Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Increase the polishing area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

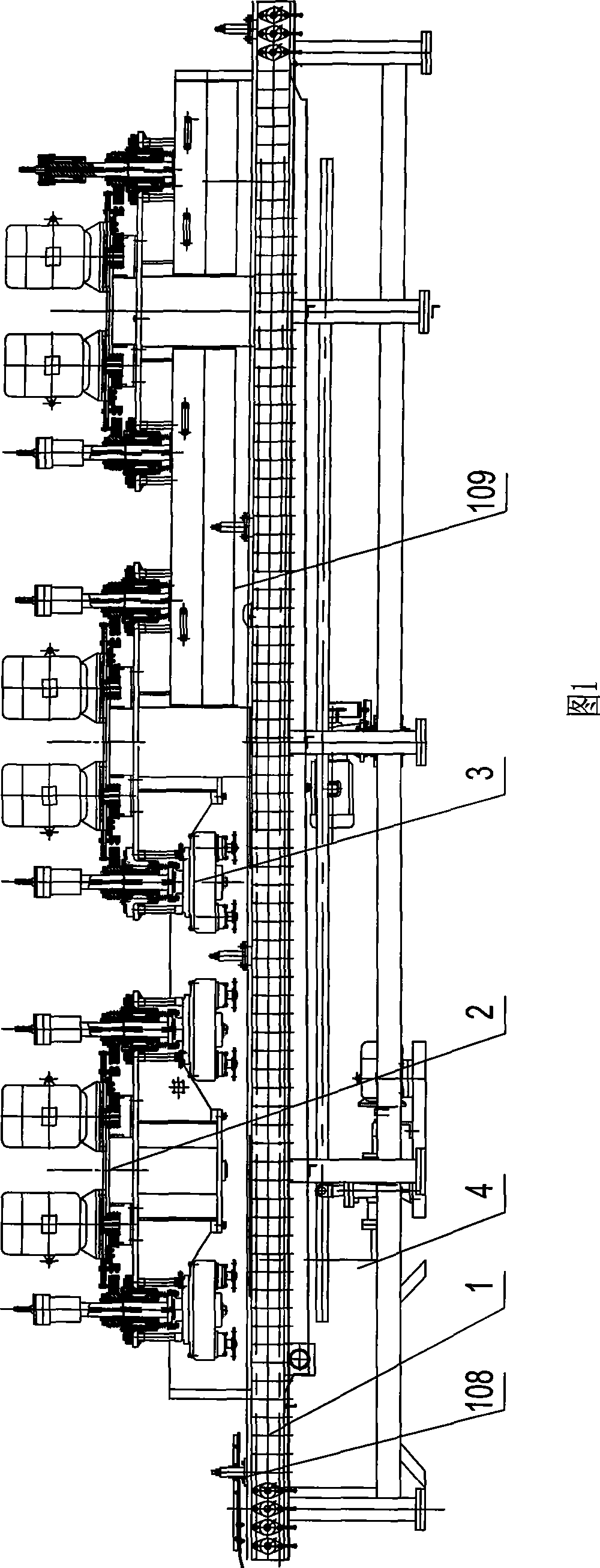

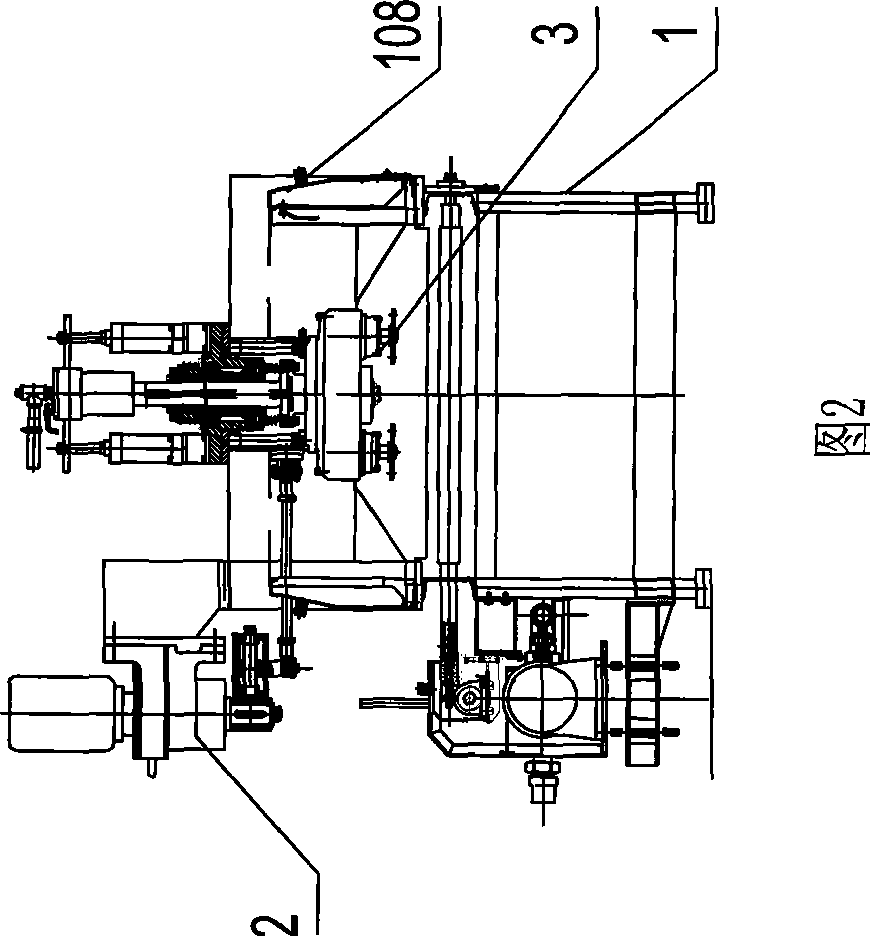

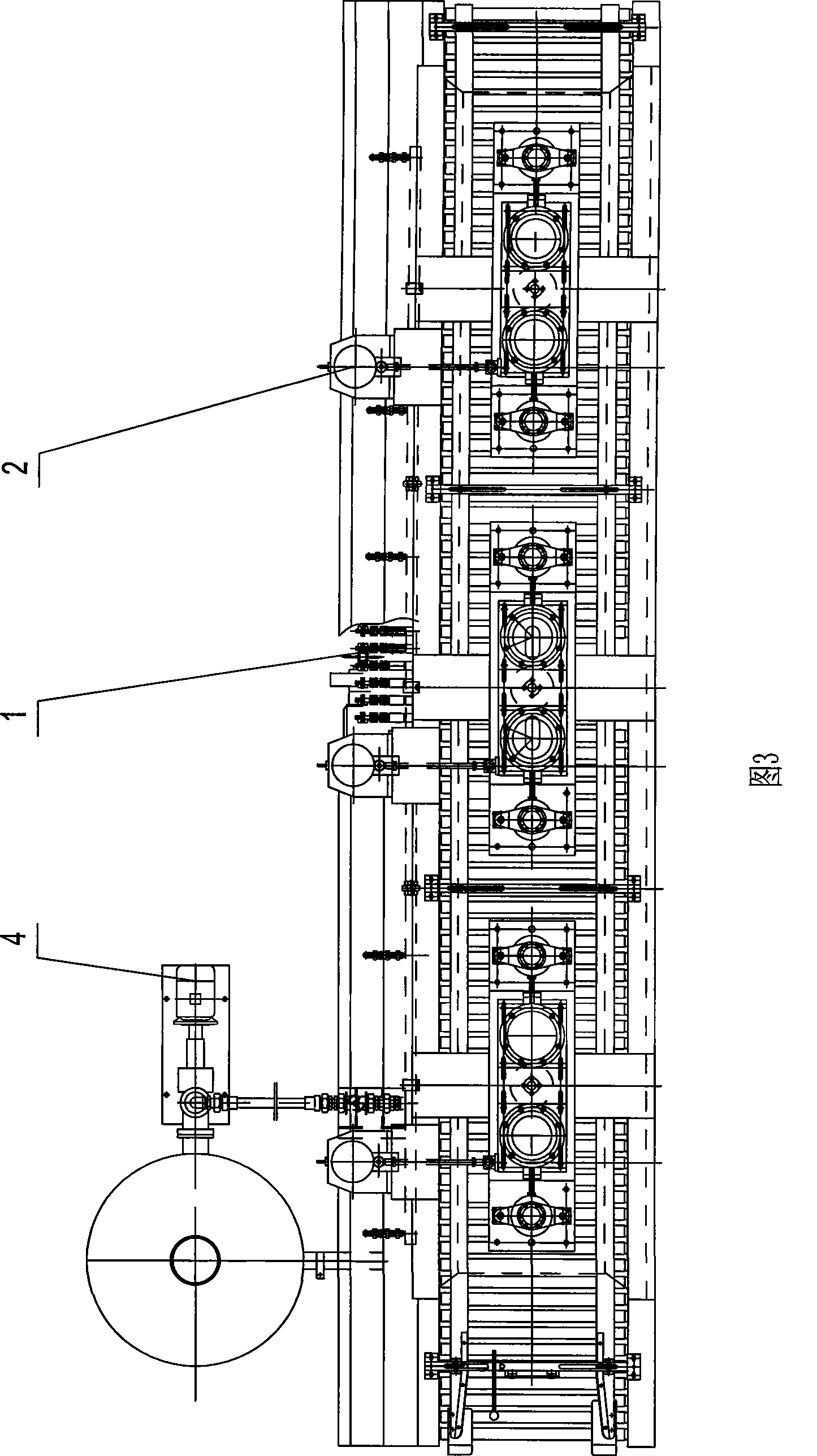

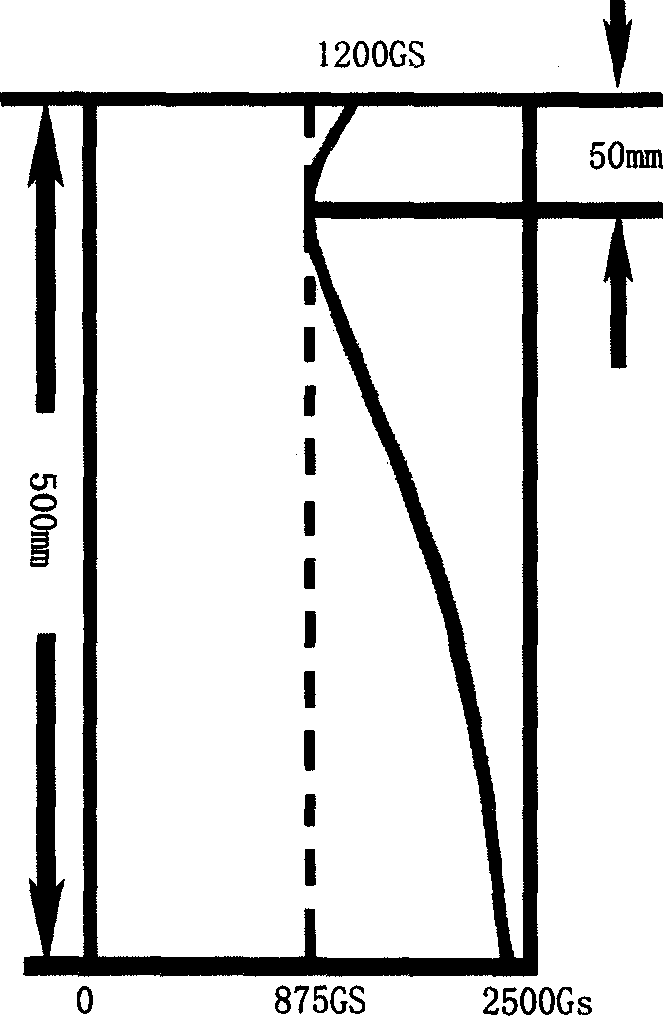

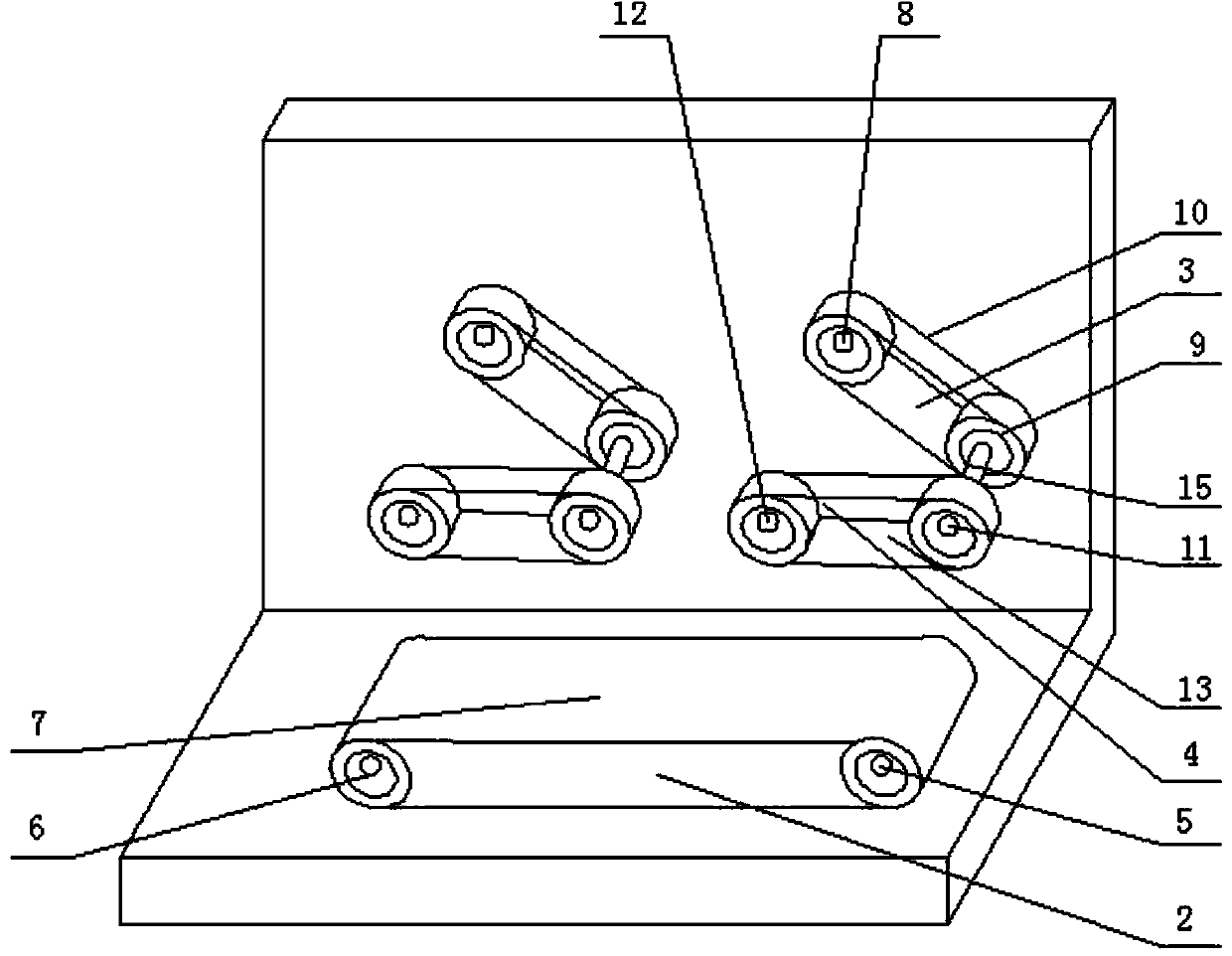

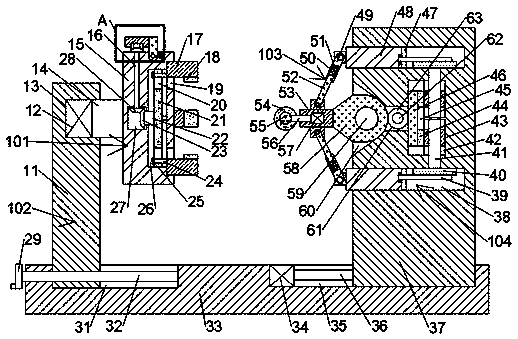

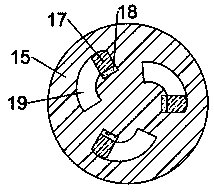

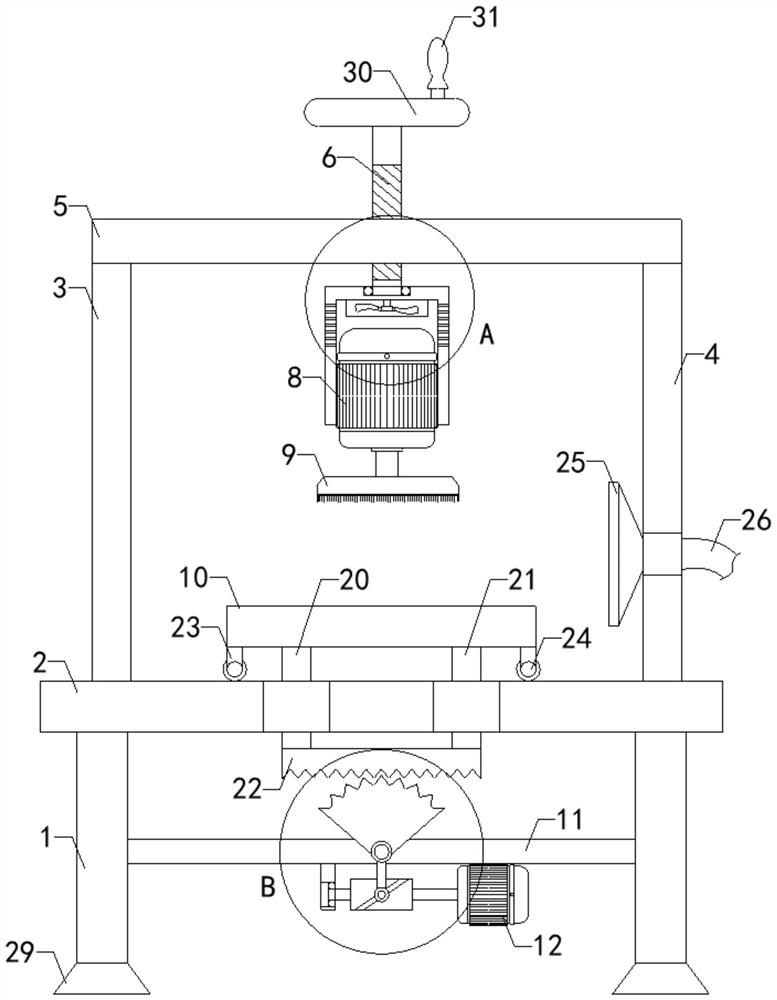

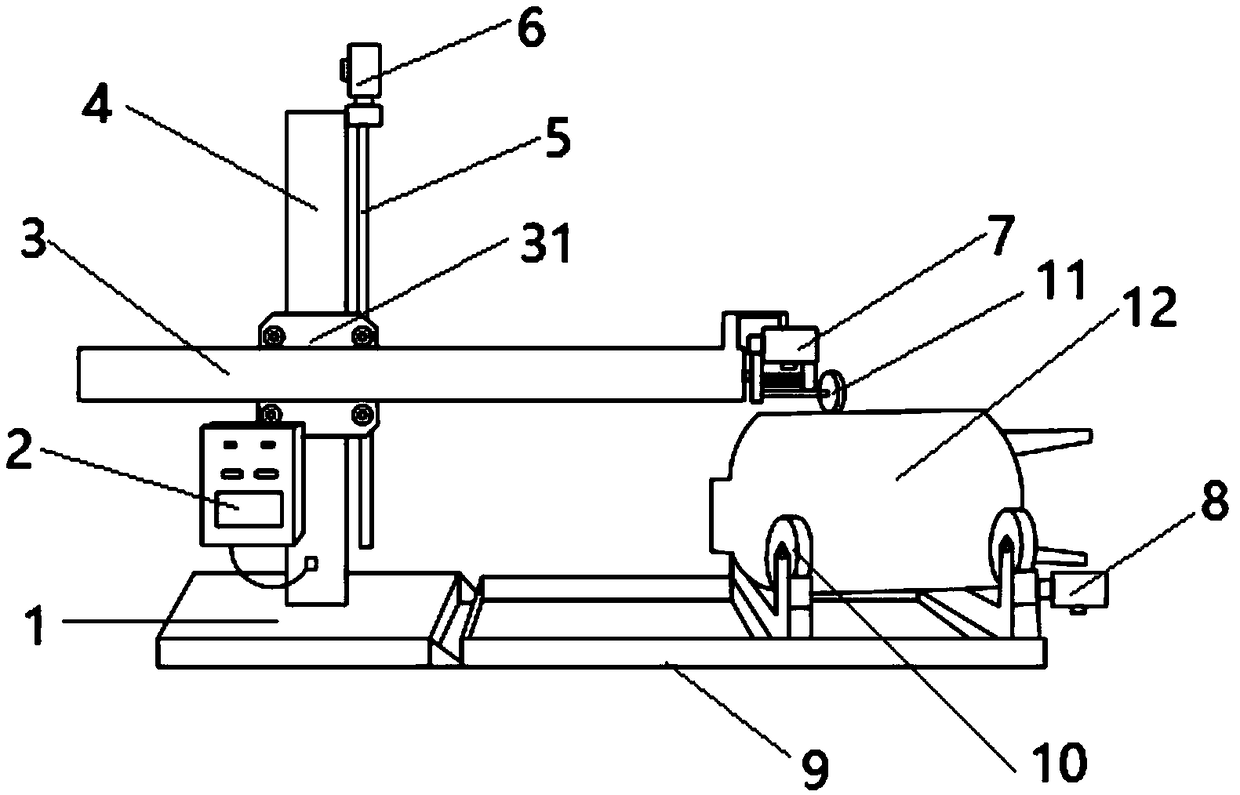

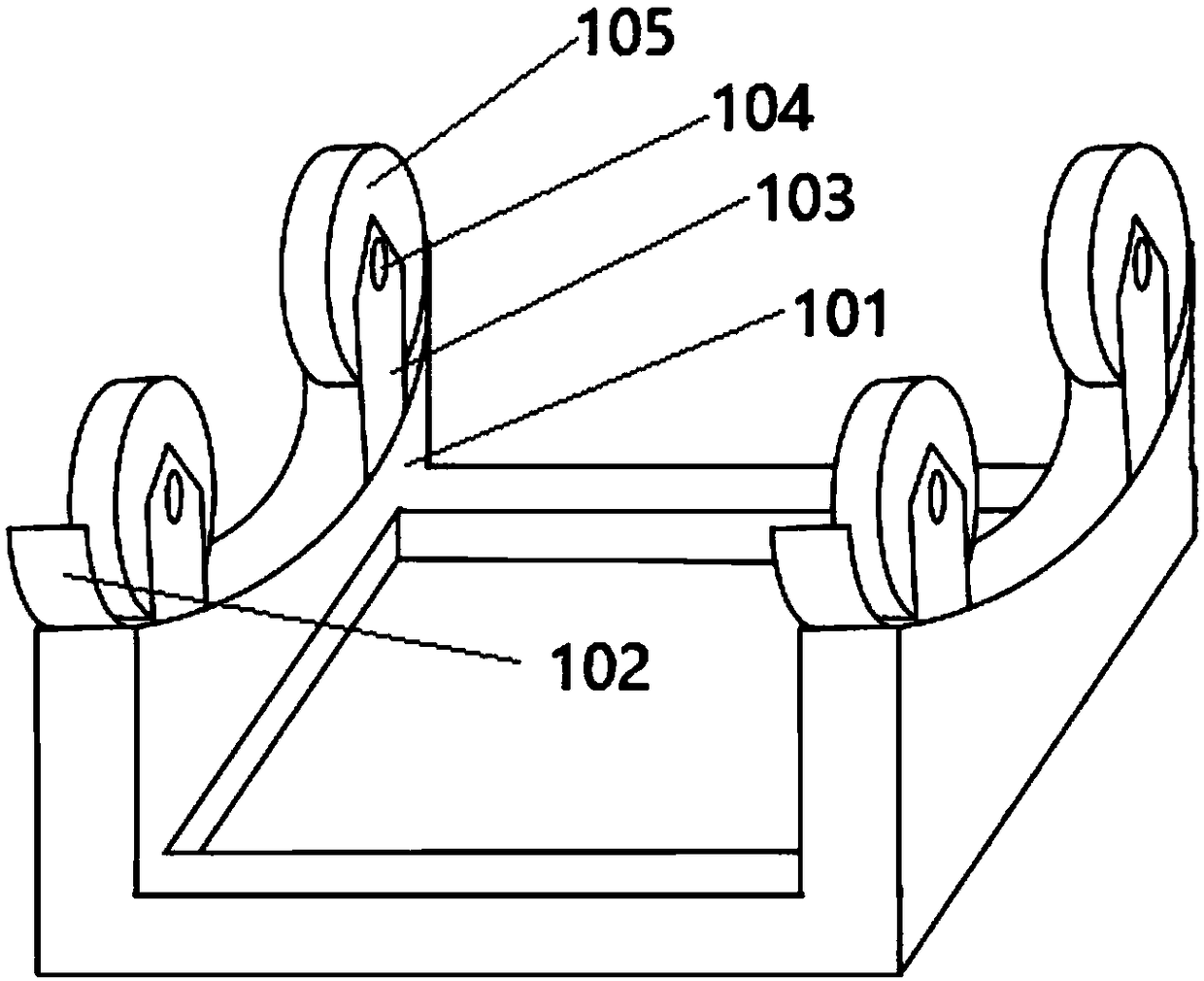

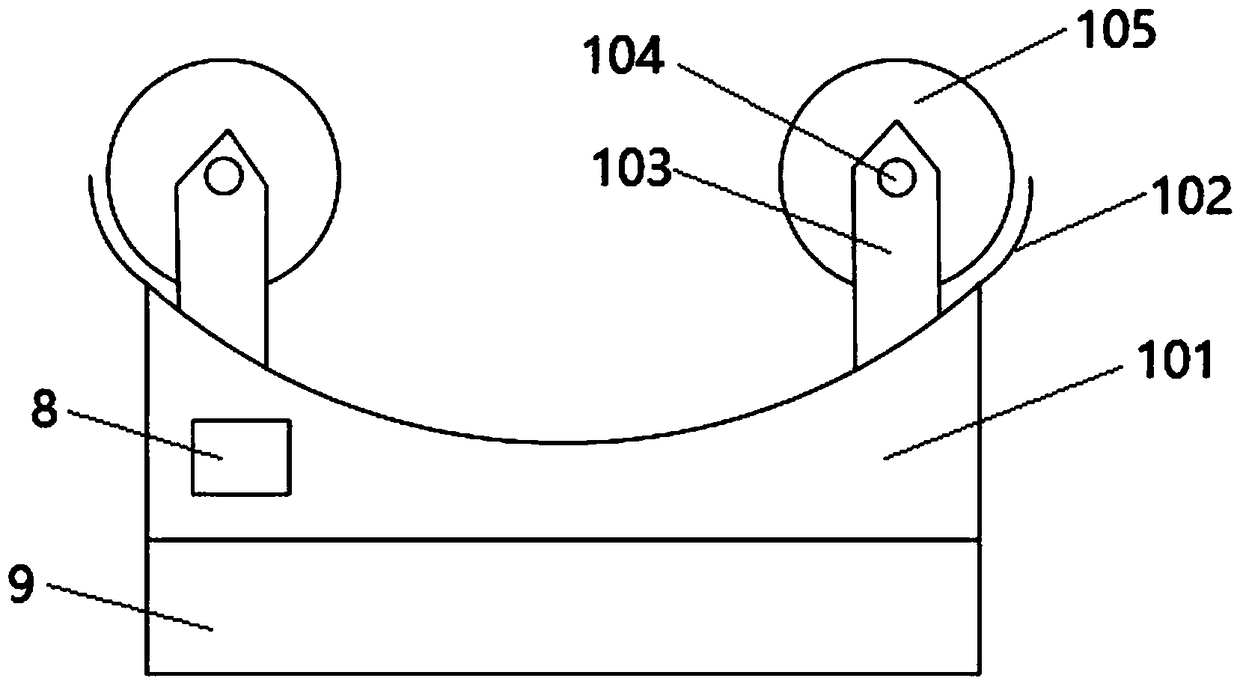

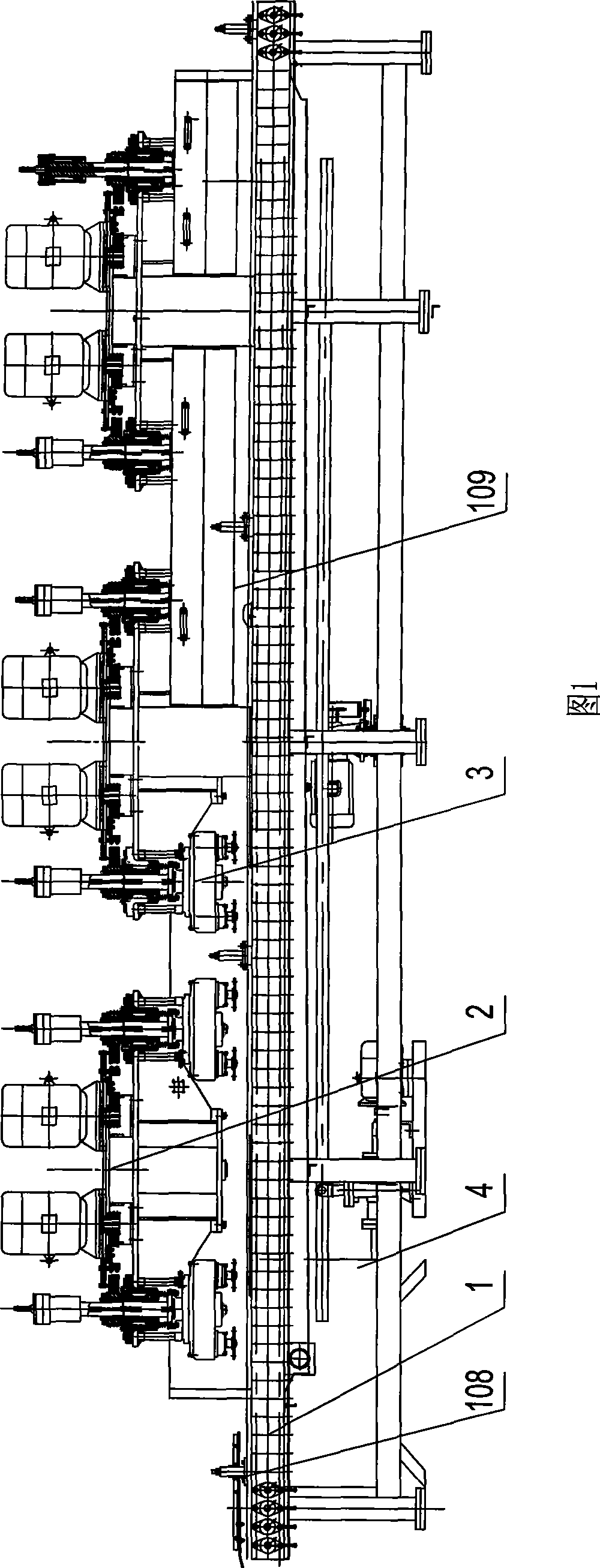

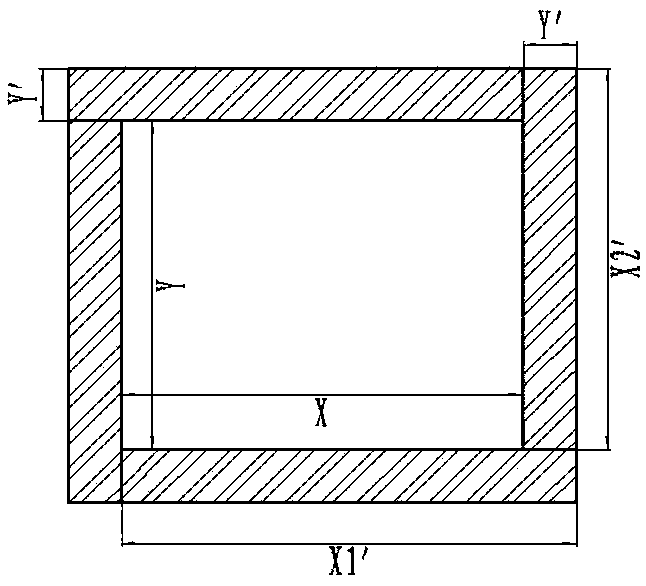

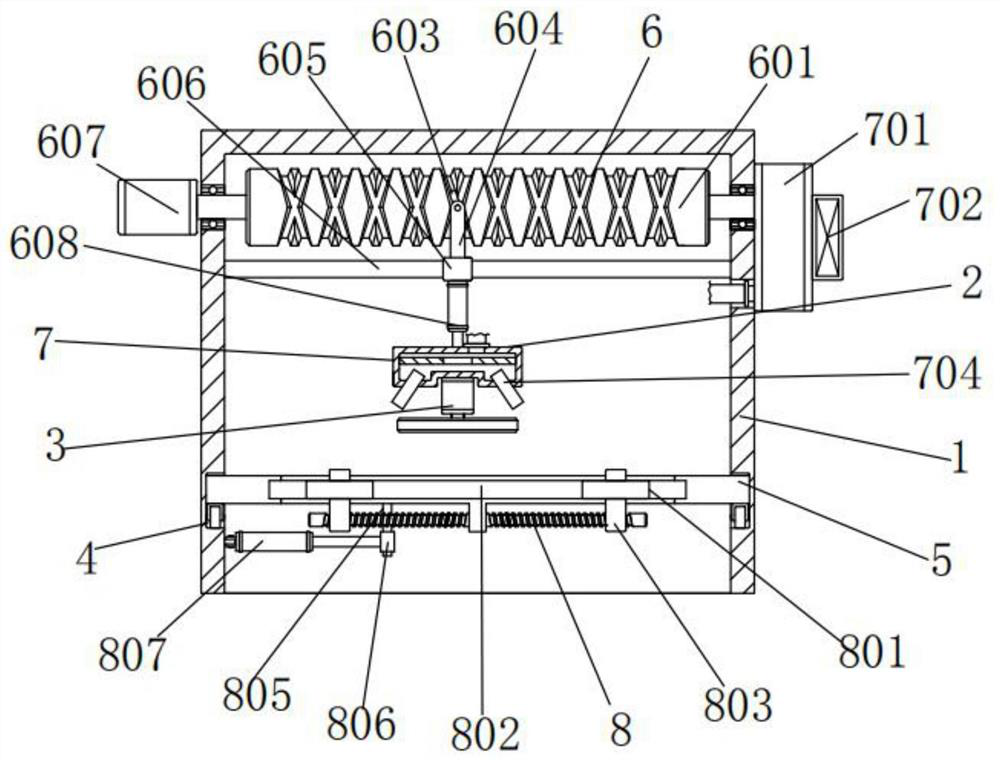

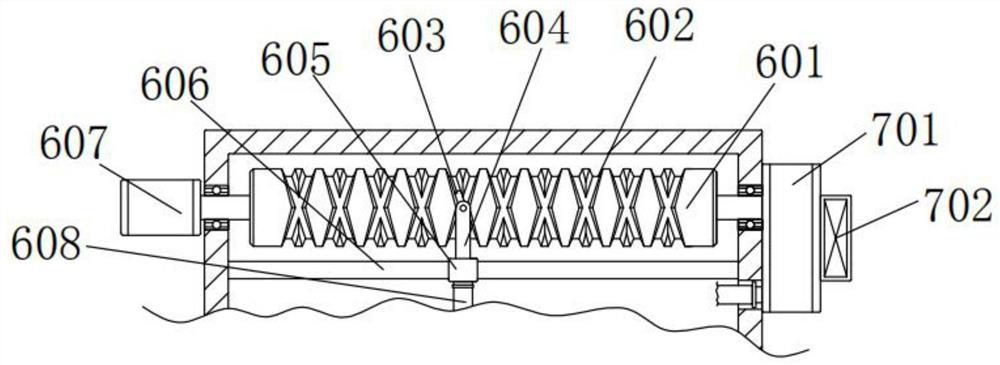

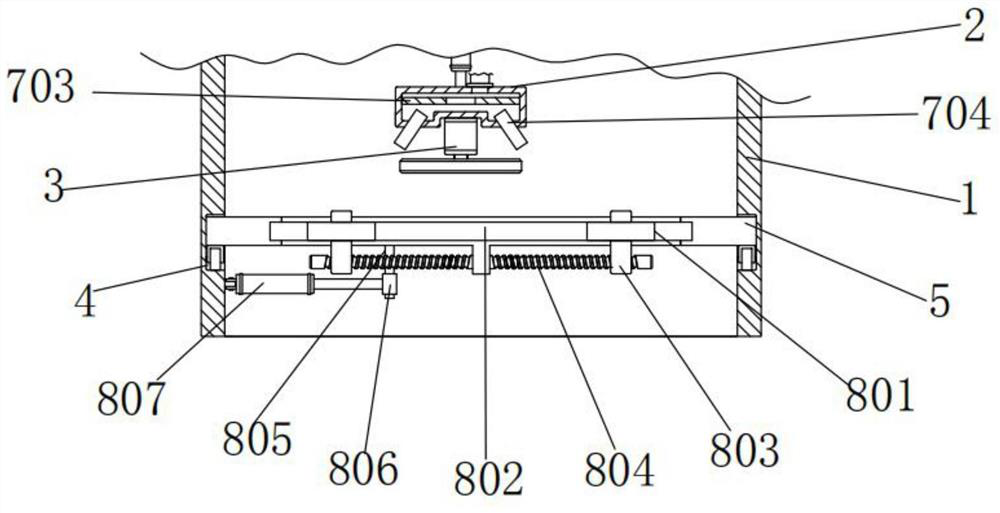

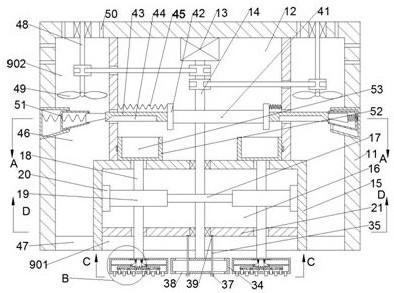

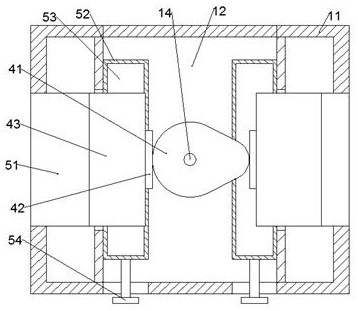

Glazing machine

ActiveCN101362312AGood grinding effectEliminate cutting marksGrinding carriagesPolishing machinesCeramic tilesEngineering

