A UAV electronic chip manufacturing equipment

An electromechanical and chip technology, which is applied in the field of UAV electronic chip manufacturing equipment, can solve the problems of polishing machine interior and chip wafer pollution, lack of grinding waste collection components, increased labor intensity of manual cleaning, etc., to ensure polishing Accuracy, simple structure, and the effect of preventing jamming and excessive wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

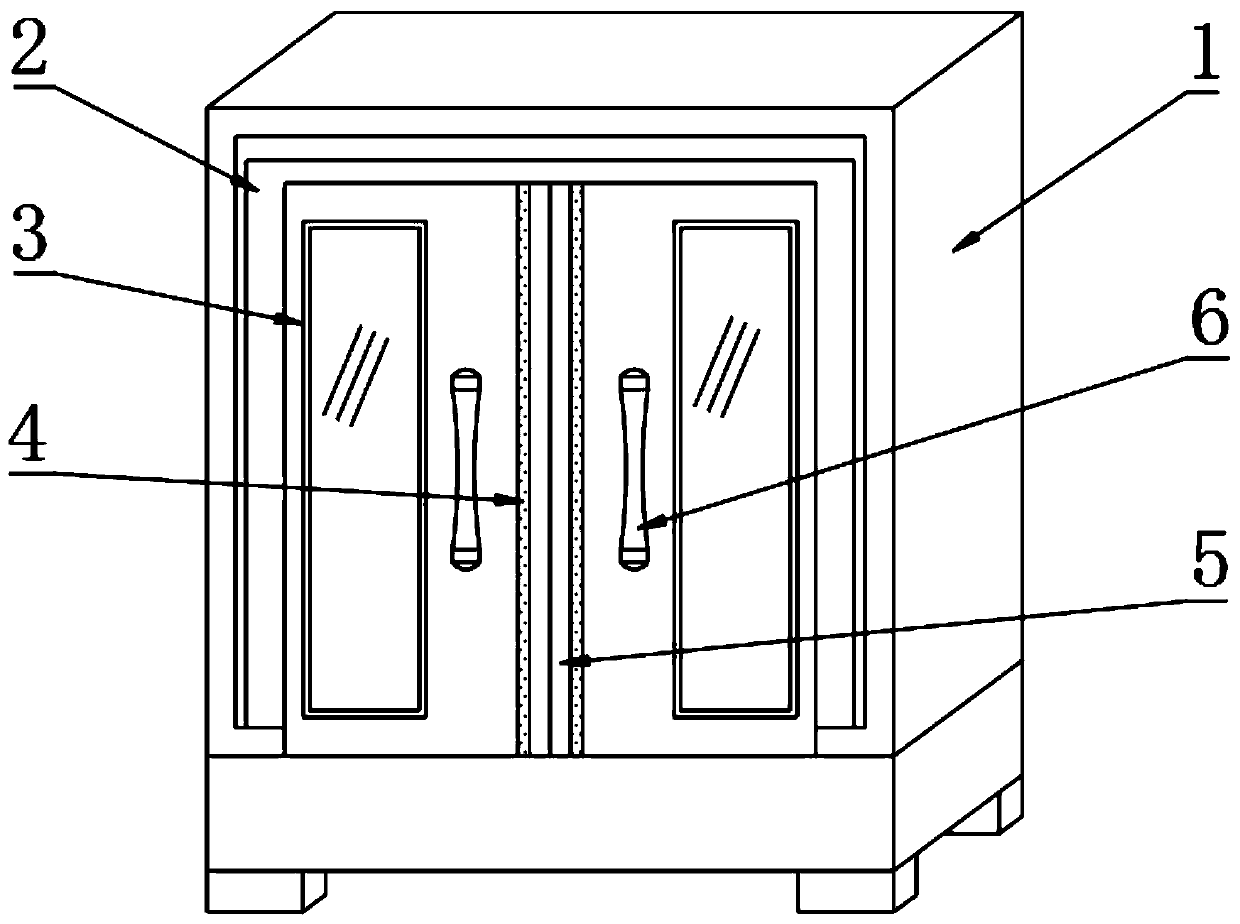

