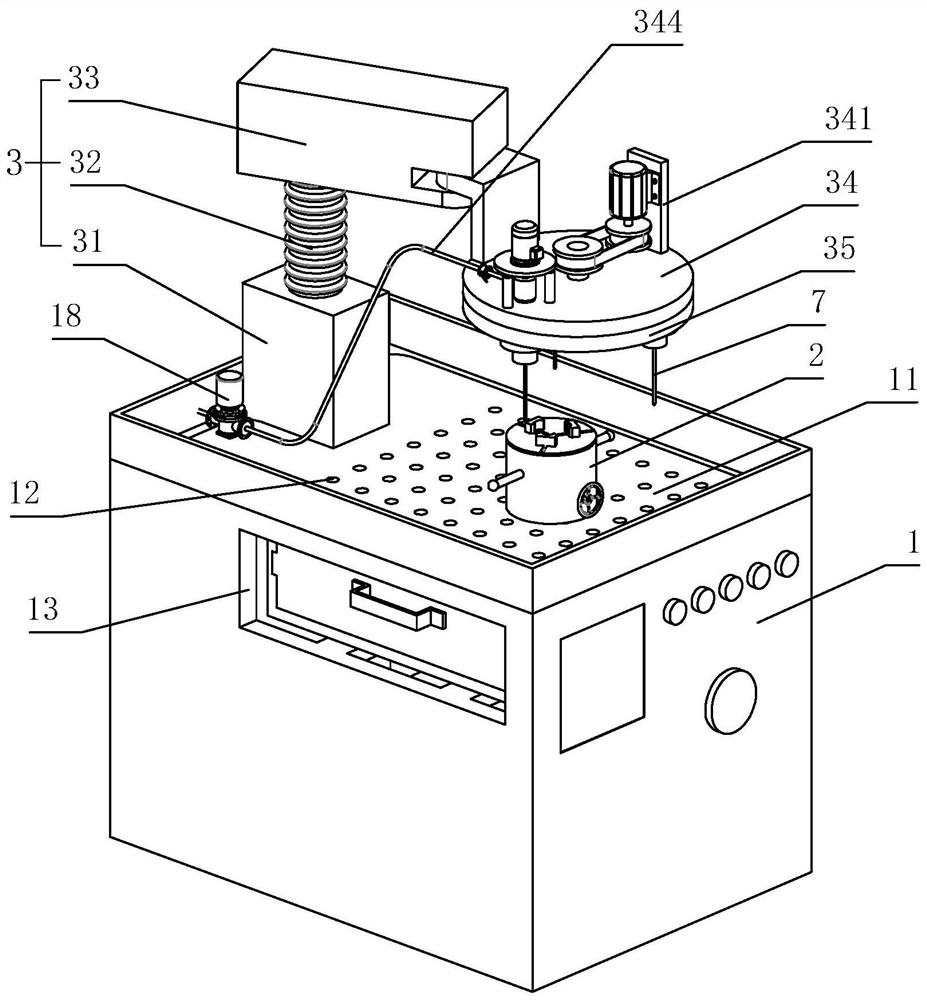

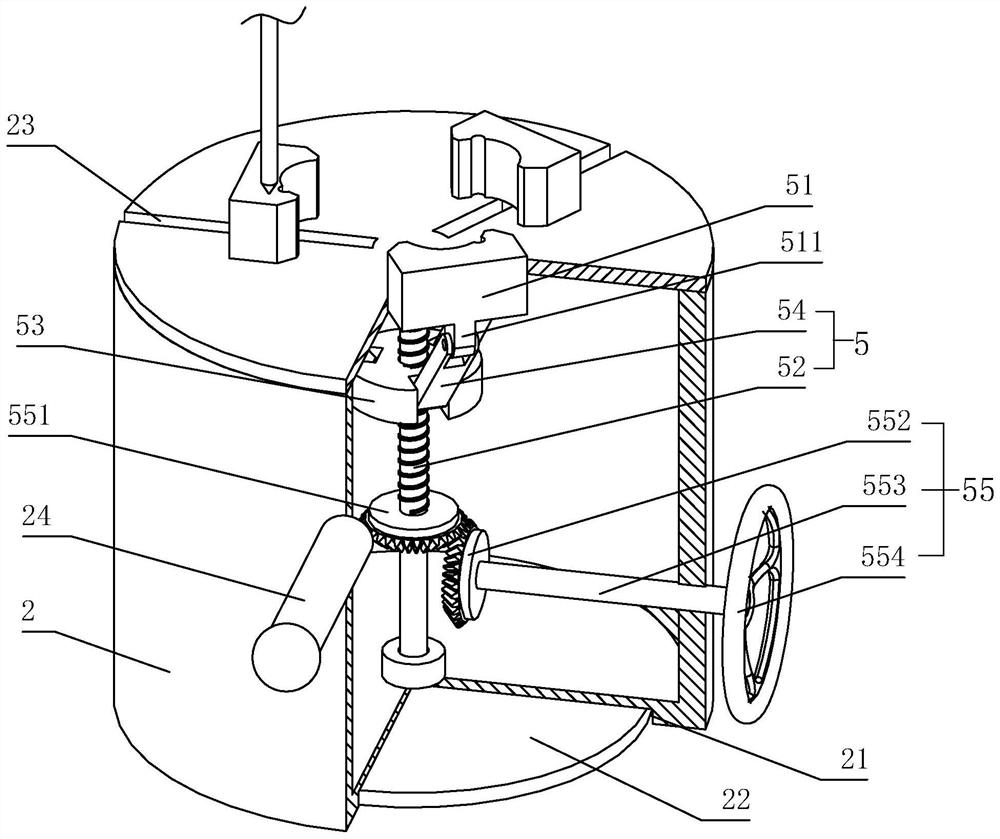

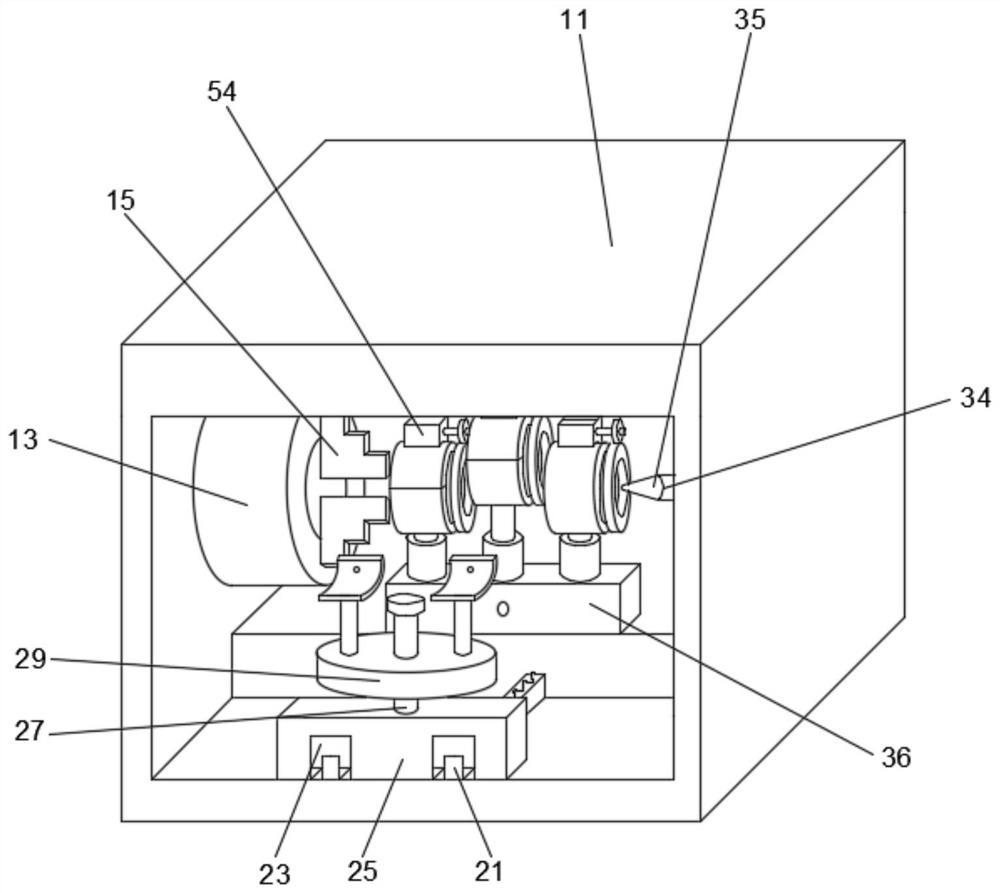

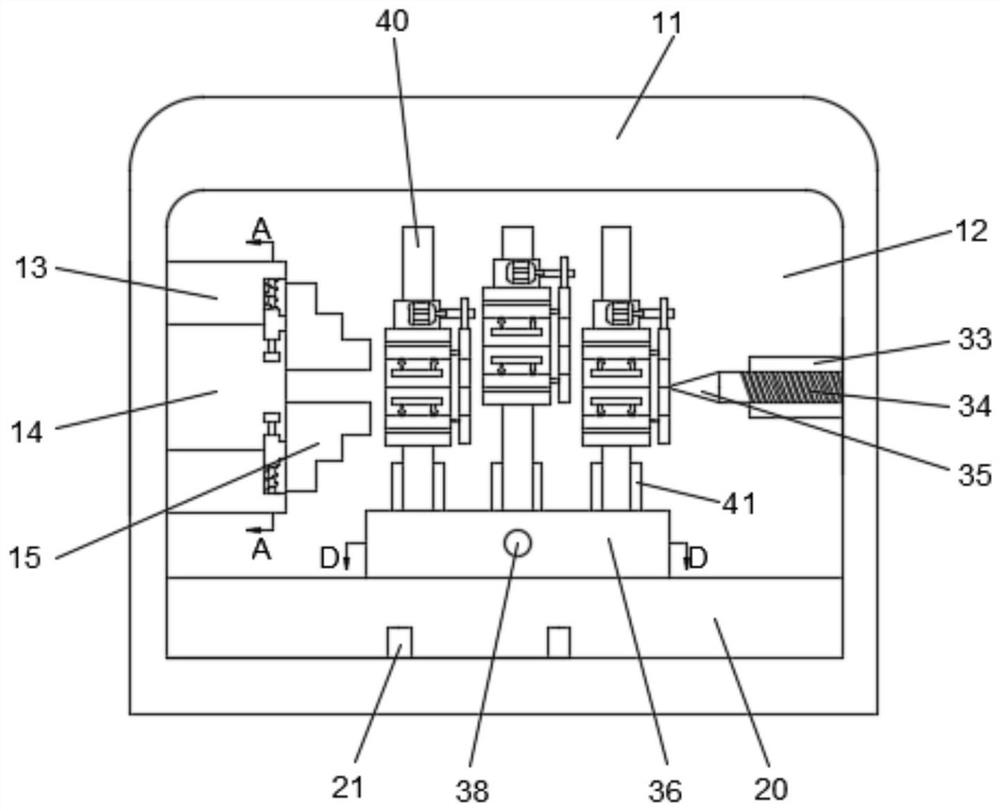

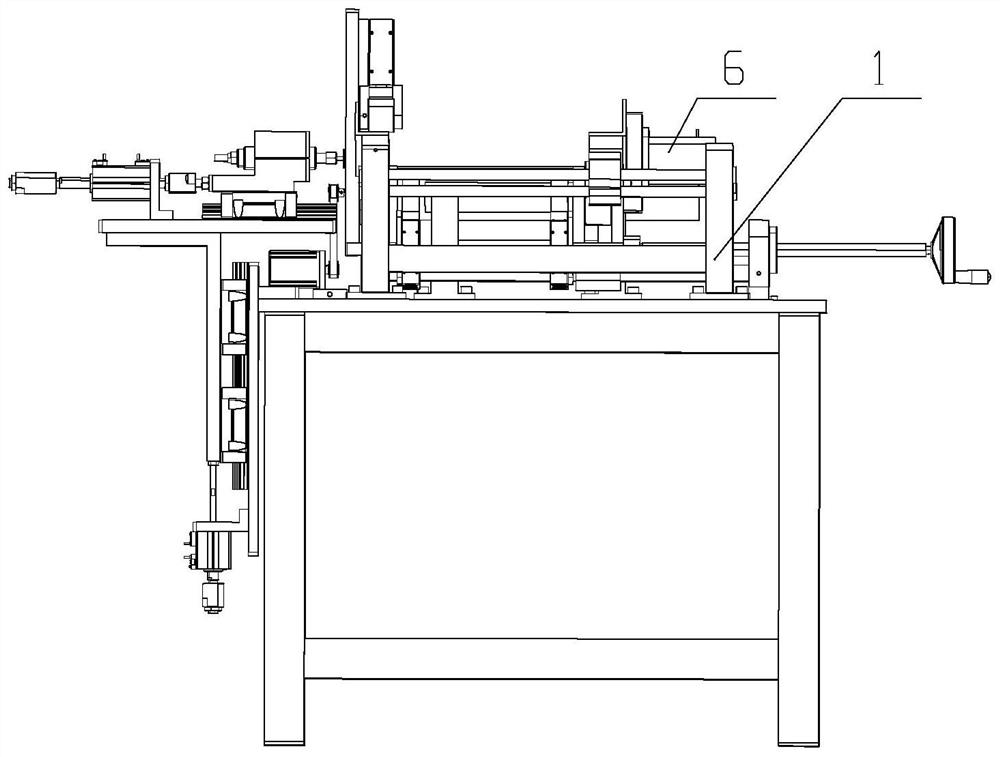

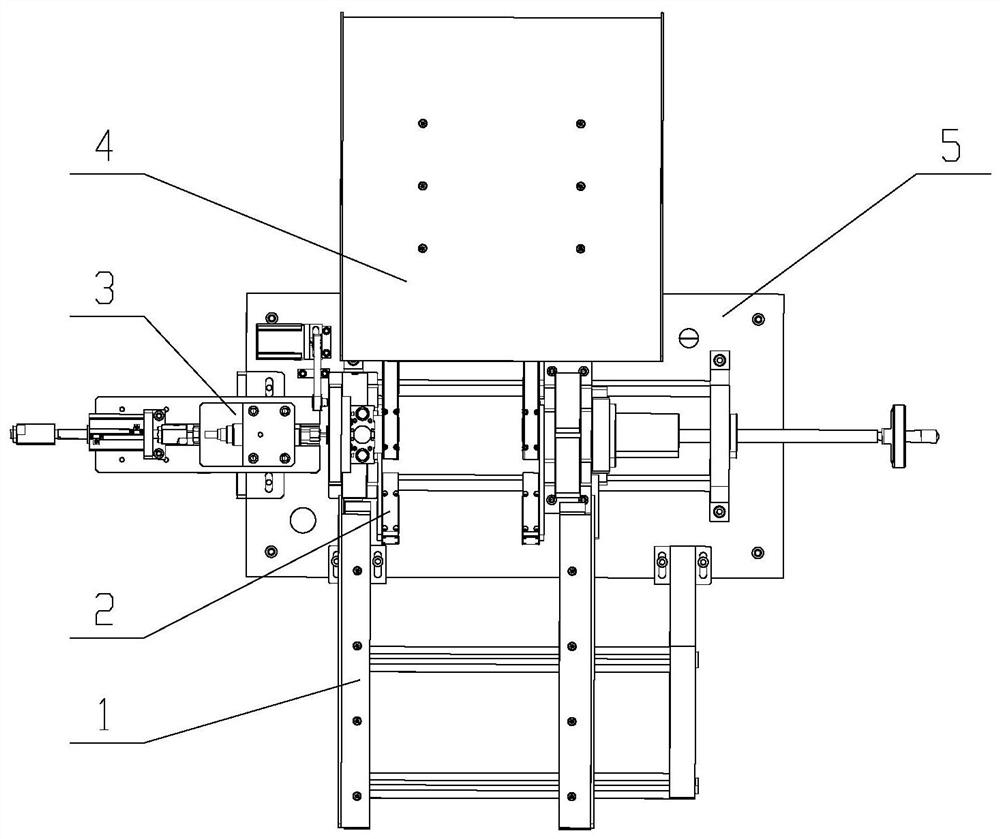

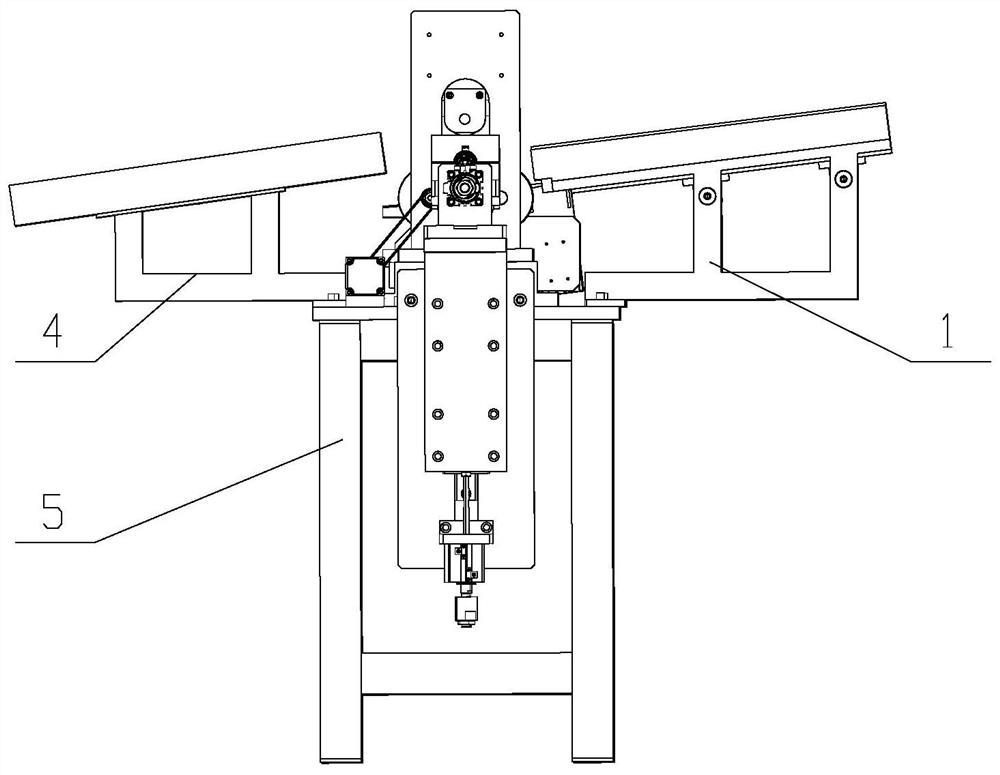

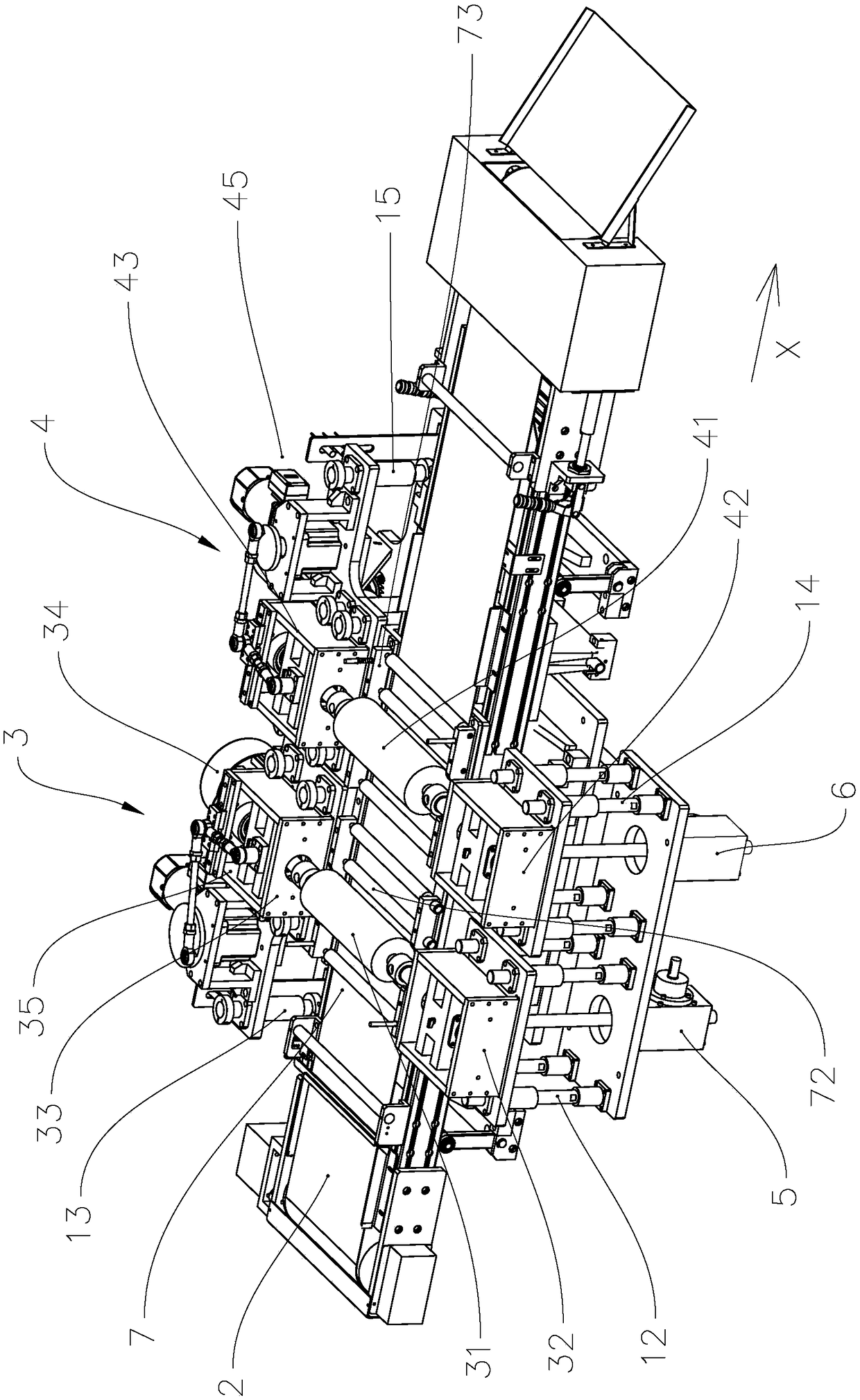

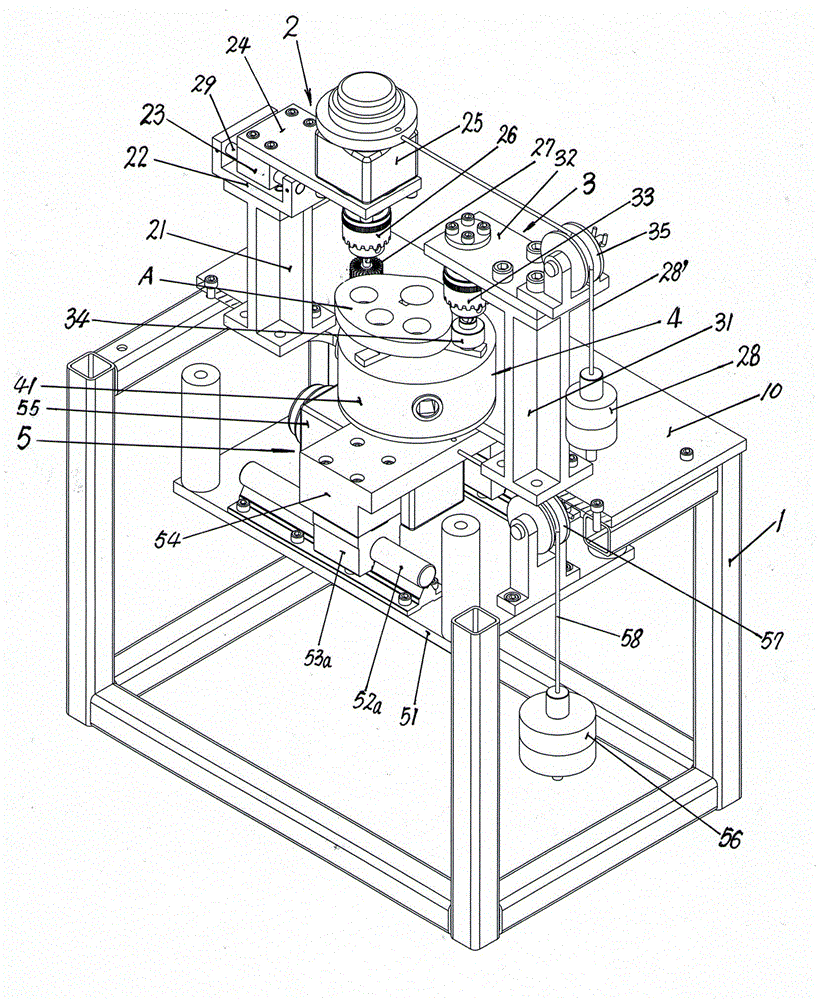

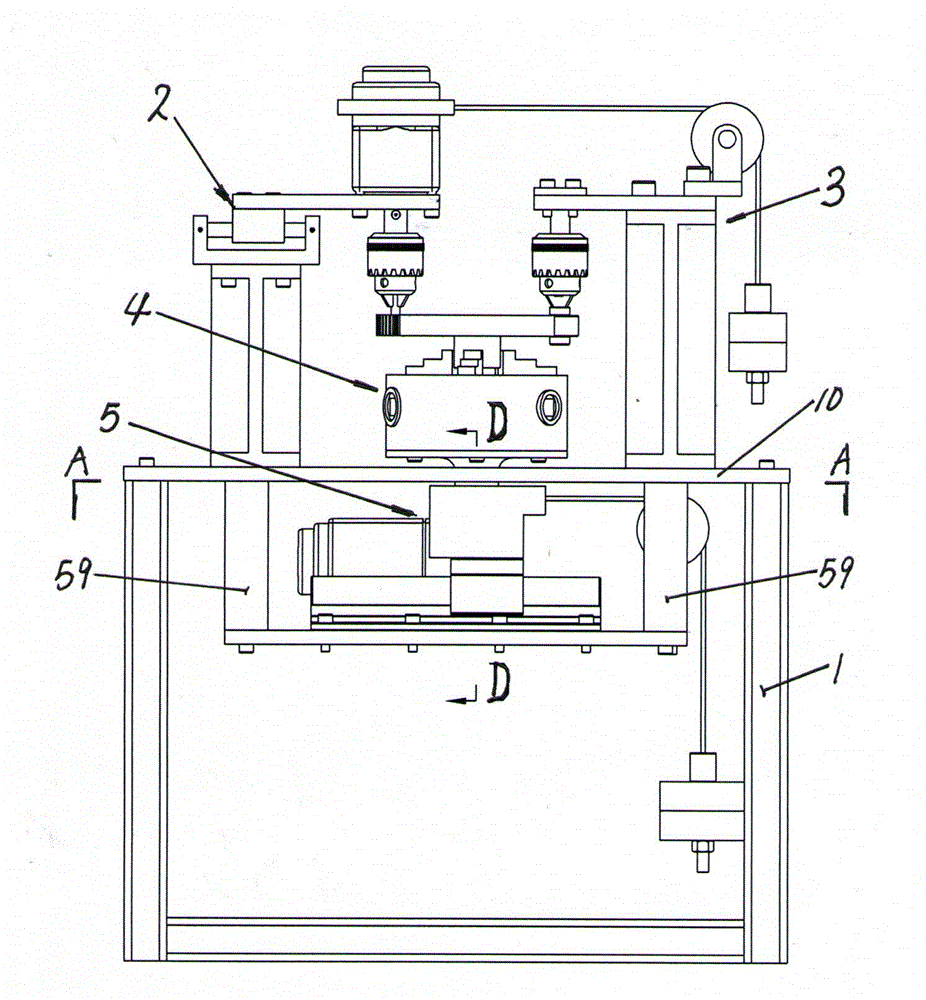

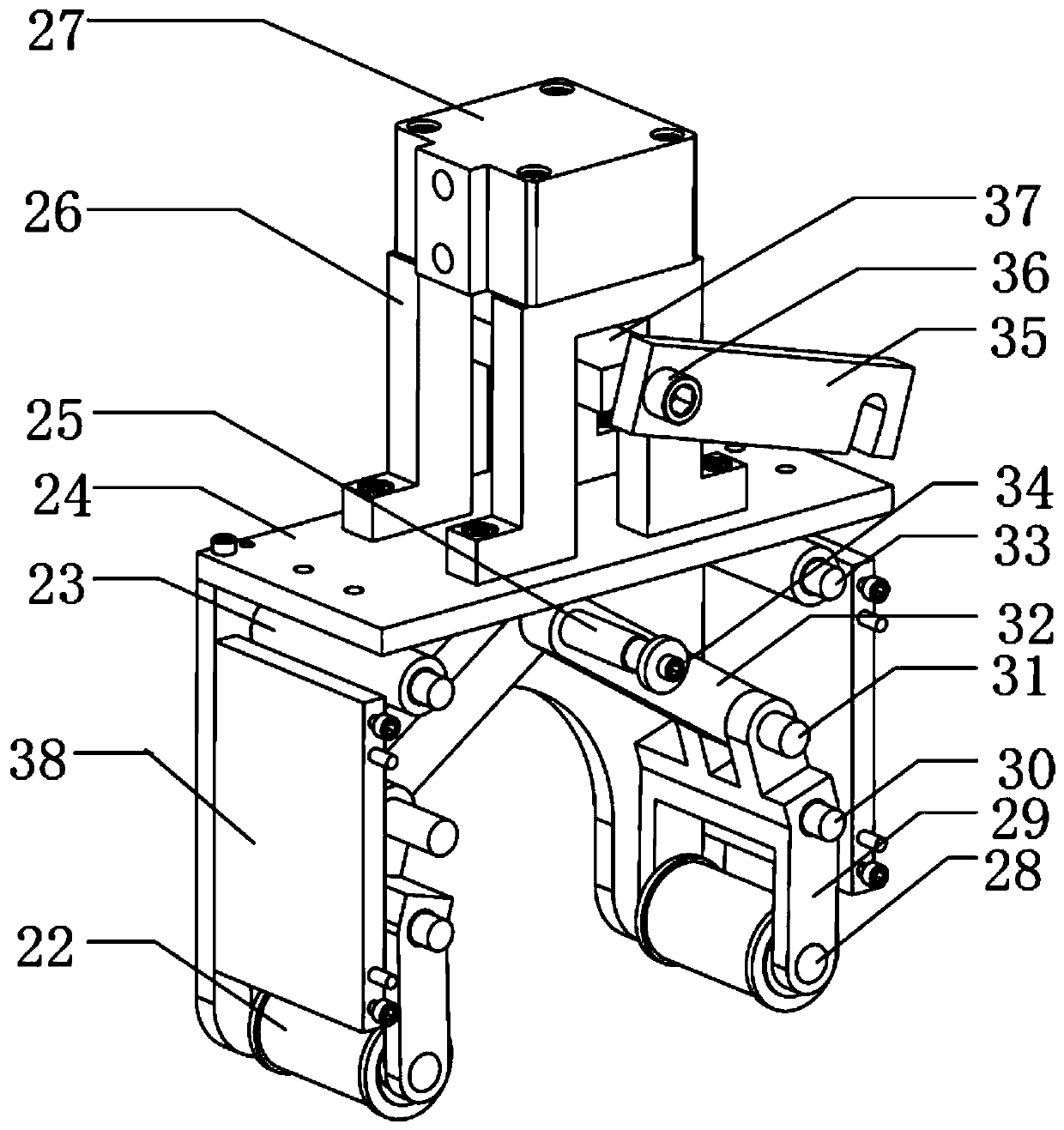

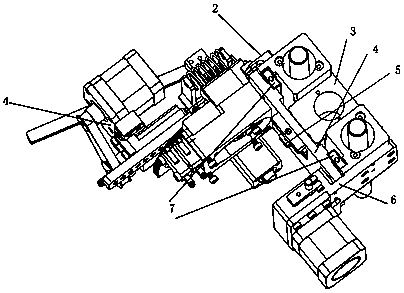

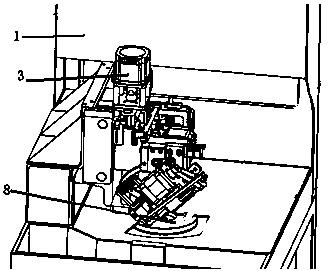

Polishing machine for curved surface of cam

ActiveCN103817575AEasy to adjustEasy to manufacturePolishing machinesBelt grinding machinesPolishingEngineering

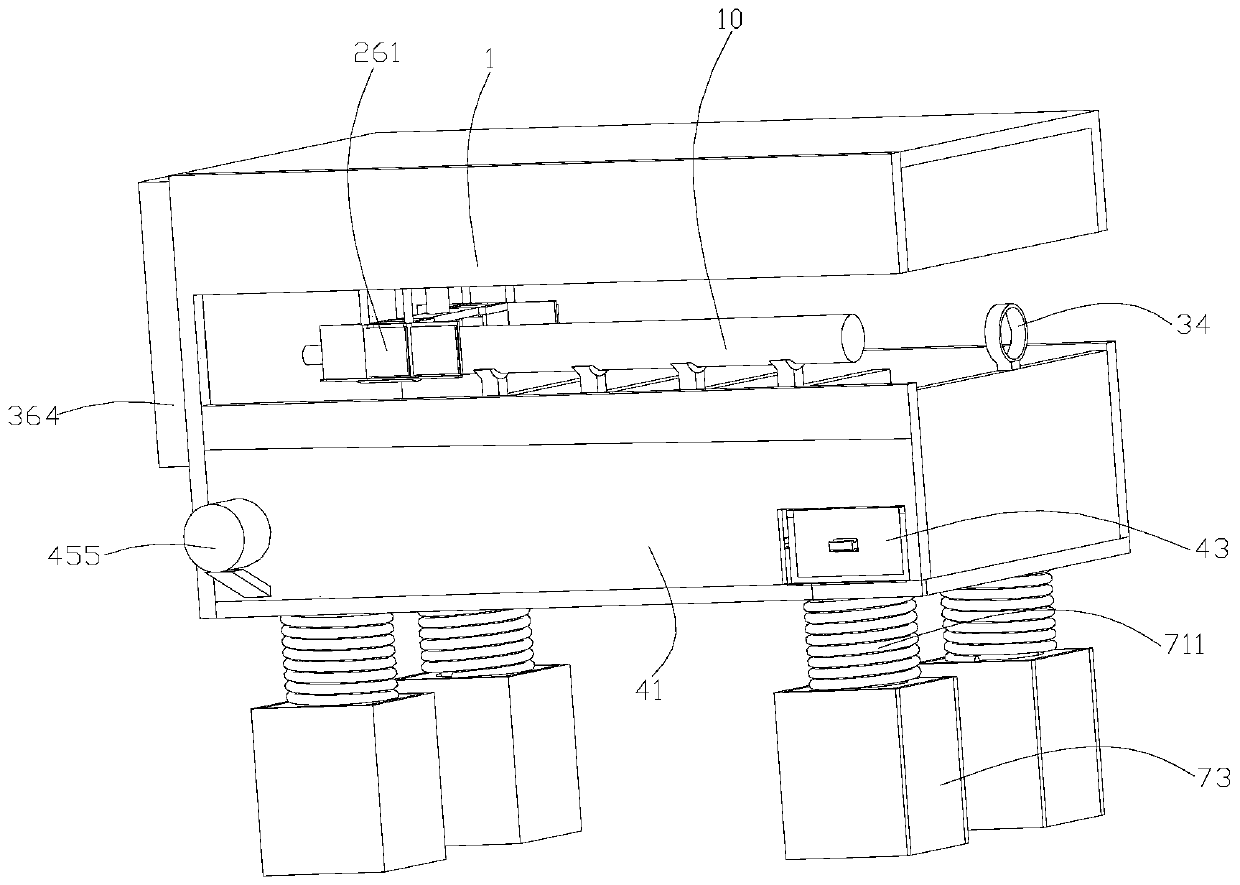

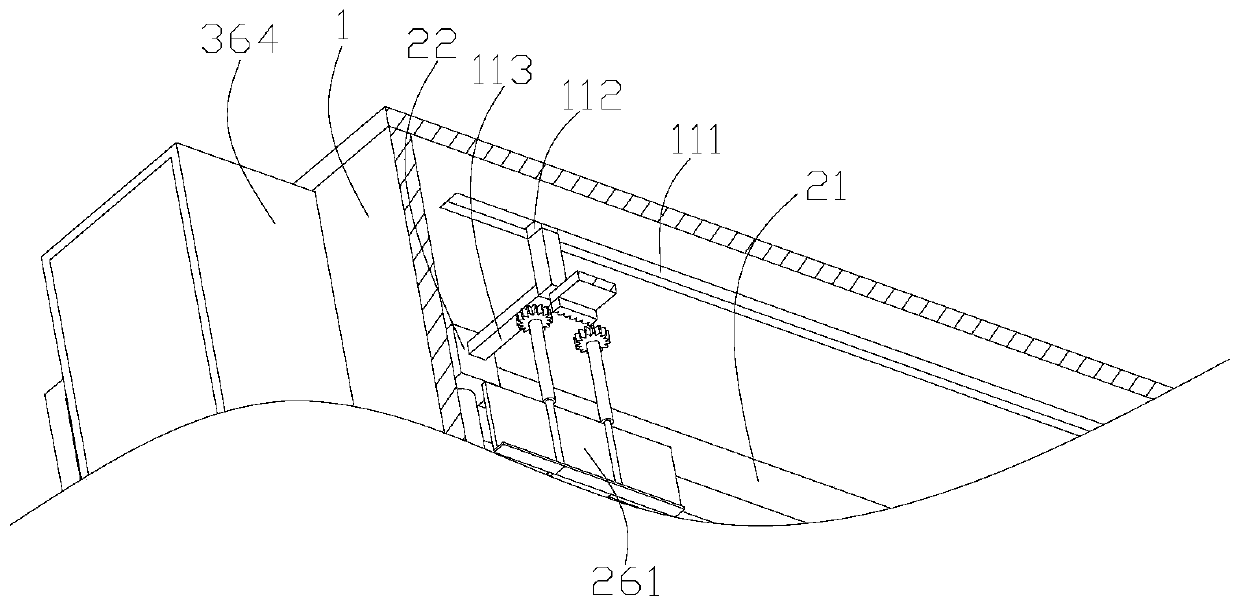

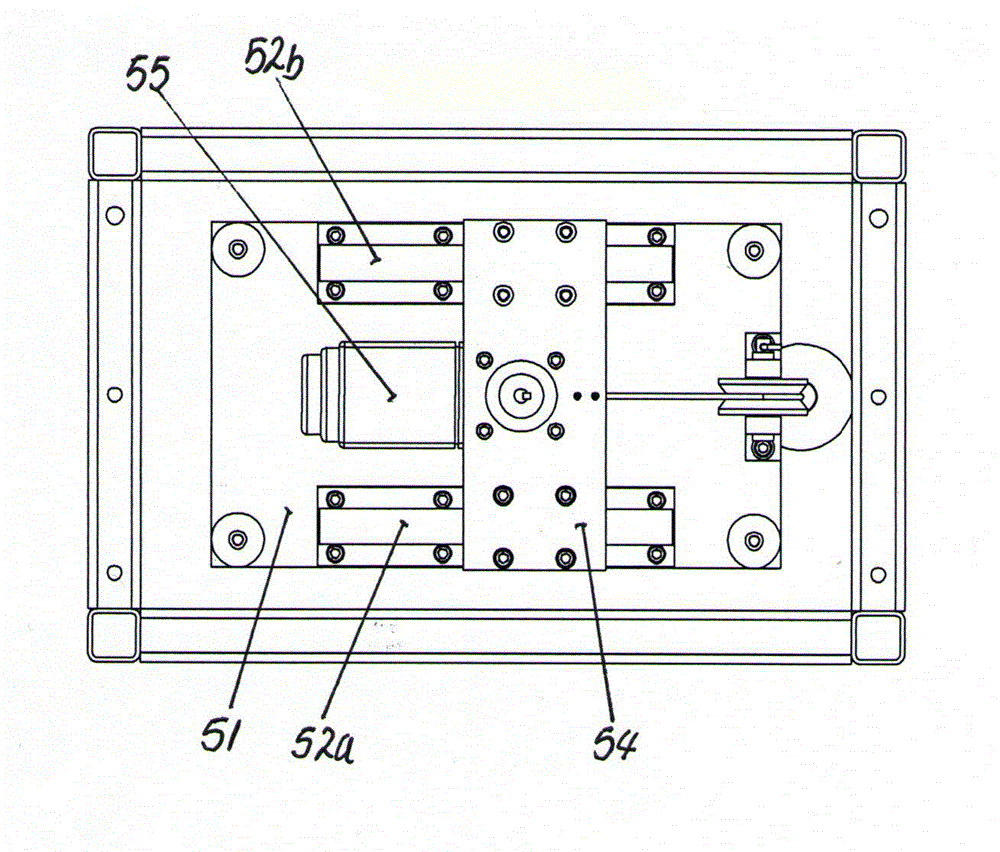

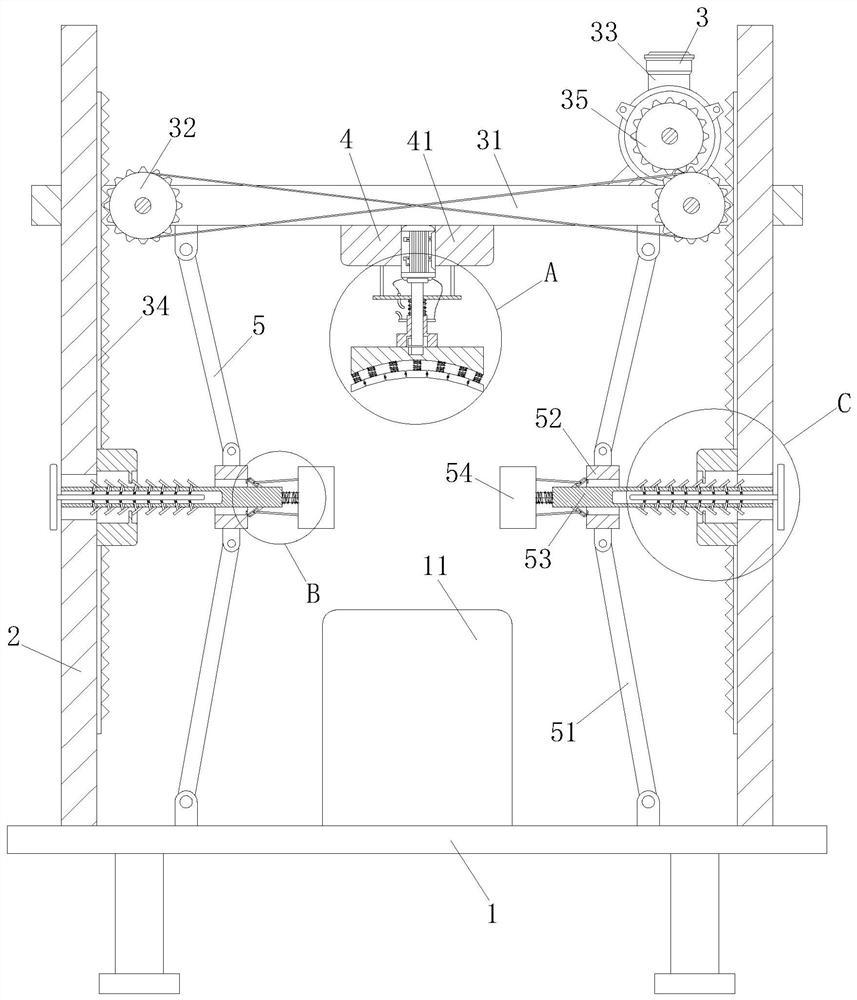

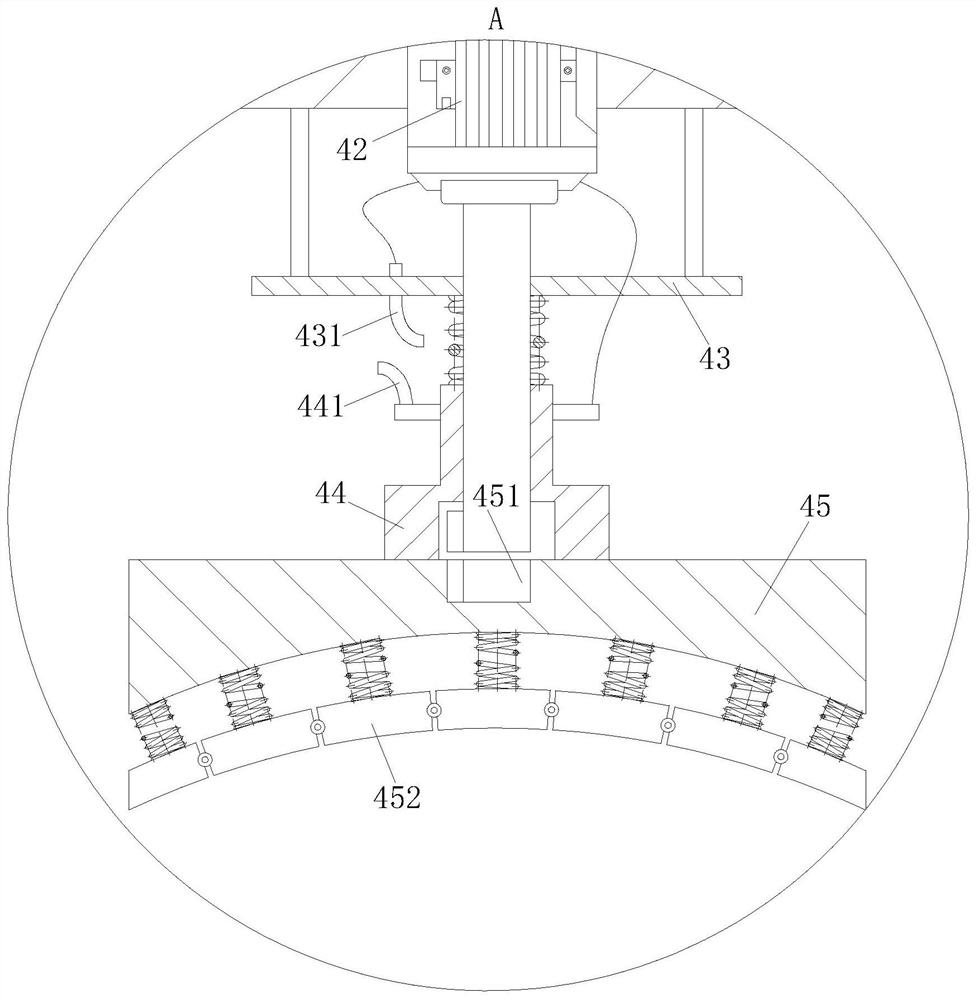

The invention relates to a polishing machine for a curved surface of a cam. The polishing machine comprises a machine frame (1), a polishing wheel device (2), a positioning wheel device (3), a cam clamp device (4) and a cam clamp rotating and gliding device (5), wherein a cam (A) is mounted on a scroll chuck (41) which slides and moves along with the cam clamp rotating and gliding device (5) under the action of a second counter weight (56), so that one side of the cam (A) is automatically adhered and leaned on a positioning wheel (34) of the positioning wheel device (3), and a connecting plate (24) of the polishing wheel device (2) slides and moves under the action of a first counter weight (28) so that a polishing wheel (27) and the other side of the cam (A) are automatically adhered and leaned to polish the curved surface of the cam (A). The polishing machine is convenient to use, good in polishing and processing precision and high in efficiency.