The invention discloses a glazing machine for glaze. The glazing machine comprises a ceramic tile delivery mechanism, and also a polishing device arranged along the extending direction of the delivery mechanism, wherein, the polishing device comprises a swing grinding bench device and a grinding head device arranged on the swing grinding bench device, and a cooling system is arranged on the grinding head device. The glaze surface glazing machine is utilized for the glaze polishing on the basis of fine polishing of a fine polishing machine. The cutting marks are eliminated to the largest extent, and the surface glossiness required by the market is reached; the polishing efficiency is high, the polishing surface is wide, the surface quality of the ceramic tile product can be effectively improved, therefore, the requirement of consumers on high quality tiles can be met.

Owner:KEDA INDUSTRIAL GROUP CO LTD

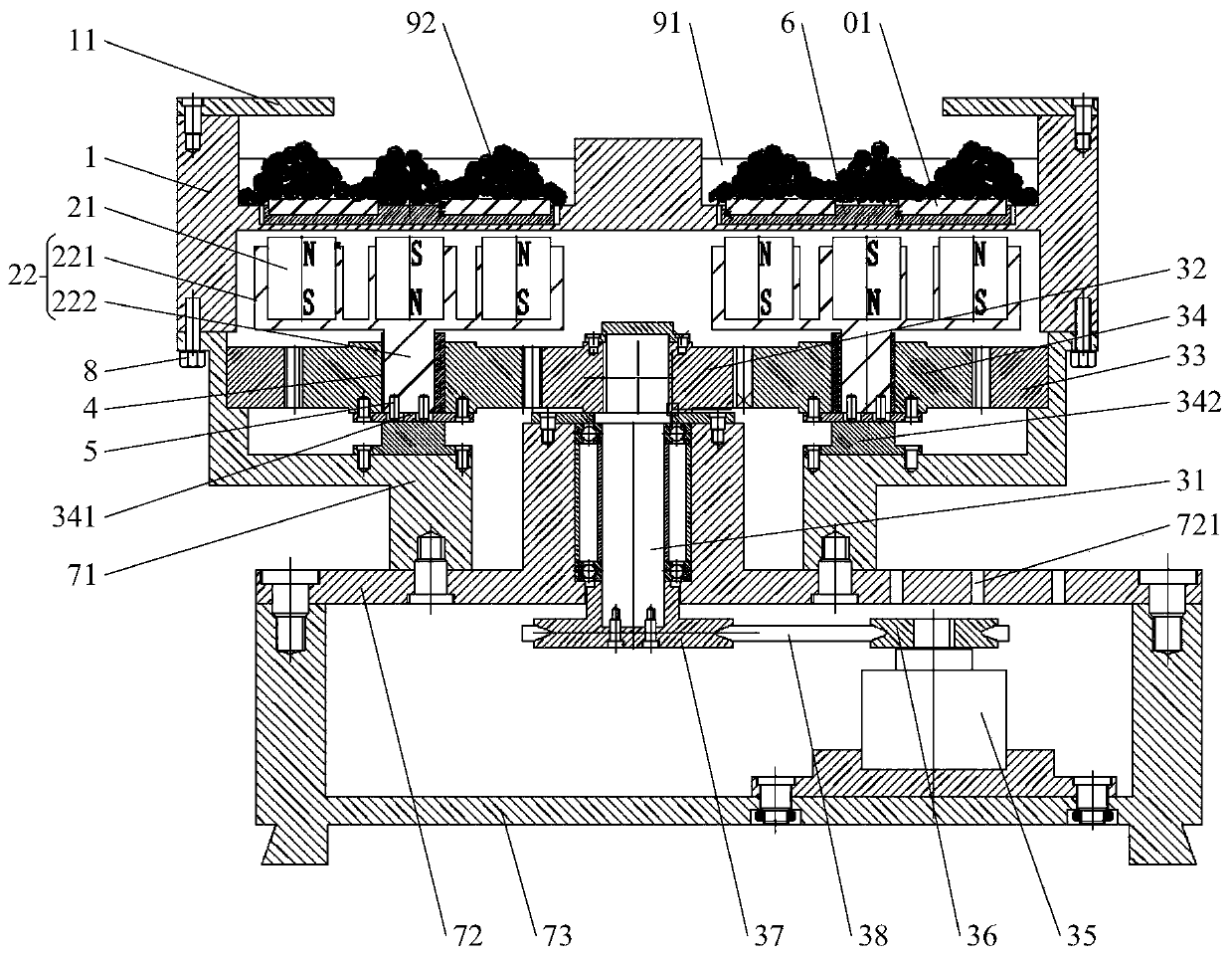

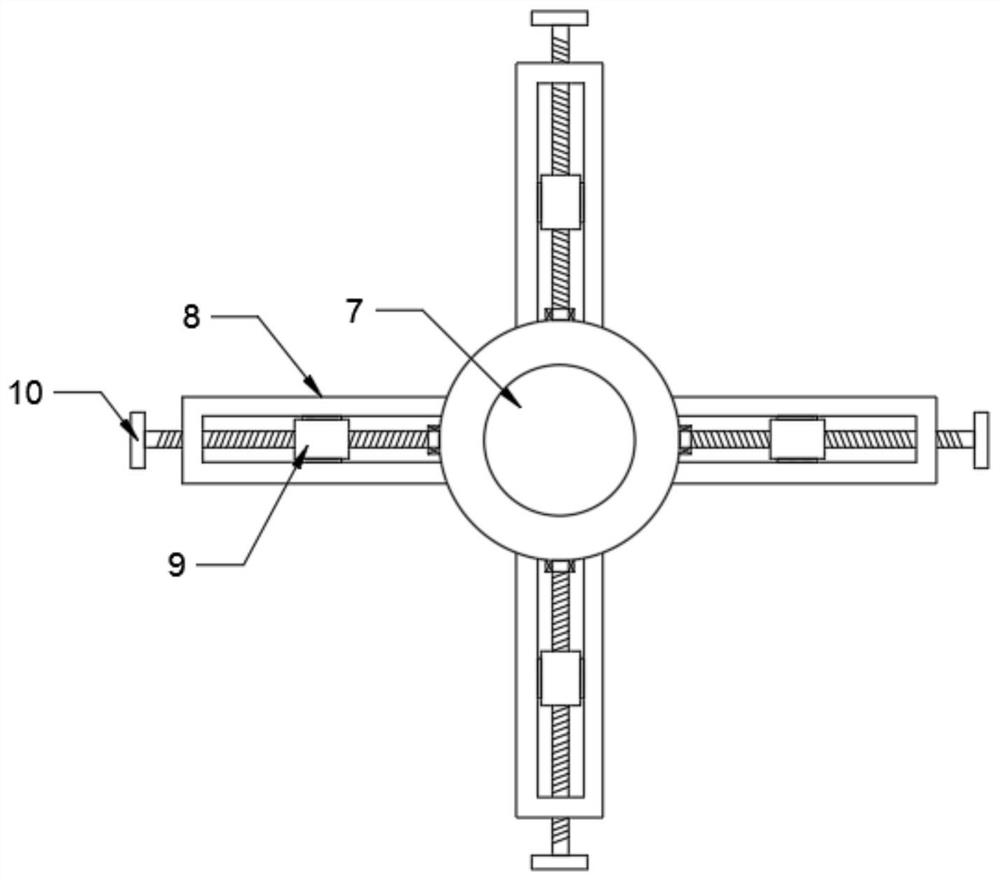

Cluster magneto-rheological grinding and polishing device and use method thereof

PendingCN110281085AIncrease the number ofSimple structureGrinding carriagesGrinding drivesMagnetic currentMagnetic poles