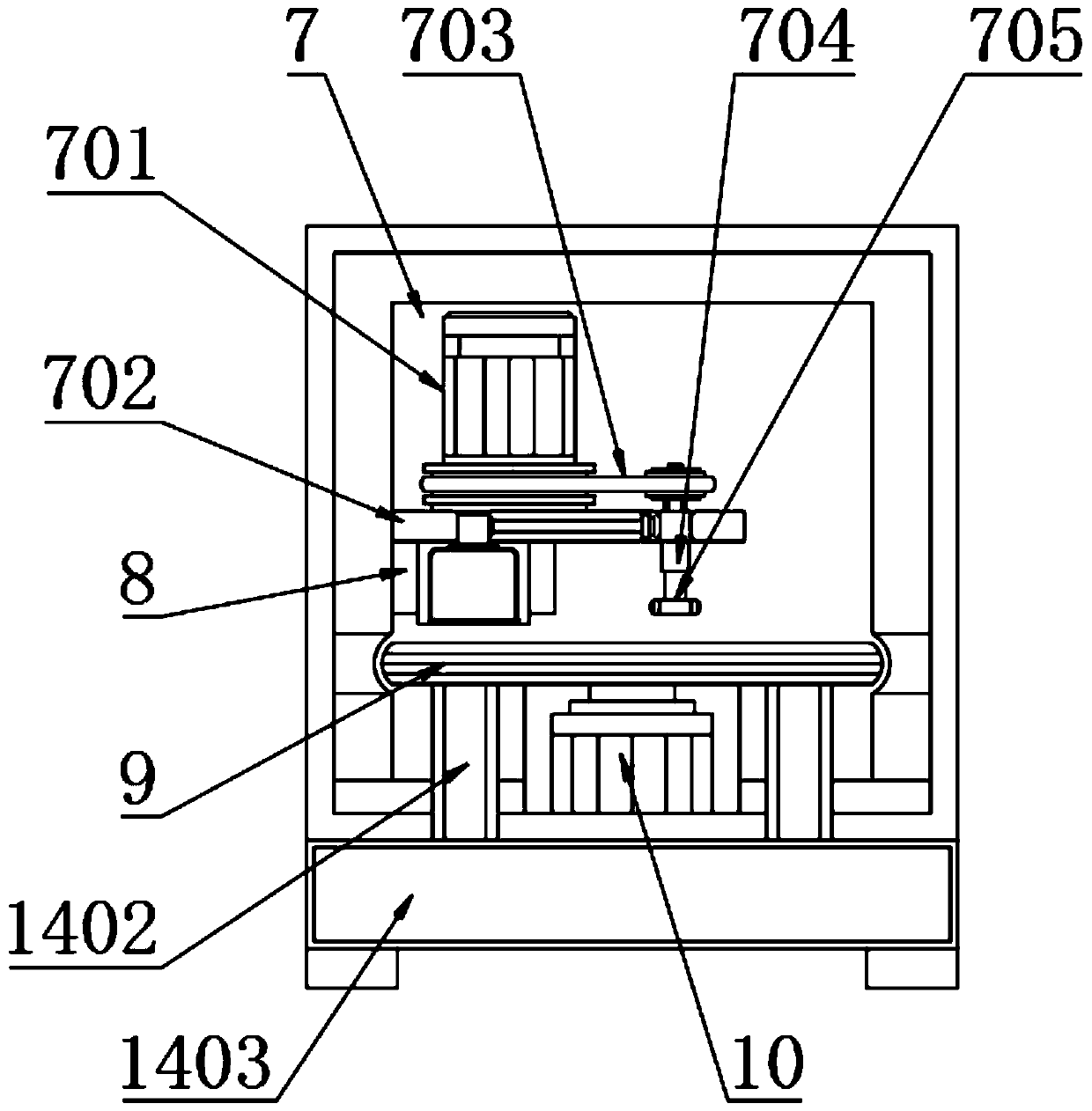

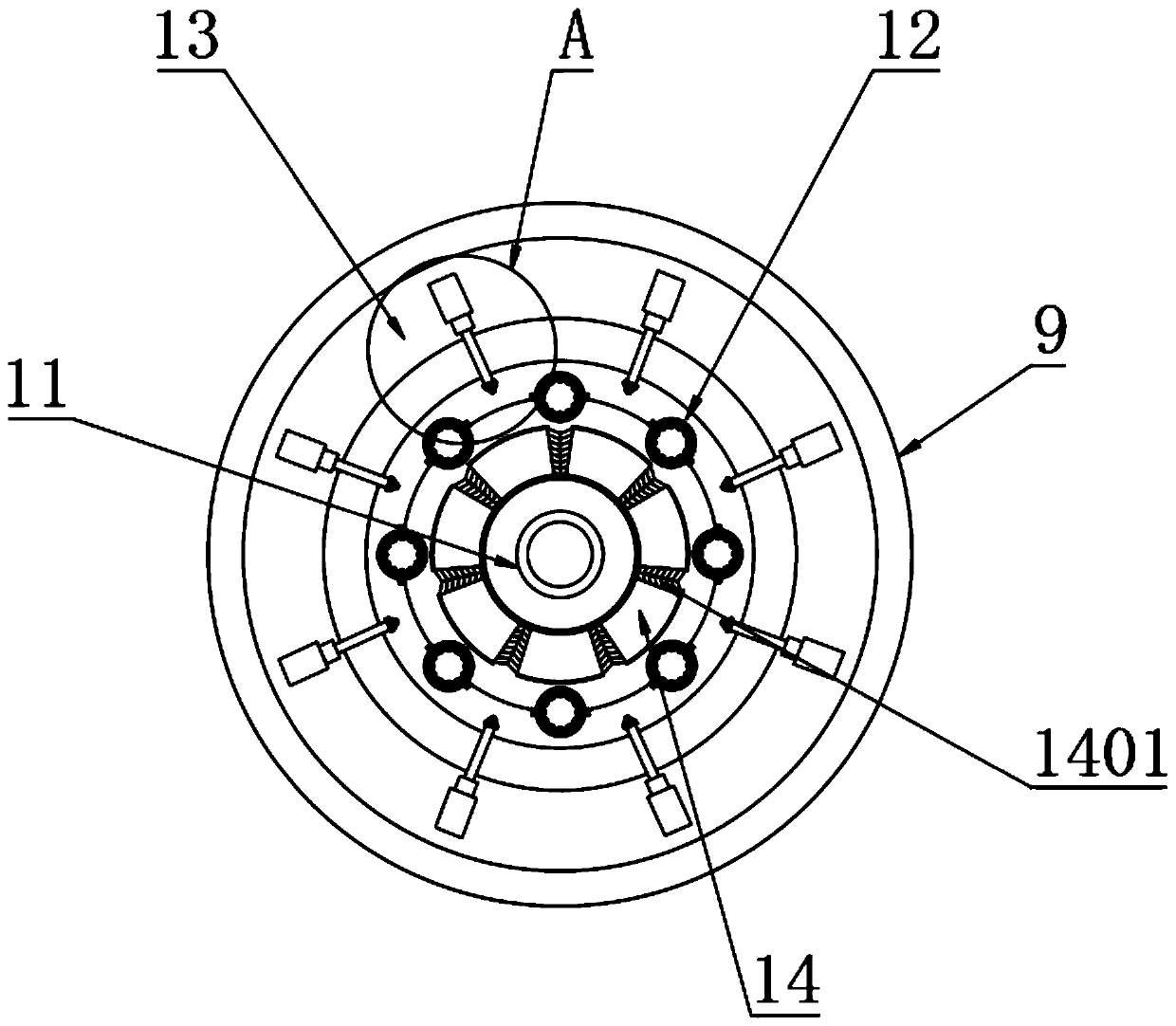

[0030] Example: such as Figure 1-6 As shown, the present invention provides a technical solution, a UAV electronic chip manufacturing equipment, including a polishing body 1, in order to facilitate people to support the polishing body 1, and make the support more stable when supporting the polishing body 1, polishing The bottom of the body 1 is fixedly supported with a support, and the bottom surface of the support is fixedly bonded with a non-slip gasket, and the outer side of the polishing body 1 is rotated with a screen door 3. To observe the polishing efficiency of the wafer, the inner side of the screen door 3 is provided with a perspective window, and the inner side of the screen door 3 is symmetrically provided with a handle 6, and the connection between the screen door 3 and the polishing machine body 1 is provided with a dust-proof rubber layer 2. A sealant edge 4 is bonded to the connection of the inner side of the shielding door 3, and the outside of the sealant ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com