Owner:DANDONG TOP ELECTRONICS INSTR GRP

Polishing device for communication equipment production

ActiveCN110977738AEasy to useImprove work efficiencyGrinding carriagesPolishing machinesElectric machineGear wheel

The invention belongs to the technical field of polishing devices and specifically relates to a polishing device for communication equipment production. The polishing device comprises a base, slide plates, a transmission unit and a polishing unit, wherein a workbench is disposed on the top end of the base; the slide plates are symmetrically and vertically installed on the base; the transmission unit comprises a pressing plate, a No. 1 gear, a No. 1 motor and a rack; the polishing unit comprises a No. 1 plate, No. 2 motor, a No. 2 plate, a rotation block and a polishing block; and the polishingblock is in rotatable connection to the bottom end of the rotation block, and a groove matched with the output end of the No. 2 motor is formed in the part, close to the output end of the No. 2 motor, of the polishing block. Through coordination of the base, the slide plates, the transmission unit and the polishing unit, communication devices of different shapes and sizes can be polished, so theuse effects and the use scope of the polishing device are increased; great convenience is brought to workers; and the working efficiency of the workers is increased.

Owner:临沂高新人才教育发展集团有限公司

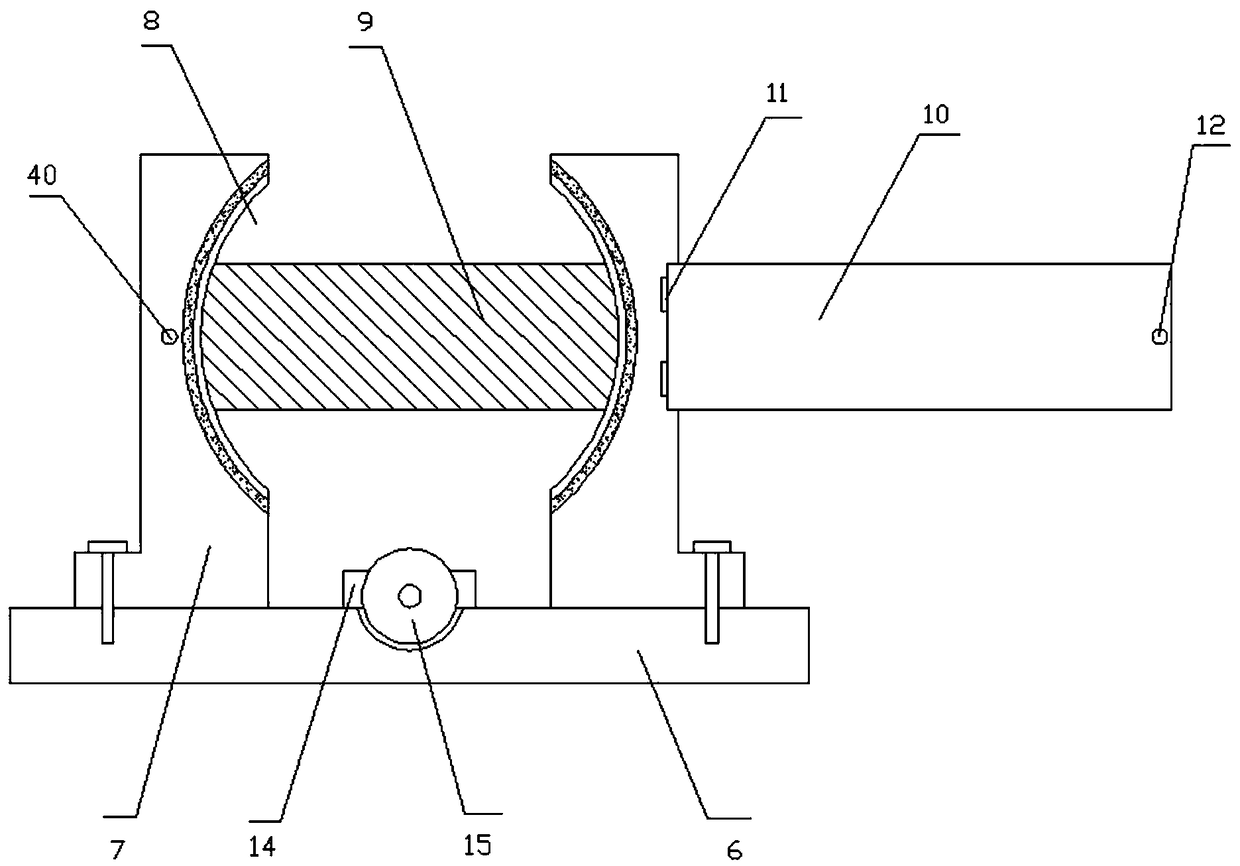

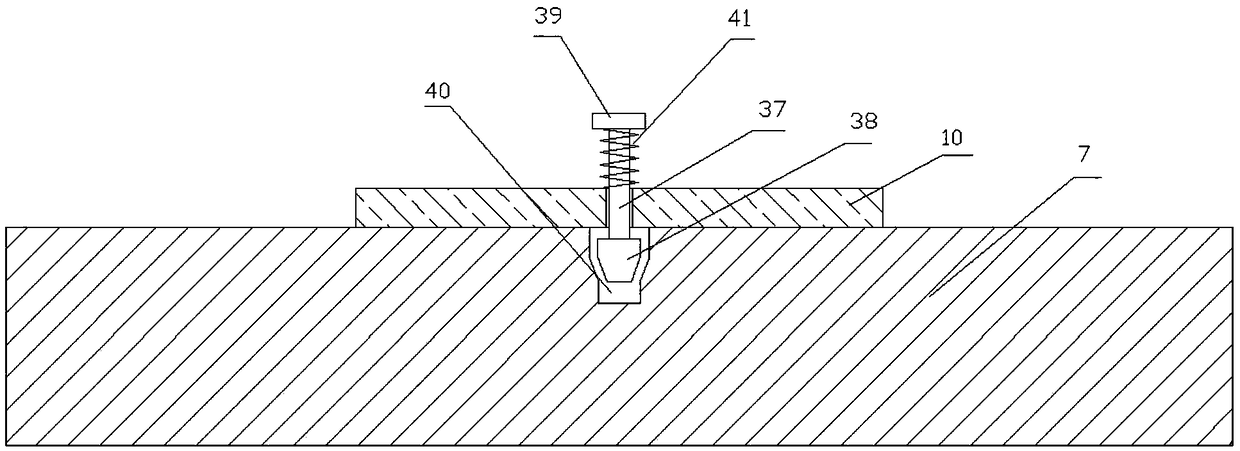

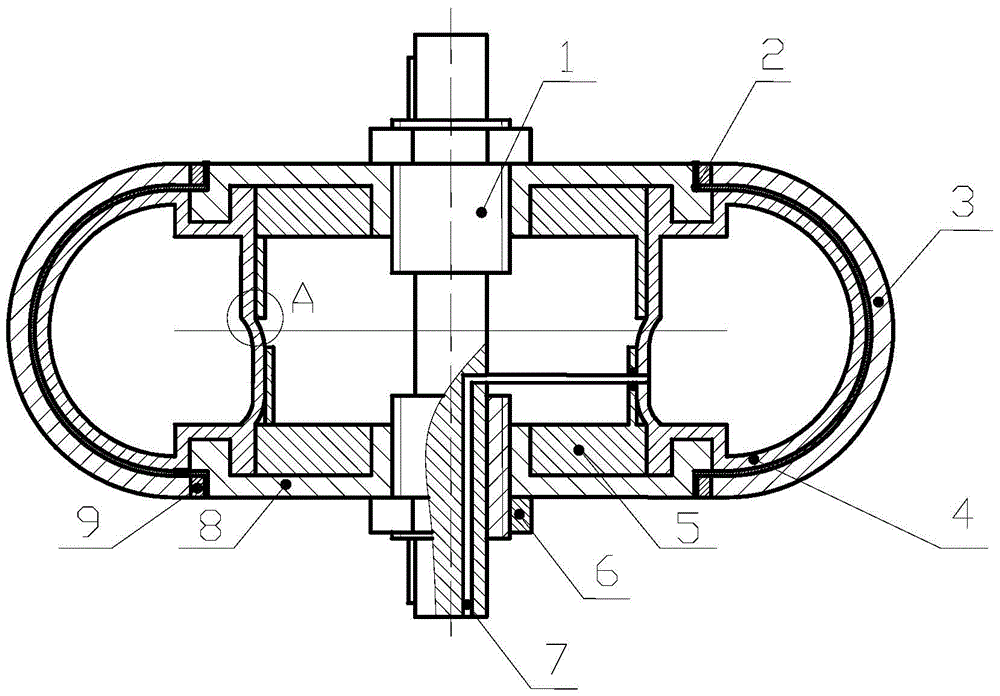

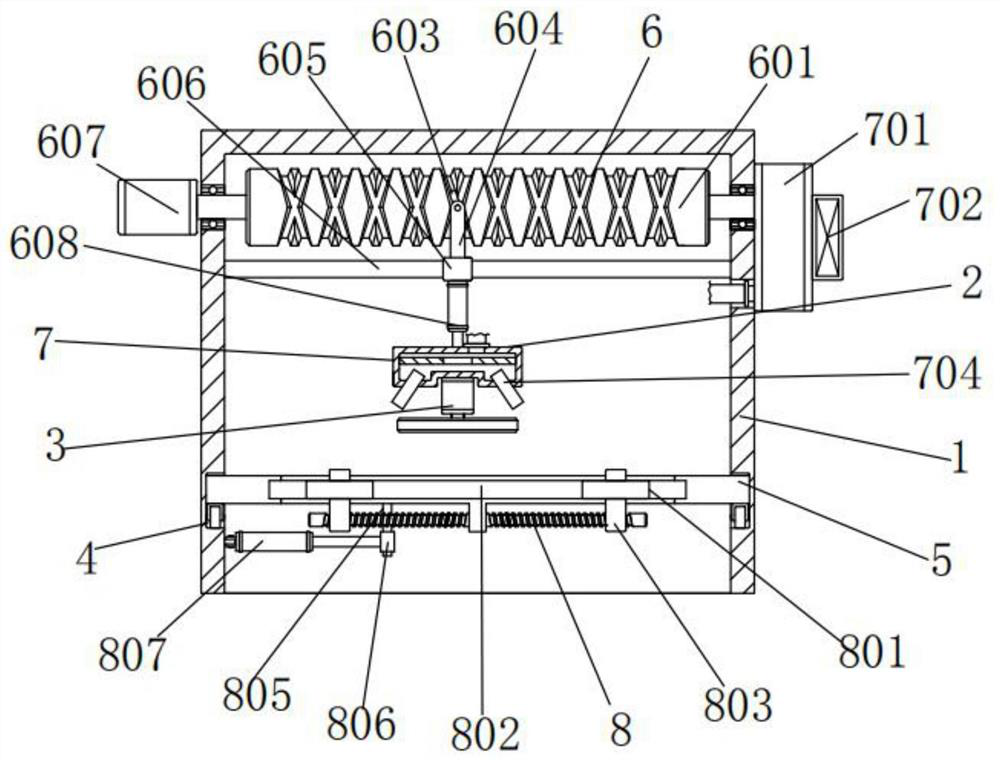

Self-balancing PE ball core polishing machine

PendingCN110524401AImprove polishing efficiencyStable polishing conditionsGrinding carriagesPolishing machinesSocial benefitsMechanical engineering

The invention discloses a self-balancing PE ball core polishing machine. The machine is composed of a PE ball core clamping device and a polishing wheel feeding device, PE ball cores are respectivelyclamped on the left side and the right side of the PE ball core clamping device, the left side and the right side of the polishing wheel feeding device drive polishing wheels respectively, and synchronous polishing and feeding are conducted on the two PE ball cores. Due to the fact that the vibration force on the left side and the right side can be counteracted in the polishing process, meanwhile,the residual unbalanced force can be removed through pose adjustment of the arch-shaped support, and high-precision PE ball core polishing can be achieved without interference of the vibration force.In addition, the two PE ball cores are polished at the same time, and therefore the polishing efficiency is twice that of a traditional machine. The polishing machine has the characteristics of highefficiency and high precision, so that the polishing machine is applied to full-automatic polishing of the PE ball core, the production efficiency and the product quality grade of the PE ball core canbe greatly improved, and remarkable economic and social benefits are brought.

Owner:ZHEJIANG QINGFA PIPE TECH

Iron rod polishing equipment

InactiveCN111496663AEfficient grinding and polishingAffect the grinding effectGrinding carriagesPolishing machinesPolishingEngineering

The invention discloses iron rod polishing equipment. The iron rod polishing equipment comprises a box, a grinding device arranged in the box, a clamping device used for clamping iron rods, a waste scrap collection device arranged at the outer bottom of the box and vibration reduction devices. The vibration reduction devices comprise supporting columns arranged at the bottom of the box, press parts connected with the supporting columns, vibration reduction seats cooperating with the press parts, vibration reduction assemblies arranged in the vibration reduction seats and fourth elastic parts arranged on the supporting columns in a sleeving manner. One end of each fourth elastic part is connected with the bottom of the box, and the other ends of the fourth elastic parts are connected with the vibration reduction seats. According to the iron rod polishing equipment, iron rods can be ground and polished comprehensively and efficiently; iron scraps ground down from iron rods can be removedin time by the waste scrap collection device in the grinding process, and the situation that waste scraps are accumulated on the box to influence the iron rod grinding effect is avoided; and stability of the whole equipment is high, the polishing precision to iron rods can be guaranteed, and the grinding effect to iron rods is good.