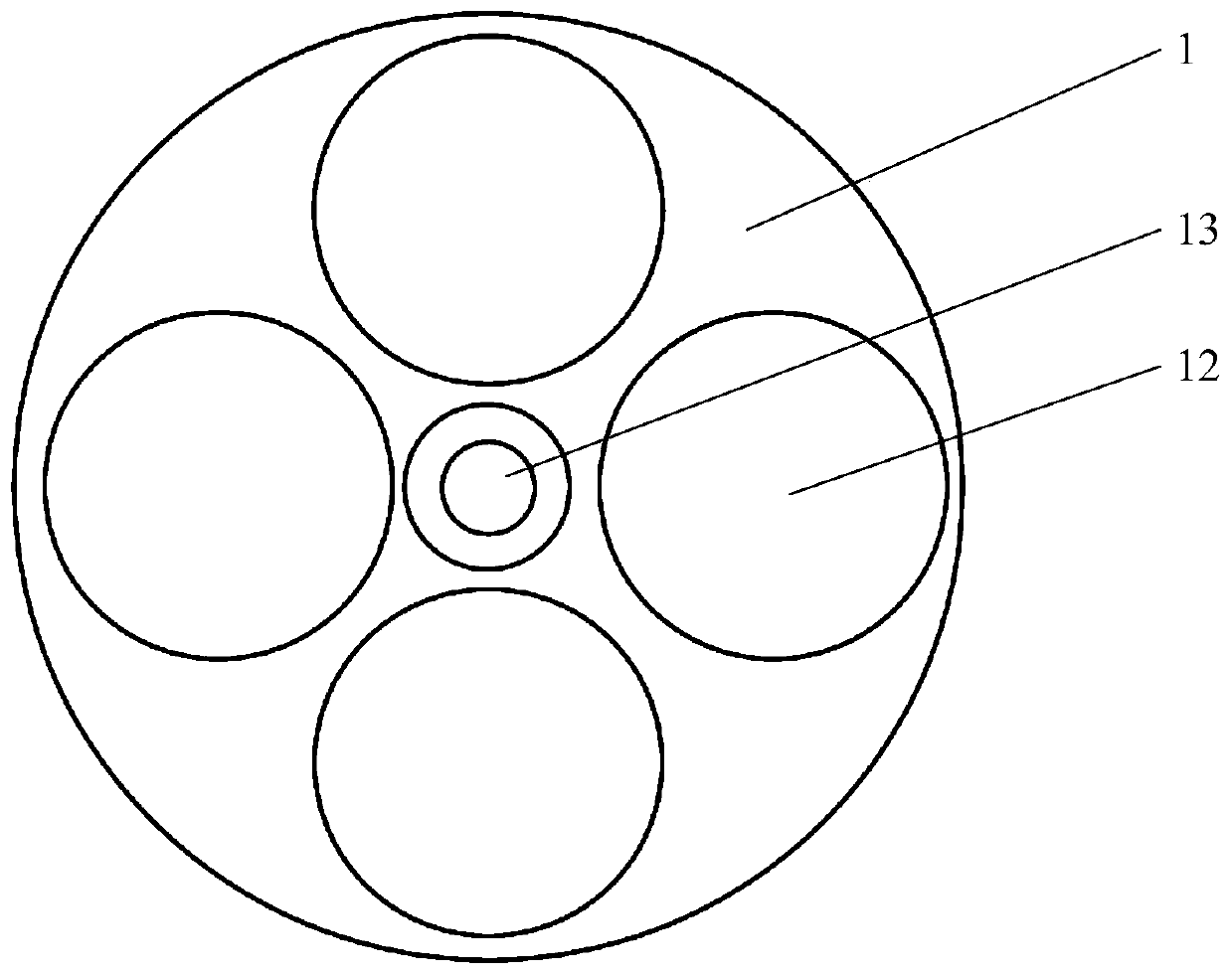

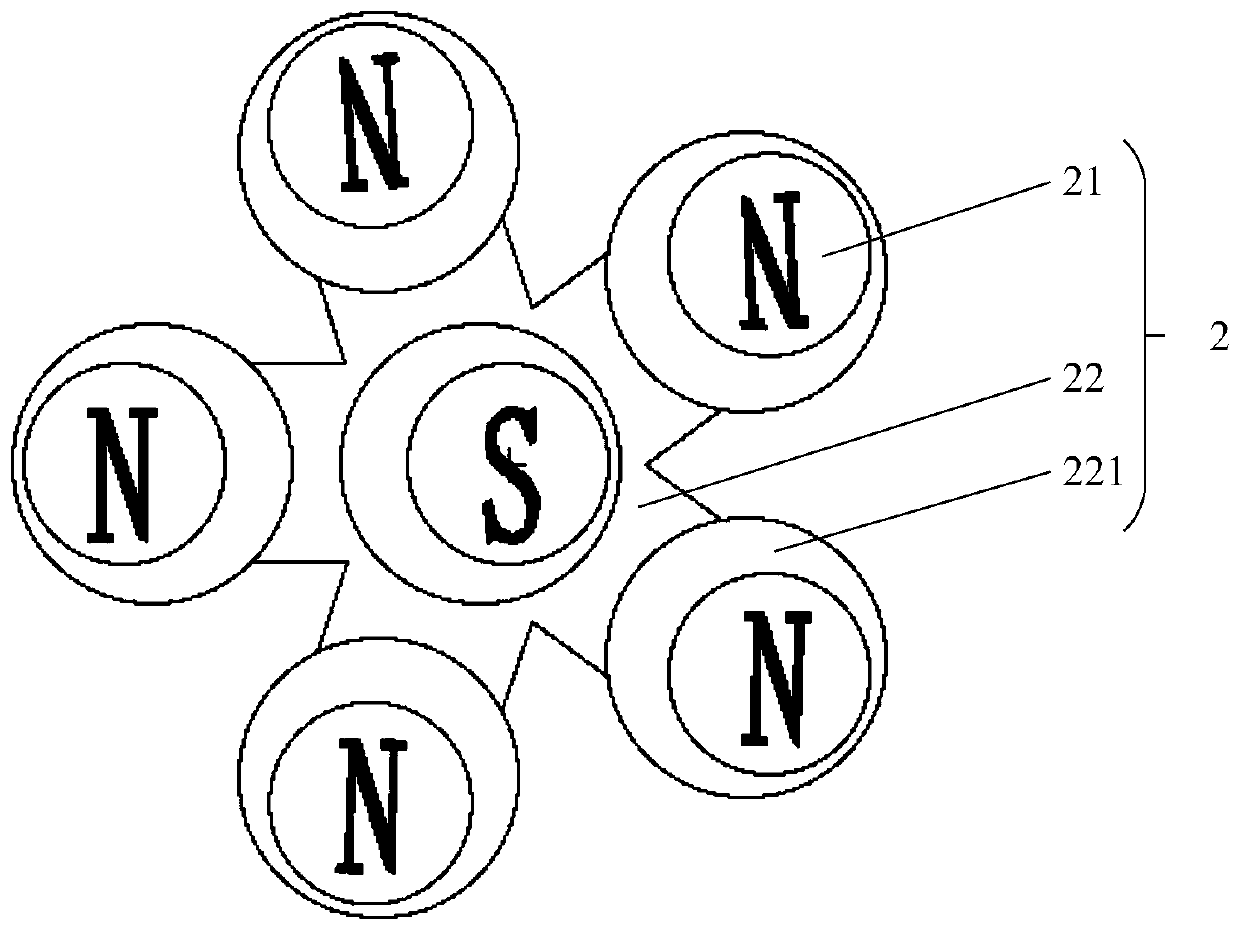

The invention discloses a cluster magneto-rheological grinding and polishing device. The cluster magneto-rheological grinding and polishing device comprises a polishing disc, at least one magnet assembly arranged below the polishing disc, a magnetic pole drive device and a supporting device. At least one groove is formed in the bottom face of the polishing disc, polishing adsorption pads are arranged in the grooves, and each polishing adsorption pad is provided with at least one workpiece bearing groove. A cavity for containing magneto-rheological polishing liquid is formed by the side wall and the bottom face of the polishing disc. Abrasive materials of the magneto-rheological polishing liquid comprise nano abrasive material particles, a binding agent and micro magnetic particles, and the nano abrasive material particles wrap the outer surfaces of the micro magnetic particles under the effect of the binding agent. Each magnet assembly comprises at least two magnets arranged according to a preset rule, so that a flexible polishing pad formed by the magneto-rheological polishing liquid completely covers the surfaces of workpieces. The magnetic pole drive device is connected with the magnet assemblies and used for driving the magnet assemblies to carry out auto-rotation and revolution. The polishing disc is arranged on the supporting device in a height-adjustable manner. The invention further discloses a use method of the cluster magneto-rheological grinding and polishing device.

Owner:GUANGDONG UNIV OF TECH

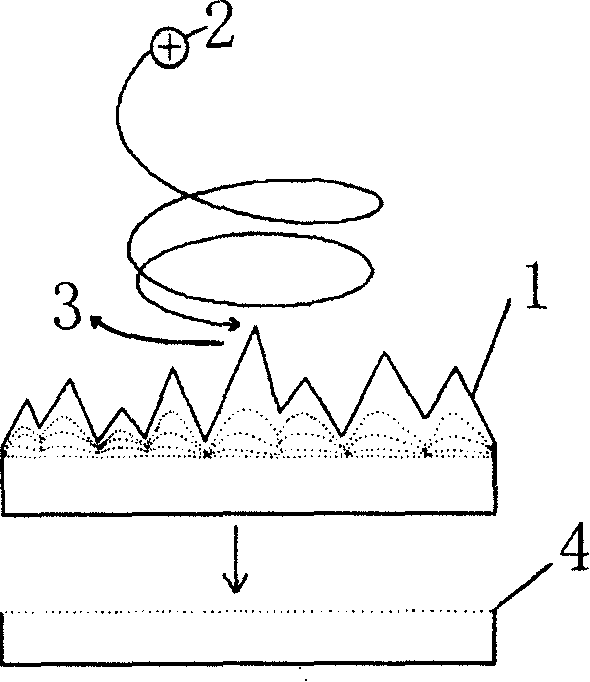

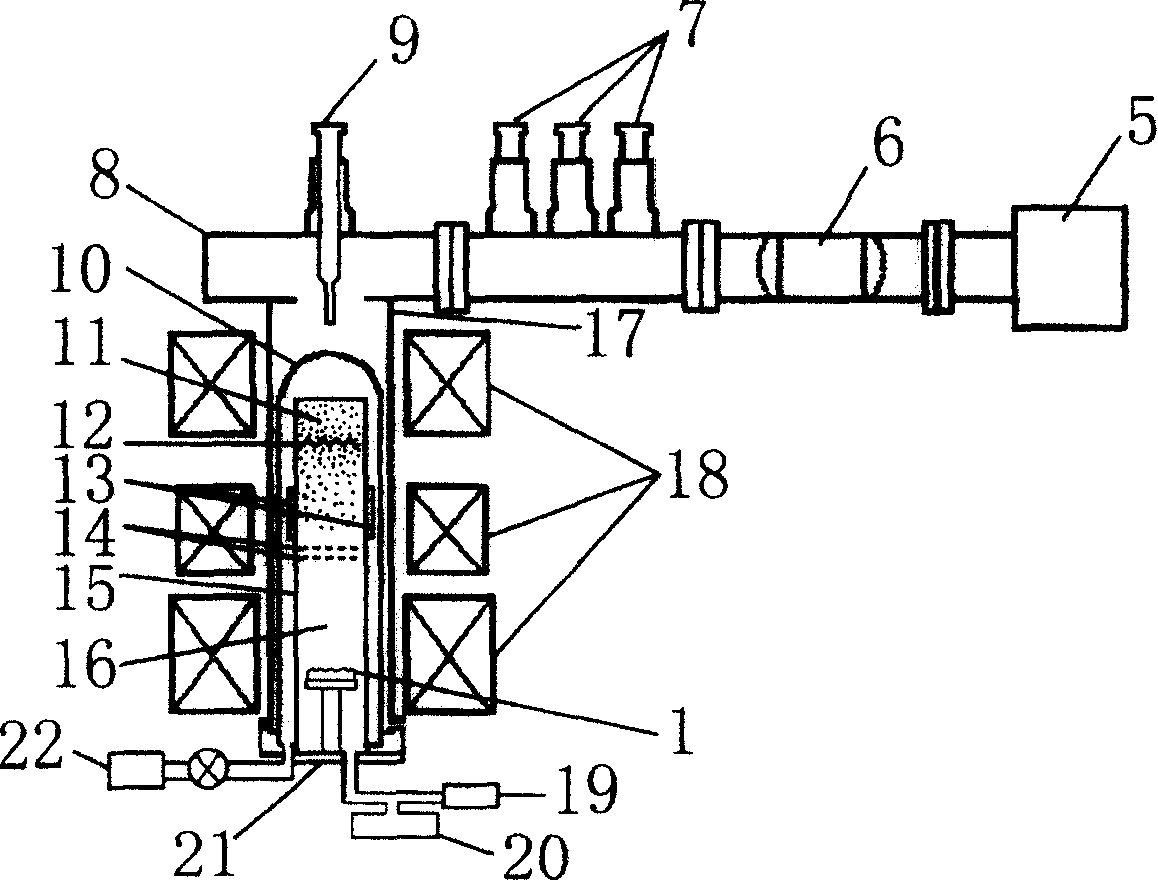

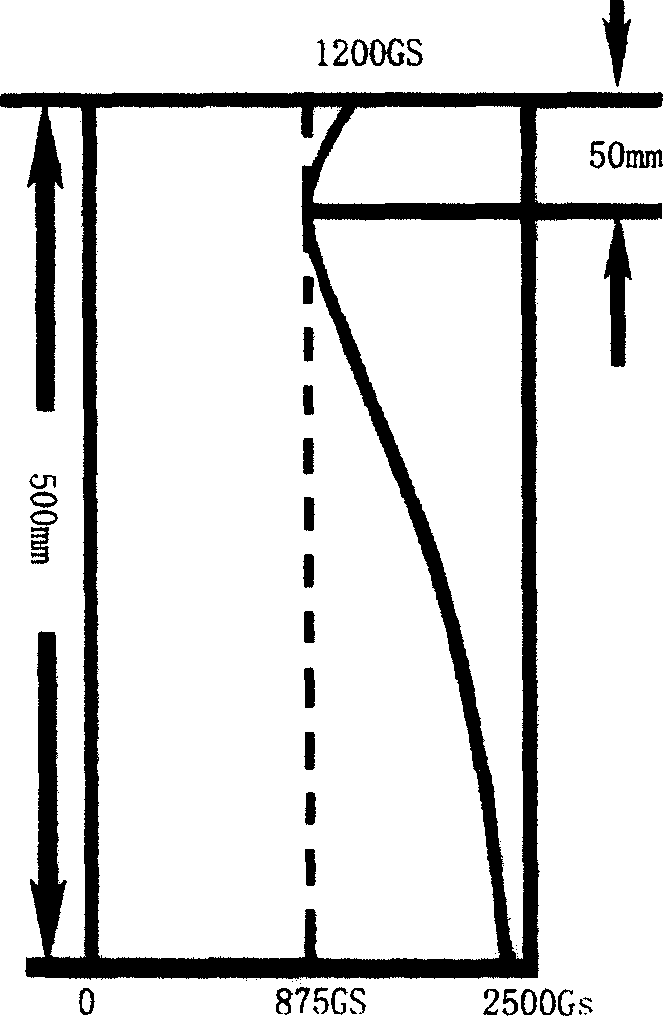

Method and apparatus for polishing large-scale diamond membrane

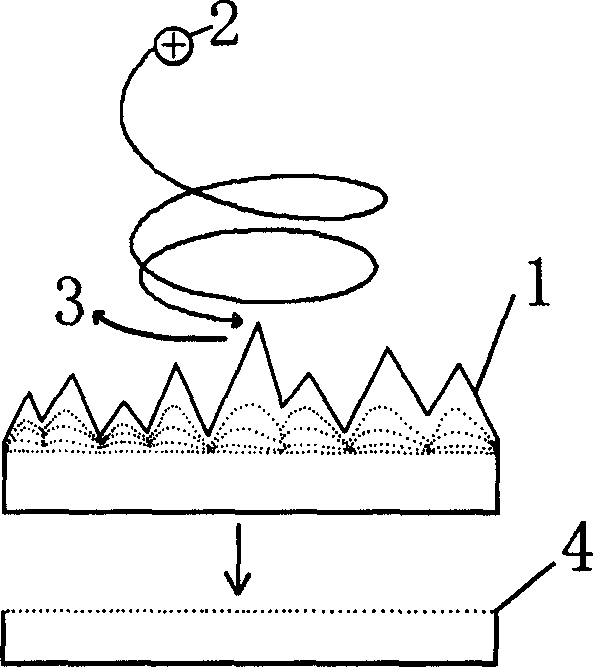

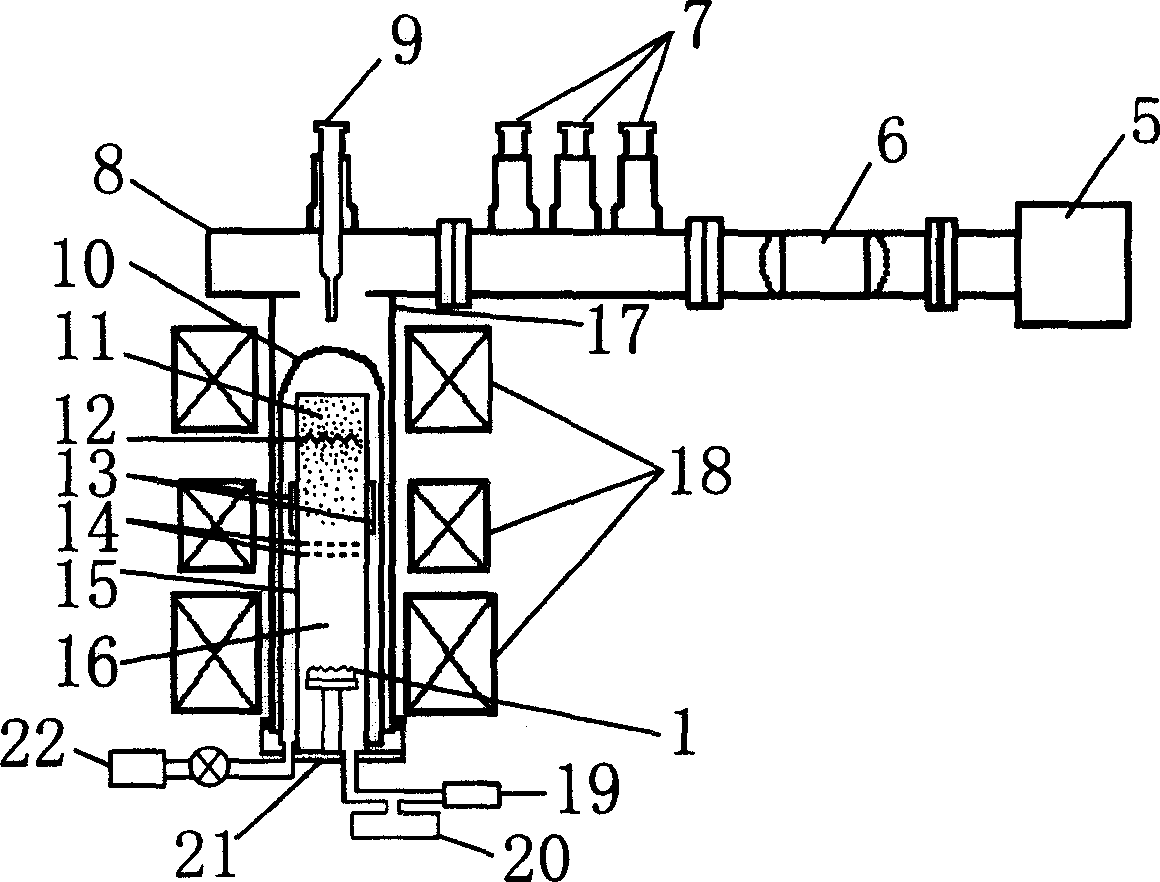

InactiveCN1779001AImprove polishing efficiencyIncrease the polishing areaAfter-treatment detailsPlasma techniqueChemistryMovement control

