A superfine polishing process for metal products

A technology for metal products and fine polishing, applied in the field of polishing technology, can solve problems such as pneumoconiosis and other diseases, splashing of metal products, dust environment pollution, etc., to improve polishing effect, ensure polishing accuracy, and ensure the effect of personal safety.

Inactive Publication Date: 2020-06-05

杭州临安恒达精密仪表元件厂

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Metal products can be seen everywhere in our life. During the processing of metal products, metal products need to be polished to make the surface of metal products smooth. The rough surface will not affect the feel, and it will also appear smooth because of the surface. Dazzling, polishing is an important process that affects product quality, but a large amount of dust will inevitably be generated during the polishing process, and along with the polishing work, because the direct contact between the polishing wheel and the surface of the metal product will make the metal The splashing of product fragments will inevitably cause great harm to the staff, especially if it is not effectively controlled, and the staff will easily cause diseases such as pneumoconiosis after inhalation, and the dust will cause certain pollution to the surrounding environment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

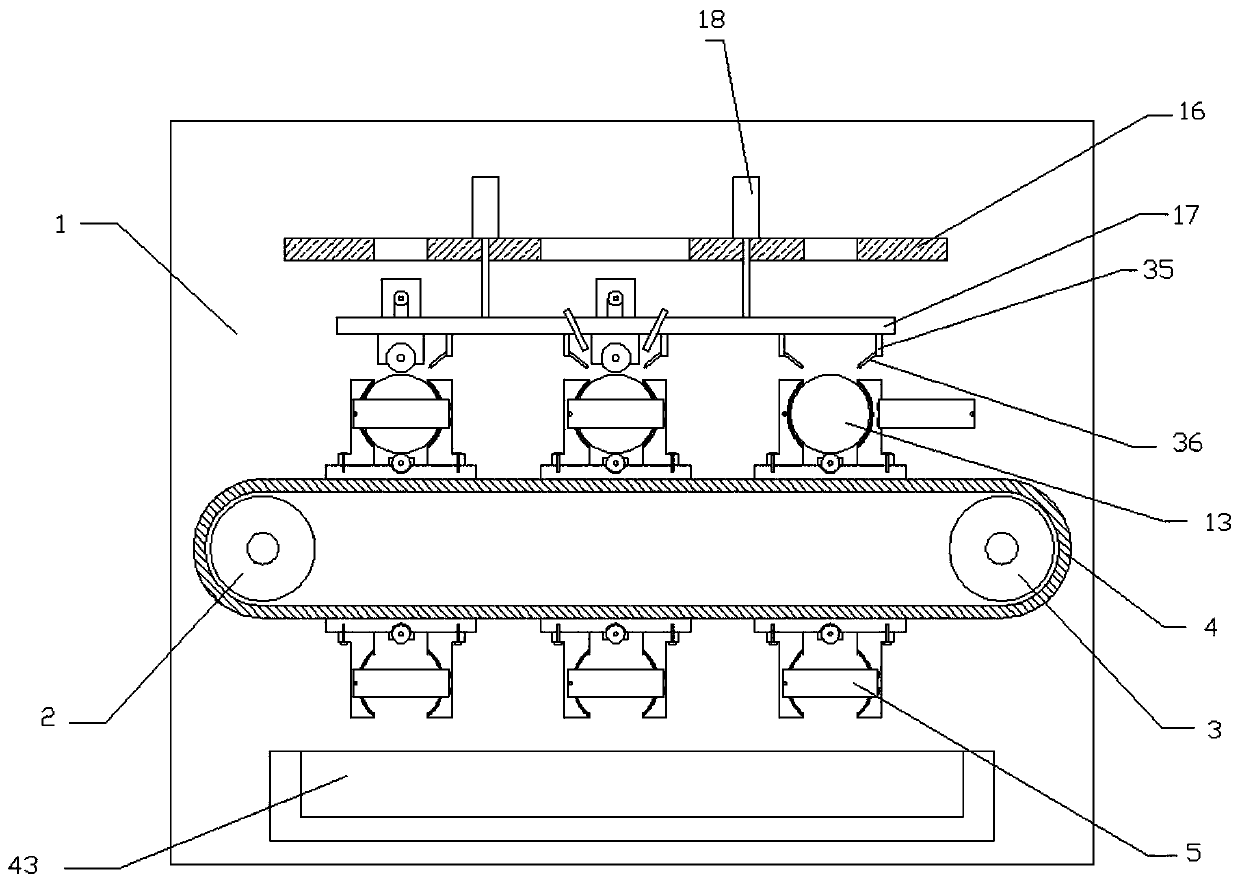

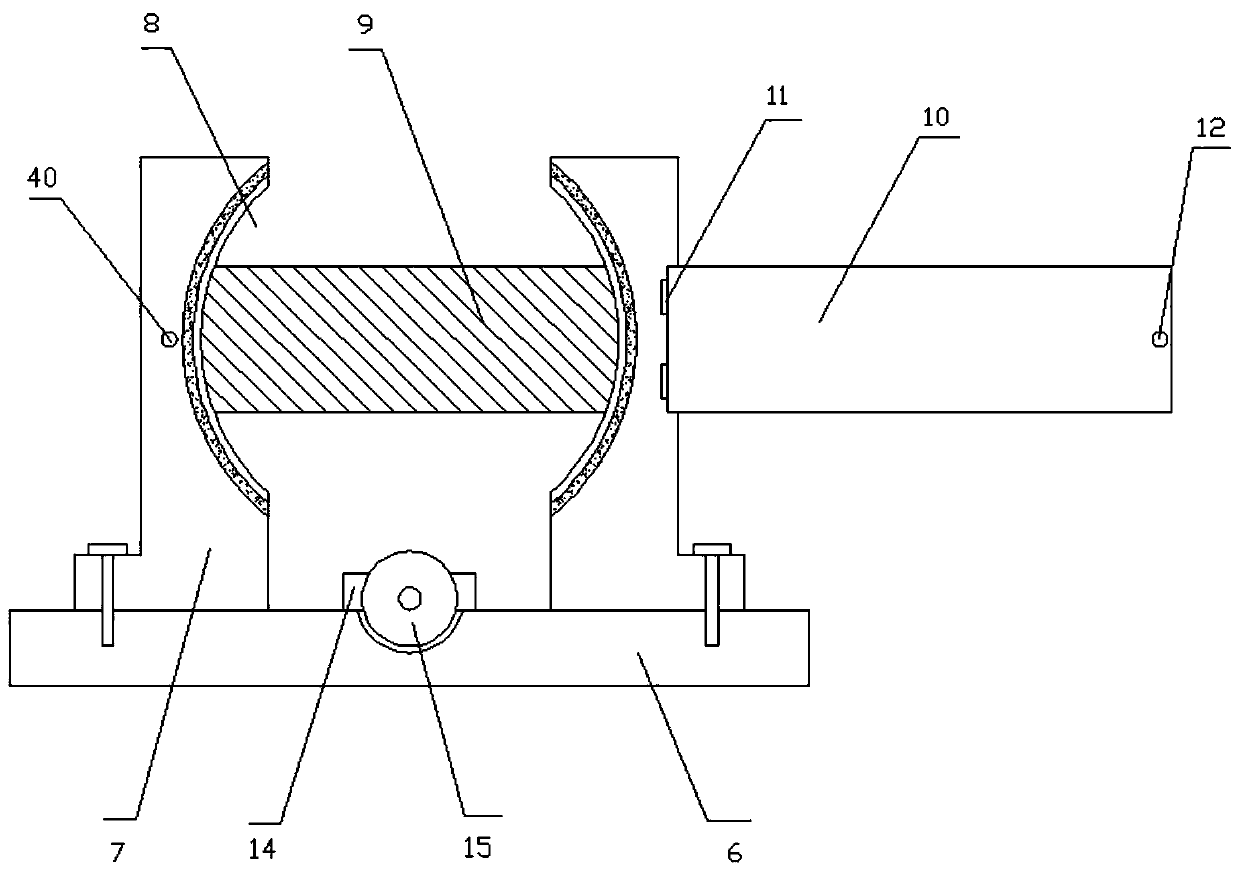

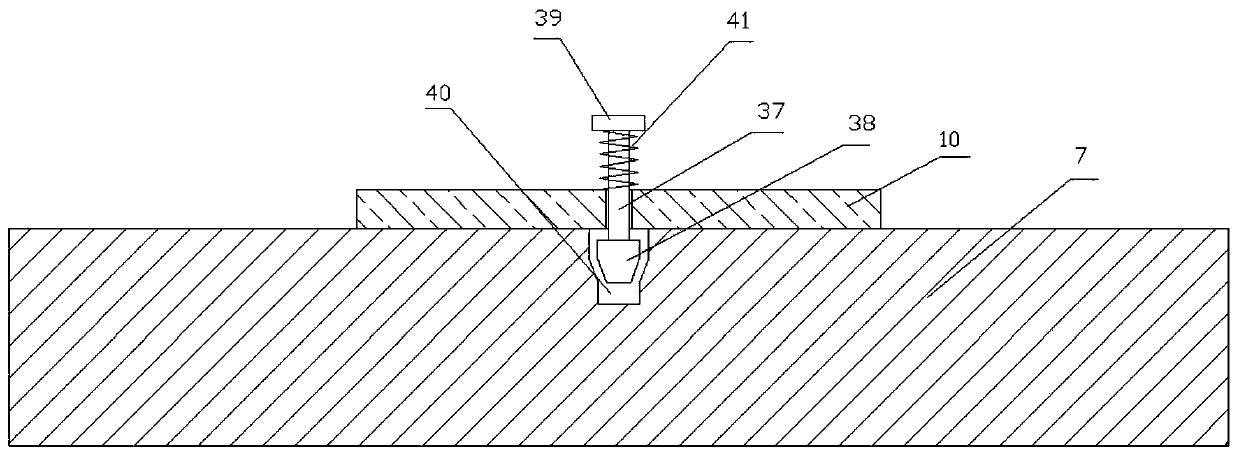

[0045] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a super-fine polishing process for metal products. The super-fine polishing process comprises the following steps of (1) cleaning the surfaces of the metal products with cleaning liquid; (2) performing first-time polishing on the surfaces of the metal products, and spraying the metal products with polishing liquid A in the first-time polishing process; (3) performing first-time washing on the metal products with deionized water after first-time polishing is completed; (4) performing second-time polishing on the surfaces of the metal products after first-time washing is completed, and spraying the surfaces of the metal product with polishing liquid B in the second-time polishing process; (5) performing second-time washing on the metal products with deionized water after the second-time polishing is completed; and (6) after second-time washing is completed, stoving and drying the surfaces of the metal products with hot air at 45 DEG C to 55 DEG C. The super-fine polishing process is specially used for polishing the side walls of the metal products of cylindrical structures, the polishing effect is improved, the polishing precision is ensured, dust avoiding andenvironment protection are achieved, and personal safety of an operator is guaranteed.

Description

technical field [0001] The invention relates to a polishing process, in particular to an ultra-fine polishing process for metal products. Background technique [0002] Metal products can be seen everywhere in our life. During the processing of metal products, metal products need to be polished to make the surface of metal products smooth. The rough surface will not affect the feel, and it will also appear smooth because of the surface. Dazzling, polishing is an important process that affects product quality, but a large amount of dust will inevitably be generated during the polishing process, and along with the polishing work, because the direct contact between the polishing wheel and the surface of the metal product will make the metal The splashing of product fragments will inevitably cause great harm to the staff, especially if it is not effectively controlled, and the staff will easily cause diseases such as pneumoconiosis after inhalation, and the dust will cause certai...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B24B1/00

CPCB24B1/00

Inventor 汪天伟洪荣跃

Owner 杭州临安恒达精密仪表元件厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com