Owner:浙江安尚电气有限公司

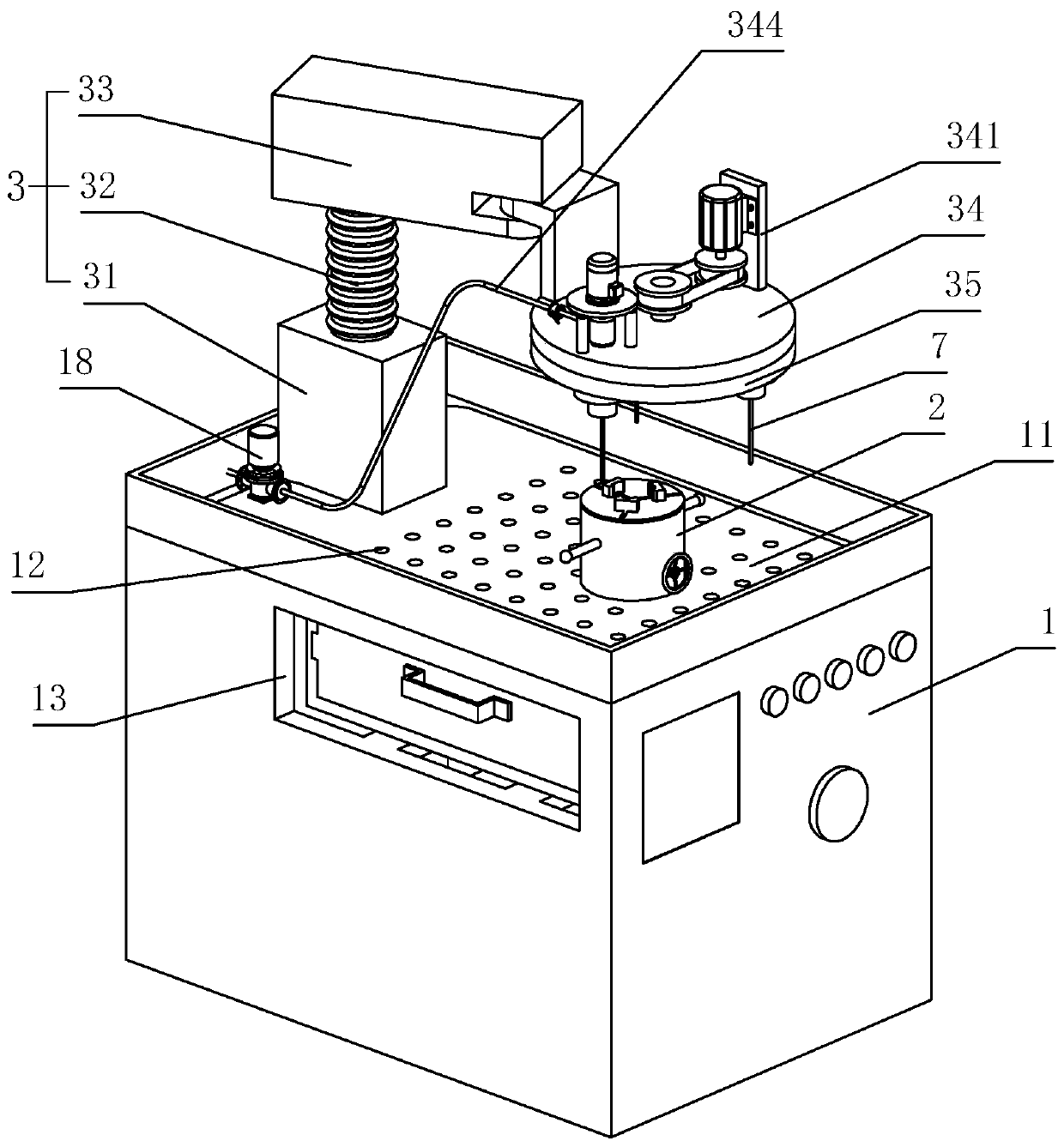

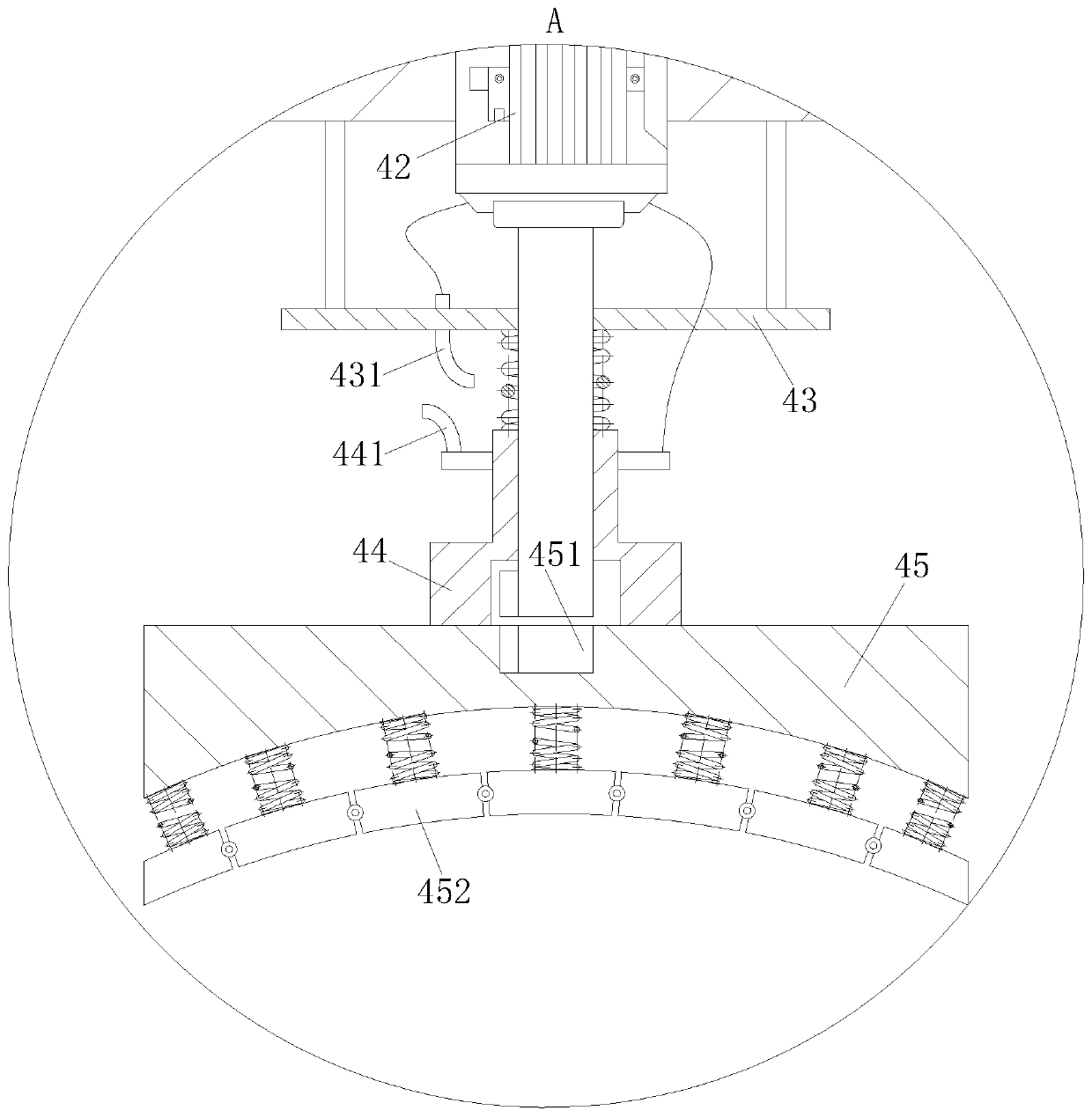

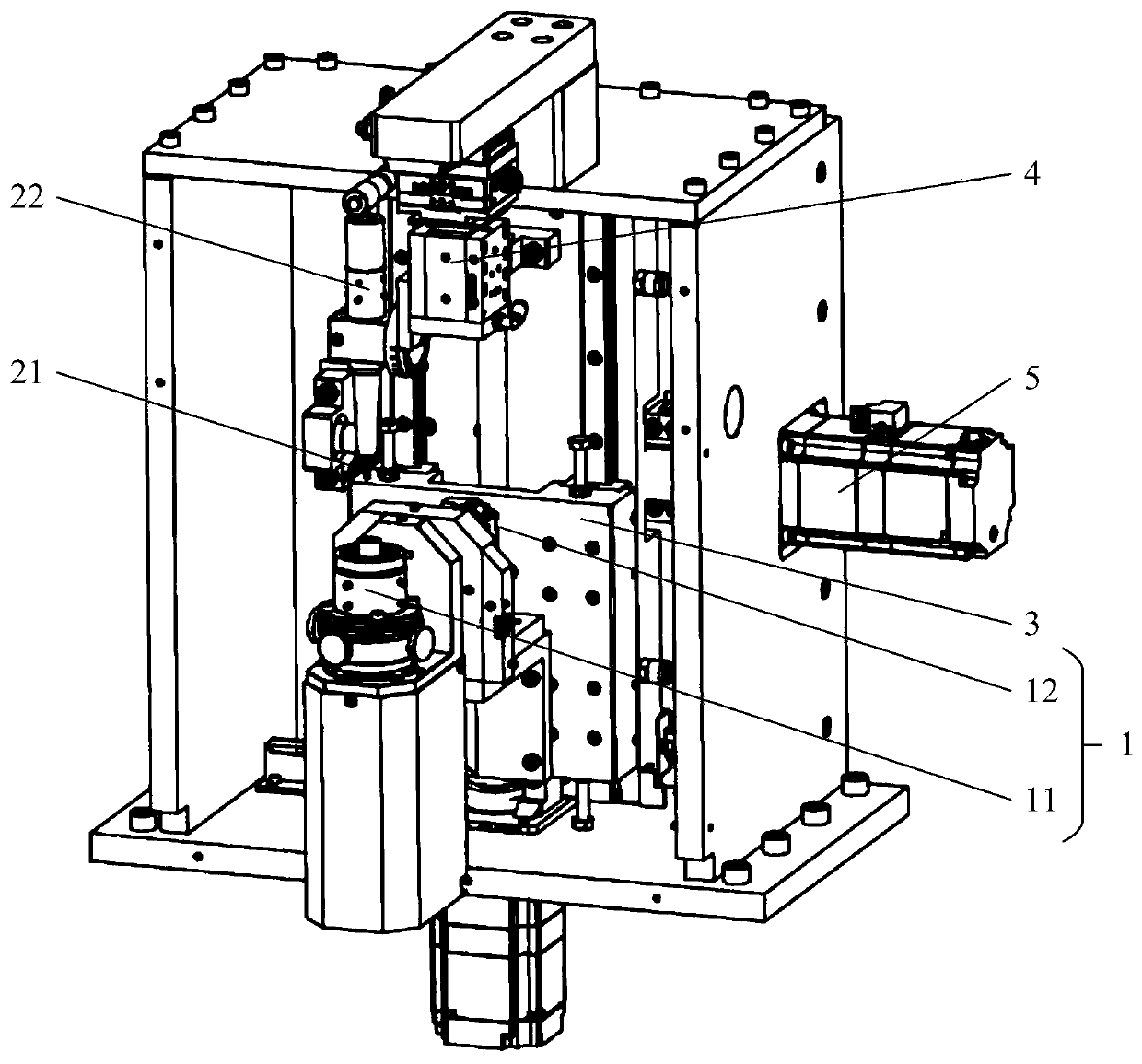

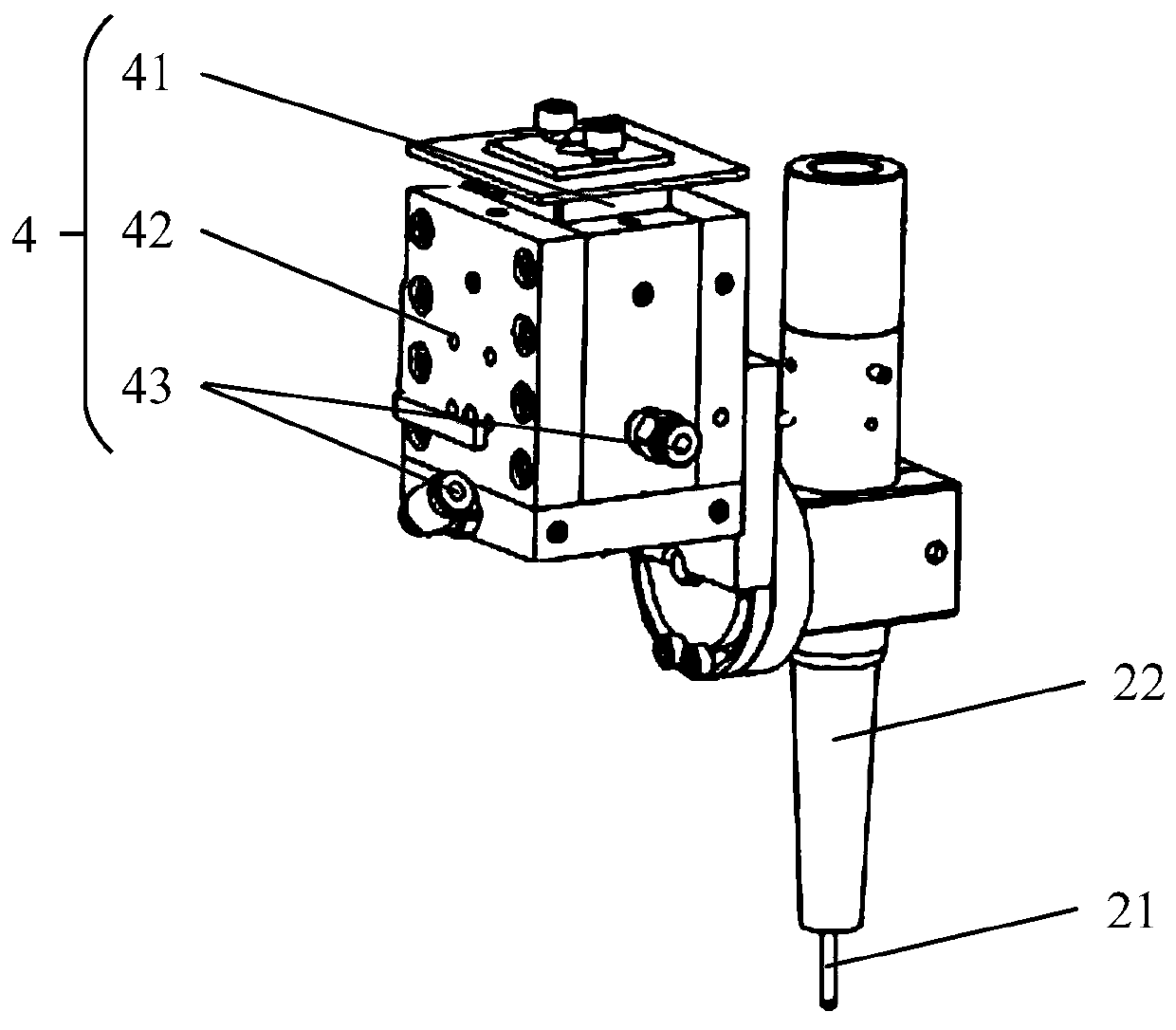

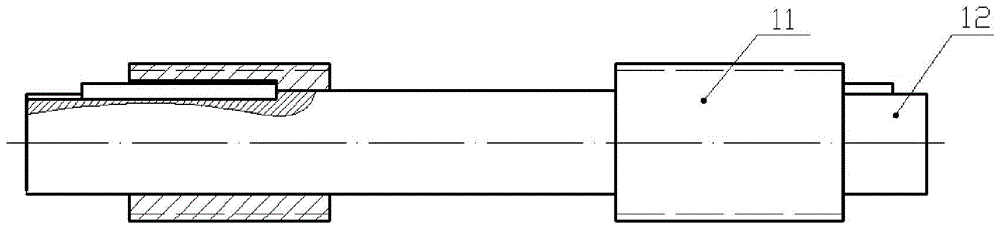

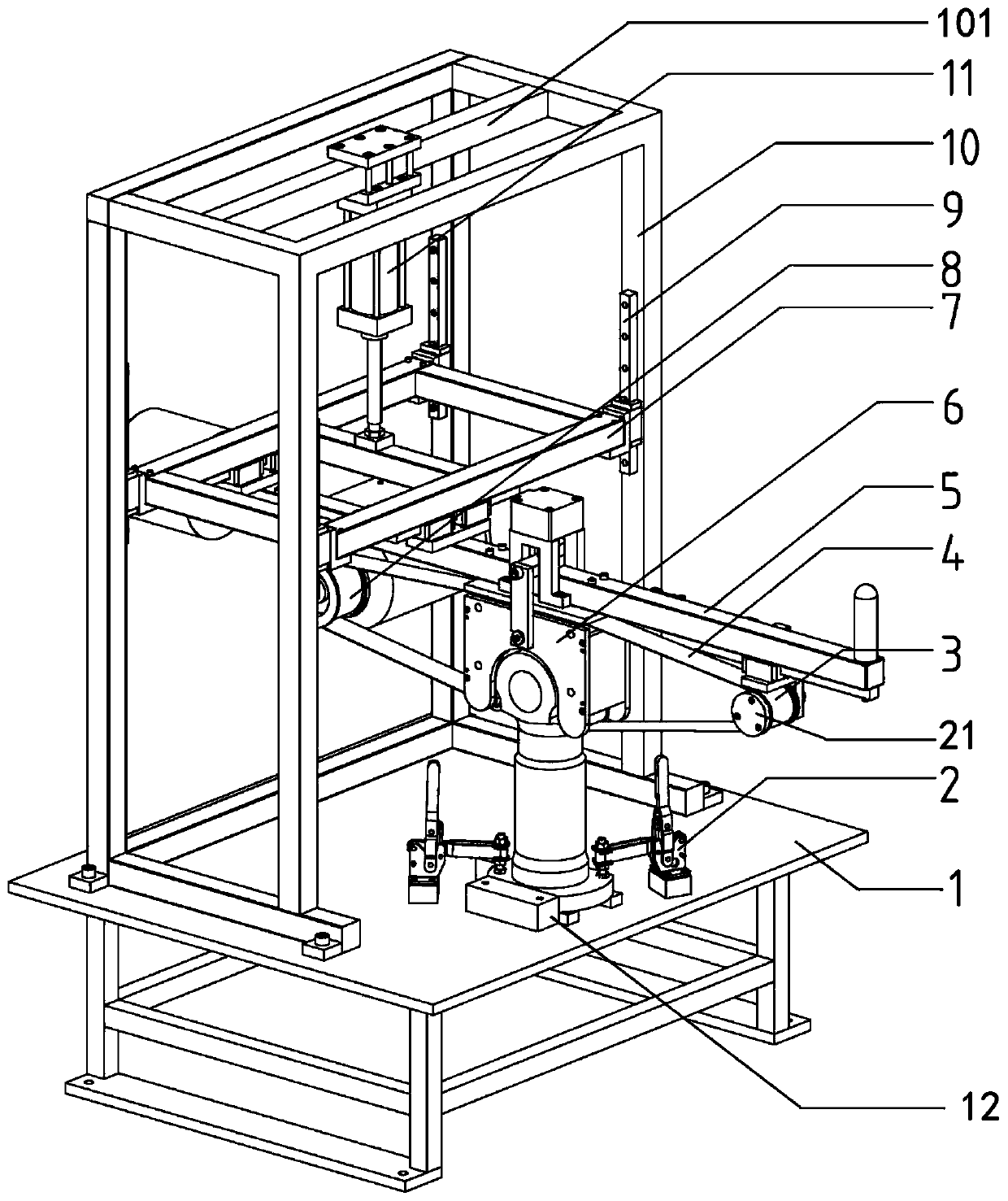

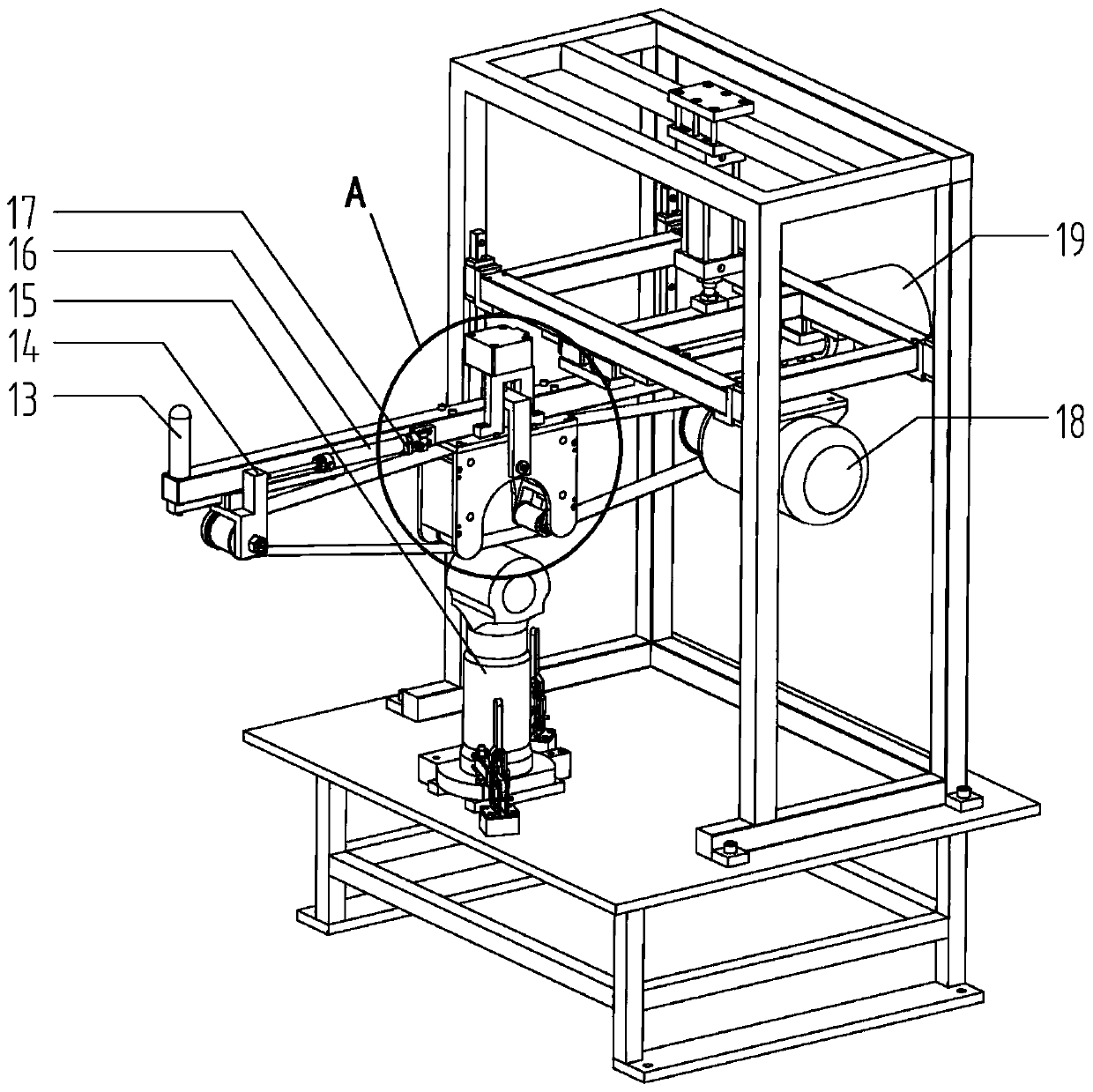

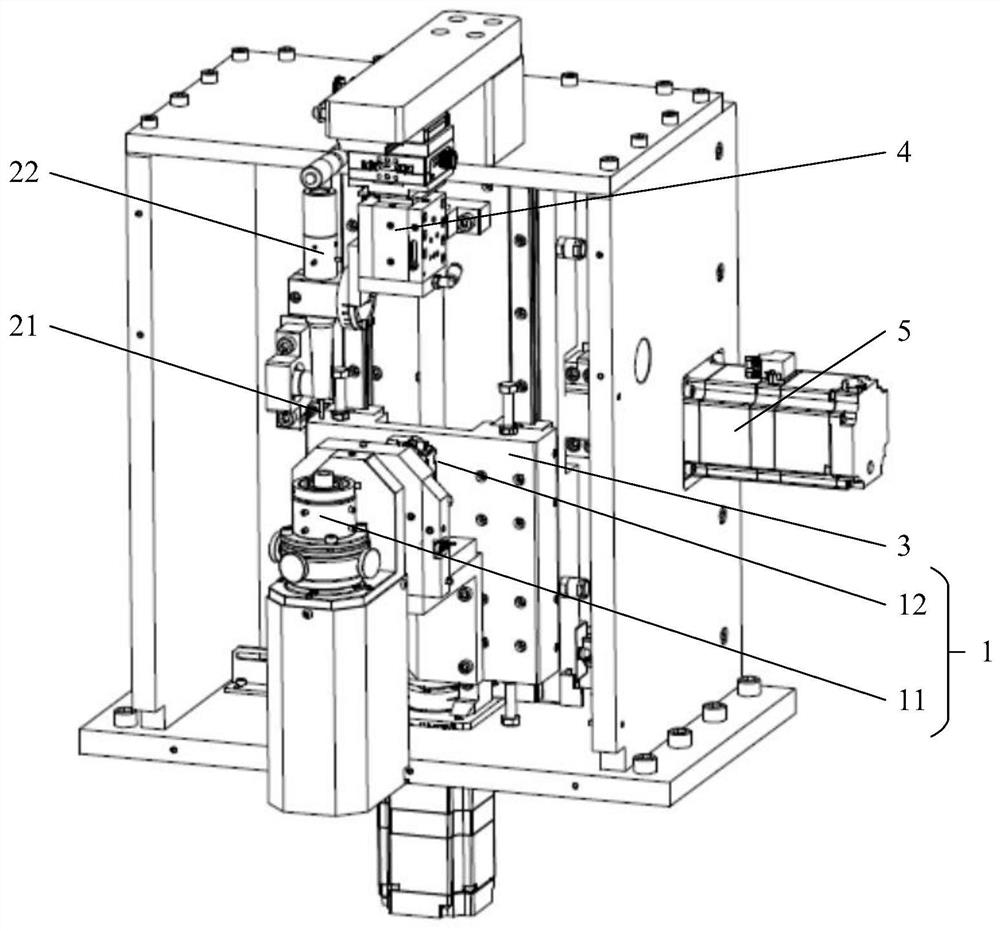

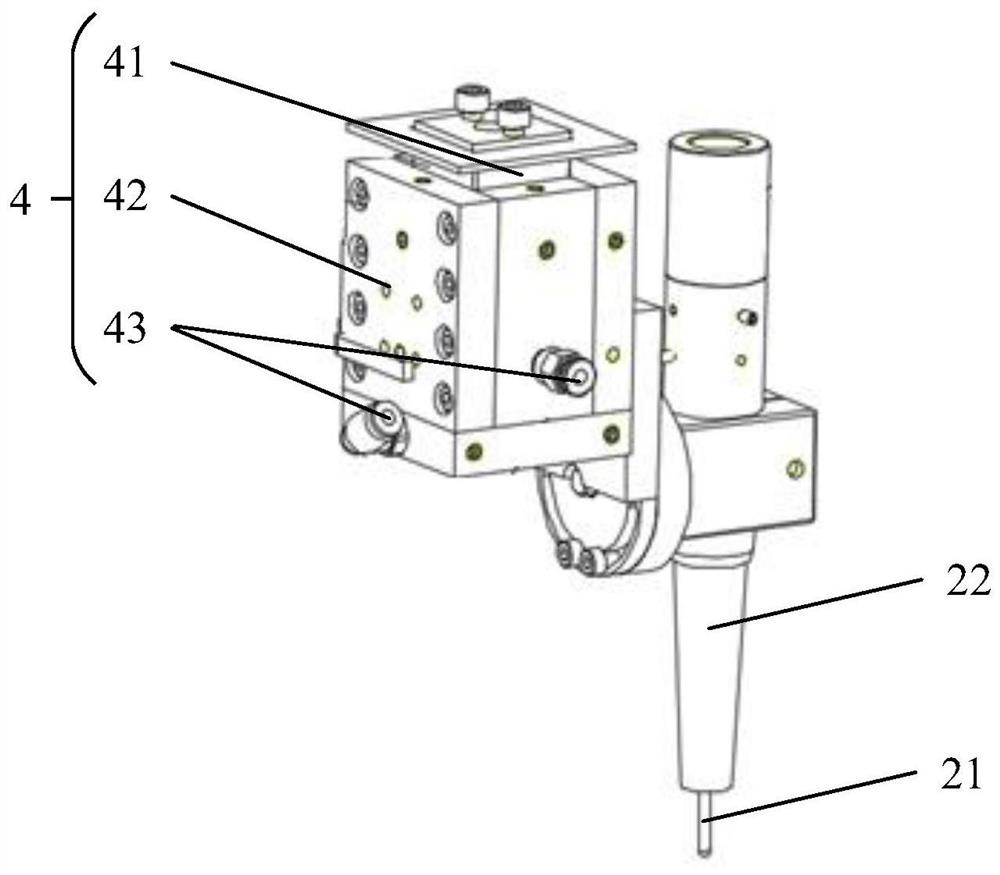

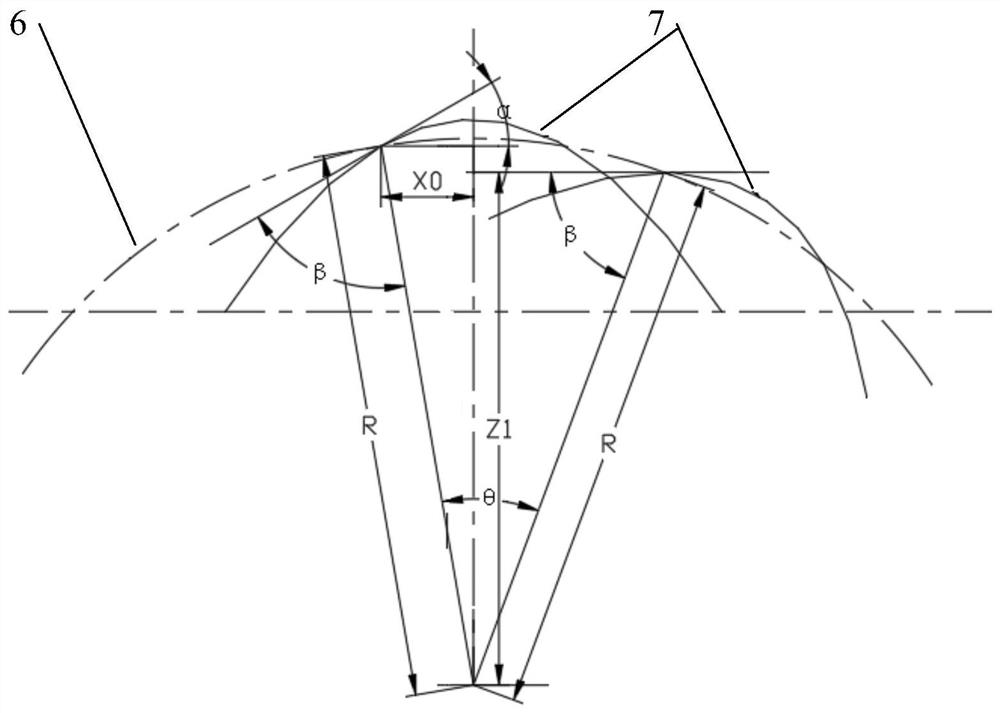

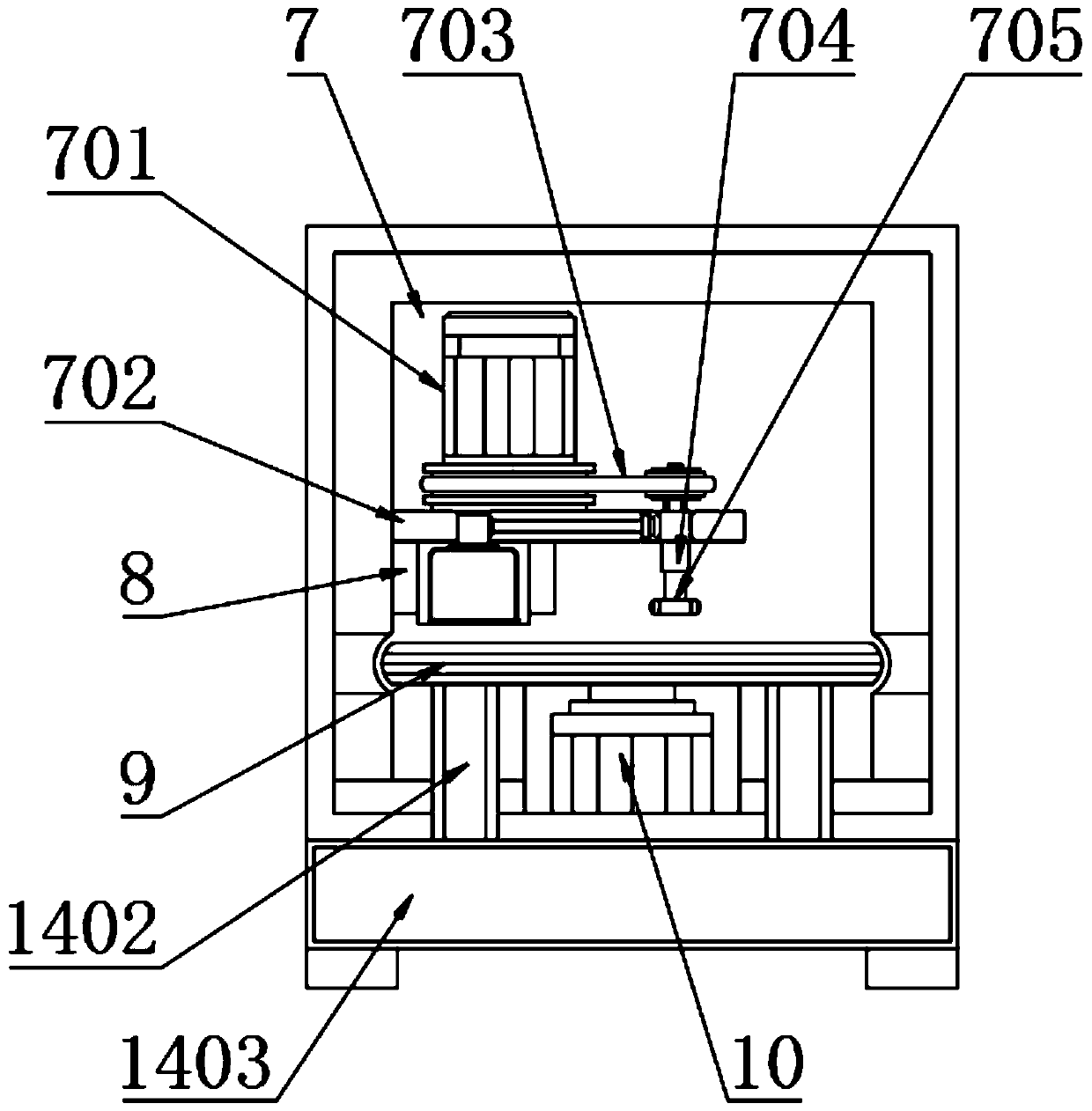

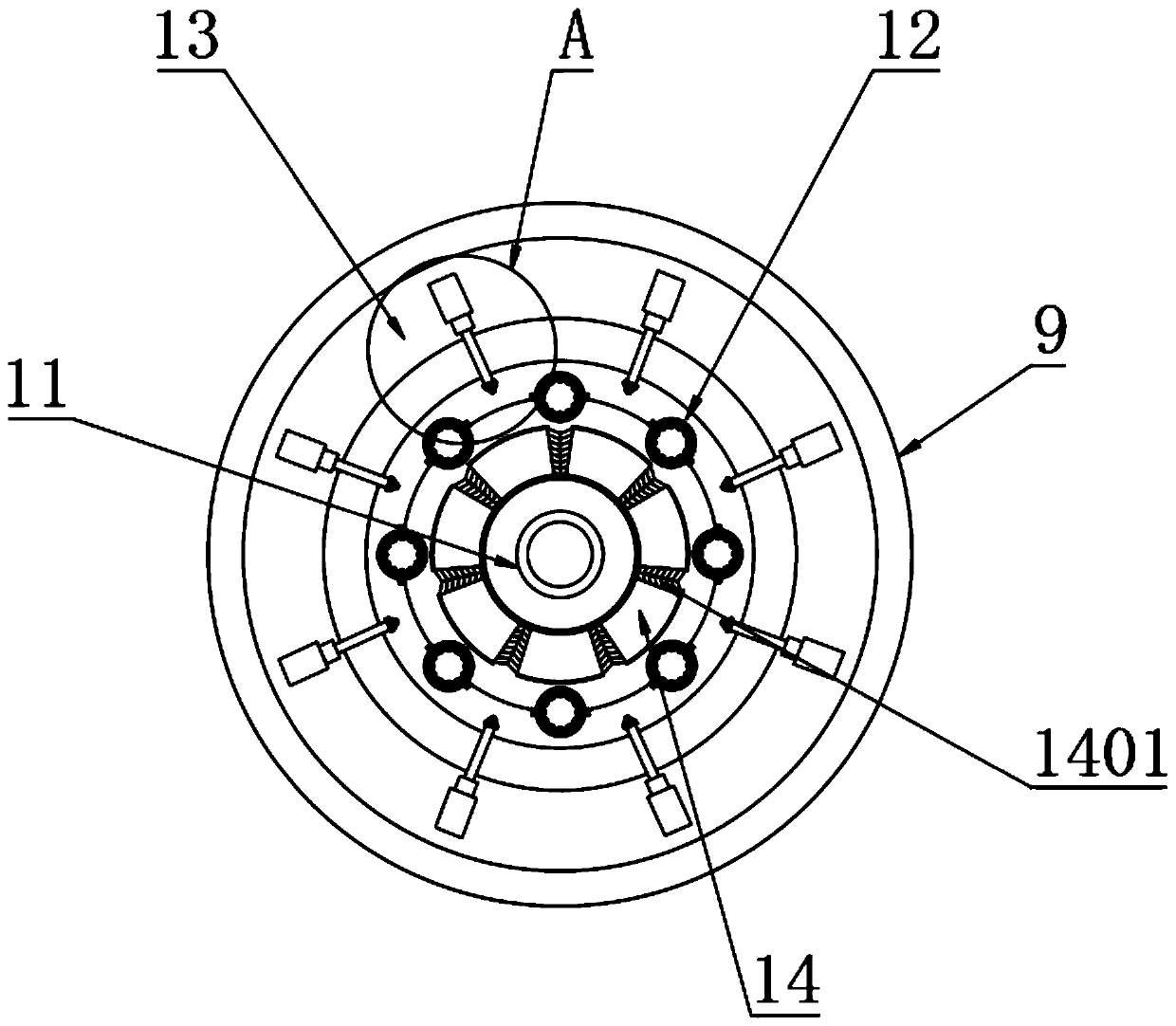

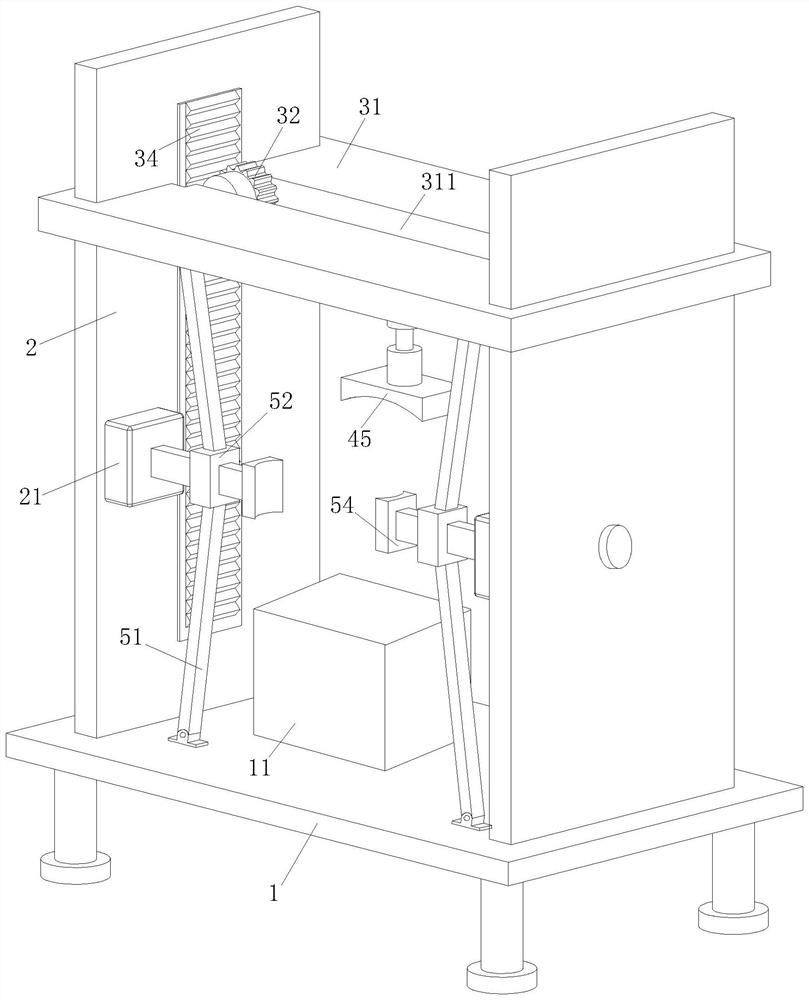

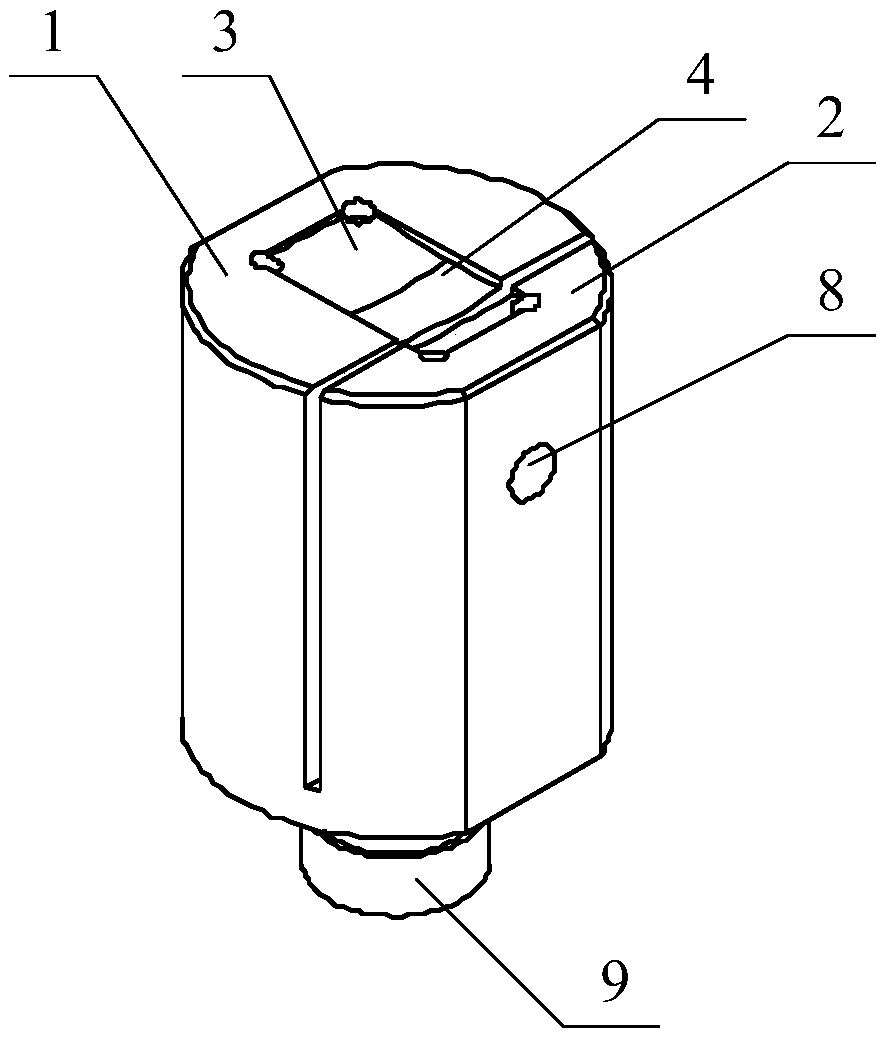

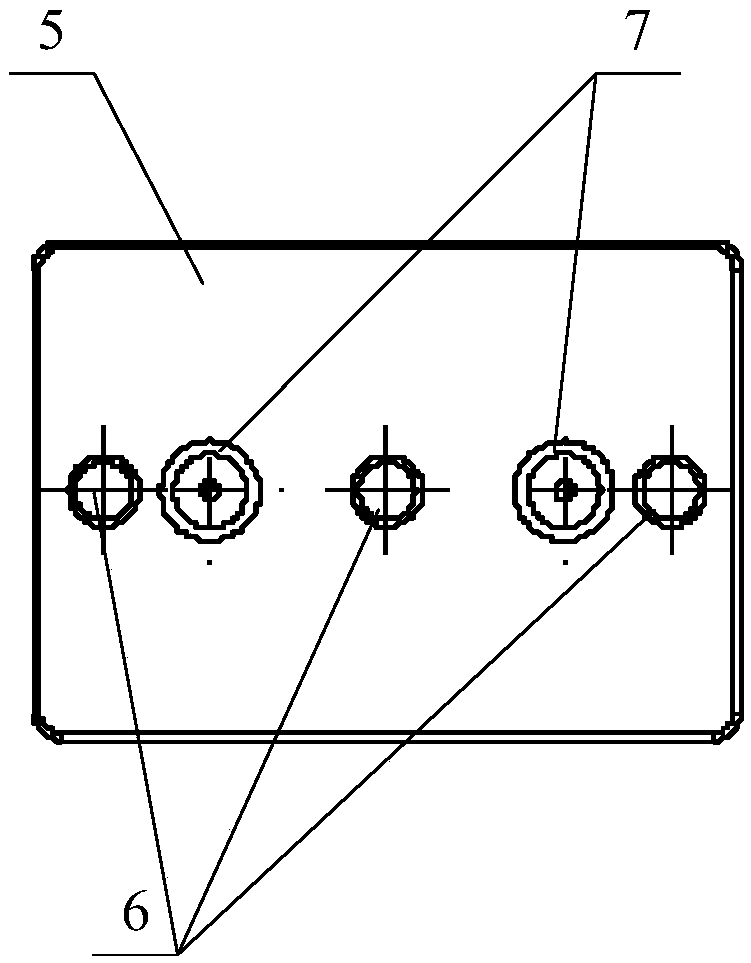

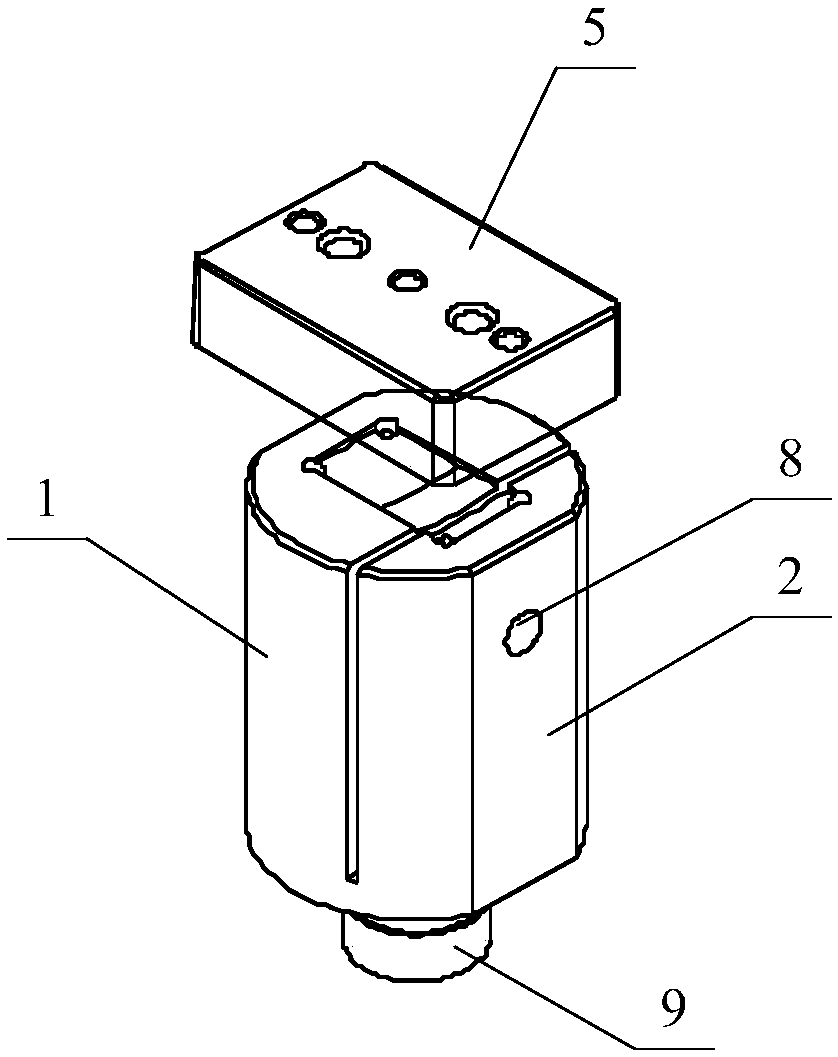

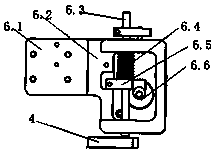

Constant-pressure polishing device for aspheric optical element and constant-pressure polishing method thereof

ActiveCN110253383AGuaranteed polishing accuracyGuaranteed stabilityPolishing machinesOptical surface grinding machinesProcessing accuracyLinear drive

The invention discloses a constant-pressure polishing device for an aspheric optical element. The device comprises a rotating assembly which is used for arranging a workpiece and driving the workpiece to rotate, a polishing part which is in contact with the workpiece and is used for polishing the workpiece, a polishing shaft for arranging the polishing part, a first linear driving device which is connected to the rotating assembly and is sued for driving the rotating assembly to linearly move and driving the workpiece to axially move along the polishing shaft, and a movement controller which is connected to the rotating assembly and the first linear driving device, wherein the movement controller is used for controlling the rotating assembly and the first linear driving device to synchronously move; a preset correspondence relation is generated between the output displacement of the first linear driving device and the output rotating angle of the rotating assembly, so that the position difference of each processing position, in the axial direction of the polishing shaft, of a molded surface of the workpiece in the rotating process of the rotating assembly can be compensated through the output displacement. The device is high in processing accuracy; the stability of the polishing removing capacity is ensured; and the polishing is uniform and reliable. The invention also discloses a constant-pressure polishing method of the aspheric optical element.