A method and an equipment for extended diamond film polishing. It includes such steps as follows: produce electron cyclotron resonance plasm by microwave stimulatingú”high-frequency power was coupled to ion in plasm by ion convoluted vibratingú¼so that the kintic temperature of ion was increased to 10í½40eV; control ion movement by derivative electrode and graded magnetic field so that etching reaction may occur between specific carbon atom that to be wiped off and the ion as the ion moves to the surface of diamond filmú”Volatile gas generated and polishing completed. The equipment consists of four partsú‘plasma generating unitú¼ion heating up unitú¼ion movement controlling unit and etching reaction and polishing unit. Advantages are high polishing efficiencyú¼large polishing dimensionú¼high precision and non pollution of diamond film surface.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

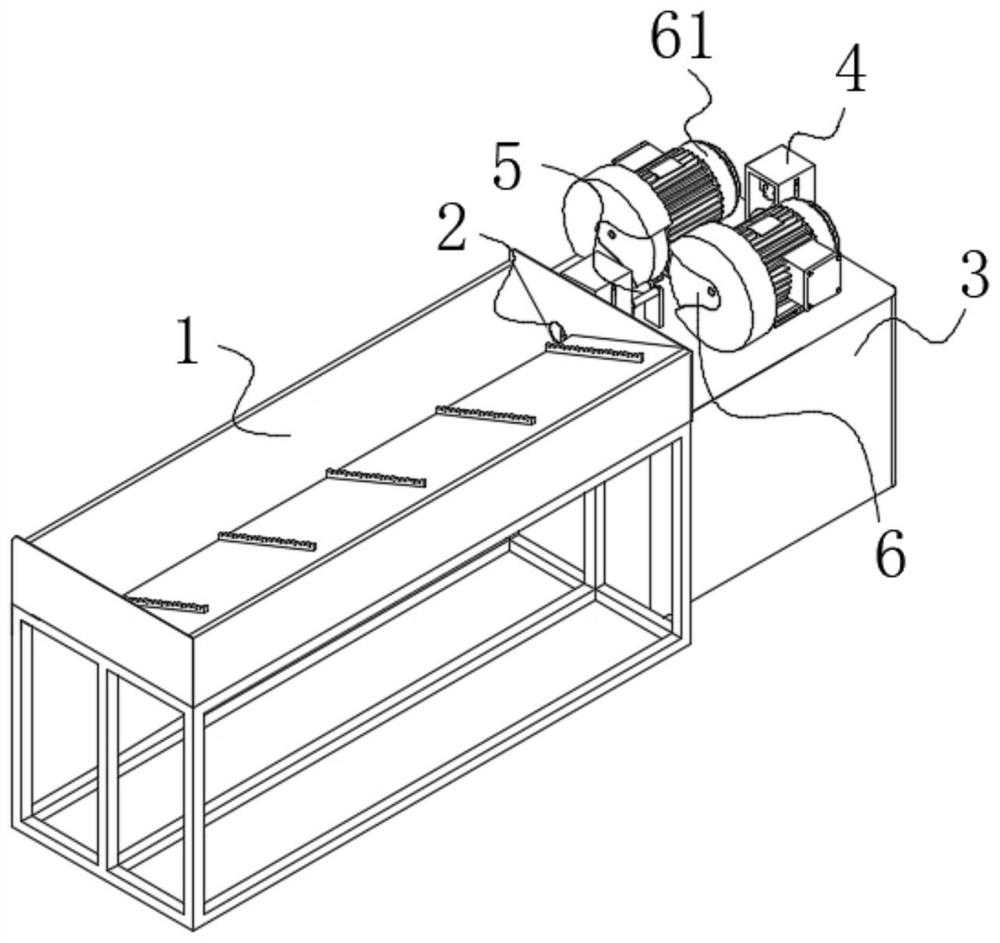

Belt polishing machine

InactiveCN104175195APolished evenlyImprove work efficiencyBelt grinding machinesDrive wheelEngineering

The invention provides a belt polishing machine, and belongs to the mechanical field of polishing machines. The belt polishing machine comprises a bracket, wherein a conveying device is arranged on the horizontal surface of the bracket, and driving devices and polishing devices are arranged on the vertical surface; the conveying device comprises a driving roller, a driven roller and a conveying belt, the driving roller and the driven roller are arranged on the horizontal surface of the bracket, and the conveying belt is arranged between the driving roller and the driven roller and performs stepping type circulating motion; each driving device comprises a driving wheel, a driven wheel and a driving belt, the driving wheel and the driven wheel are fixed on the vertical surface of the bracket, and the driving belt is arranged between the driving wheel and the driven wheel; and each polishing device comprises a polishing driving wheel, a polishing driven wheel and a polishing abrasive belt, the polishing driving wheel is connected with the polishing driven wheel which is fixed on the vertical surface of the bracket, and the polishing abrasive belt is arranged between the polishing driving wheel and the polishing driven wheel. The belt polishing machine has the advantages of high polishing work efficiency, good polishing effect, low reworking rate and convenience in replacement of the driving belt and the polishing abrasive belt.

Owner:TIANJIN JINGLUN COPPER PROD

Process for flattening diamond film by utilizing compound diamond-like carbon (DLC) film

InactiveCN101935825AEliminate shortcomingsQuality improvementChemical vapor deposition coatingDiamond-like carbonSurface roughness

The invention relates to a process for flattening a diamond film by utilizing a compound diamond-like carbon (DLC) film. The process comprises the following steps of: (1) preparing a diamond film by adopting a conventional deposition process, wherein a silicon wafer of which one side is polished is used as a substrate; (2) depositing a DLC film on the silicon wafer deposited with the diamond film by adopting a chemical vapor deposition method; and (3) flattening the DLC film by adopting a chemical and mechanical polishing method so as to obtain a highly flattened diamond film. The preparation method has the advantages of simplicity, low removal quantity, small surface hardness, high polishing efficiency, and the like, overcomes the defects of various removal type polishing processes, increases the polishing area and improves the film quality; the grinding material of non-diamond powder is adopted, thus the cost can be greatly reduced; proved by experiments, the diamond film of which the surface roughness Ra is smaller than 1.5nm can be obtained at high efficiency with original properties unchanged.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

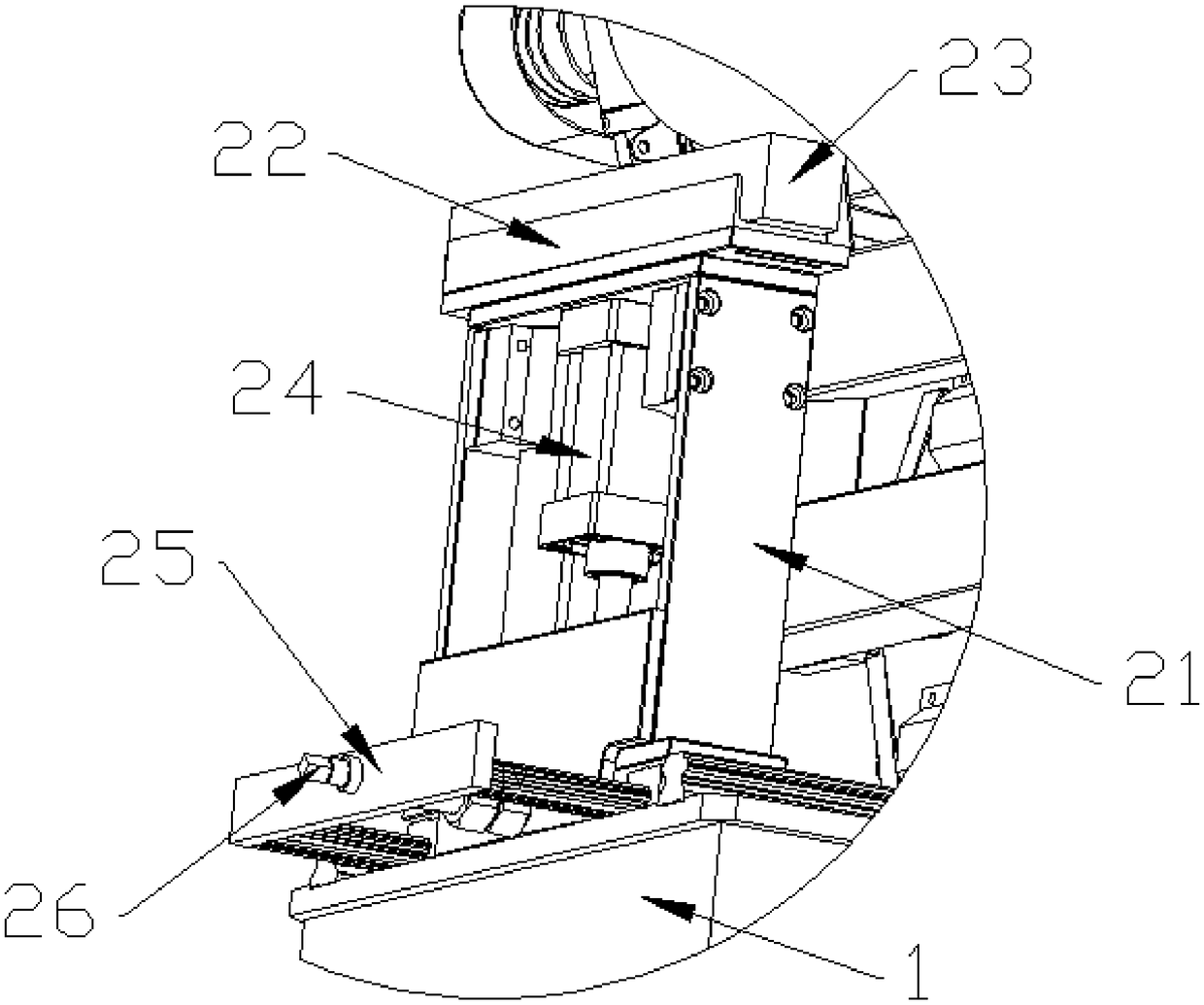

Automatic polishing machine adaptable to curved surfaces

InactiveCN111136563AImprove clamping effectHigh degree of automationGrinding carriagesPolishing machinesPolishingEngineering

The invention discloses an automatic polishing machine adaptable to curved surfaces. The automatic polishing machine comprises a base, a supporting body and a polishing body; a first moving cavity anda power cavity which have upward openings are formed in the base; the first moving cavity is located on the left side of the power cavity; the supporting body is arranged on the bottom wall of the first moving cavity in a leftwards-and-rightwards sliding manner; the polishing body is arranged on the bottom wall of the power cavity in a leftwards-and-rightwards sliding manner; and a chuck is rotationally arranged on the right side surface of the supporting body. According to the automatic polishing machine, curved surface positions of objects can be polished under the elastic action through driving control reverse pressurization, the automation degree is high, the polishing effect is remarkably improved, the problems of curvature failures or damage to the curved surfaces due to manual polishing of the curved surfaces are reduced effectively, meanwhile, the clamping effect of the objects having the curved surfaces can be enhanced through rotating clamping, and the objects having the curved surfaces cannot fall due to polishing.

