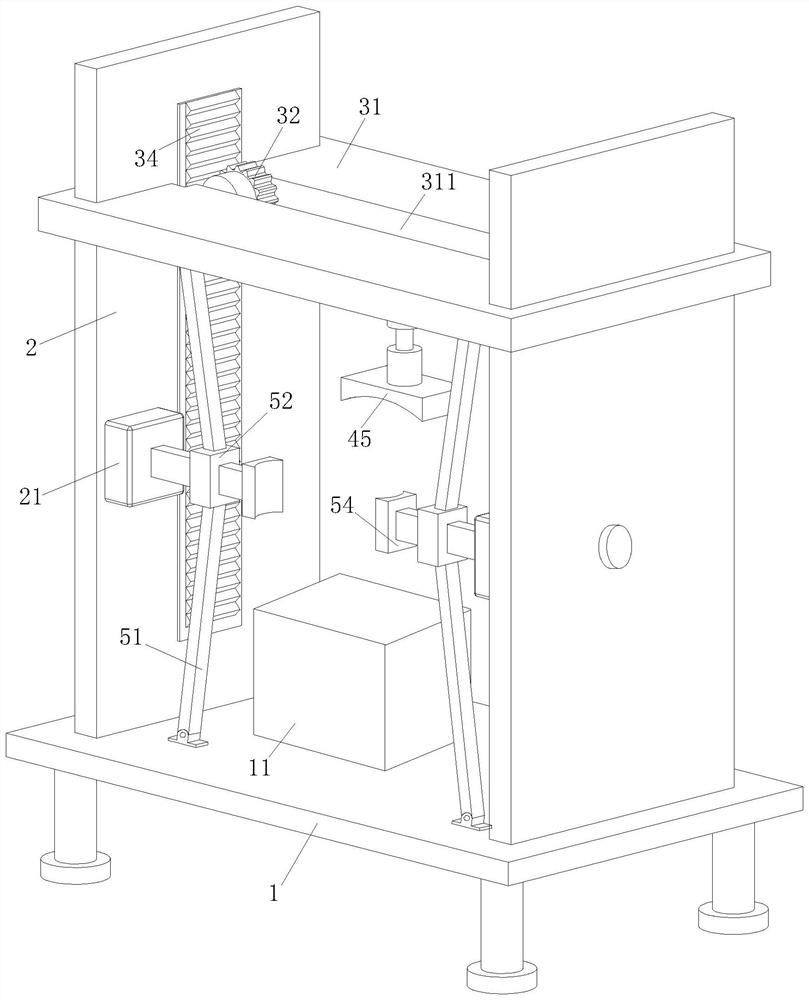

A polishing device for communication equipment production

A technology of communication equipment and polishing device, which is applied to grinding driving device, metal processing equipment, grinding/polishing equipment, etc., can solve the problem of reducing the use effect and working efficiency of polishing equipment, unable to adapt to the shape and size of parts processing, and difficult to work in size. Adjustment and other issues to achieve the effect of strengthening the use effect and range of use, enhancing the overall use effect, and ensuring the polishing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