Owner:GUANGDONG UNIV OF TECH

Grinding and polishing device and process for denture processing

ActiveCN111251143BRestricted movementEasy to adjust the positionGrinding drivesLapping machinesFixed prosthodonticEngineering

Owner:泉州市超维医疗科技有限公司

Polishing machine for automobile engine crankshaft

PendingCN114734362AImprove efficiencyPolished evenlyGrinding carriagesPolishing machinesElectric machineryEngineering

The invention relates to the technical field of crankshaft polishing, in particular to an automobile engine crankshaft polishing machine which comprises a main box body, a polishing cavity is formed in the main box body, a telescopic clamping column is arranged on the left wall in the polishing cavity, a clamping cavity is formed in the telescopic clamping column, and a clamping table is fixedly arranged on the right end face of the telescopic clamping column. Displacement grooves which are provided with rightward openings and are evenly distributed are formed in the right side of the telescopic clamping column, fixing rods are fixedly arranged on the side walls, away from the clamping cavity, of the displacement grooves, telescopic springs capable of stretching out and drawing back are arranged on the outer circle faces of the fixing rods, and guiding sliding rails which are symmetrical left and right are fixedly arranged on the lower wall of the front side of the polishing cavity. The placing plate is fixedly arranged in the fixing shell, the friction shaft is rotationally arranged in the placing plate, the friction cavity is formed in the friction shaft, the contact shell is fixedly arranged on the side, away from the circle center of the fixing shell, of the friction cavity, the friction block makes contact with the crankshaft, rotating polishing is driven through rotation of the motor, efficiency is improved, polishing is uniform, and deformation is not likely to happen.