Owner:PUJIANG YIYAN MASCH EQUIP CO LTD

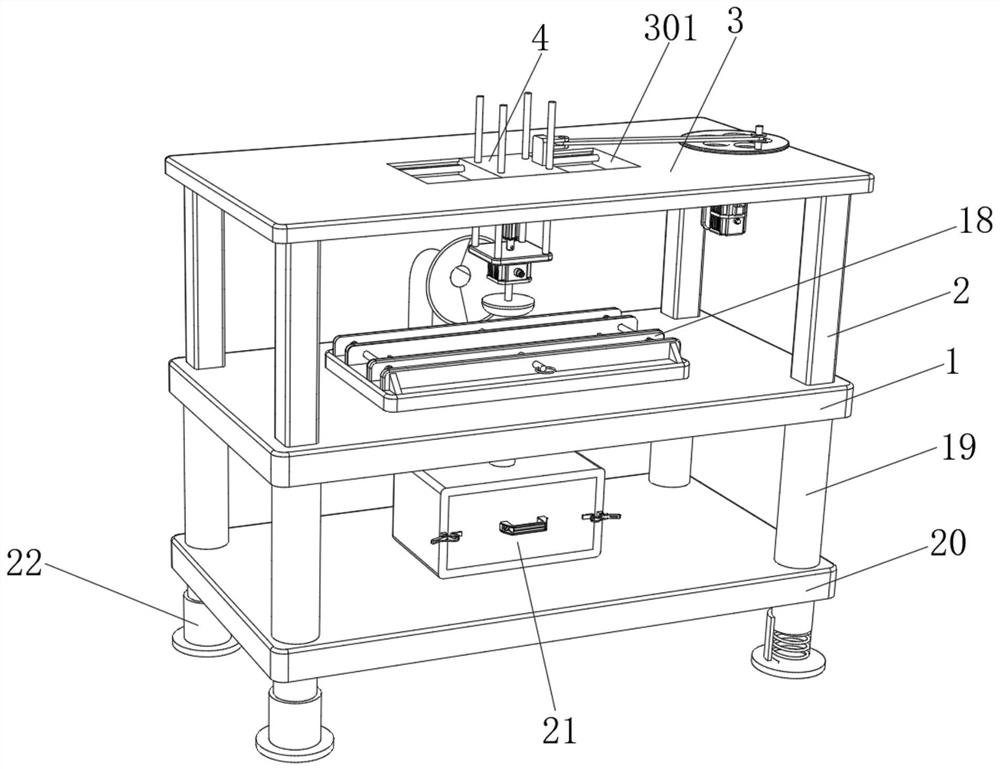

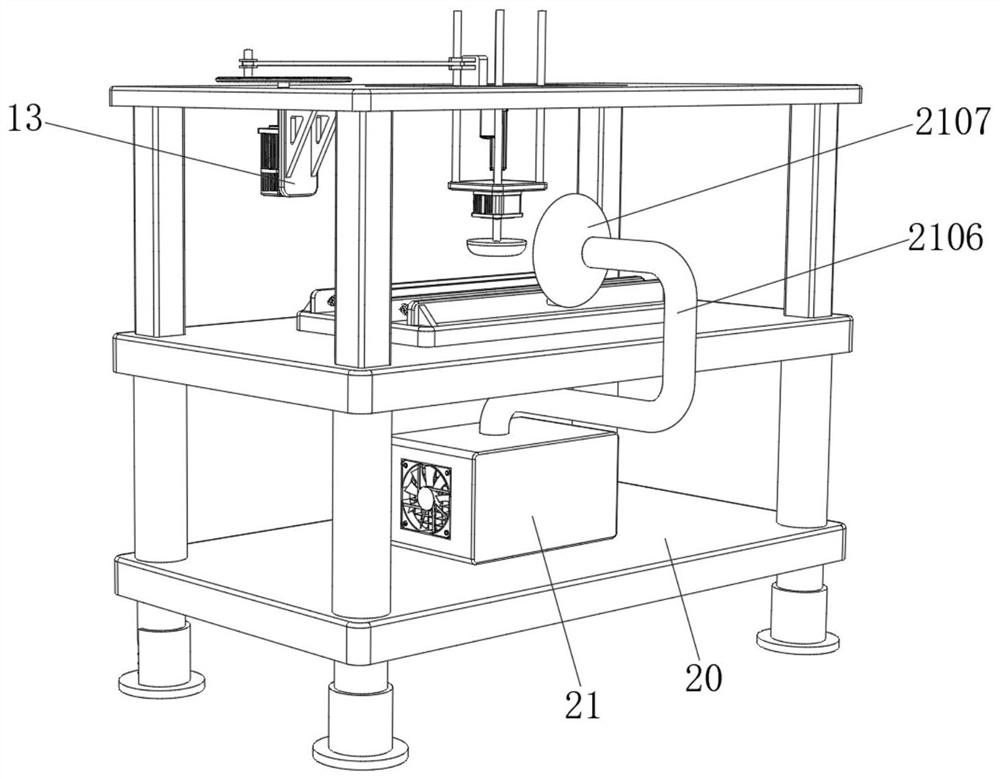

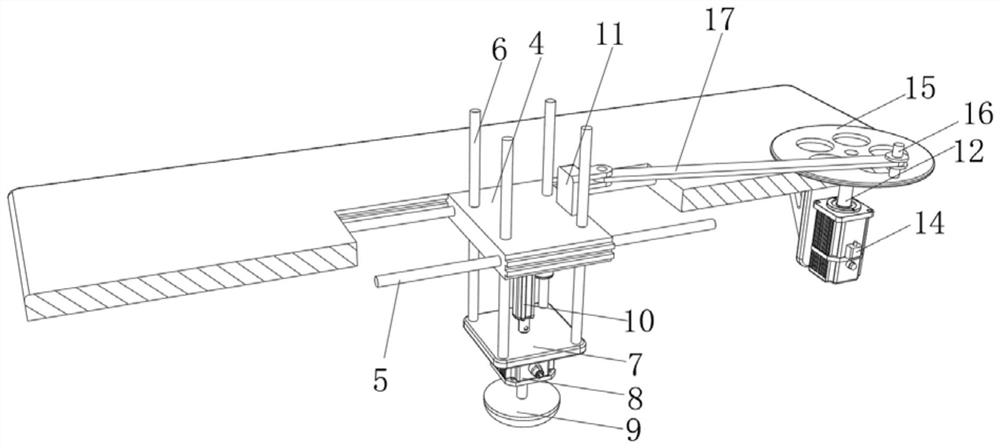

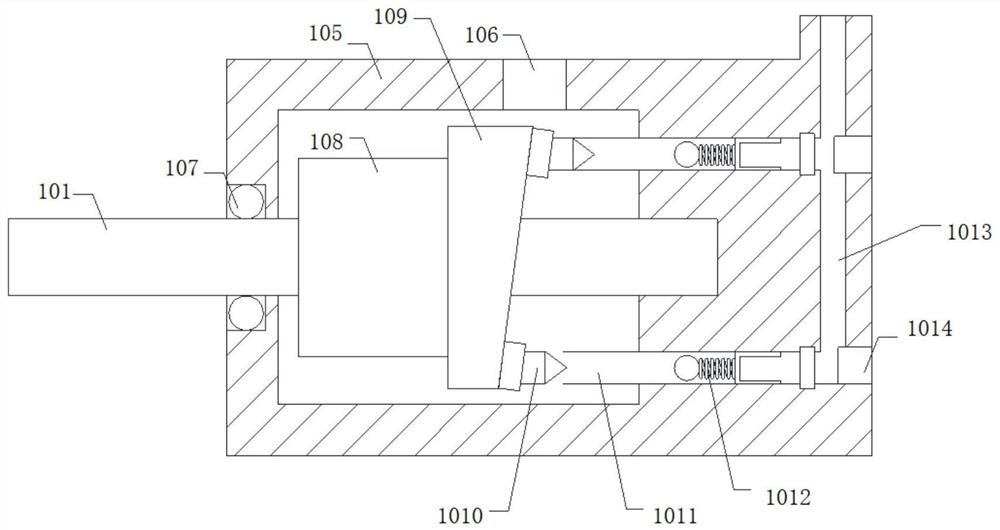

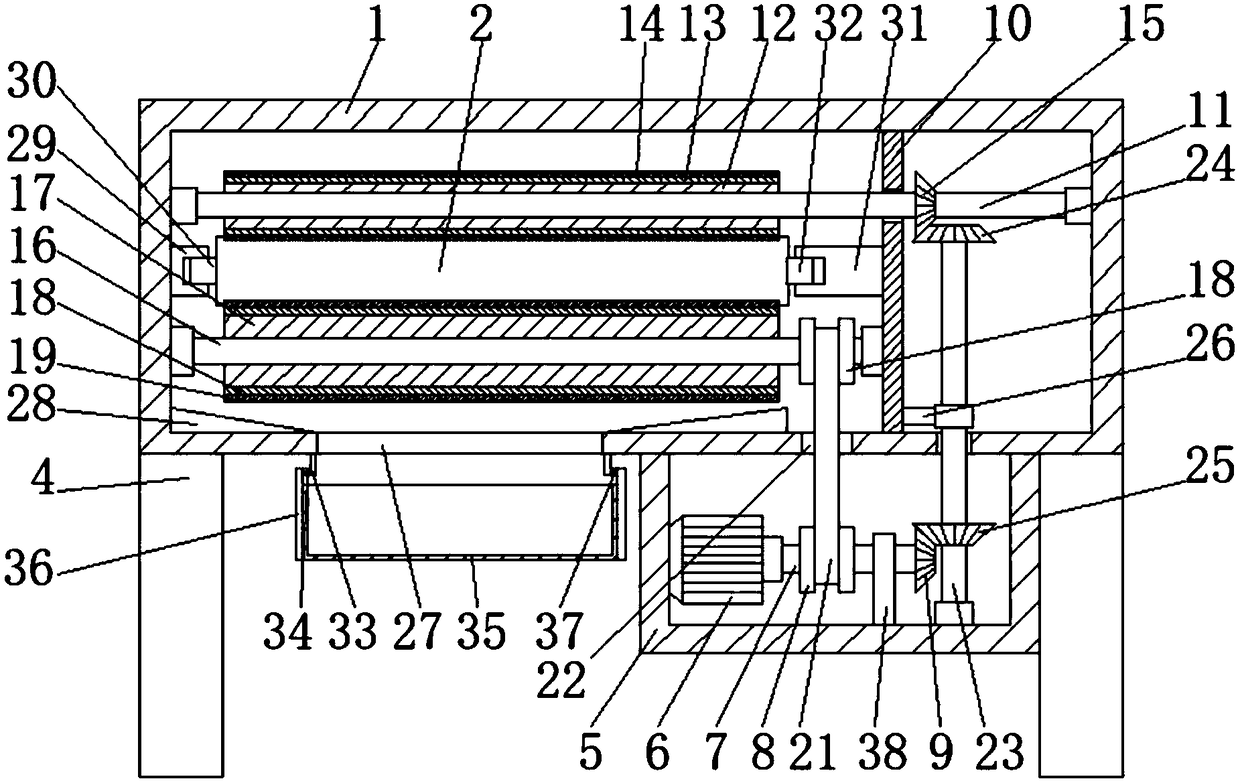

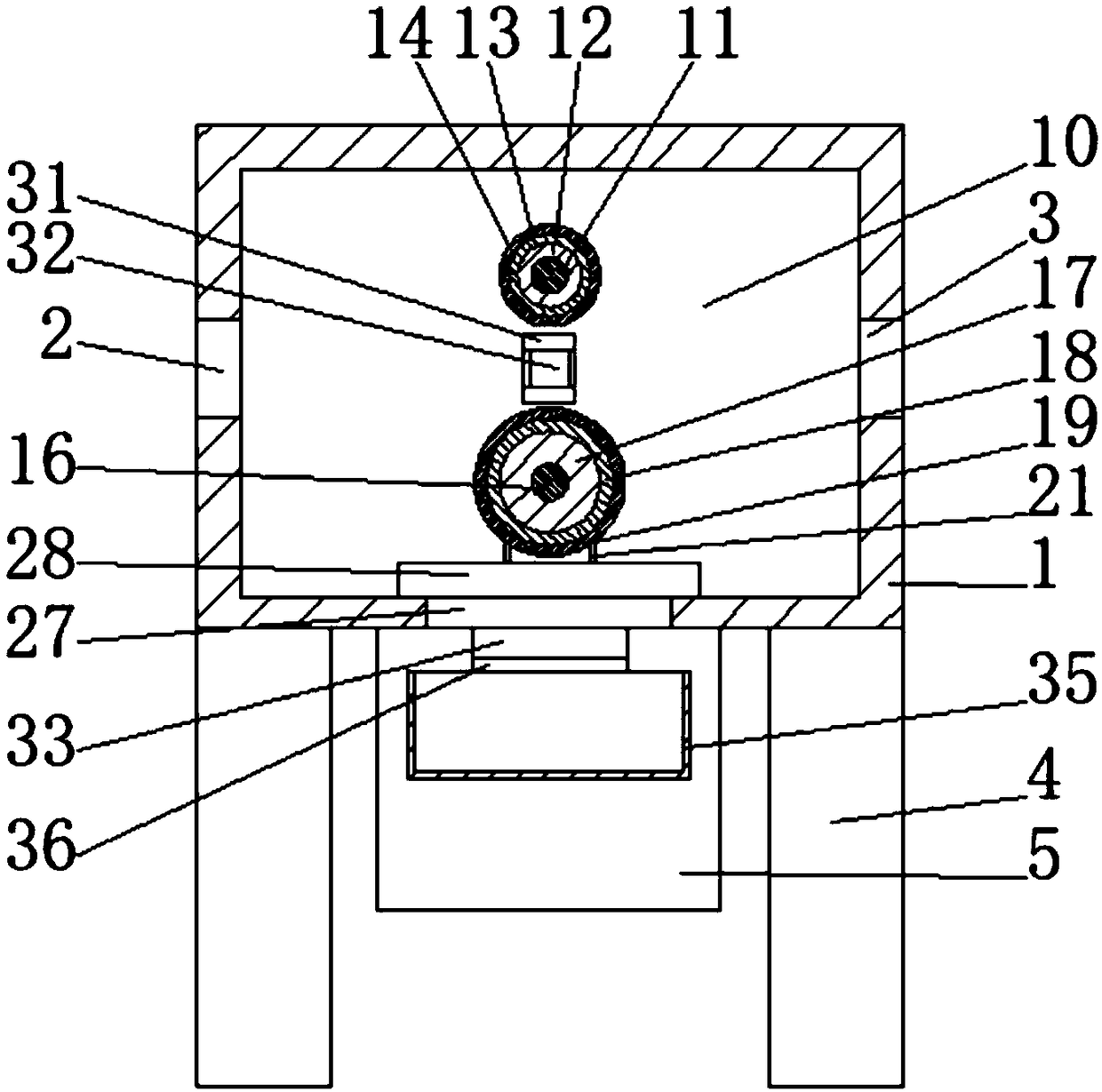

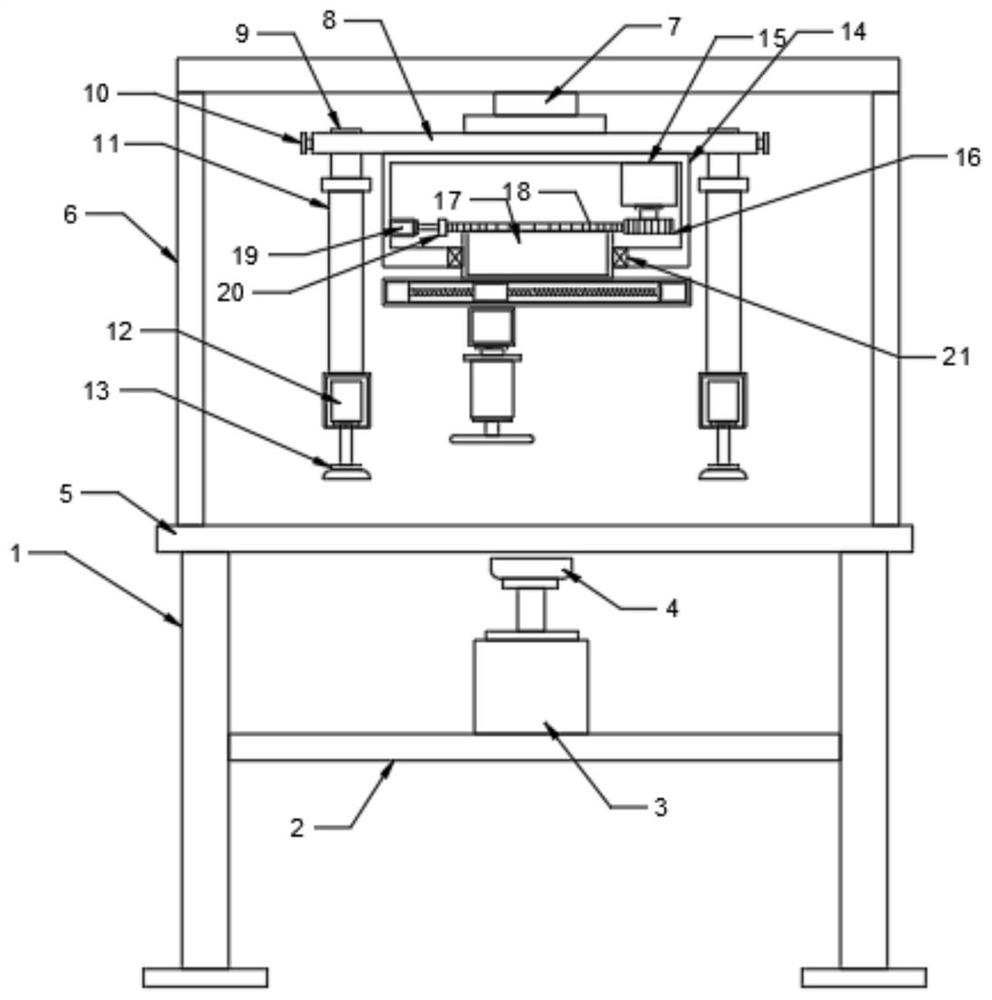

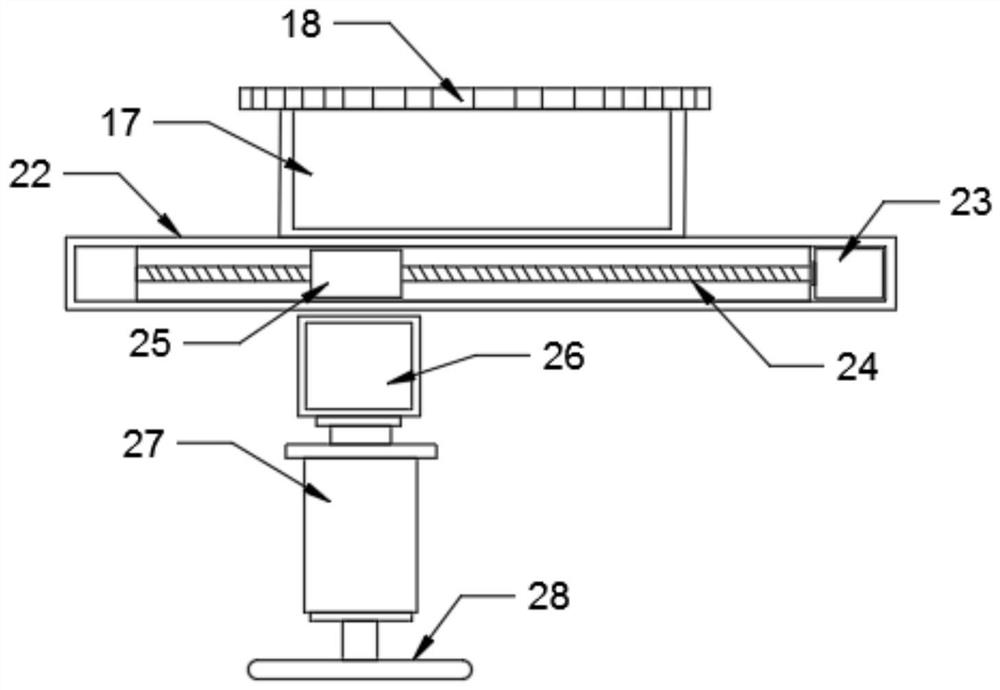

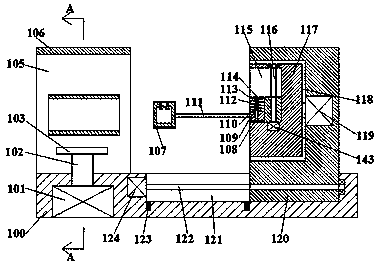

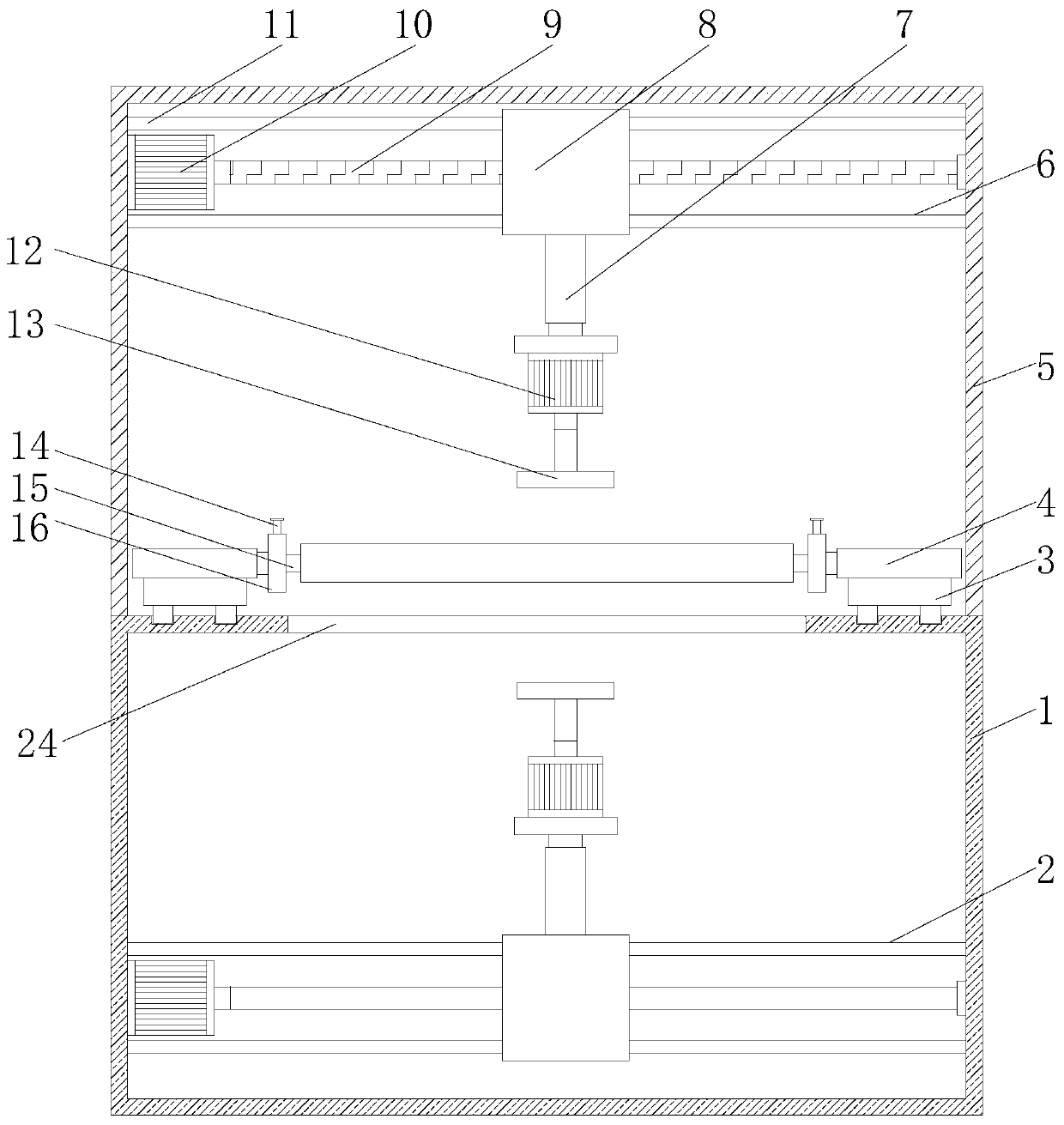

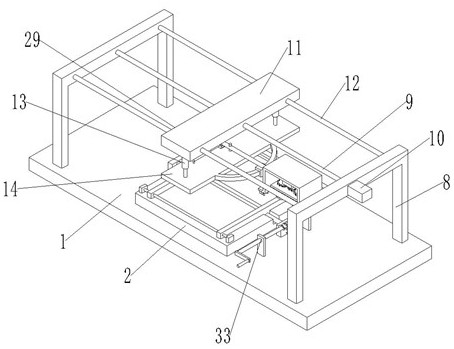

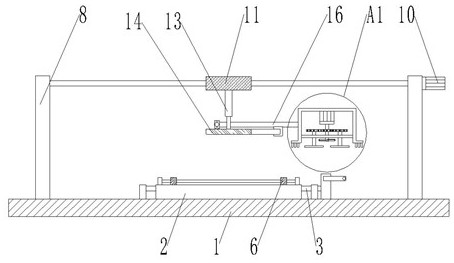

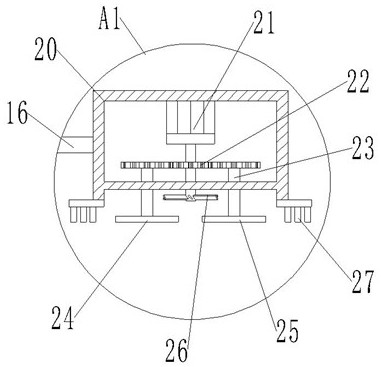

Polishing device for semiconductor preparation

ActiveCN112123171AIncrease the polishing areaImprove work efficiencyPolishing machinesDispersed particle filtrationCrankElectric machinery

The invention relates to the technical field of semiconductor processing equipment, and discloses a polishing device for semiconductor preparation. The polishing device comprises a workbench; first stand columns are fixedly connected to the four corners of the upper surface of the workbench; a top plate is fixedly connected to the upper surfaces of the first stand columns; a sliding groove is formed in the middle of the upper surface of the top plate; a sliding platform is glidingly connected to the inner wall of the sliding groove; and sliding rods are inserted in the front side and the backside of the right side surface of the sliding platform. According to the polishing device for semiconductor preparation, a second driving motor, a rotating shaft, a rotating disc, a crank, a connecting plate and the sliding platform are used in cooperation, the second driving motor drives the rotating disc to rotate through the rotating shaft, and the rotating disc drives the sliding table to moveleftwards and rightwards through the crank, so that the polishing area of the device for semiconductor products is further increased, the device can be used for polishing relatively-long semiconductor products, and the working efficiency of the device is further improved.

Owner:JIANGSU ETERN +2

Preparation method of chemical material slurry plunger pump with composite coating, and product thereof

ActiveCN111826602AImprove corrosion resistanceReduce stress shockMolten spray coatingPolishing machinesOrganic solventSand blasting

The invention relates to the technical field of a plunger pump, and particularly relates to a preparation method of a chemical material slurry plunger pump with composite coating, and a product thereof. The preparation method comprises the following preparation steps: performing undercutting for a part where coating of a plunger base body is, thereby reserving 0.25-0.35mm coating thickness, chamfering 40-50 degrees for a connection part between a coating edge and the base body; executing organic solvent degreasing and baking for the base body; then, performing sand blasting, using a clamp forprotecting a non-coating area; preheating the base body to 90-110 DEG C, spraying a nickel chrome bottom layer coating, wherein spraying current is 350-450A, voltage is 35-40V, and coating thickness is 0.08-0.12mm; spraying a chromic oxide coating, wherein spraying current is 500-600A, voltage is 40-50V, and coating thickness is 0.2-0.4mm; performing vacuum impregnation hole sealing, wherein impregnation time is 10-20 minutes, heating curing is executed after surface drying, and curing time is 1.5-2.5 hours; and using a grinding machine to perform grinding processing for the plunger, wherein grinding processing comprises three working procedures including coarse grinding, fine grinding and polishing. The chemical material slurry plunger pump with composite coating, prepared by the method of the invention has high corrosion resistance and abrasion resistance.

Owner:德清创智科技股份有限公司

Board polishing device for furniture production

InactiveCN109590864AStay tightIncrease the polishing areaBelt grinding machinesEngineeringMechanical engineering

The invention relates to the field of furniture production, in particular to a board polishing device for furniture production. The board polishing device comprises a housing, a feeding opening, a discharging opening, polishing driving wheels and a polishing belt, wherein the polishing belt is arranged on the two polishing driving wheels in a surrounding manner; a row of pressing wheels which arehorizontally and uniformly arranged are arranged on the polishing belt on the lower side, and are mounted on a horizontal lower supporting frame through a rotating shaft; supporting rods which vertically penetrates upwards through a bracket are fixedly connected to two ends of the lower supporting frame; the upper ends of the supporting rods are fixedly connected with a horizontal crossbeam; a horizontal conveying mechanism is horizontally arranged in the feeding opening; and the boards are placed on the mechanism. According to the board polishing device disclosed by the invention, the pressing wheels are arranged, so that the polishing belt is pressed on the board, the polishing region is enlarged, and the polishing efficiency is improved; the boards are pushed on the horizontal conveyingmechanism, and through the block of a pushing plate, the phenomenon of slipping cannot be generated, and the polishing is guaranteed; and a baffle can be recycled, so that the mounting time is shortened, and the production efficiency is improved.

Owner:张玉真

Processing device for polishing bamboo wood

InactiveCN108544345ASolve the problem of small polishing area and low work efficiencyIncrease the polishing areaBelt grinding machinesGrinding/polishing safety devicesEngineeringPulley

The invention discloses a processing device for polishing bamboo wood. The processing device comprises a shell of which the rear side is provided with a feeding port, and the front side of the shell is provided with a discharging port; and four corners of the bottom of the shell are all fixedly connected to support legs, and the right side of the bottom of the shell is fixedly connected to a storage box. According to the processing device, through cooperative application of the shell, the feeding port, the discharging port, the support legs, the storage box, a motor, a rotating rod I, a belt pulley I, a bevel gear I, a partition plate, a rotating rod II, a connecting shaft I, an elastic sleeve I, a polishing abrasive belt I, a bevel gear II, a rotating rod III, a connecting shaft II, a belt pulley II, an elastic sleeve II, a polishing abrasive belt II, a belt, an opening, a rotating rod IV, a bevel gear III, a bevel gear IV and a fixed rod, the problems that an existing table type polishing machine can be used for polishing only one side in one time, the polishing area is small and the working efficiency is low are solved; the processing device has the advantages that the two sidesof a plate can be polished simultaneously, the polishing area is large, the working efficiency is high and the like, and the processing device facilitates people to use.