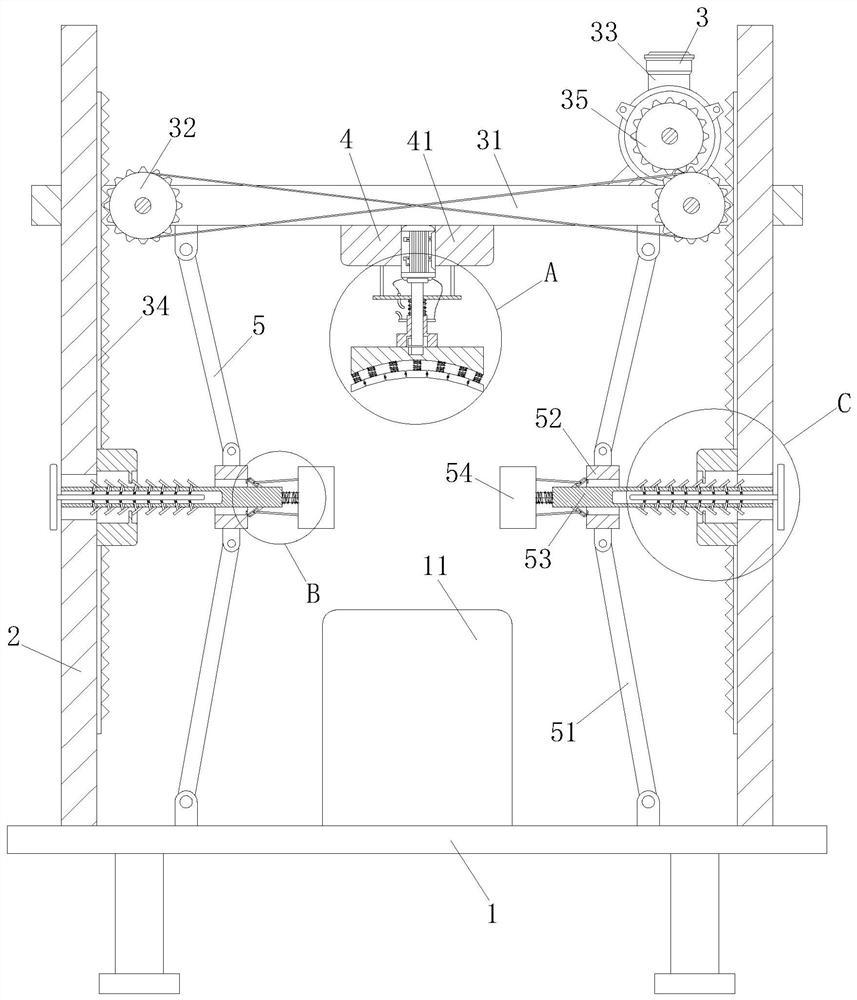

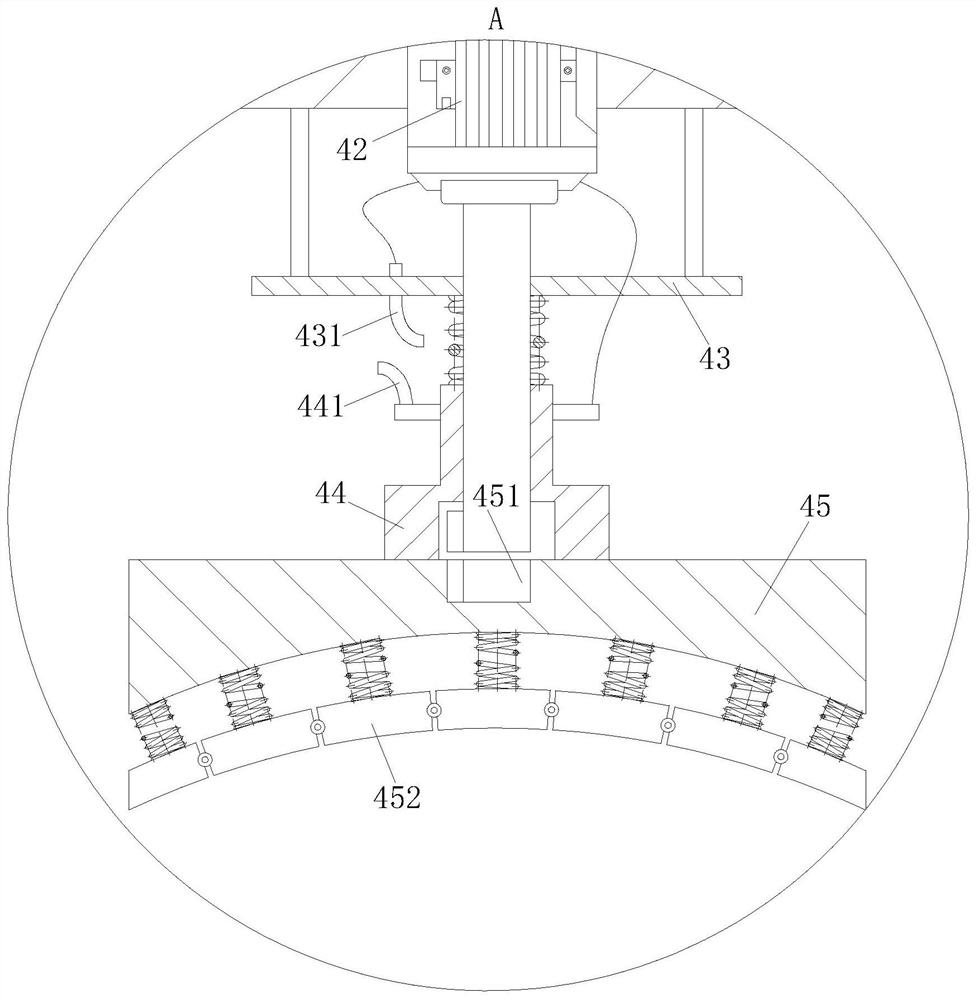

[0023] As an embodiment of the present invention, a fixed unit 5 is arranged symmetrically between the pressure plate 31 and the base 1; the fixed unit 5 includes a connecting rod 51, a push block 52, a push rod 53 and a fixed block 54; The number of rods 51 is two, and one end of the two connecting rods 51 is hinged on the push block 52 at the same time, and the other end is respectively hinged on the bottom end of the pressing plate 31 and the top end of the base 1; No. 1 through hole 521; the push rod 53 is slidably connected in the No. 1 through hole 521, and the side wall of the push rod 53 is symmetrically provided with a No. 1 shrapnel 531; The end of the push block 52 is in contact with the side wall of the push block 52, and there is a chute 532 inside the No. 1 shrapnel 531; the fixed block 54 is installed on the end of the push rod 53 through a spring, and the fixed block 54 is symmetrical near the No. 1 shrapnel 531. A strut 541 is provided so that the end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com