Owner:杜晨晨

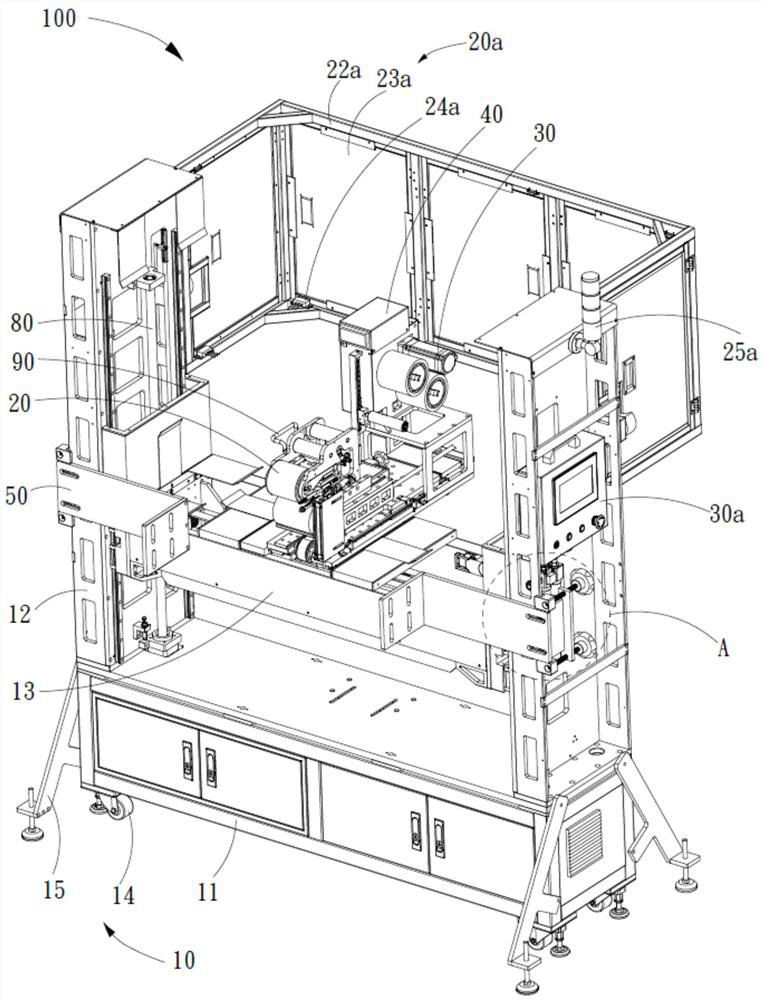

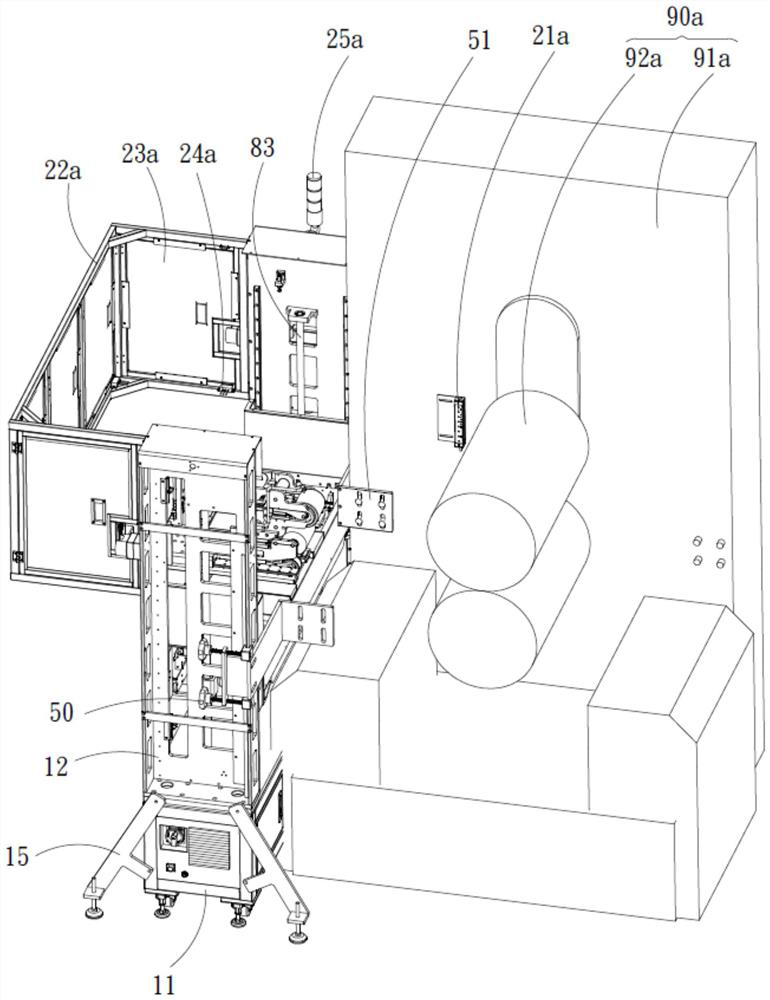

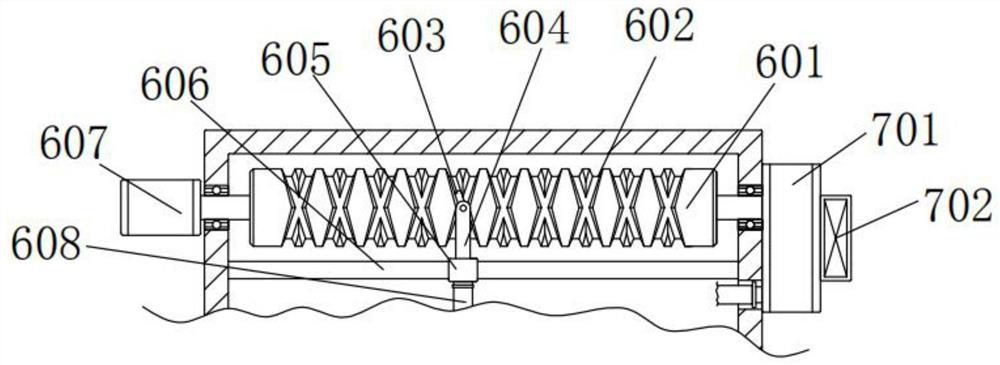

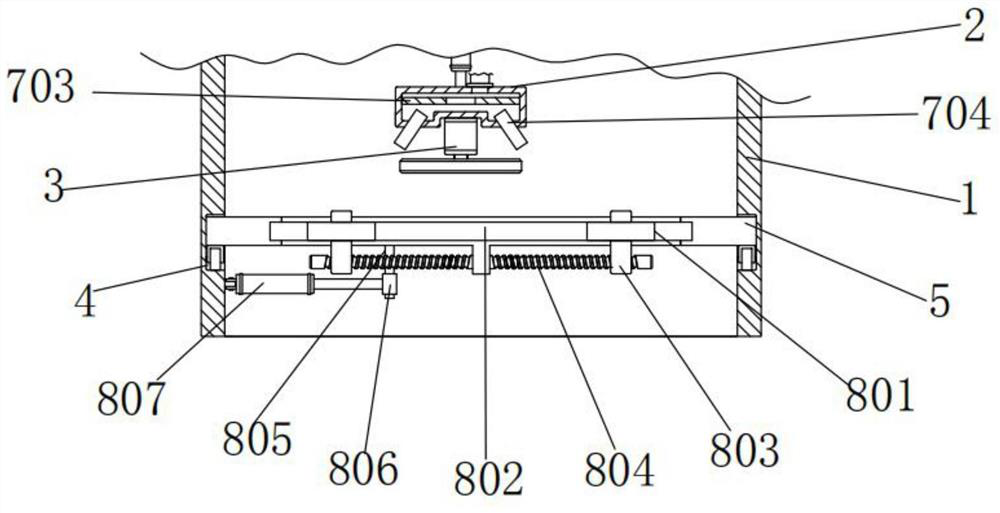

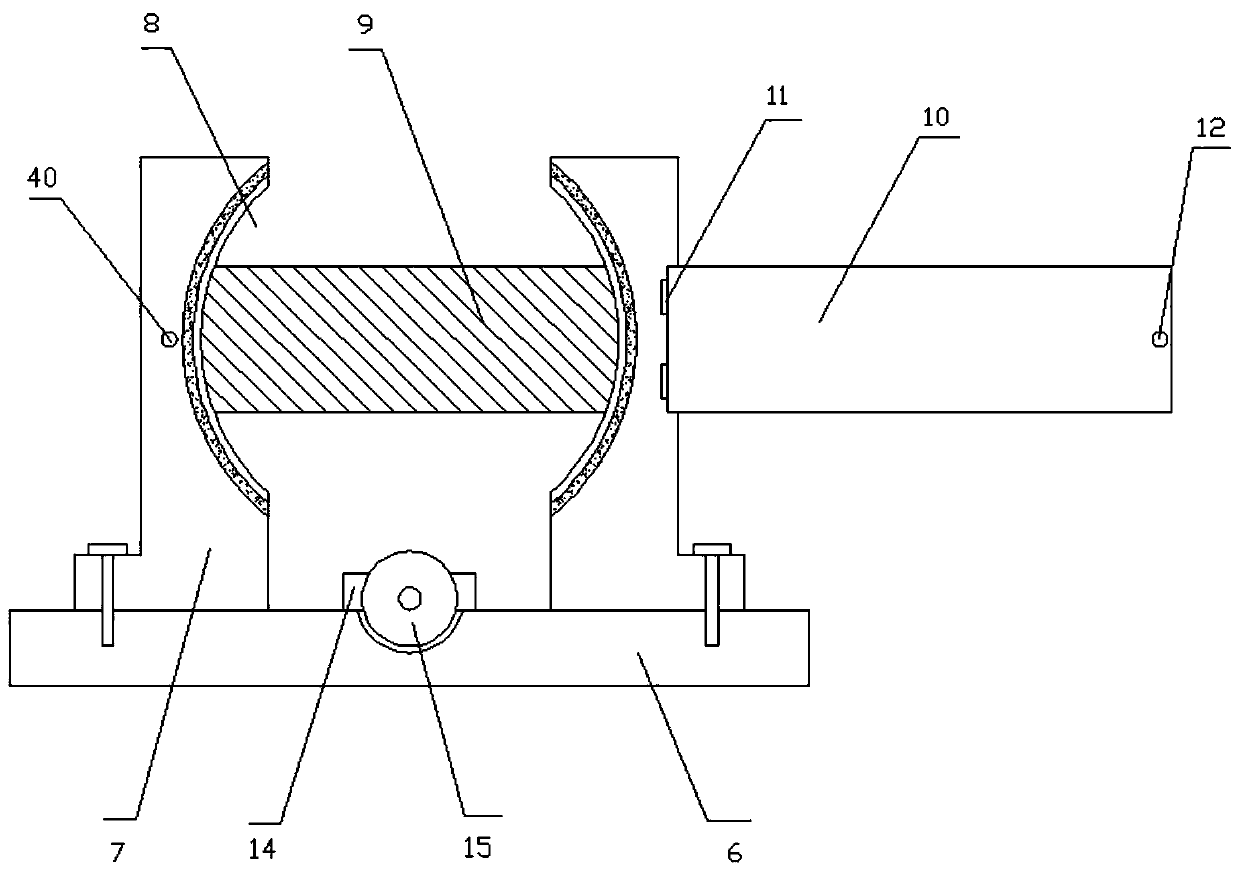

Steel pipe internal polishing machine and polishing method thereof

ActiveCN113442050AReasonable structureEasy to usePolishing machinesGrinding drivesPipe fittingPolishing

The invention provides a steel pipe internal polishing machine and a polishing method thereof. A feeding and discharging mechanism is arranged on one side of the top of a supporting base, a laying-off and discharging mechanism is arranged on the other side of the top of the supporting base, a rotary supporting mechanism is arranged between the feeding and discharging mechanism and the laying-off and discharging mechanism, and a clamping device is arranged on the rotary supporting mechanism; and the clamping device clamps a to-be-polished pipe fitting and drives the to-be-polished pipe fitting to rotate, a dust removal mechanism is arranged on one side of the rotary supporting mechanism, and a scrap removal polishing mechanism is arranged on the other side of the rotary supporting mechanism and comprises a scrap removal polishing head and a feeding mechanism. The scrap removal polishing head is located in a pipe of the to-be-polished pipe fitting and is driven by the feeding mechanism to move in the length direction of the to-be-polished pipe fitting. By means of the steel pipe internal polishing machine and the polishing method thereof, steel pipes with different diameters can be supported, the height of the scrap removal polishing head can be adjusted, the applicability to to-be-polished pipe fittings with different pipe diameters and the precision consistency during scrap removal polishing are achieved, the polishing efficiency is high, the service life is long, and environmental pollution is avoided.

Owner:晋义机械设备(上海)有限公司

Disc airbag polishing head with adjustable arc radius

The invention discloses a circular arc radius adjustable disc type air bag polishing head, and relates to air bag polishing tools. The disc type air bag polishing head is provided with adjusting screw rods, an annular air bag support, an annular elastic outer layer, an annular elastic inner layer, an elastic inner layer fixing sleeve, adjusting flanges, an air bag support fixing sleeve and a polishing material layer. The adjusting screw rods are provided with adjusting threaded sleeves and spindle connecting rods. The annular elastic inner layer is bonded with the elastic inner layer fixing sleeve, the elastic inner layer fixing sleeve is provided with a supporting plate, and the supporting plate is provided with a slotted hole. The elastic inner layer fixing sleeve and the annular elastic outer layer are integrally placed into a clamping groove of the adjusting flanges. The air bag support fixing sleeve enables the annular air bag support to be fixed on the adjusting flanges and to be closely matched with the adjusting flanges, and the annular elastic outer layer is directly arranged on the annular air bag support in an injection molding mode. The adjusting threaded sleeves are screwed into the two screw rods respectively, the spindle connecting rods are placed into the adjusting threaded sleeves, and the polishing material layer is bonded on the surface of the annular elastic outer layer. The air bag circular arc radius is adjustable, dynamic balance performance is good, and positioning accuracy and machining accuracy are improved obviously.

Owner:XIAMEN UNIV

Online polishing equipment for roller

ActiveCN113601346AEasy to useLow costGrinding drivesBelt grinding machinesPulp and paper industryInductor

The invention relates to online polishing equipment for a roller. The online polishing equipment comprises a rack, a polishing assembly, a detection assembly and a parallel adjusting assembly. The polishing assembly comprises a polishing support and a polishing wheel. The polishing wheel is rotationally connected with one end of the polishing support. The detection assembly comprises a detection sliding block and a displacement sensor. The detection sliding block is arranged on the rack in a sliding manner. The polishing support is arranged on the detection sliding block in a sliding manner. The displacement sensor is arranged on the polishing support and used for detecting the parallelism degree of the roller of a roller press and the polishing wheel. The parallel adjusting assembly is connected with the roller press and the rack so as to adjust the distance between the rack and the roller press. According to the online polishing equipment for the roller, the detection sliding block drives the displacement sensor to move along the roller so as to detect the parallelism degree of the roller and the polishing wheel, the distance between the rack and the roller press is adjusted through the parallel adjusting assembly according to information fed back by the displacement sensor, the polishing wheel is parallel to the roller, and the polishing precision is ensured. The online polishing equipment for the roller is convenient to use, the cost is reduced, the grinding period is shortened, and the polishing precision is improved.

Owner:东莞兆泰机械设备有限公司

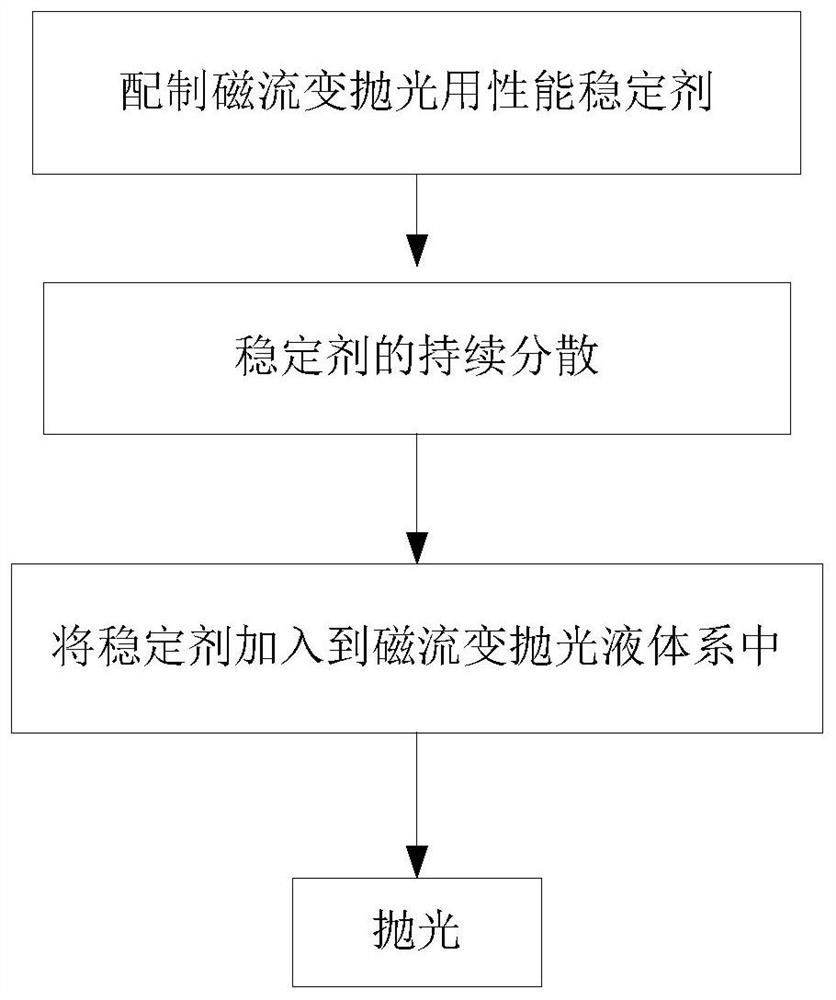

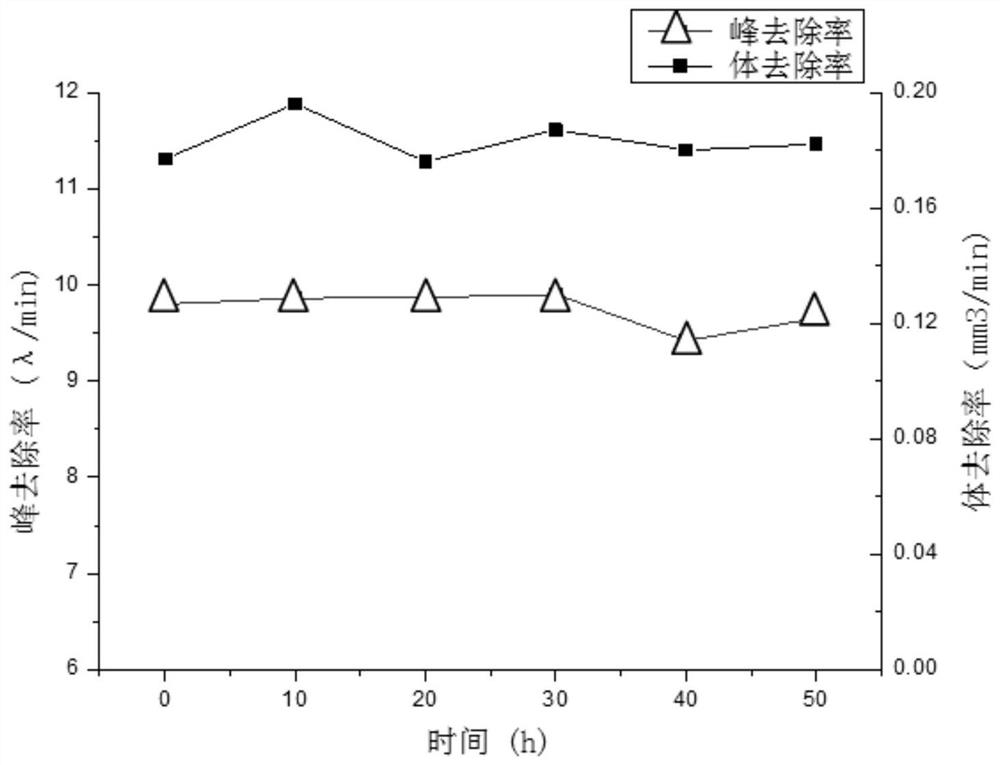

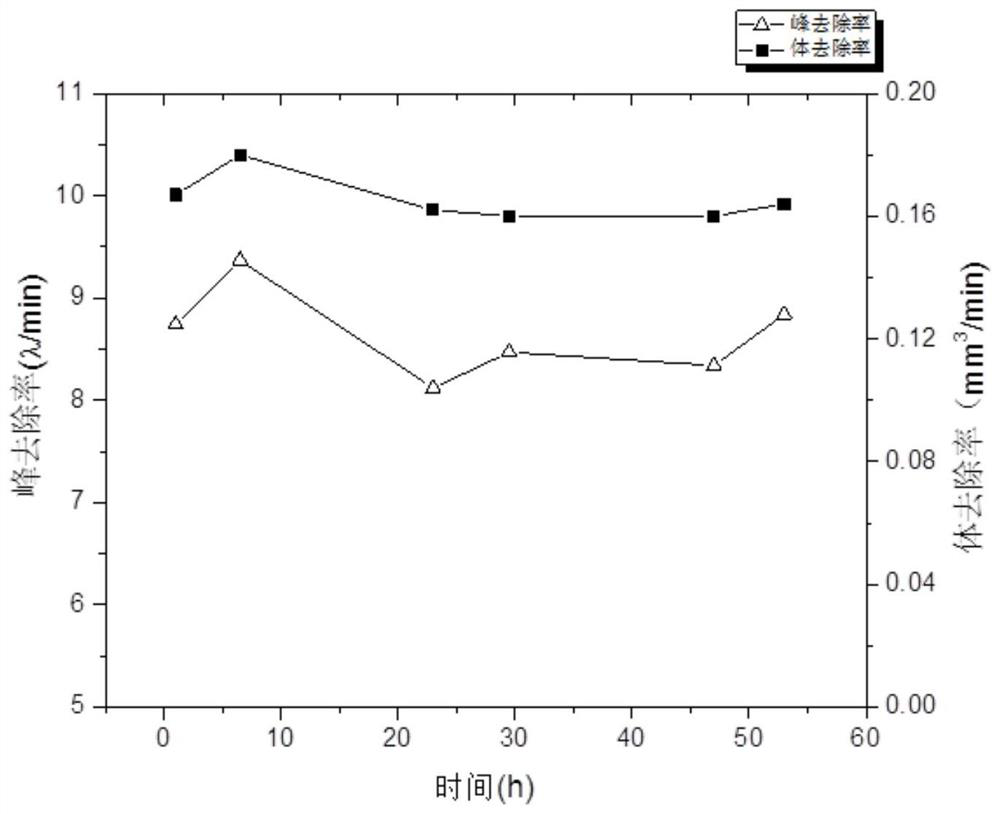

Method for maintaining polishing efficiency of magnetorheological polishing liquid, stabilizer and preparation method of stabilizer

PendingCN112980333ASimple compositionEasy to operatePolishing compositions with abrasivesWettingOxidizing agent

The invention discloses a method for maintaining the polishing efficiency of a magnetorheological polishing liquid, a stabilizer and a preparation method of the stabilizer, and solves the technical problems that the polishing efficiency stability of an existing magnetorheological polishing solution is poor, and the long-time use requirement cannot be met. The stabilizer comprises the following components in percentage by mass: 12%-30% of abrasive particles, 0.5%-5% of a wetting agent, 0.05%-5% of a dispersing agent, 0.2%-3% of an antioxidant and the balance of water. The magnetorheological polishing liquid has the advantages that the polishing efficiency is stable after the stabilizer is added, and long-time use is met.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

Nanometer diamond polishing solution and preparation method thereof

InactiveCN108864947AGood dispersionAvoid growing upPolishing compositions with abrasivesBlack pointSURFACTANT BLEND

The invention discloses a nanometer diamond polishing solution and a preparation method thereof. The nanometer diamond polishing solution is prepared from the following components in percentage by weight: 0.5-5 percent of modified nanometer diamond, 4-10 percent of polyol surfactant, 0.1-2 percent of dispersant, 0.02-1 percent of corrosion inhibitor and the balance of pH regulator and water, wherein the modified nanometer diamond is obtained by grafting the surface of nanometer diamond powder with carboxyl groups. For the nanometer diamond polishing solution and the preparation method providedby the invention, the modified nanometer diamond is grafted to the polyol surfactant, so that the modified nanometer diamond is stable in dispersion, ensures the polishing accuracy and remarkably lower the risk that the polishing surface is scratched; in addition, the modified nanometer diamond is difficult to separate the polishing solution, so that the phenomenon that particles fall off to cause the chip cutting speed to drop rapidly and formation of black points on the polishing surface are avoided; and in addition, sedimentation can not occur among the modified nanometer diamond althoughflocculation occurs, and the nanometer diamond polishing solution has the reparability ability and can be applied to the finish polishing field of magnetic heads, artificial crystals, gemstones and the like.