Owner:安吉铸卫竹木制品有限公司

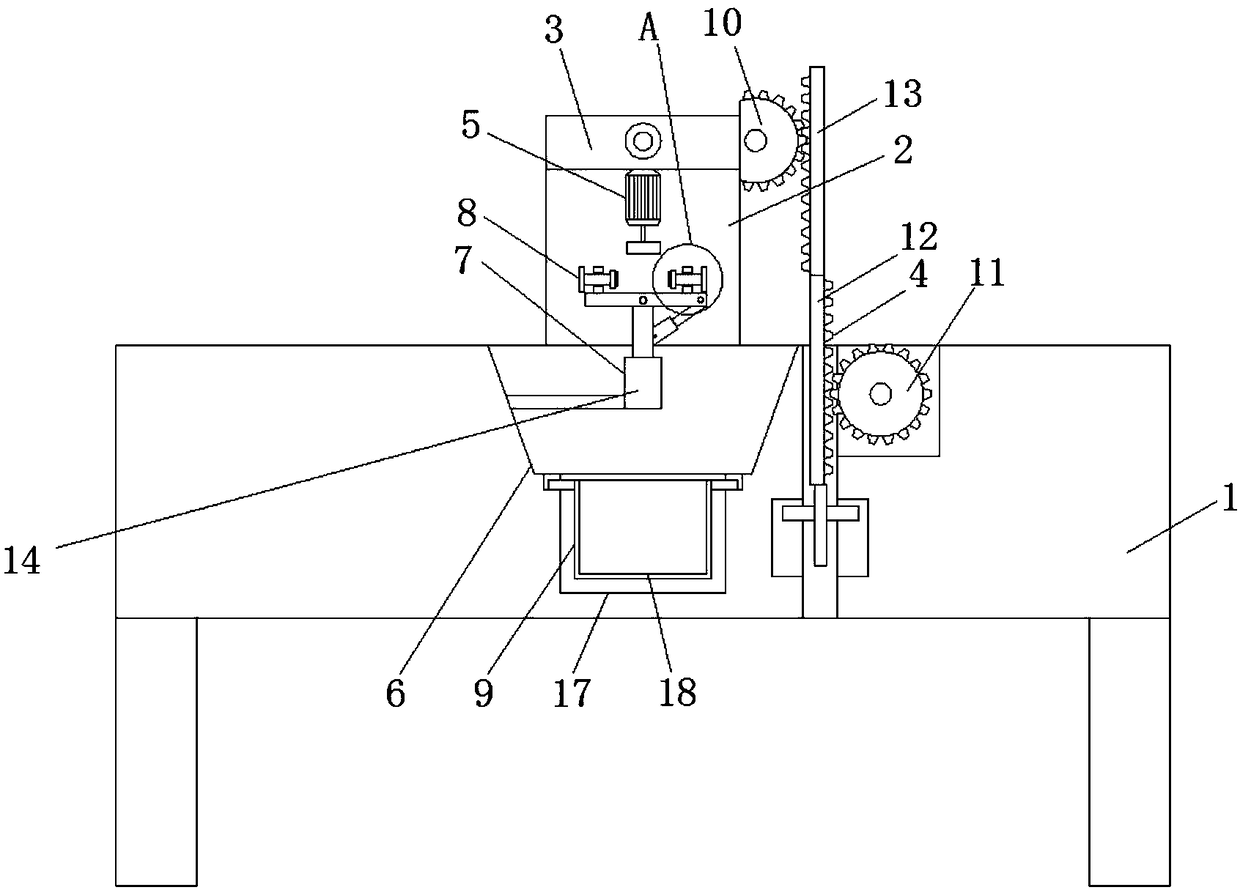

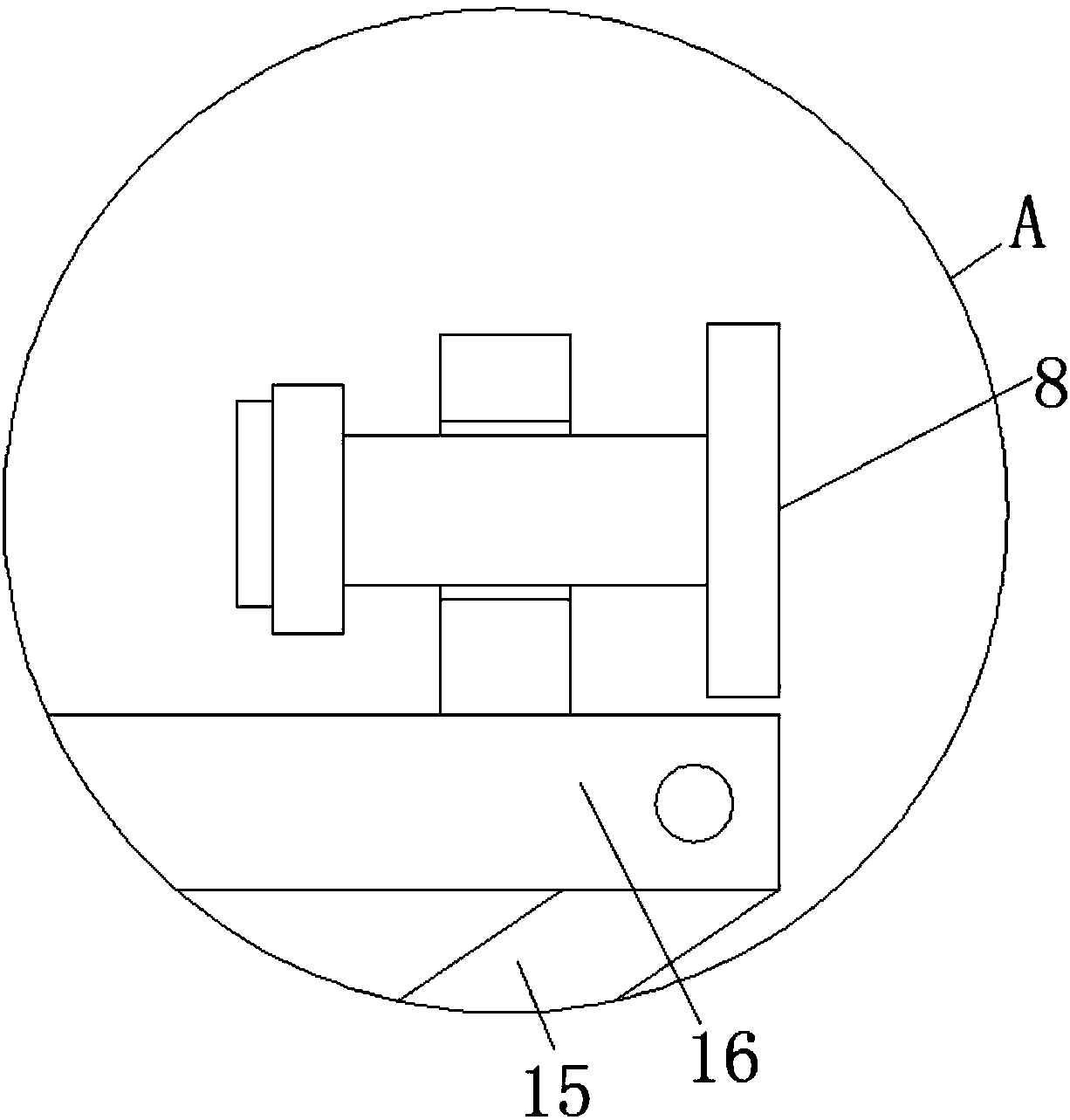

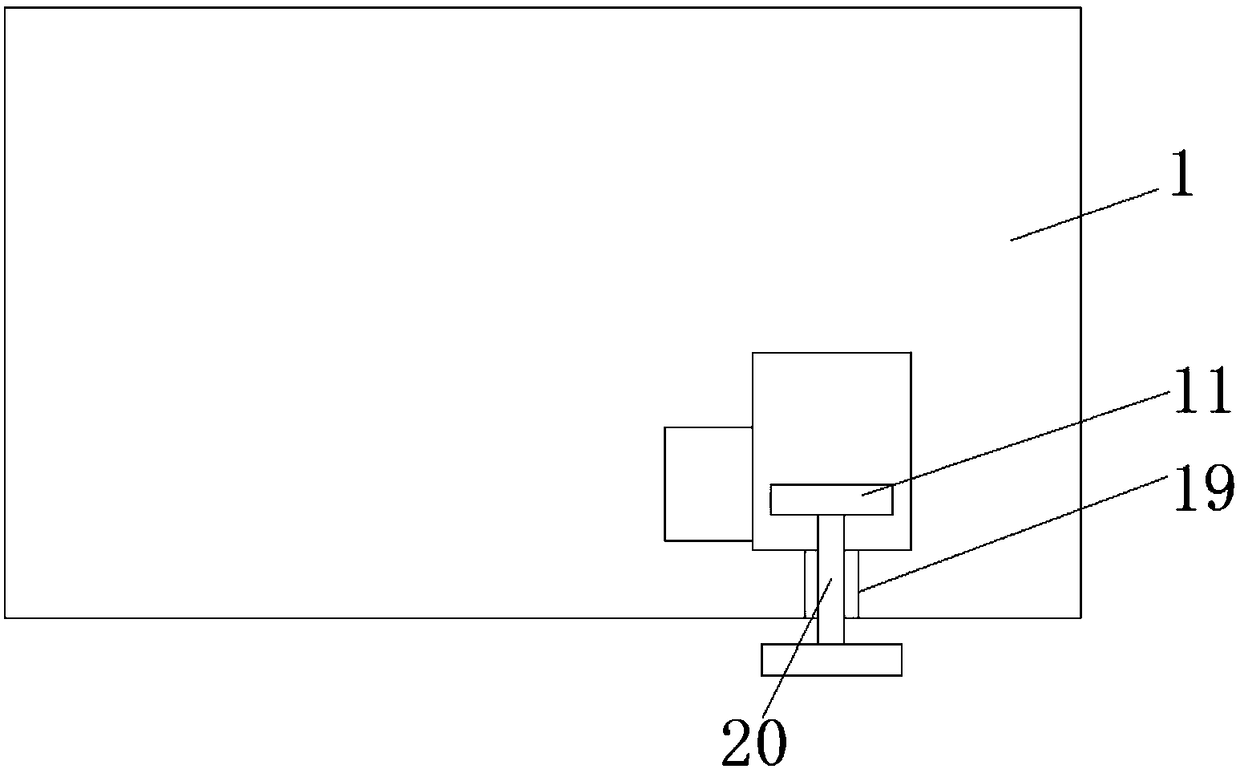

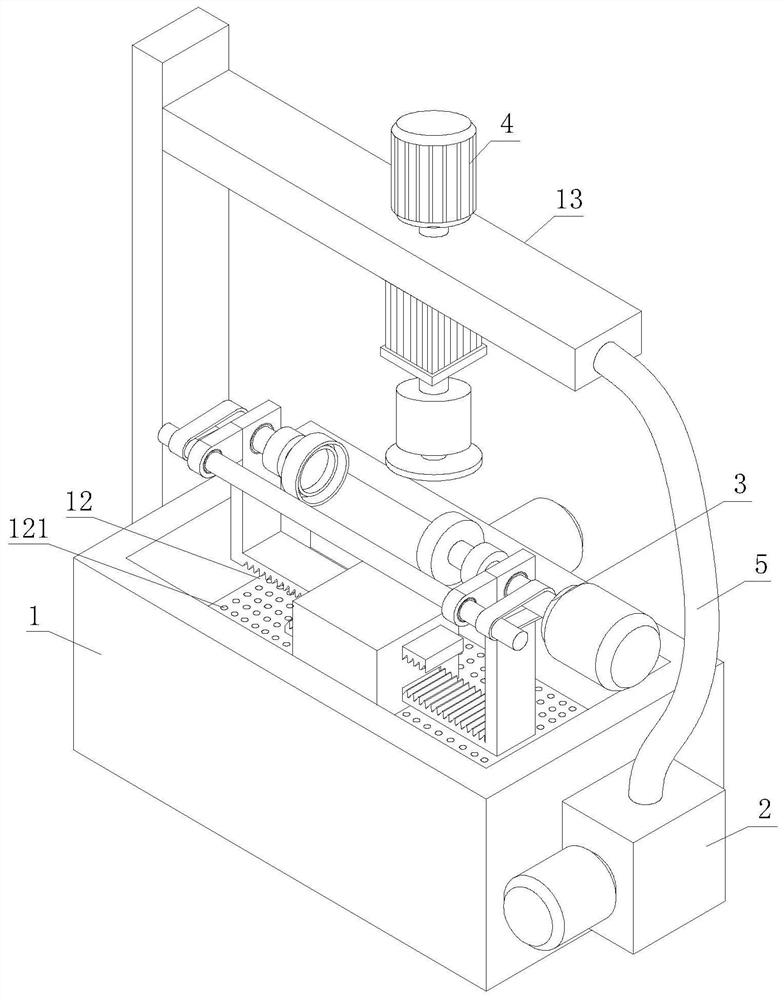

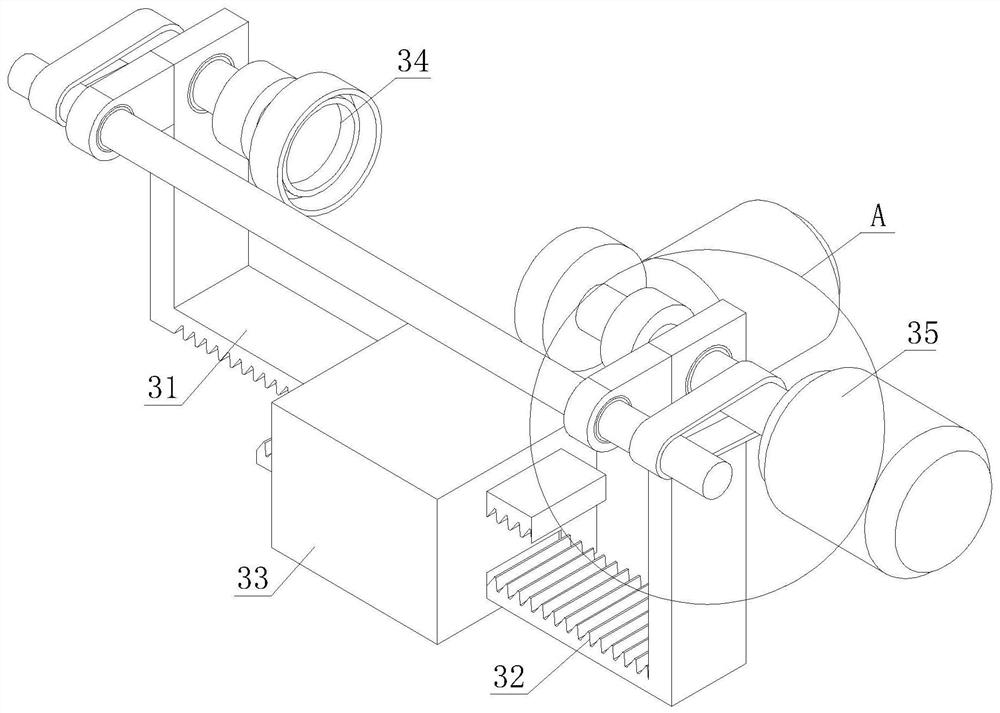

Polishing machining table for Miao silver jewelry

PendingCN108500835ANearbyIncrease the polishing areaGrinding carriagesGrinding bedsTransverse planeEngineering

The invention discloses a polishing machining table for Miao silver jewelry. The polishing machining table comprises a working table. The rear side of the top of the working table is fixedly connectedwith a supporting plate. The top of the front face of the supporting plate is rotationally connected with a transverse plate. A drive mechanism is arranged on the right side of the top of the workingtable. The bottom of the transverse plate is fixedly connected with a polishing mechanism. A collection tank is arranged at the position, corresponding to the polishing mechanism, of the top of the working table. The tank wall on the left side of the collection tank is fixedly connected with a fixed mechanism. The left side and the right side of the top of the fixed mechanism are fixedly connected with clamps. A recycling mechanism is arranged at the position, located below the fixed mechanism, in the collection tank. The right side face of the transverse plate is fixedly connected with a tooth plate engaged with the drive mechanism. According to the polishing machining table for the Miao silver jewelry, the silver jewelry can be polished at multiple angles, and the polished face is larger; the structure is simple, and operation is convenient; and scraps generated during polishing can be recycled, and use and popularization are facilitated.

