A device for polishing the circular arc surface of connecting rod

一种圆弧面、连杆的技术,应用在磨削/抛光设备、制造工具、磨床等方向,能够解决抛光精度难以保证、打磨抛光难度大、产品笨重等问题,达到位置可靠、方法简单、成本低廉的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

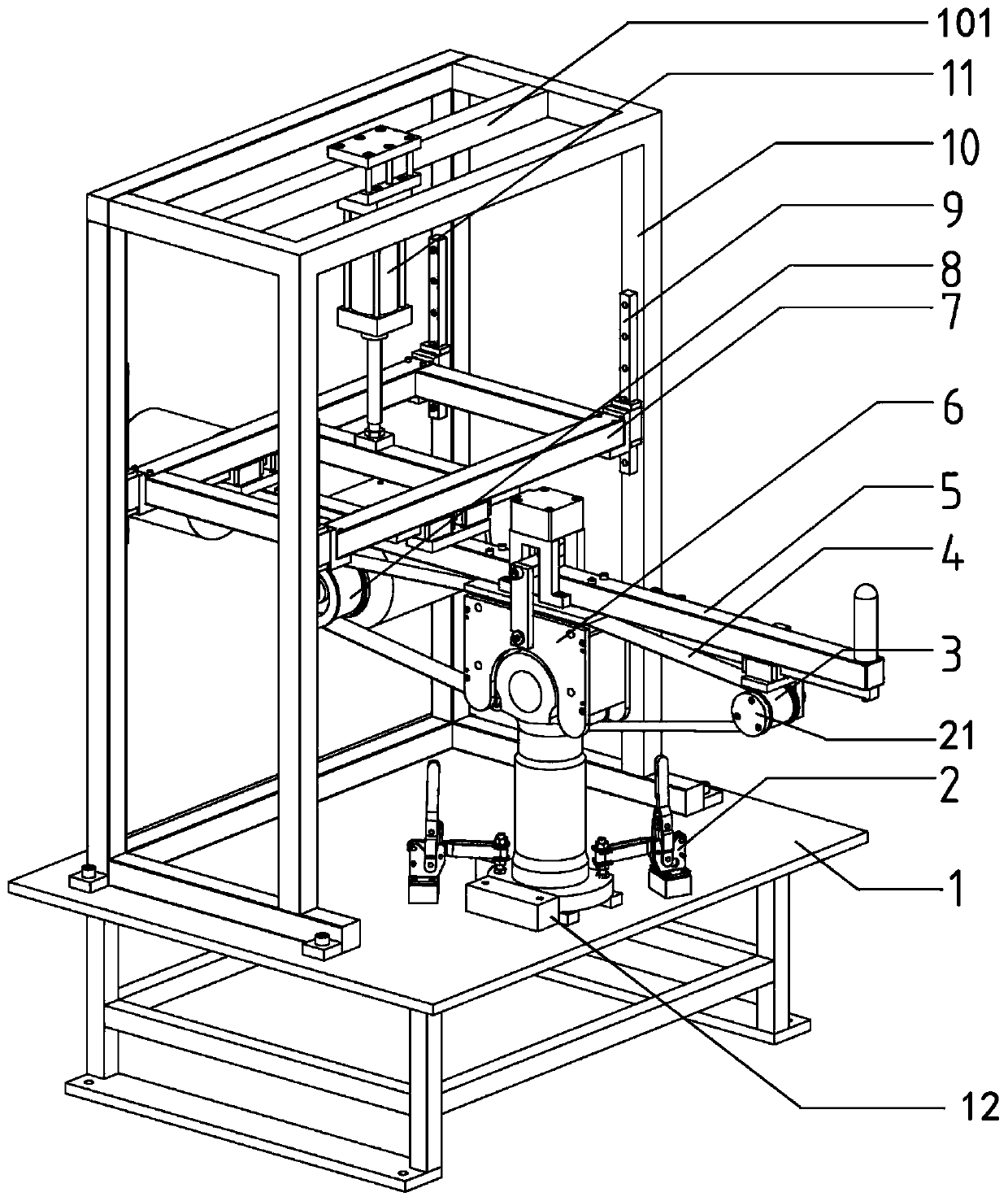

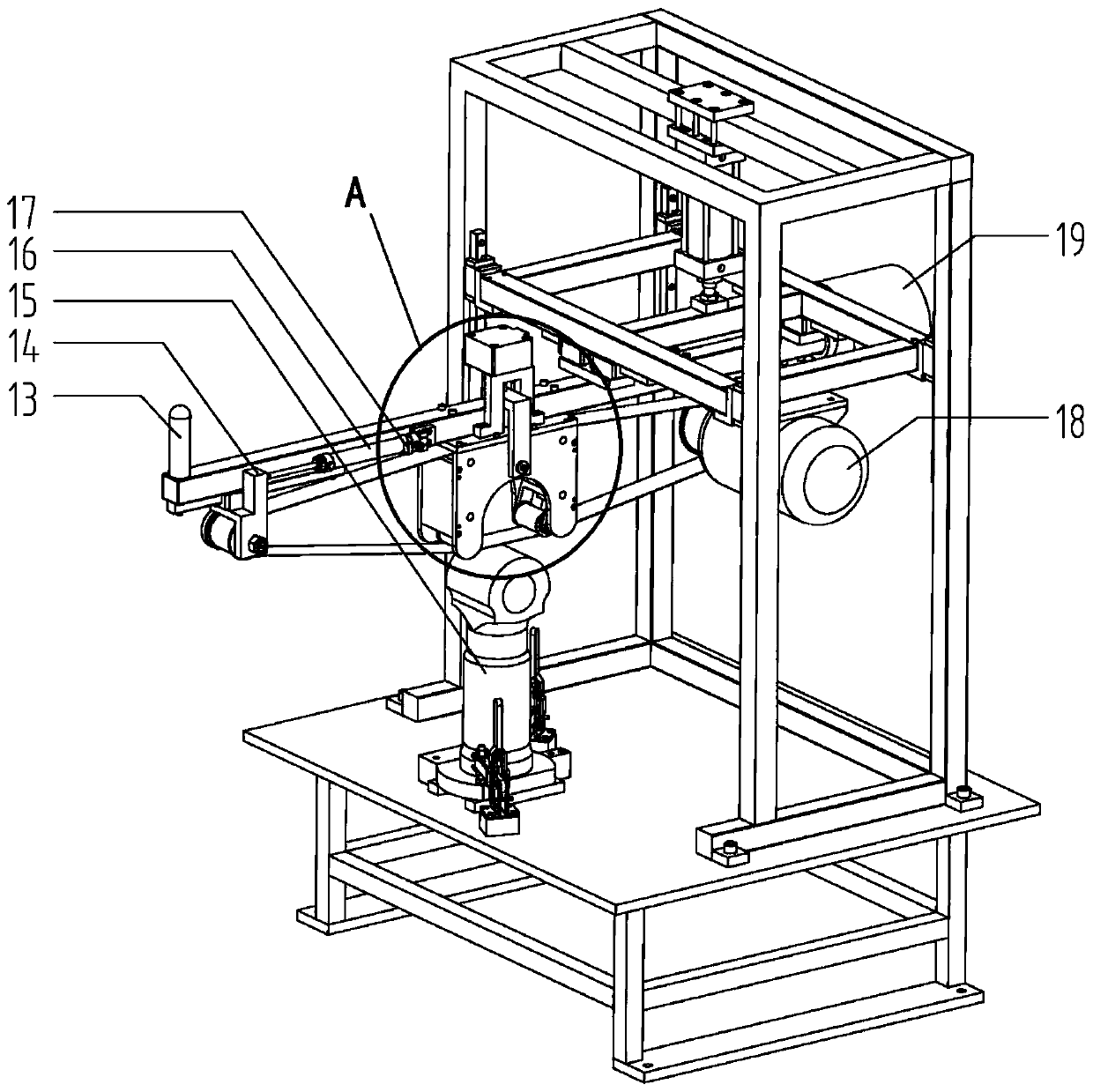

[0037] The present invention will be further described below in conjunction with drawings and embodiments.