Owner:成都天成鑫钻纳米科技股份有限公司

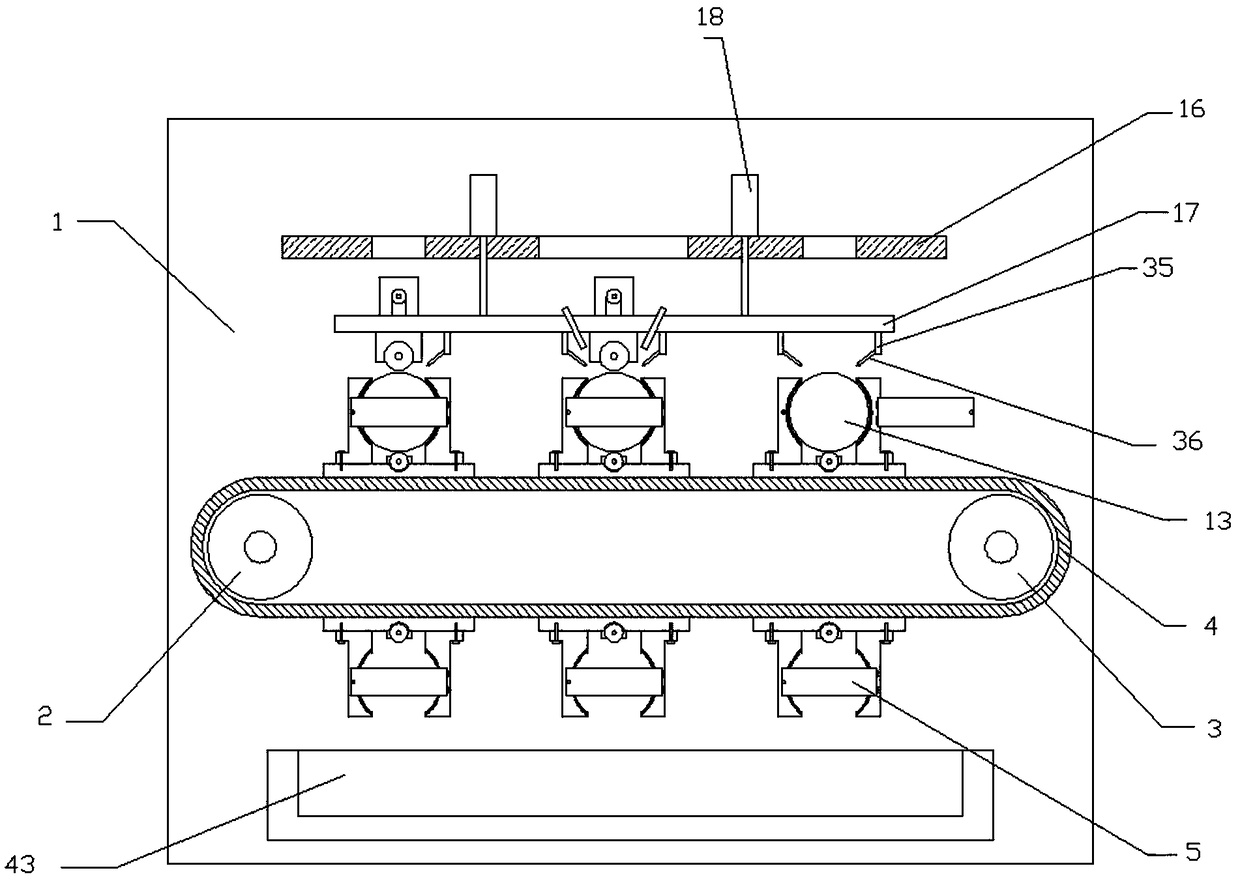

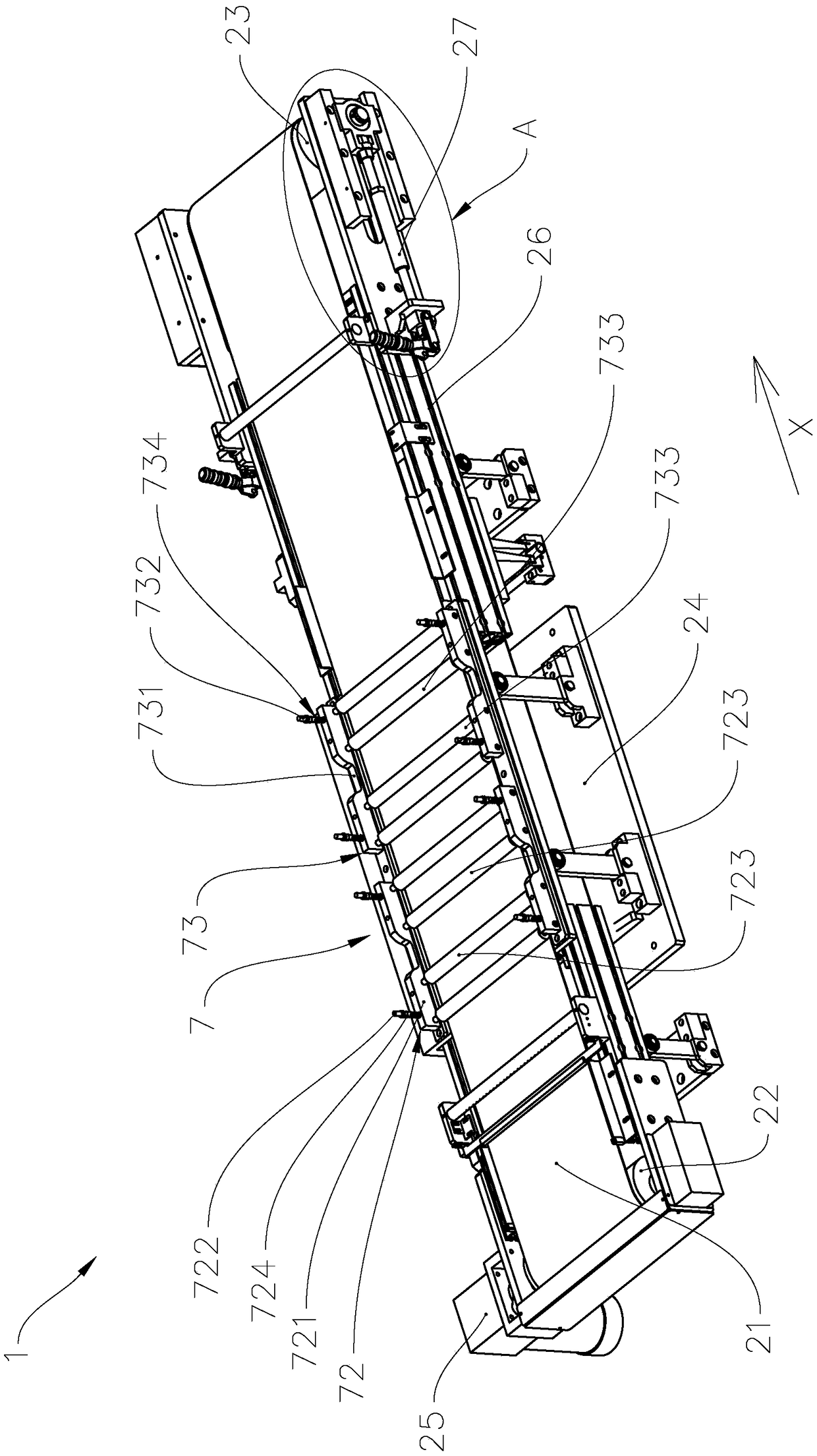

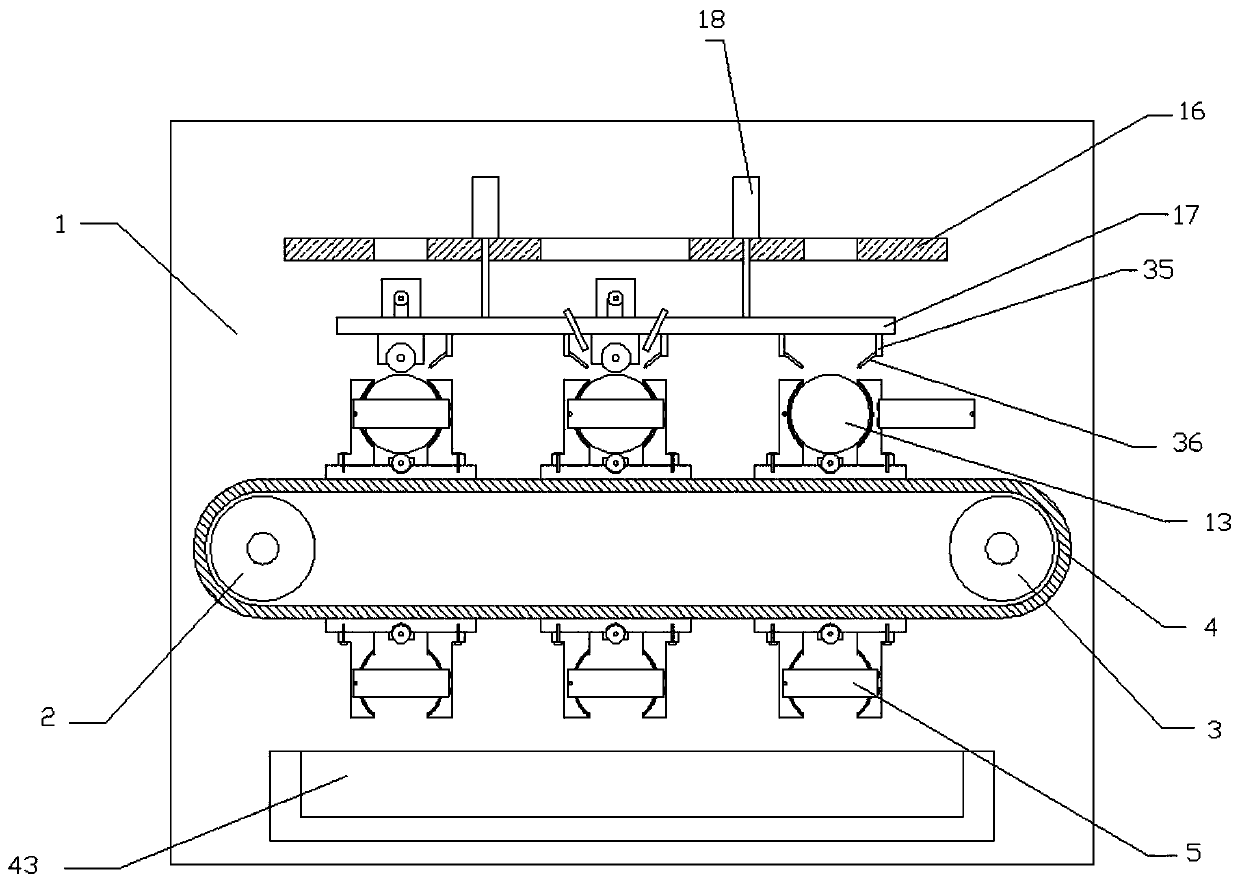

Precise polishing equipment for increasing friction force

PendingCN109227294AGuaranteed sandingGuaranteed polishing accuracyGrinding carriagesGrinding drivesEngineeringFriction force

The invention provides precise polishing equipment for increasing friction force. The precise polishing equipment comprises a workbench, a conveying line and a first sand roller device; the conveyingline is installed on the workbench, the first sand roller device comprises a first sand roller, a first connecting base, a second connecting base, a first driving unit and a second driving unit, the two ends of the first sand roller are connected with the first connecting base and the second connecting base respectively, and the first connecting base and the second connecting base are located at the two opposite sides of the conveying line respectively in the conveying direction of the conveying line; the conveying line is located between the first sand roller and a mounting face of the workbench, the first driving unit drives the first sand roller to rotate relative to the first connecting base and the second connecting base around the axis of the first sand roller, and the second drivingunit drives the first sand roller to slide relative to the first connecting base and the second connecting base in the axial direction of the first sand roller. The precise polishing equipment for increasing the friction force has the advantages that the machining precision is high, the production efficiency is high, and friction sheets can be automatically ground and polished.

Owner:GUANGDONG HESHI AUTOMATION TECH CO LTD

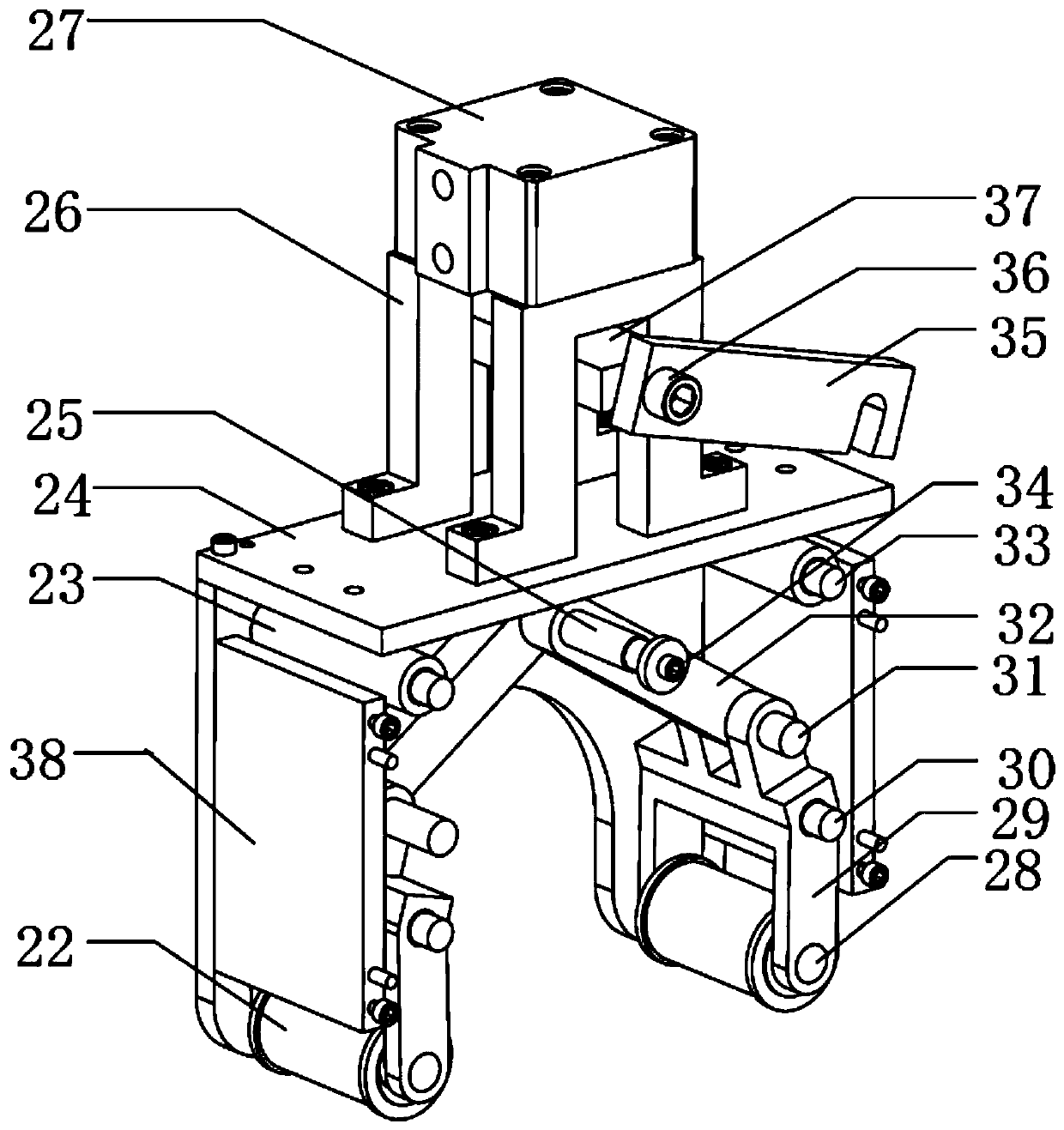

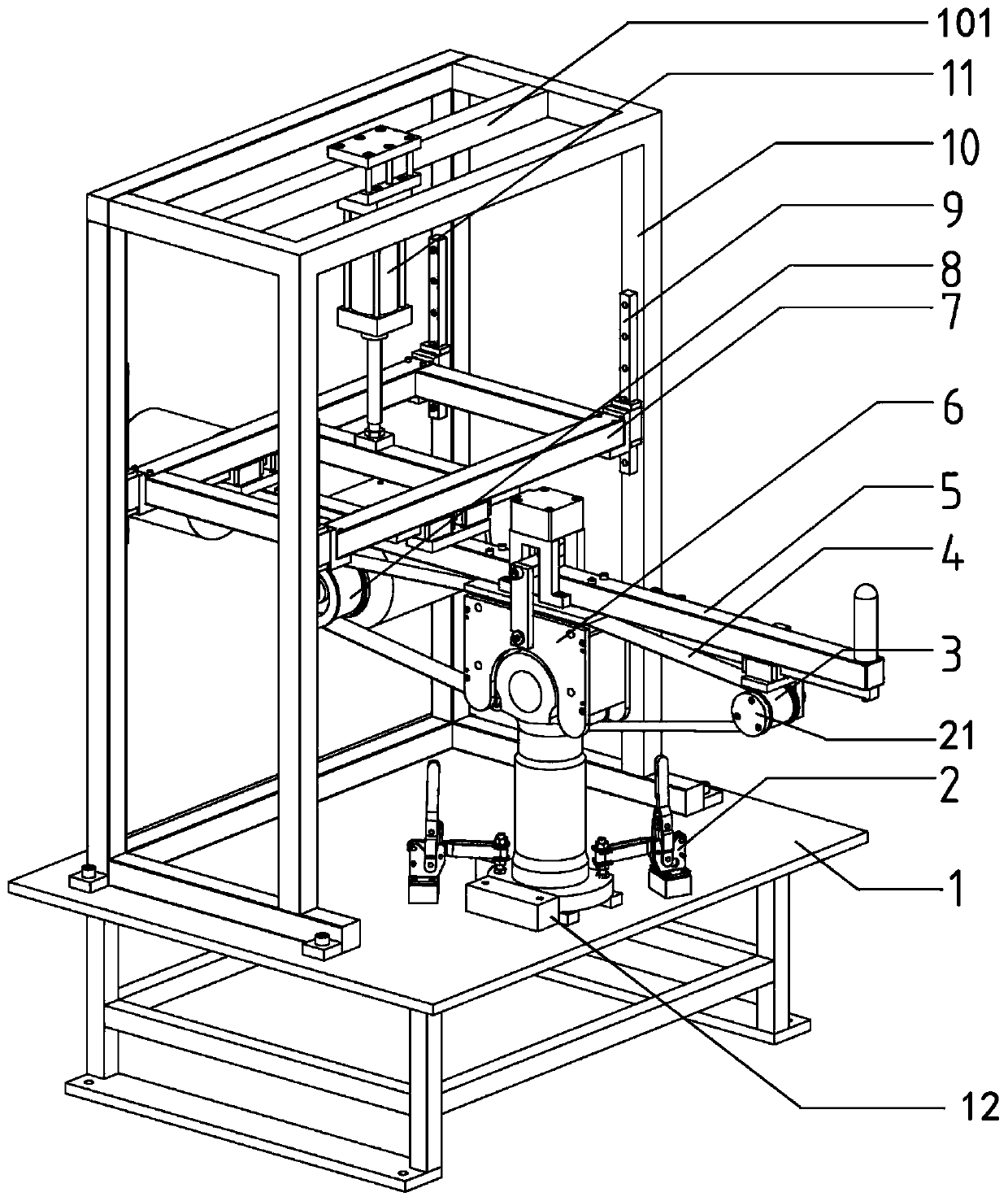

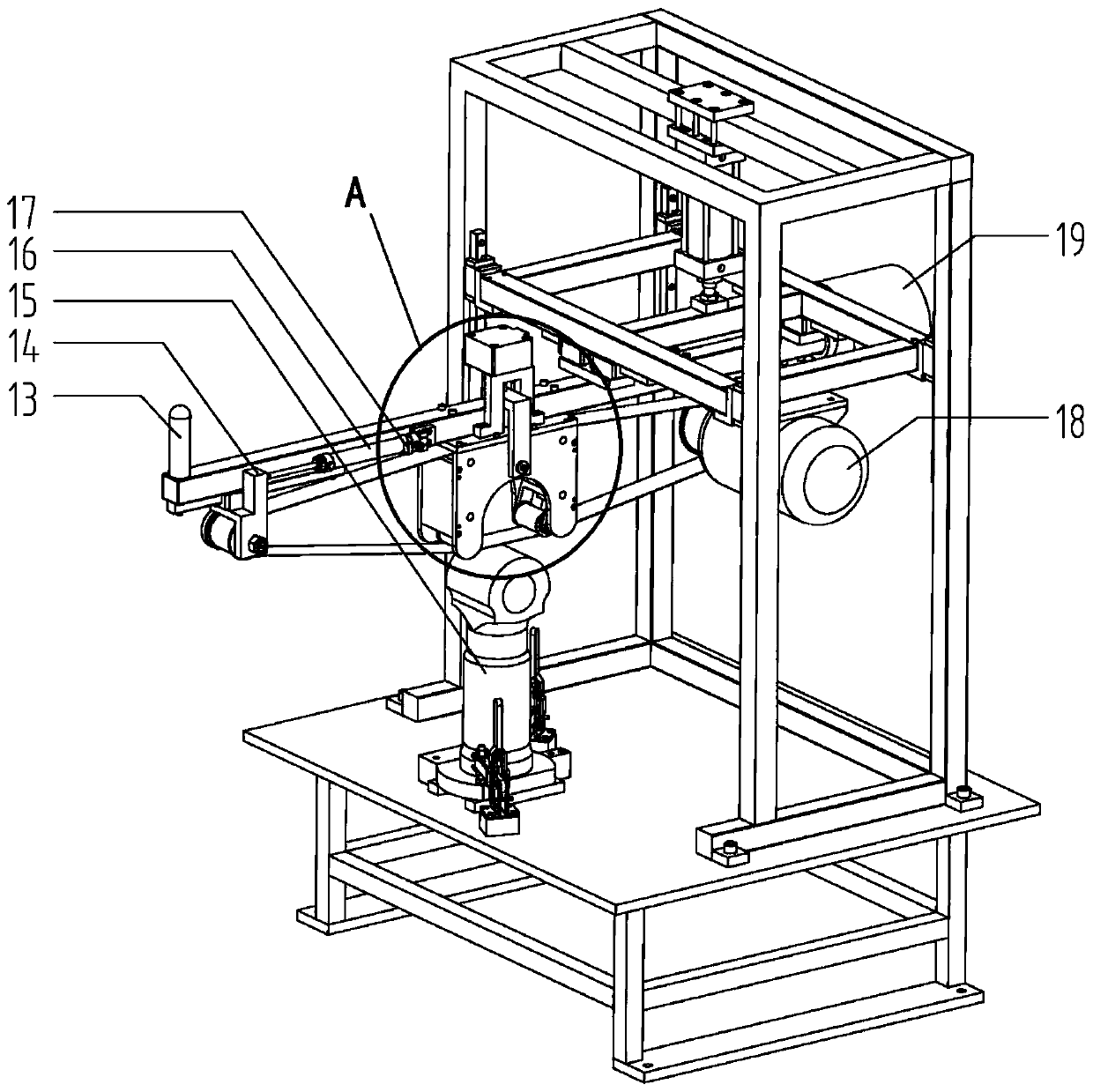

Polishing method and device of circular arc surface of connecting rod

ActiveCN110370097AAchieve polishSimple methodBelt grinding machinesEngineeringMechanical engineering

The invention provides a polishing method and device of a circular arc surface of a connecting rod. The method comprises the following steps: fixing a connecting rod workpiece, and upwards positioningthe circular arc surface, to be polished, of the connecting rod; lifting the positions of polishing belts until the polishing belts are positioned onto the circular arc surface of the connecting rod;clamping the polishing belts at two sides of the circular arc surface of the connecting rod, wherein the polishing belts are close to the whole circular arc surface, to be polished, of the connectingrod workpiece, and the polishing belts and an end point of the circular arc surface of the connecting rod workpiece are subjected to tangent relationship, so that the stress to the polishing belts and the circular arc surface of the connecting rod workpiece is consistent; and operating the polishing belts to polish the circular arc surface of the connecting rod. The device comprises a workpiece fixing unit, a lifting unit, a left and right moving unit and a polishing belt operating unit. With the adoption of the method and the device, the outer circular arc surface with an included angle of about 200 degrees of the connecting rod can be polished; in addition, the device is simple in structure, quick to assemble, convenient to use, high in processing efficiency, high in polishing accuracy,time and force saving, and wide in applicable scope; the a wide circular arc surface can be polished.

Owner:荆州环球汽车零部件制造有限公司

Constant pressure polishing device and constant pressure polishing method for aspheric optical element

ActiveCN110253383BGuaranteed polishing accuracyGuaranteed stabilityPolishing machinesOptical surface grinding machinesPolishingEngineering

The invention discloses a constant-pressure polishing device for an aspheric optical element, which comprises: a rotating assembly for setting a workpiece and driving the workpiece to rotate; a polishing piece for contacting with the workpiece and polishing the workpiece; The polishing shaft; the first linear driving device connected with the rotating assembly, used to drive the rotating assembly to move linearly, so that the workpiece moves along the axial direction of the polishing shaft; the motion controller connected with the rotating assembly and the first linear driving device, It is used to control the synchronous movement of the rotary assembly and the first linear drive device. The output displacement of the first linear drive device has a preset corresponding relationship with the output rotation angle of the rotary assembly, so that the output displacement compensates the machining of the workpiece surface during the rotation of the rotary assembly. The positional difference in the axial direction of the polishing axis. The constant pressure polishing device has high processing precision, can ensure the stability of the polishing removal amount, and makes the polishing uniform and reliable. The invention also discloses a constant pressure polishing method for the aspheric optical element.

Owner:广州精点科技有限公司

Dust-free polishing device for metal products

PendingCN112247797AIncrease the polishing areaImprove polishing efficiencyGrinding carriagesPolishing machinesPolishingTransverse groove

The invention discloses a dust-free polishing device for metal products. The dust-free polishing device for the metal products comprises a machine body, a box body is arranged in the machine body, grooves are machined in the left side and the right side of the inner wall of the machine body, and a reciprocating assembly is arranged on the upper portion in the machine body. According to the dust-free polishing device for the metal products, a polishing device body can transversely slide in a reciprocating mode through clearance fit between a sliding groove and a sliding block, clearance fit between a lantern ring and a transverse rod and rotation of a round roller, then the polishing area of plates is enlarged, the polishing efficiency of the plates is improved, and the working time is saved; plates of different sizes can be fixed through threaded connection of a stud and a supporting block and clearance fit of a sliding plate and a transverse groove, the fixing position is always located in the middle of a sliding base, and therefore the use applicability is improved, the plates are more stable in the polishing process, and the polishing precision is guaranteed; and through annulardistribution of supporting pipes and corresponding arrangement of the supporting pipes and the polishing device body, annular dust collection can be conducted on the polishing position during polishing, and then dust-free polishing is achieved.

