Cam surface polishing machine

A polishing machine and cam technology, applied in the polishing machine field, can solve the problems of high processing cost, low accuracy, time-consuming and labor-intensive, etc., and achieve the effects of convenient operation, good precision and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

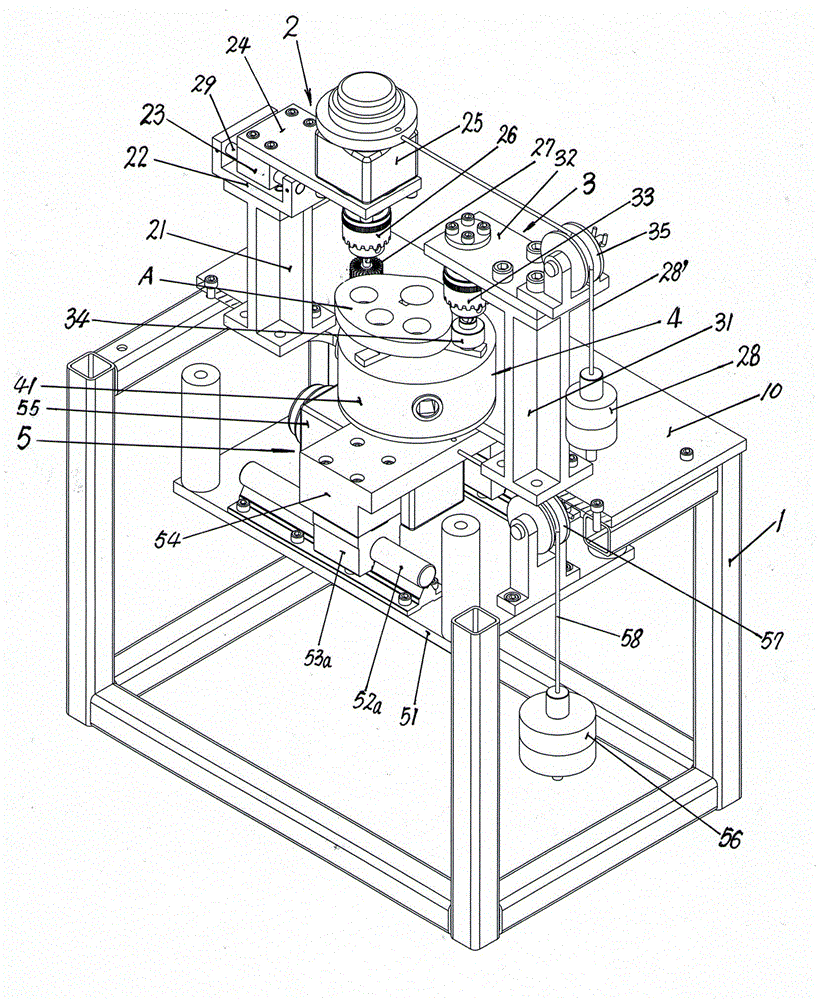

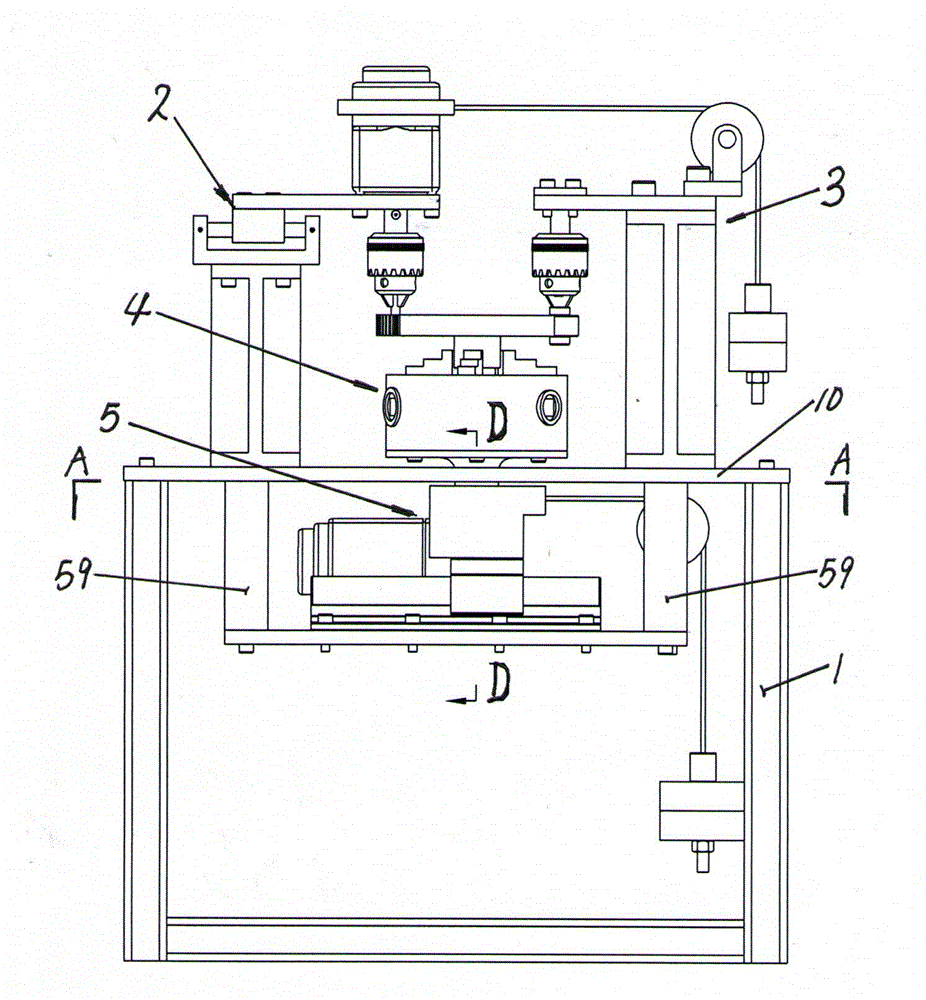

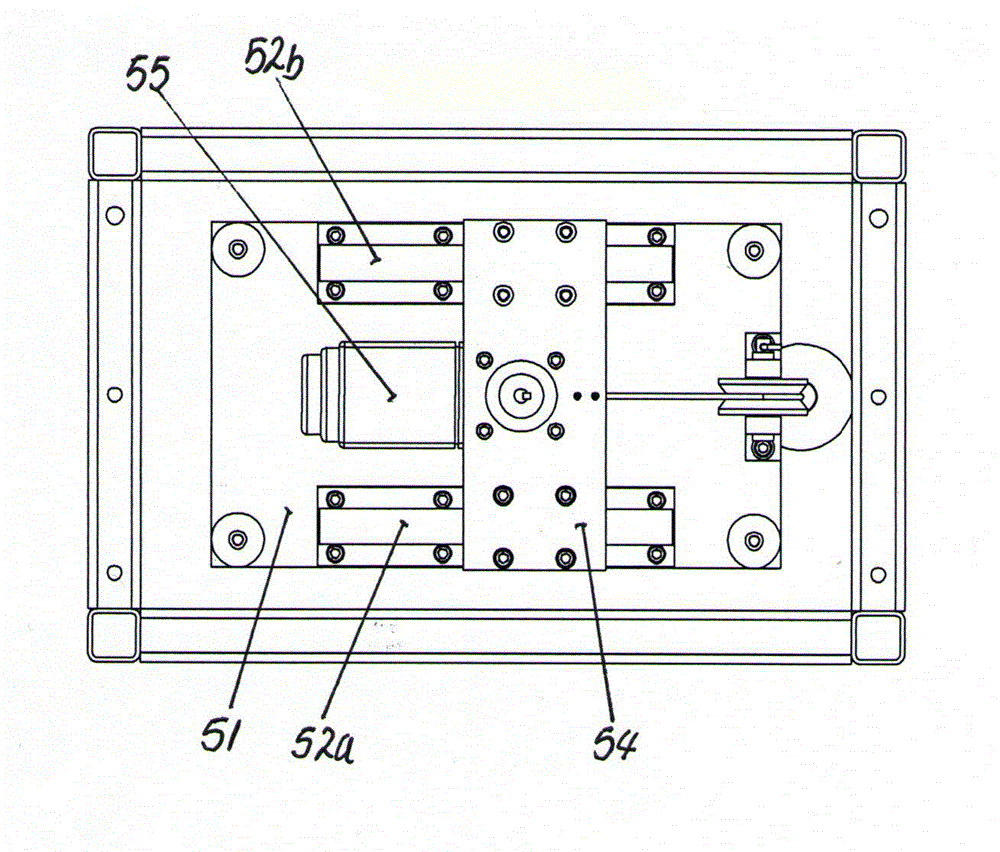

[0015] The present invention consists of a frame 1, a polishing wheel device 2, a positioning wheel device 3, a cam clamp device 4, and a cam clamp rotating and sliding device 5;

[0016] Polishing wheel device 2 is made of support 21, slide seat 22, slide block 23, connecting plate 24, motor 25, polishing wheel chuck 26, polishing wheel 27, the first weight 28, the lower end of support 21 and the table top of frame 1 10 is fixedly connected, the slide seat 22 is fixedly connected to the upper end of the support 21, the slide block 23 cooperates with the slide bar 29 on the slide seat 22, the connecting plate 24 is fixedly connected with the slide block 23, the motor 25 is fixedly installed on the connecting plate 24, polished The wheel chuck 26 is fixedly installed on the shaft end of the motor 25, and the polishing wheel 27 is plugged and fixedly connected with the polishing wheel chuck 26 through its shaft rod. Connect, drive the connecting plate 24 to slide and move;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com