[0038] The specific implementation steps of the method for polishing the circular arc surface of connecting rod of the present invention are as follows:

[0039] S1. Put the connecting rod 15 close to the limit block 12 of the device of the present invention, pull two quick clamps 2 to clamp the connecting rod, and place the connecting rod to be polished with the arc surface upward;

[0040] S2. Turn on the switch of the lifting cylinder 11, so that the lifting cylinder 11 drives the lifting seat 7, and drives the polishing belt operation unit to descend, so that the polishing belt 4 is positioned on the arc surface of the connecting rod;

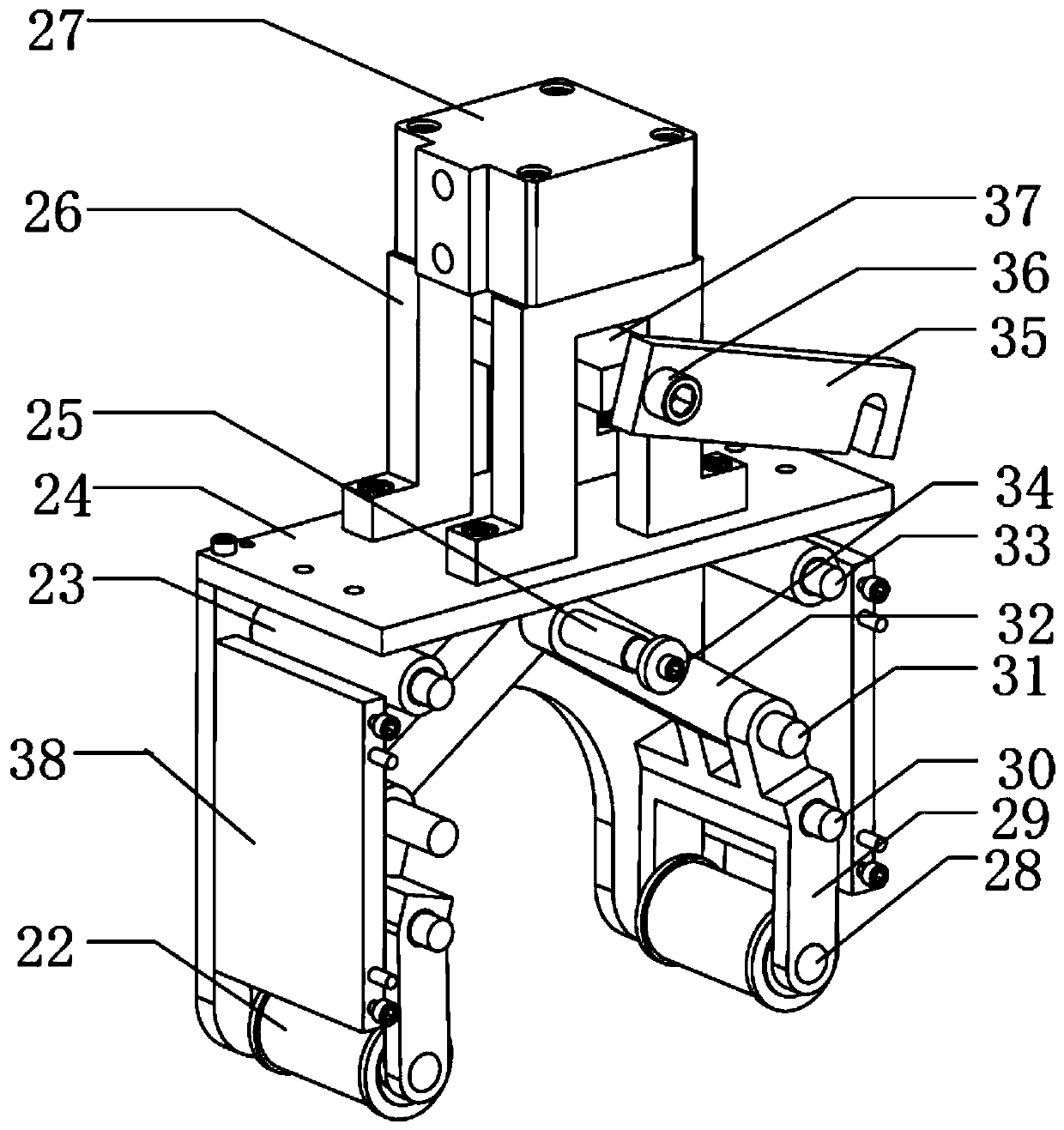

[0041]S3, start the switch of the hinge loose clamp cylinder 27, the hinge clamp cylinder 27 drives the hinge loose clamp connecting seat 37, drives the follower pin 25 to go down, and the hinge clamp 29 clamps the polishing belt 4 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com