Owner:深圳市誉豪金属制品有限公司

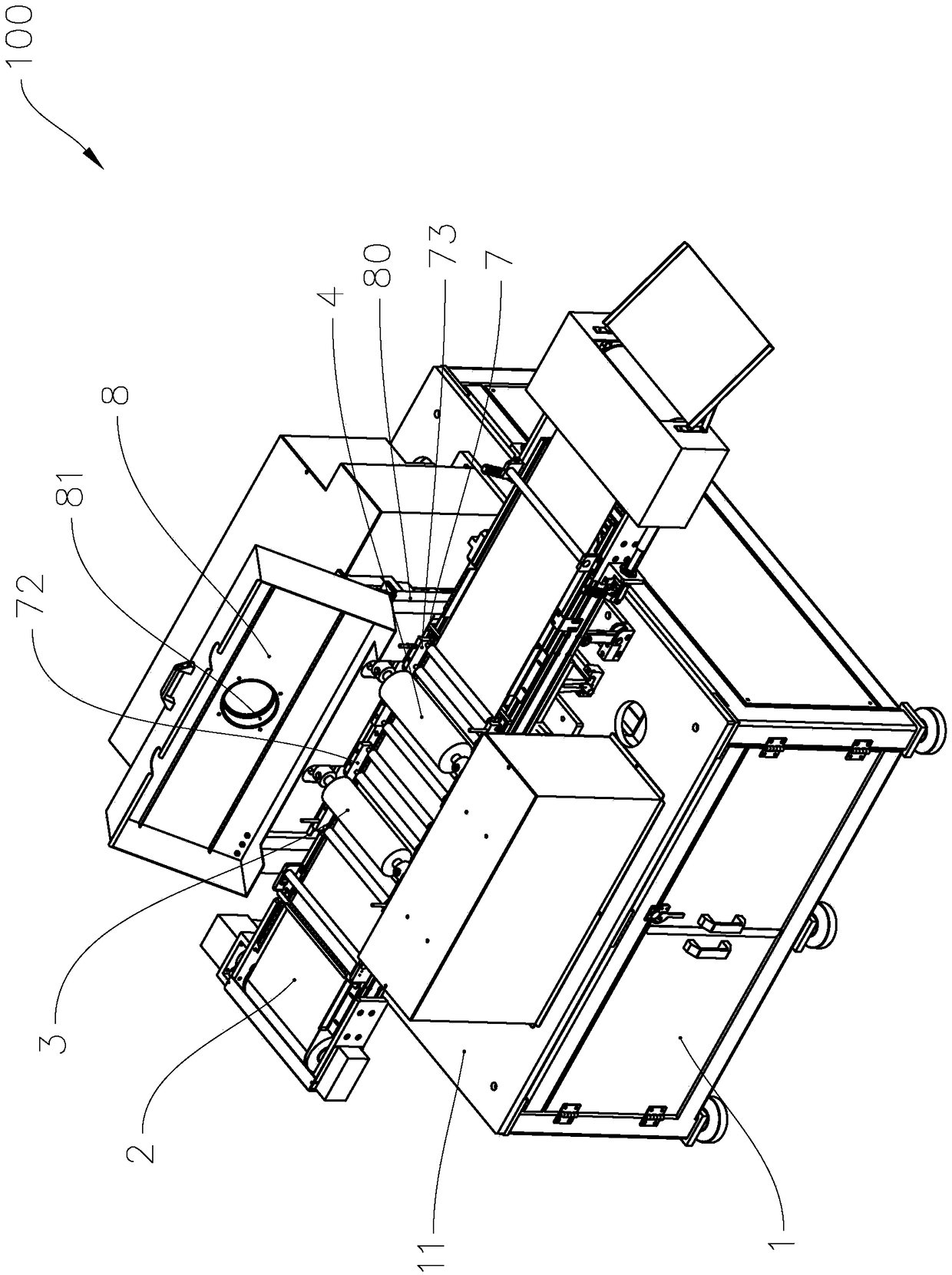

Cam surface polishing machine

ActiveCN103817575BEasy to adjustEasy to manufacturePolishing machinesBelt grinding machinesEngineeringCam

The cam curved surface polishing machine of the present invention comprises a frame (1), a polishing wheel device (2), a positioning wheel device (3), a cam clamp device (4), and a cam clamp rotating and sliding device (5); the cam (A) is installed On the three-jaw chuck (41), under the action of the second weight (56), the three-jaw chuck (41) slides and moves with the cam clamp rotation sliding device (5), so that one side of the cam (A) Automatically abut on the positioning wheel (34) of the positioning wheel device (3), the connecting plate (24) of the polishing wheel device (2) slides and moves under the effect of the first weight (28), so that the polishing wheel (27 ) automatically abuts against the other side of the cam (A) to polish the curved surface of the cam (A). The utility model has the advantages of convenient use, good polishing precision and high efficiency.

Owner:DANDONG TOP ELECTRONICS INSTR GRP

A UAV electronic chip manufacturing equipment

InactiveCN109304649BEasy to holdNo deflectionPolishing machinesGrinding work supportsWaferUncrewed vehicle

Owner:北京圣龙缘科技有限公司

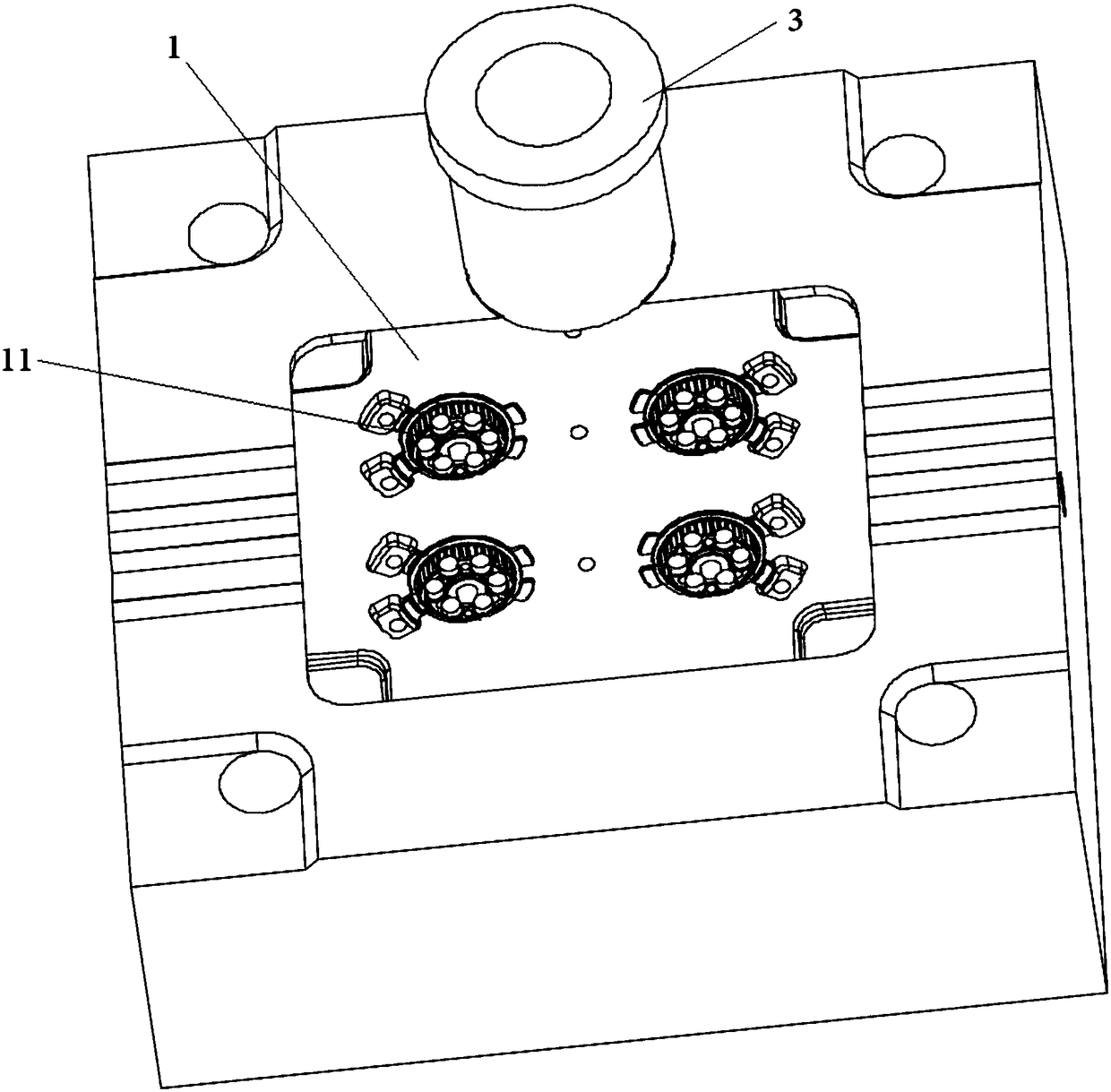

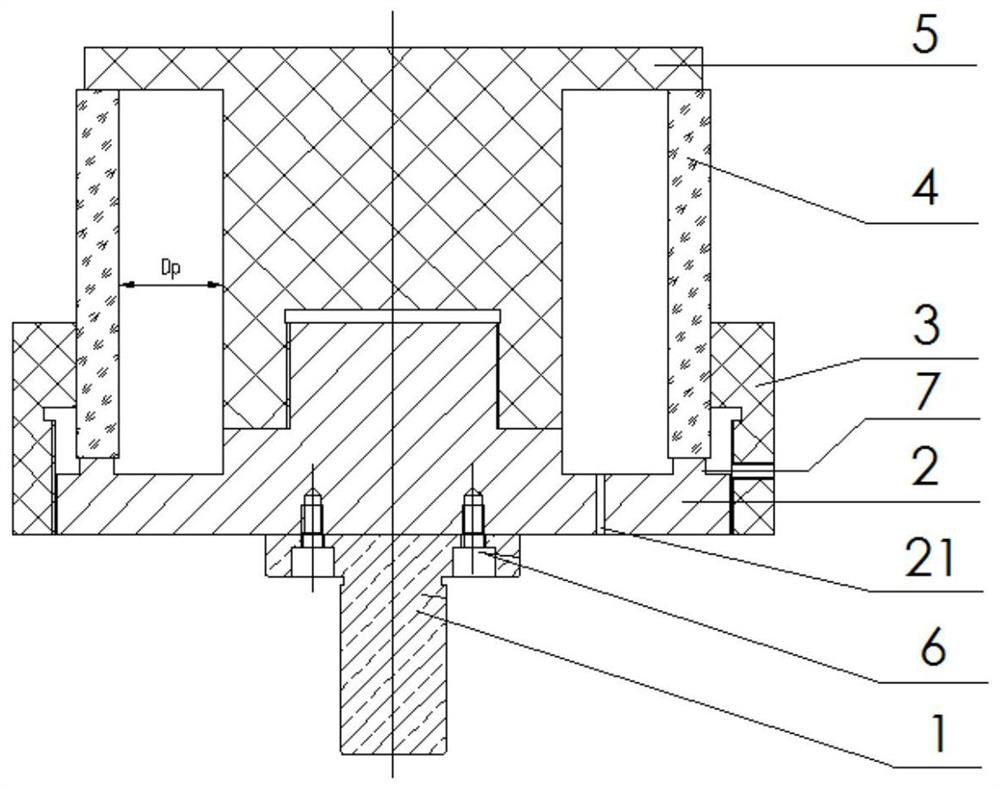

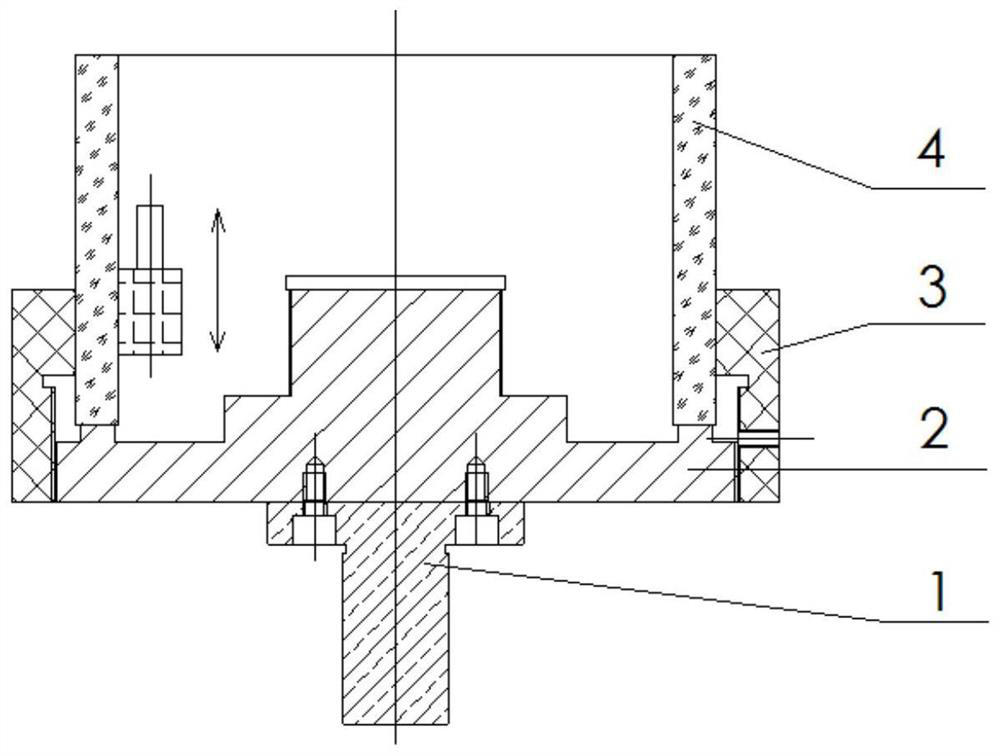

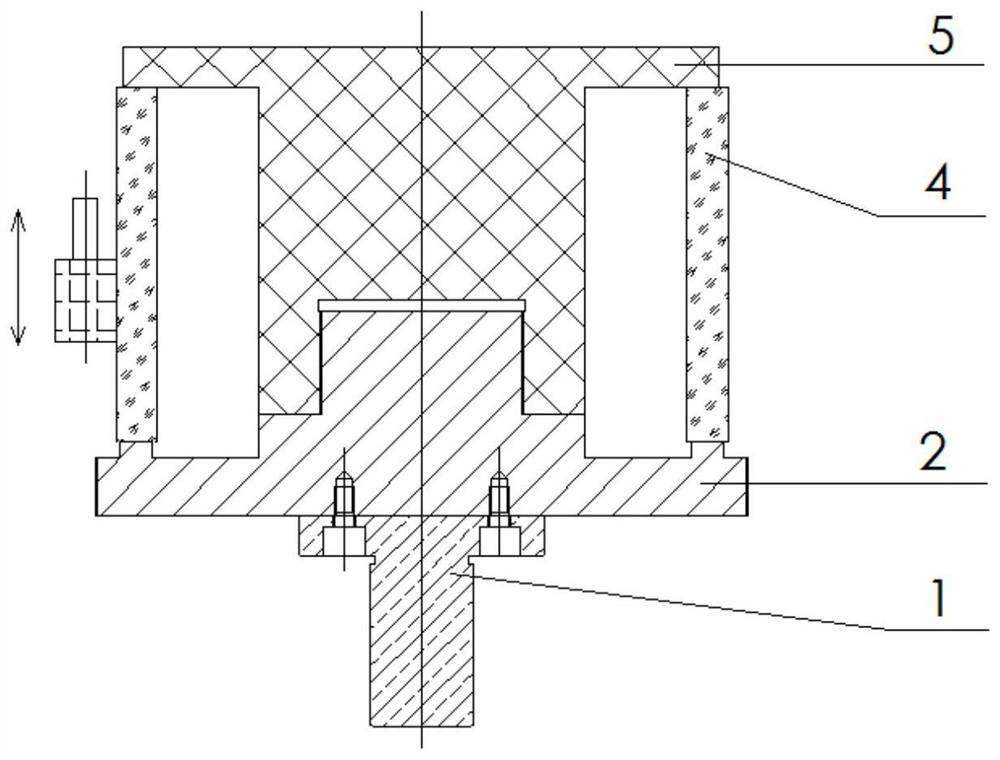

Mold for large belt wheel machining and manufacturing method thereof

PendingCN108380844AImprove cold and heat balance performanceImprove cooling effectSurface roughnessDie casting

The invention relates to the field of large belt wheel machining, in particular to a mold for large belt wheel machining and a manufacturing method of the mold. In order to solve the problem of incapability of existing a draft angle when a die casting method is adopted to manufacture large belt wheels, the invention provides the mold for large belt wheel machining. The mold comprises a fixed moldcore, a movable mold core and a flow separation cone; a casting cavity groove provided with a tooth groove structure on the side wall is formed in the top of the fixed mold core; the movable mold corecovers the top of the fixed mold core; a casting cavity cover opposite to the casting cavity groove is arranged at the bottom of the movable mold core; a feeding channel communicating with the flow separation cone and the casting cavity cover is formed in the bottom of the movable mold core; the inner surface roughness of the casting cavity groove and the casting cavity cover is within Ra 0.2; and PST penetration layers with hardness of at least 75 HRC are arranged on the surfaces of the fixed mold core and the movable mold core. In the mold for large belt wheel machining, the inner surfacesof the casting cavity groove and the casting cavity cover are high in smoothness, so that the mold opening resistance is greatly reduced, and the problem of incapability of existing the draft angle when the die casting method is adopted to manufacture the large belt wheels is solved.

Owner:SHANGHAI PRECISE IND

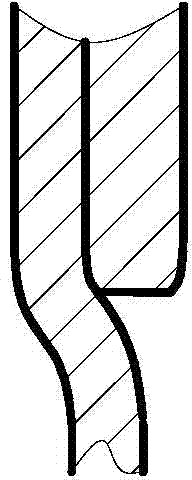

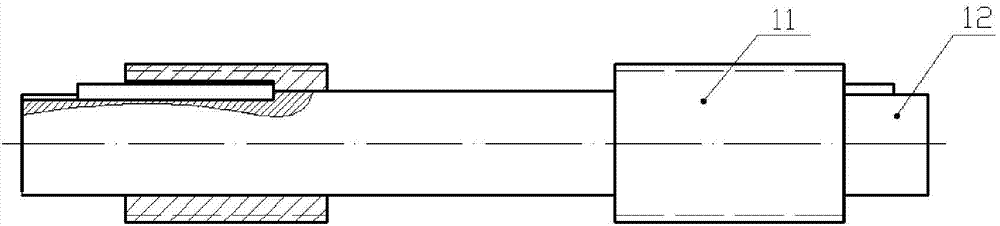

Method and tool for polishing inner and outer walls of cylindrical optical part

InactiveCN112338703AGuaranteed stabilityGuaranteed shape and position accuracyOptical surface grinding machinesLensPolishingEngineering

The invention provides a tool and method for polishing the inner and outer walls of a cylindrical optical part. The tool and method are used for solving the problem that in the prior art, a cylindrical optical part cannot be mechanically polished. The polishing tool comprises a power connector, a base, a lantern ring and a gland. The base and the gland are both round in basic shape. The part is fixed through the base; when the outer wall is polished, the part is limited and stabilized through the gland; and when the inner wall is polished, the part is limited and stabilized through the lanternring. According to the tool and method for polishing the inner and outer walls of the cylindrical optical part, the inner wall and the outer wall of the optical part are polished through one-time positioning; when the inner wall is polished, the lantern ring is used for assisting in fixing the part; and when the outer wall is polished, the gland is used for assisting the fixing force of the base.The gland and the base are used respectively to guarantee the stability of the part in the polishing process, so that the mechanical polishing of the inner wall and the outer wall of the cylindricaloptical part is achieved, the polishing efficiency is improved, and meanwhile the polishing precision and the shape and position precision of the part are guaranteed.

Owner:TIANJIN JINHANG INST OF TECH PHYSICS

A device for polishing the circular arc surface of connecting rod

Owner:JINGZHOU GLOBAL AUTO PARTS MFG CO LTD

A polishing device for communication equipment production

ActiveCN110977738BEasy to useImprove work efficiencyGrinding carriagesPolishing machinesElectric machineGear wheel

The invention belongs to the technical field of polishing devices, and is specifically a polishing device for communication equipment production; it includes a base, a slide plate, a transmission unit and a polishing unit; a workbench is arranged on the top of the base; Including pressing plate, No. 1 gear, No. 1 motor and rack; the polishing unit includes No. 1 plate, No. 2 motor, No. 2 plate, rotating block and polishing block; There is a matching groove at the output end of the No. 2 motor; through the cooperation of the base, the sliding plate, the transmission unit and the polishing unit, communication equipment with different shapes and sizes can be polished, thereby enhancing the use effect and use of the polishing device. The scope brings great convenience to the staff and improves the work efficiency of the staff.

Owner:临沂高新人才教育发展集团有限公司

A superfine polishing process for metal products

Owner:杭州临安恒达精密仪表元件厂

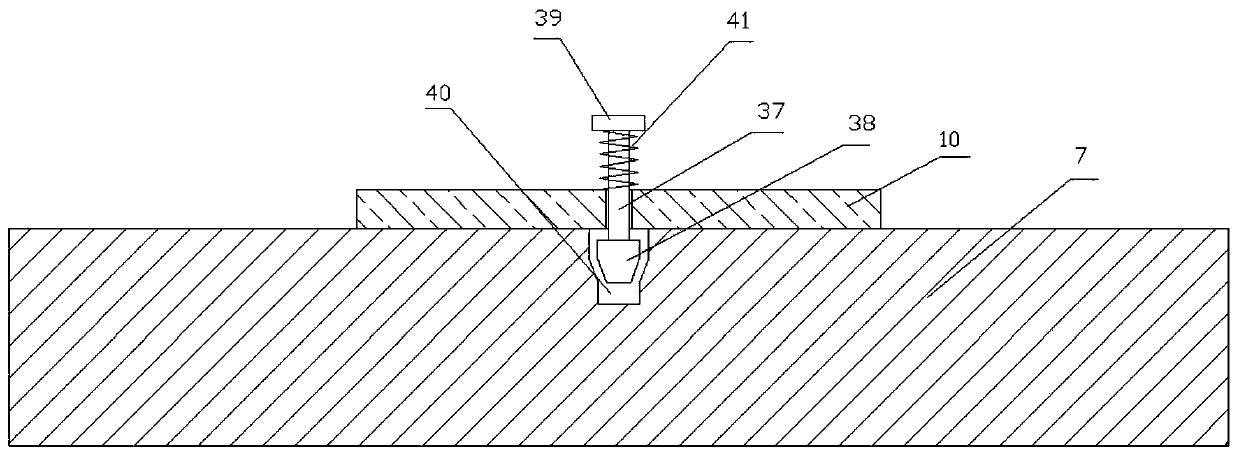

Single-sphere double-R watch cover secondary material reworking process and polishing device

InactiveCN110549168AAvoid defectsGuaranteed polishing accuracyPolishing machinesGrinding work supportsFastenerEngineering

The invention discloses a single-sphere double-R watch cover secondary material reworking process and a polishing device. The single-sphere double-R watch cover secondary material reworking process comprises the steps that a watch cover to be polished is placed in a cavity structure of the polishing device to enable the spherical face of the watch cover to be in fit with the inner wall of the cavity structure; a fastener is adjusted to enable the watch cover to be clamped and fixed in the cavity structure; a grinding cover is arranged on the watch cover, and the side, with grinding skin, of the grinding cover is in fit with the plane side of the watch cover; a pressure rod ejector pin is controlled to be aligned with an ejector pin hole in the grinding cover, polishing liquid is injected,and the grinding cover is rotated under the drive of the pressure rod ejector pin so as to polish the plane side of the watch cover. In this way, the grinding cover only polishes the plane which needsreworking polishing of the watch cover rather than polishing the two faces of the watch cover, and defects of a traditional upper-sweeping lower-polishing way are avoided.

Owner:LENS TECH CHANGSHA

Production Technology of Diamond Wire Busbar Drawing Die

ActiveCN109365554BAvoid damageImprove adaptabilityDrawing profiling toolsBusbarPolycrystalline diamond

The invention discloses a production process of a diamond wire busbar wire drawing die, relates to the technical field of wire drawing dies, and aims at the problems that sintered bodies is too high in hardness and insufficient in toughness, and polycrystalline diamond is low in radiating speed. According to the technical scheme, the production process is characterized in that the production process of the diamond wire busbar wire drawing die comprises the following steps that S2, 30% of copper powder, 20% of nickel powder, 10% of silver powder, 3% of zinc powder, 6% of tungsten powder, 8% ofmanganese powder and 21% of tin powder are uniformly mixed and fully ground, and sintered powder is obtained; and S4, a plurality of die sleeve fillers are clamped in a sintering press, the sinteringbodies are sintered and formed through the sintering press, the pressing pressure is 0.3-0.4 MPa, the temperature is raised to 610-630 DEG C at the rate of 11-14 DEG C / s and maintained for 14-15min, and then the sintering bodies are cooled to 200 DEG C or below with a furnace, and a die sleeve diamond composite is obtained. Through the production process of the diamond wire busbar wire drawing die, the hidden trouble of brittle cracks of the sintered bodies is reduced, the heat conduction performance of the sintered bodies is improved, and the heat dissipation capability of polycrystalline diamond is improved.

Owner:ZHEJIANG JINPING WIRE DRAWING DIE CO LTD

A polishing method and device for stone or glass craft products

InactiveCN105290958BGuaranteed polishing accuracyRealize industrializationBurnishing machinesPhotodetectorControl system

The invention discloses a polishing method for polyhedral stone or glass craft products. In the method, a trigger signal detected by a photoelectric detector is transmitted to a main control system, combined with input parameters in the main control system, and then passed through the main control system. The system outputs instructions to the pressure regulating system, and the pressure regulating system applies corresponding polishing pressure to the surface of polyhedral stone or glass craft products according to the output instructions. The present invention is suitable for precise polishing of polyhedral stone or glass craft products. Through the present invention, the manual polishing process can be eliminated, and industrialization can be truly realized; The polishing accuracy of stone or glass craft products will not damage the shape of the original product; the third is that the method and device are simple in principle and cost saving.

Owner:HUISHUI COUNTY CHANGDA NUMERICAL CONTROL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com