Owner:余金龙

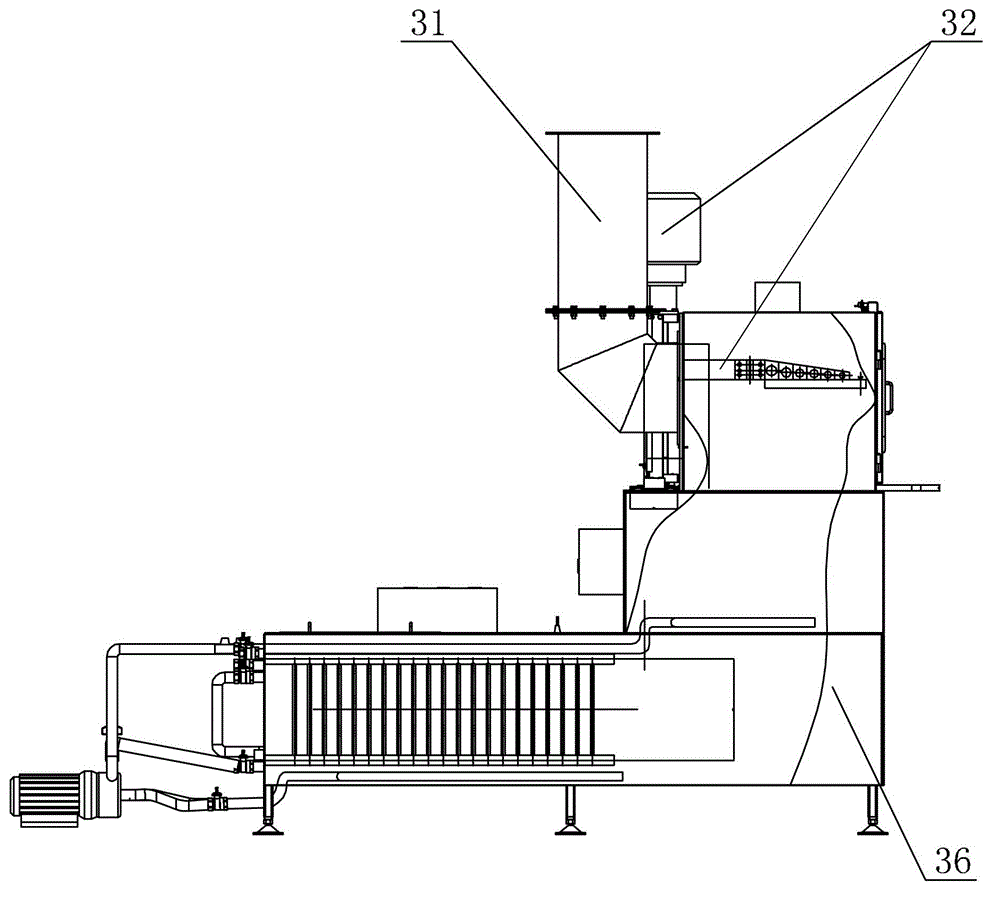

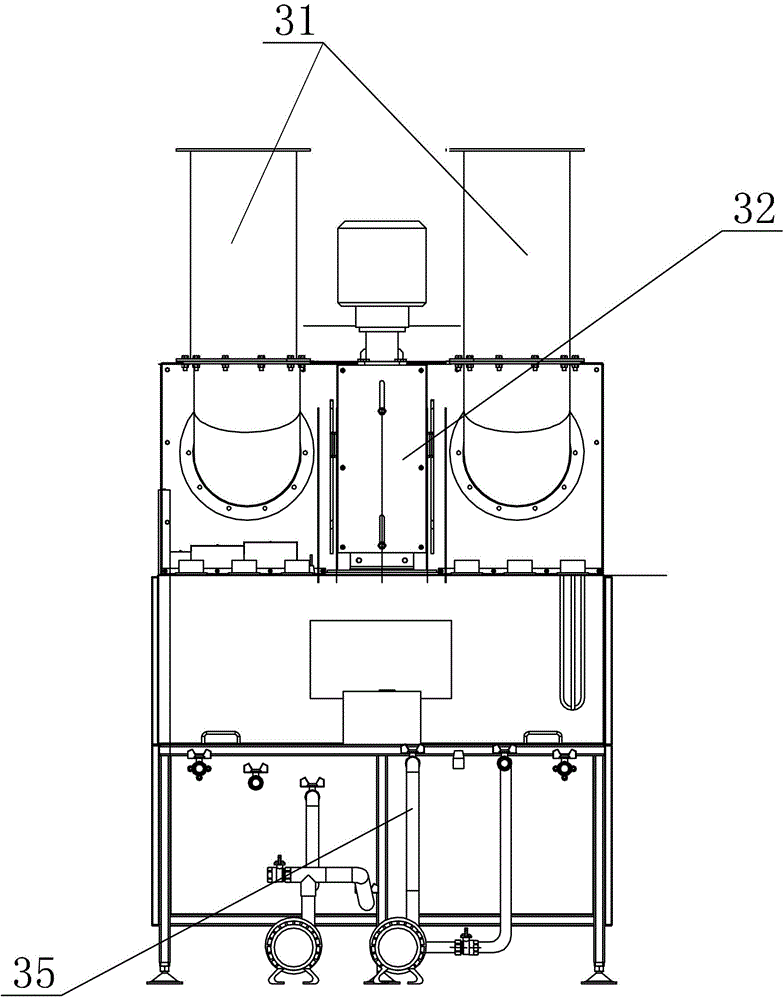

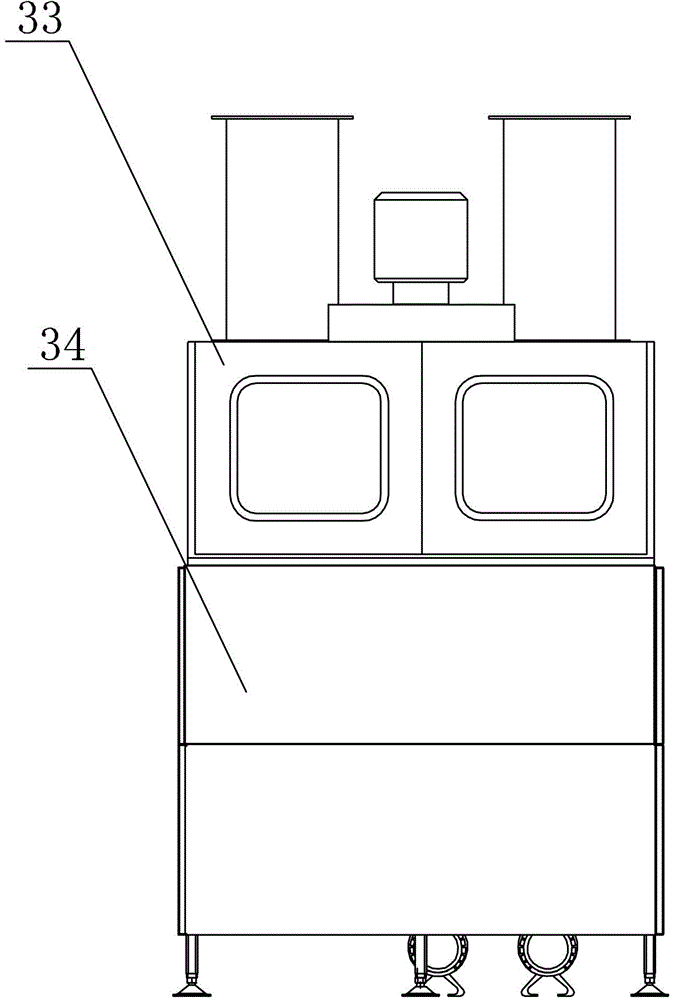

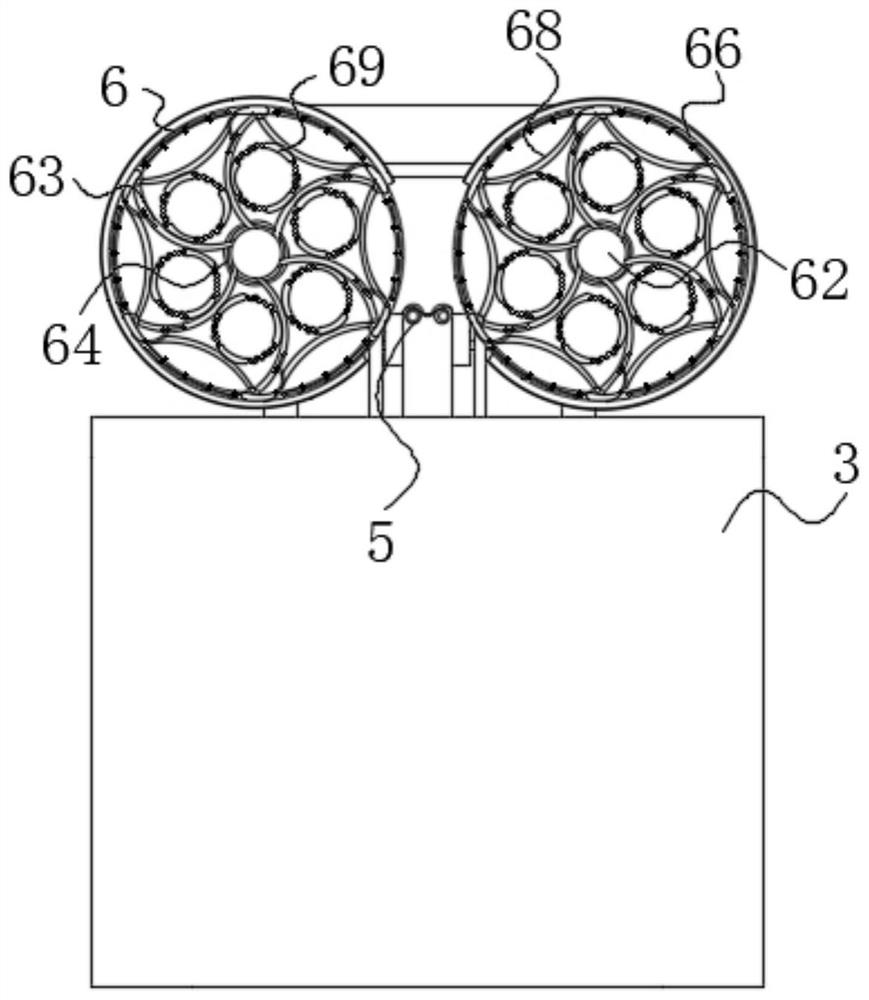

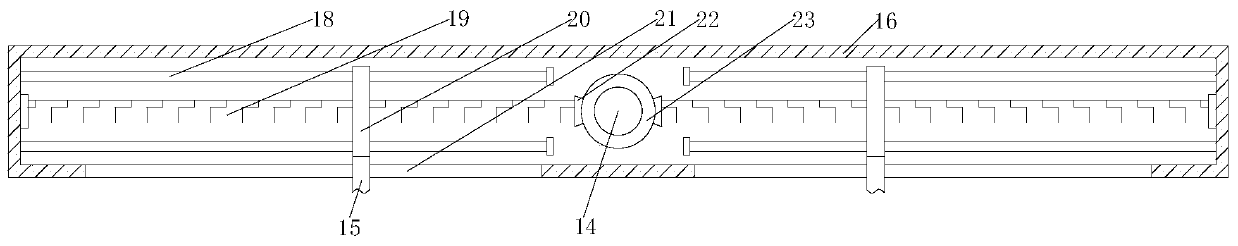

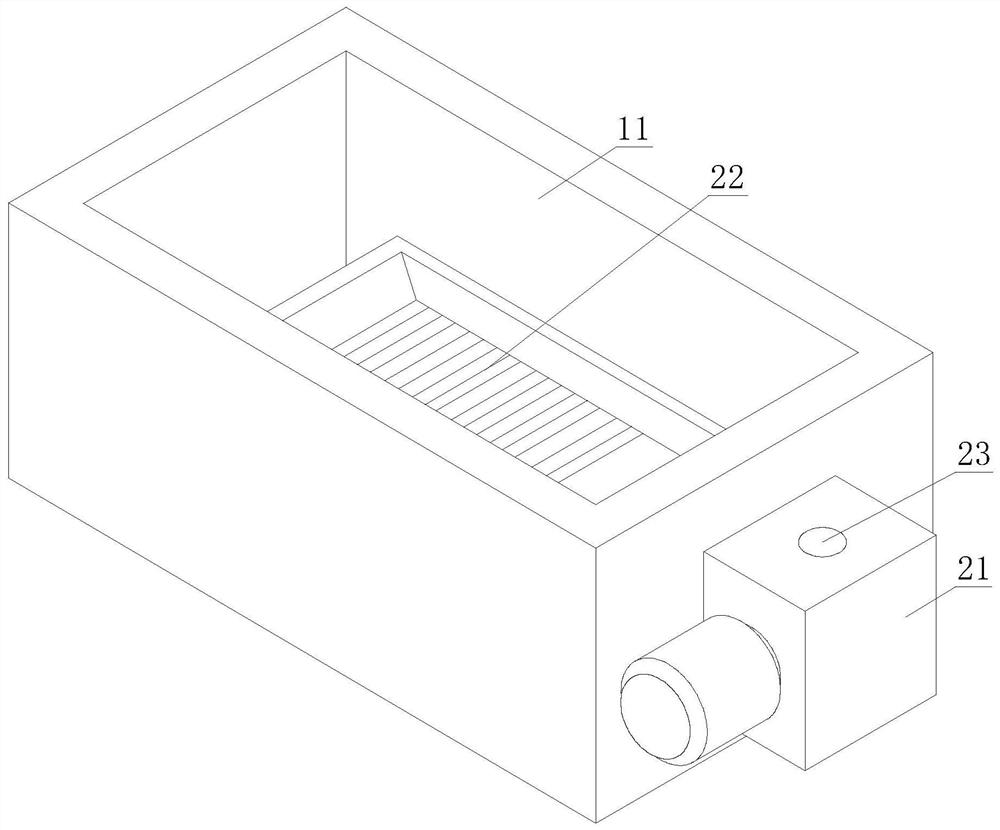

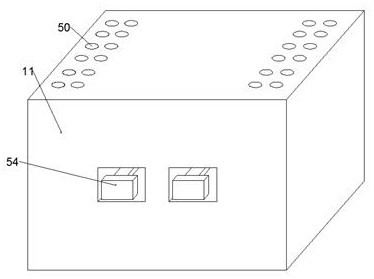

Electrolyte plasma polishing machine for mass production

ActiveCN102828186BIncrease the polishing areaSuitable for mass productionElectrolysis componentsMachine partsElectrolytes plasma

The invention provides an electrolyte plasma polisher for quantity production and relates to a plasma polisher, and the electrolyte plasma polisher is used for solving the problems that the existing polishing equipment is relatively low in production efficiency and is not suitable for large-batch production of enterprises. A circular stirring device is installed on the side wall of a liquid storage box, and the circular stirring device and the liquid storage box are mutually communicated; a top work box is located on the upper end surface of a work box; two air exhaust recovery devices are relatively installed on one side wall of the top work box; a lifting device is located between the two air exhaust devices and mounted on the side wall of the top box wall; each air exhaust device comprises an air exhaust recovery pipeline, a catcher, two baffles and a plurality of plastic balls; each catcher is arranged in the middle of each air exhaust recovery pipeline; the two baffles are horizontally arranged on the upper part of each air exhaust recovery pipeline; the plurality of plastic balls are arranged between the two baffles; and a plurality of through holes are formed in the two baffles along the axial direction. The electrolyte plasma polisher for quantity production is used for polishing machined parts on large scale.

Owner:HARBIN INST OF TECH

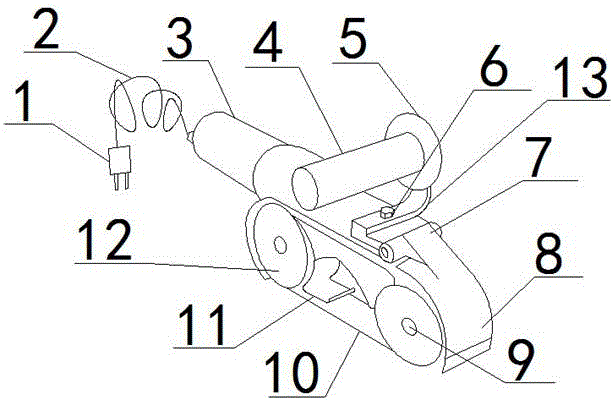

Novel portable polishing machine

InactiveCN106002558AEasy to useIncrease the polishing areaGrinding machine componentsPortable grinding machinesEngineeringMechanical engineering

The invention discloses a new type of portable polishing machine, which comprises a polishing machine body, a fixed nut, a rotating frame, a movable baffle, a rotating shaft, a polishing belt, a pressurizer, a pulley and a fixer. The plug is connected to a circuit connecting line One end of the circuit connection line; the other end of the circuit connection line is installed on the body of the polishing machine; the body of the polishing machine is provided with a fixer; the fixer is fixed on the body of the polishing machine through a fixing nut; handle; one end of the handle is provided with a sheath; the front end of the polishing machine body is provided with a rotating frame; a movable baffle is installed on the rotating frame; a polishing belt is installed at the lower end of the polishing machine body; The lower part of the polishing machine body is provided with a pressurizer. Compared with the prior art, the beneficial effect of the present invention is that the new type of portable polishing machine is easy to operate with both hands, has a large polishing area, is cheap in cost, has a long service life and is light in weight , suitable for promotional use.

Owner:彭东林

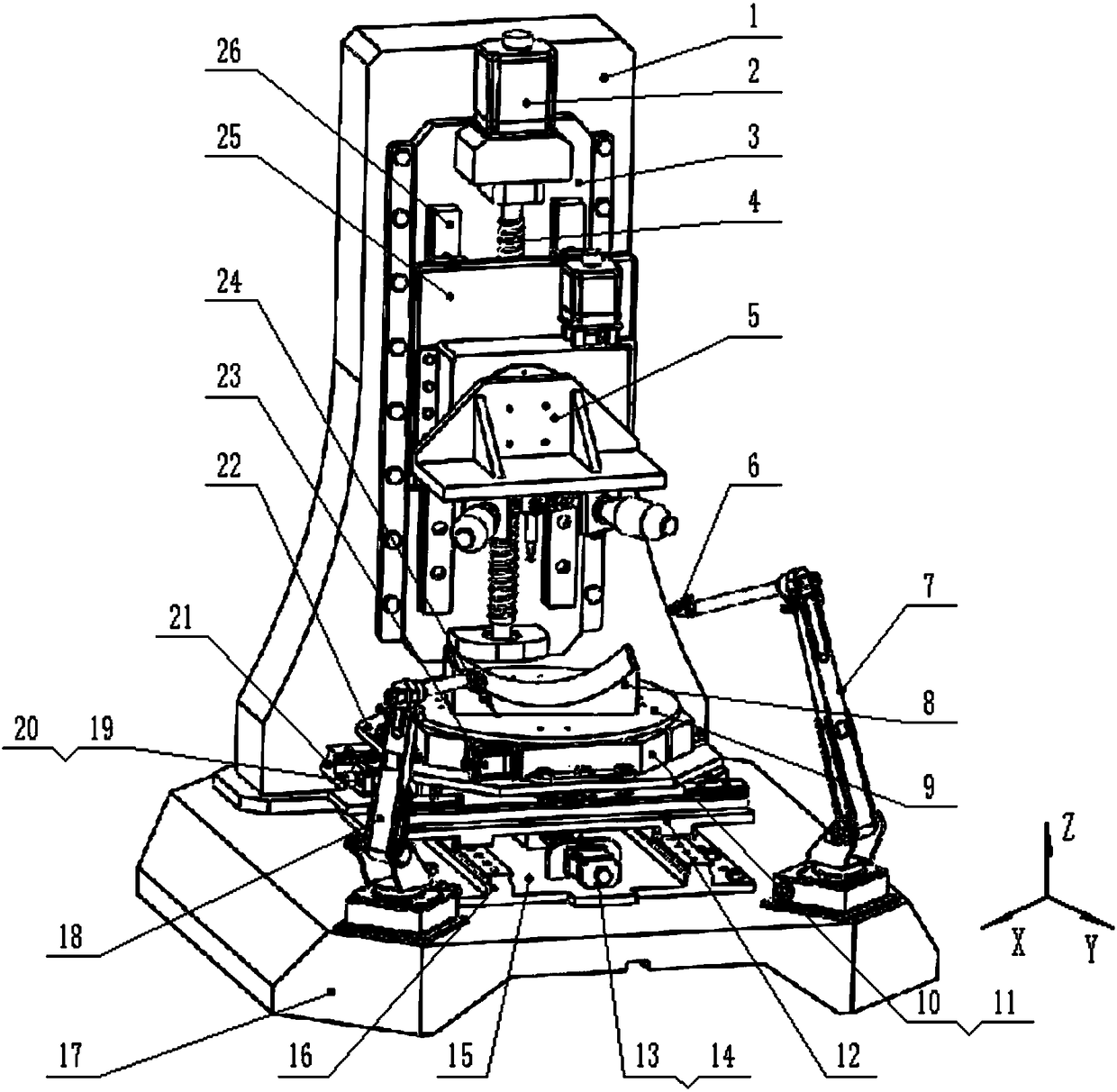

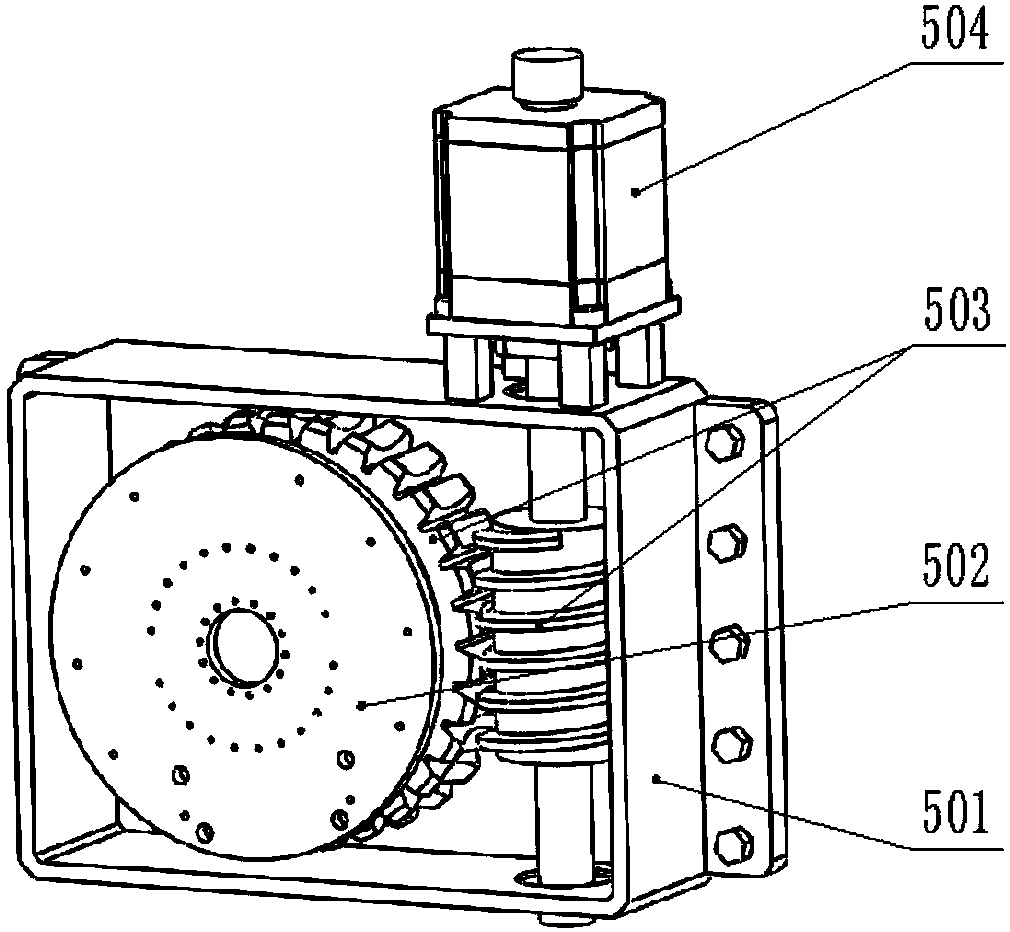

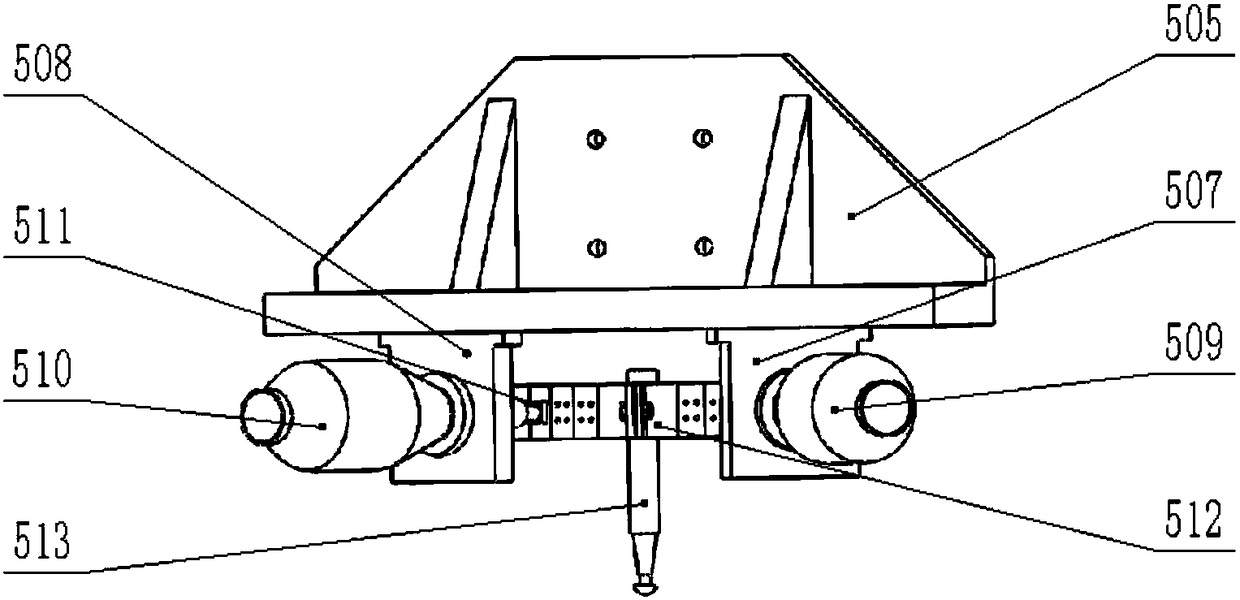

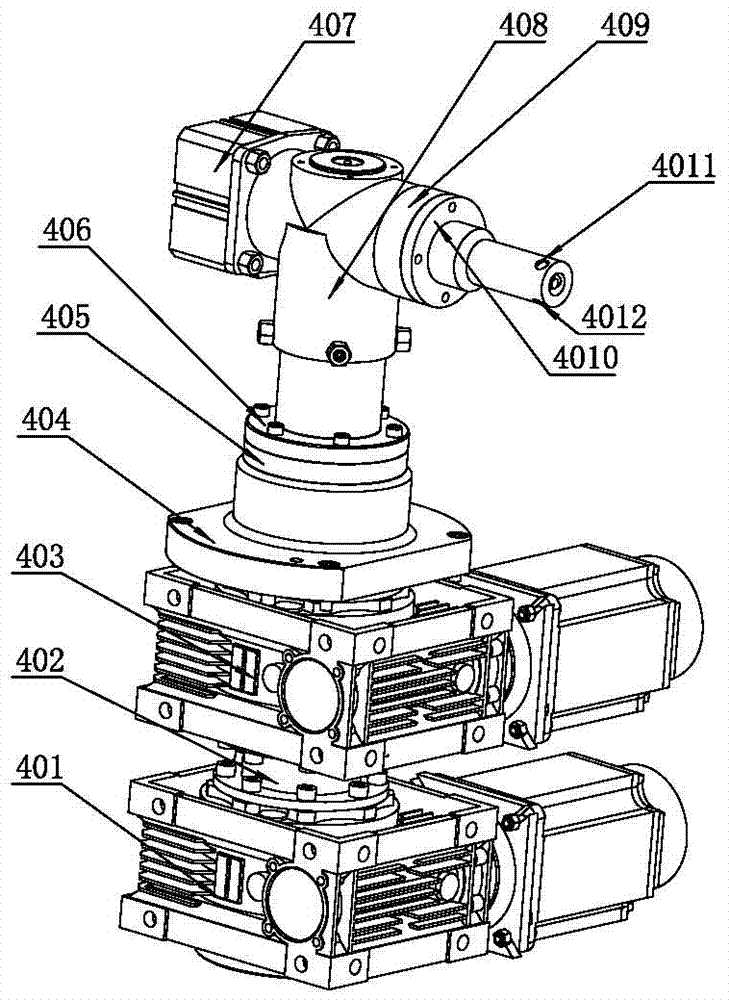

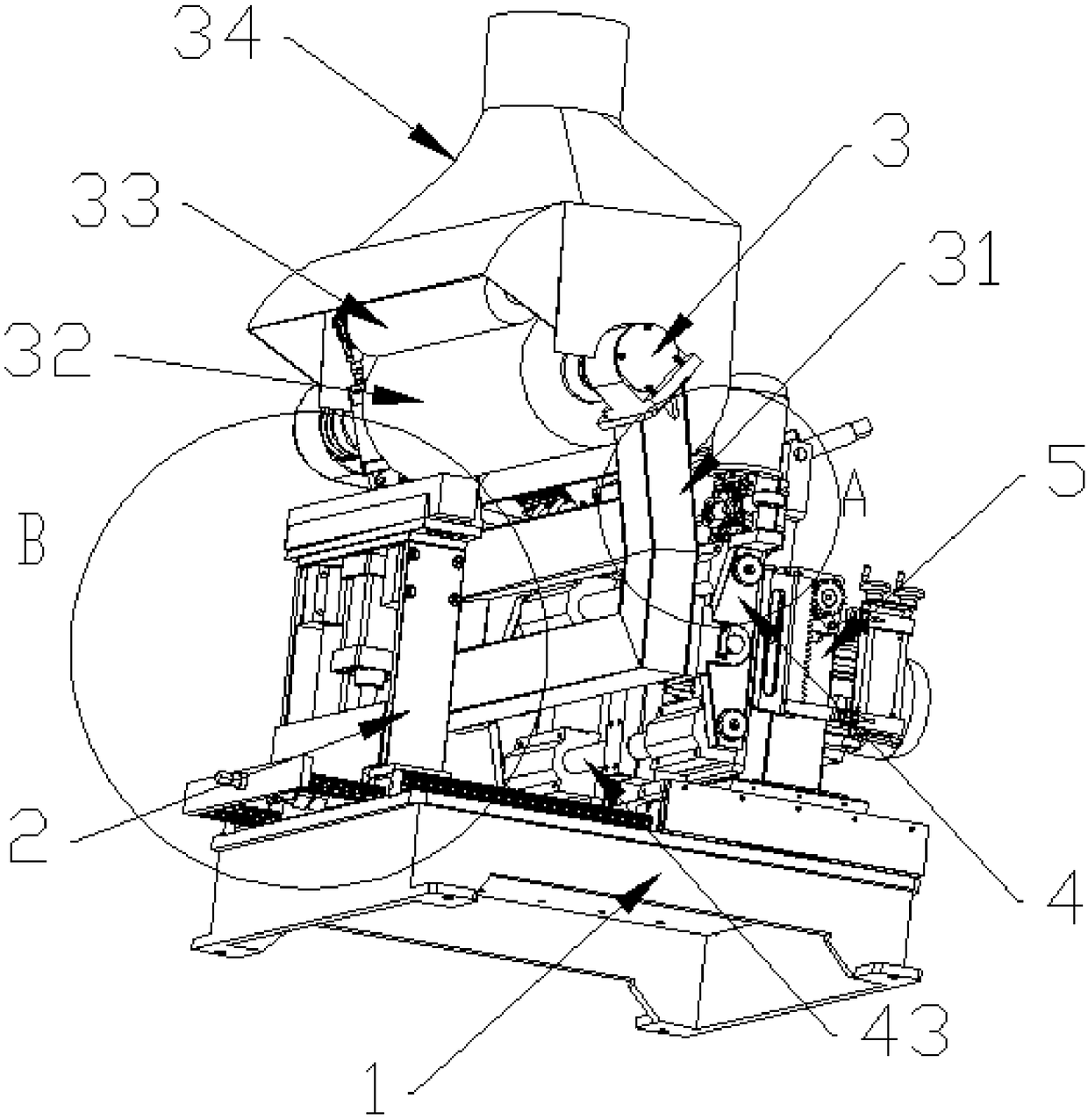

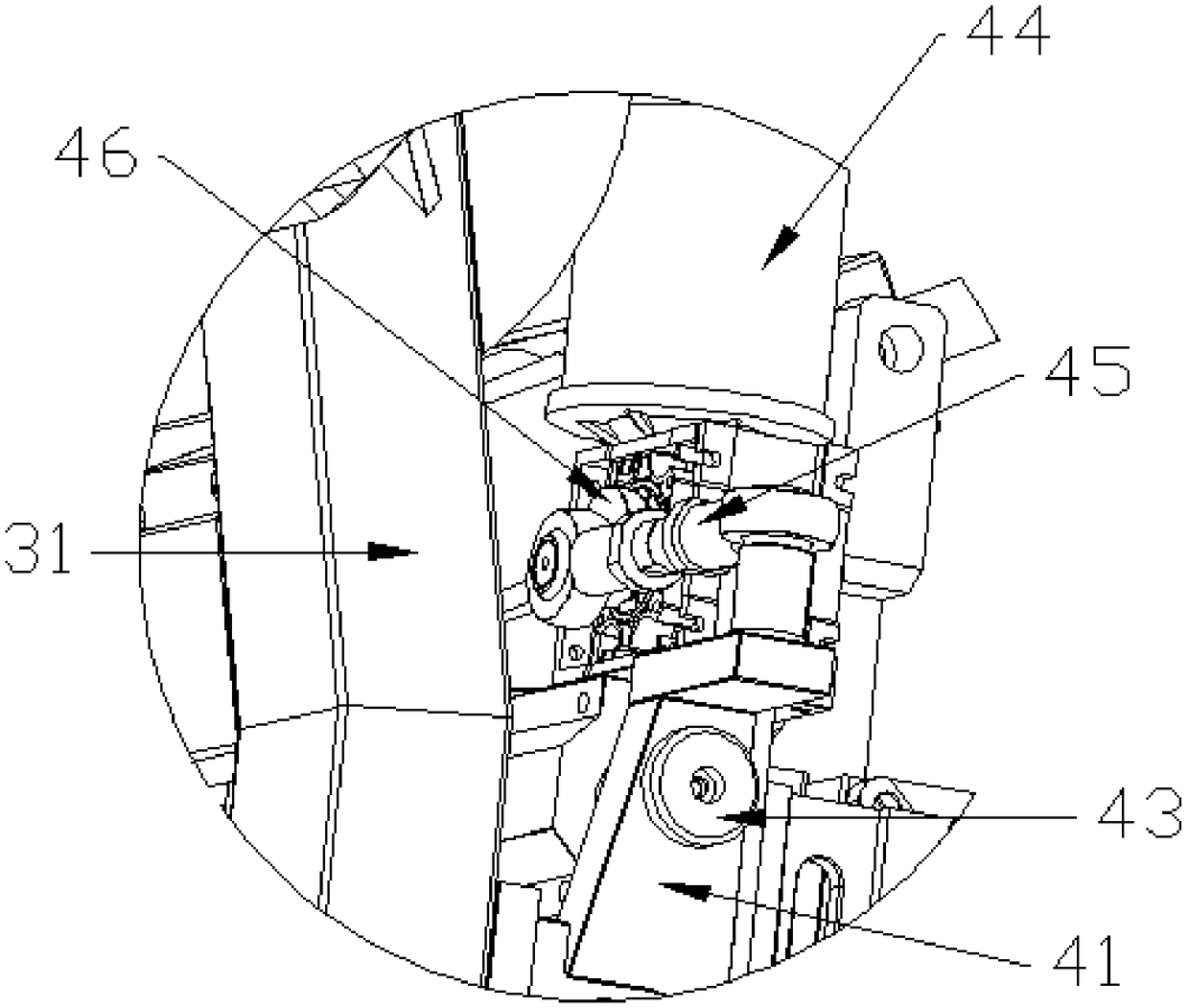

A five-axis three-dimensional ultrasonic polishing machine tool and using method thereof

ActiveCN106736991BIncrease polishing powerIncrease the polishing areaGrinding carriagesOptical surface grinding machinesCouplingUltrasonic vibration

A five-axis three-dimensional ultrasonic polishing machine tool currently consists of a frame, an The five-axis two-dimensional ultrasonic polishing machine tool composed of a workpiece online detection device was improved. The ultrasonic vibration polishing device was changed from one-dimensional ultrasonic vibration to two-dimensional ultrasonic vibration. The two-dimensional ultrasonic vibration was installed on a vertical rotating On the table, two ultrasonic devices whose included angles can be adjusted through the station adjustment holes and a polishing head base connected to the horn of the ultrasonic device are completed, and the polishing head is fixed on the base. This ultrasonic polishing machine applies two-dimensional ultrasonic vibration to the polishing head. Through two-dimensional ultrasonic coupling, it can not only increase the polishing power, but also make the movement trajectory of the polishing head evenly cover the processing area in the form of a curved reciprocating detour, significantly improving the polishing efficiency.

Owner:NORTHEASTERN UNIV LIAONING

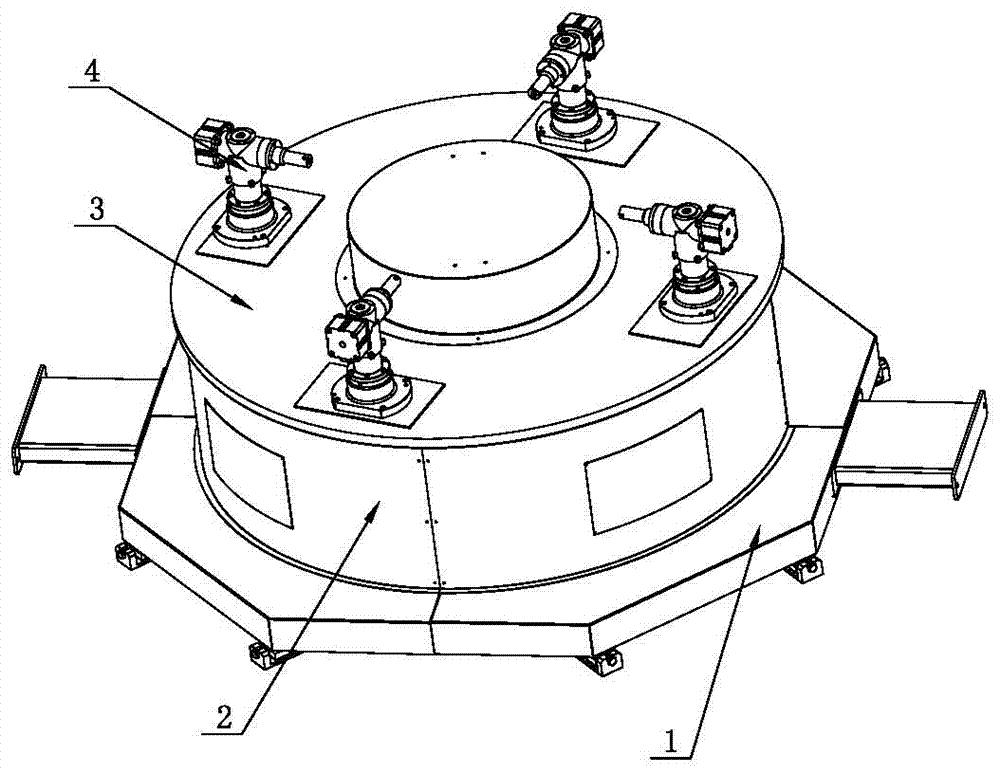

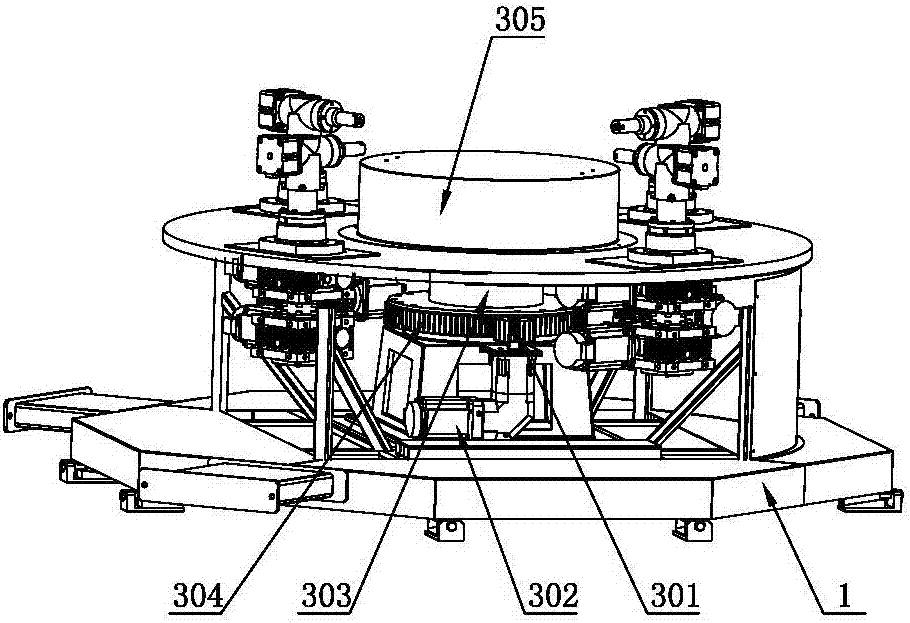

Polishing auxiliary device

PendingCN107116447ASolve the technical problem of uneven polishingPolished evenlyPolishing machinesGrinding drivesPolishingEngineering

The invention provides a polishing auxiliary device in the technical field of polishing equipment. The polishing auxiliary device comprises a base, wherein a rotatable rotating mechanism is arranged on the base; and a plurality of clamps for clamping workpieces are arranged on the rotating mechanism and can rotate. The polishing auxiliary device can polish the entire outer ring of a workpiece, increases the polishing area, is uniform in polishing and improves the polishing effect.

Owner:江苏省(扬州)数控机床研究院 +1

Surface polishing device for stainless steel product production

The invention discloses a surface polishing device for stainless steel product production. The surface polishing device comprises a supporting base, a rotating shaft and a polishing disc, a supportingplate is installed at the upper end of the supporting base, a fixing frame is installed at the upper end of the supporting plate, the rotating shaft is installed in the middle of the top end of the inner side of the fixing frame, a limiting frame is installed on the outer side of the bottom end of the rotating shaft, a sliding block is installed on the inner side of the limiting frame, a first threaded rod is installed in the middle of the sliding block, a long rod is installed at the bottom end of the sliding block, a second sucker is installed at the front end of a second telescopic motor which is installed at the bottom end of the long rod, a fixed frame is installed at the bottom end of the rotating shaft, a rotating block is arranged at the bottom end of the inner side of the fixed frame, a gear ring is installed outside the upper end of the rotating block, a rolling bearing is installed between the rotating block and the fixed frame, a first rotating motor and a gear are installed on the right side inside the fixed frame, a cylinder and a limiting plate are installed on the left side inside the fixed frame; and the polishing disc is arranged at the bottom end of the rotatingblock. The surface polishing device is reasonable in structure, stainless steel products can be conveniently fixed, and the polishing area and the polishing efficiency are effectively improved.

Owner:ZHUZHOU TIANQIAO SHUNCHEN COAL PREPARATION MACHINERY

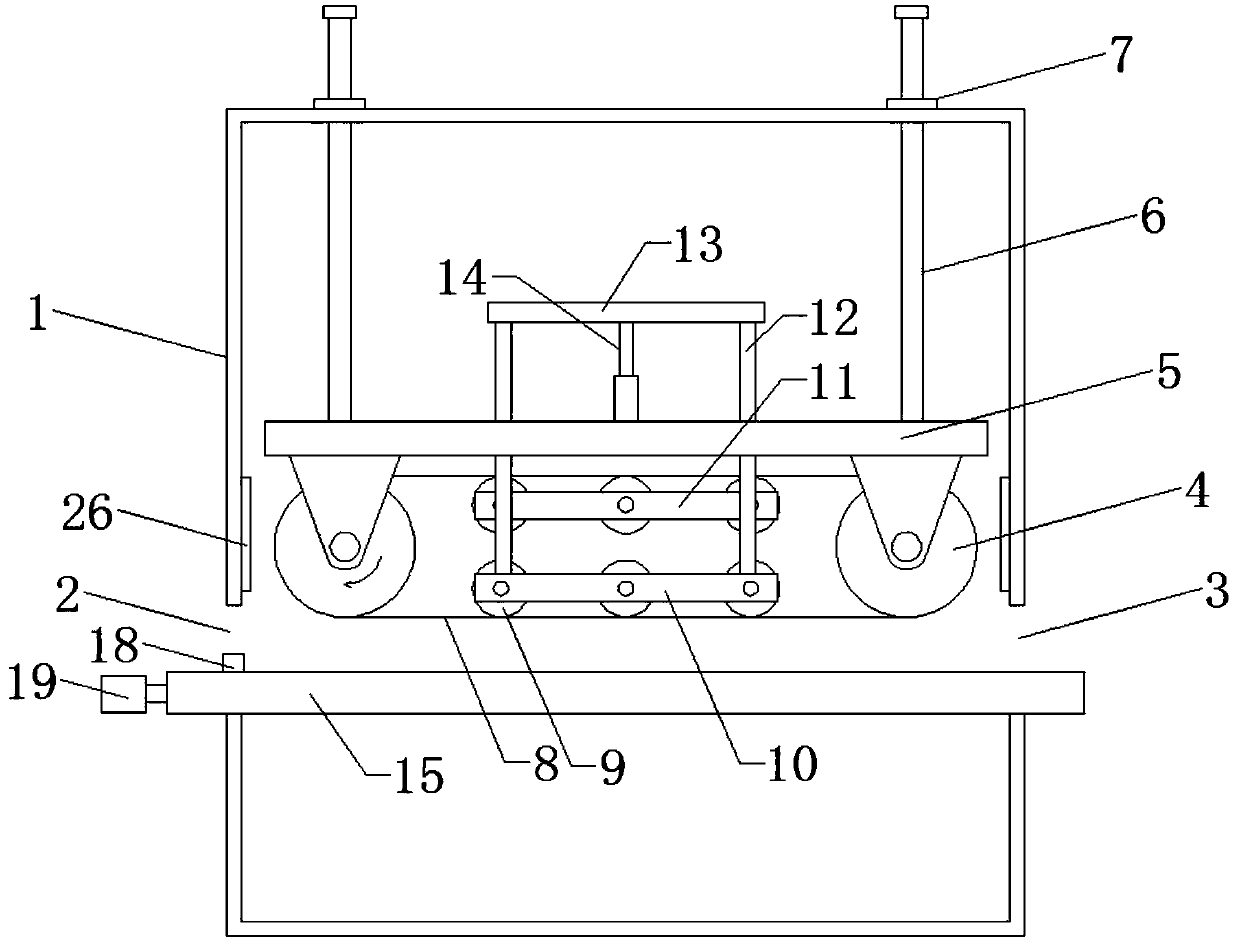

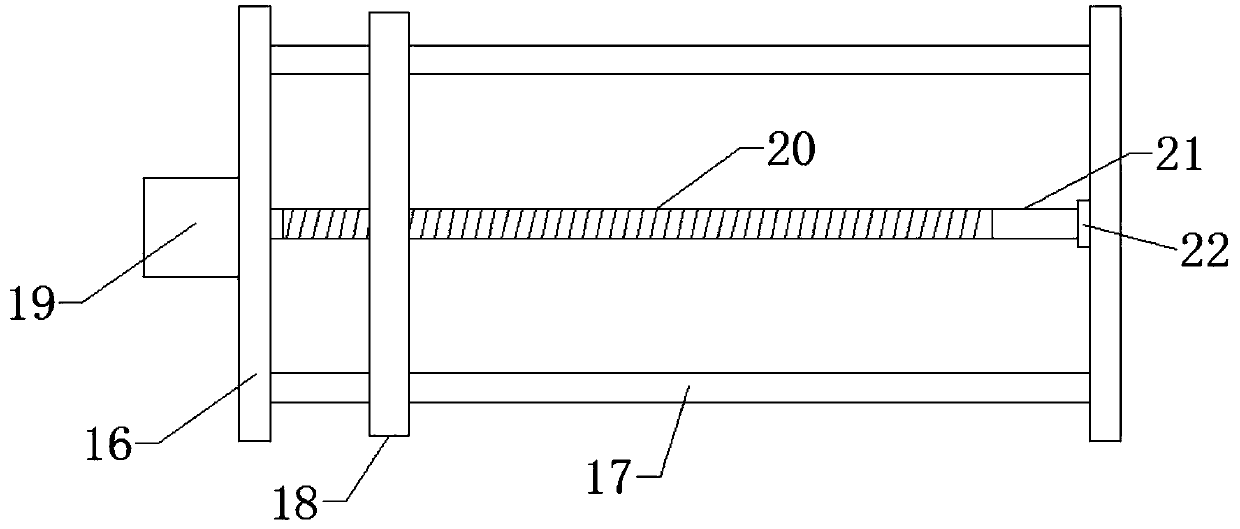

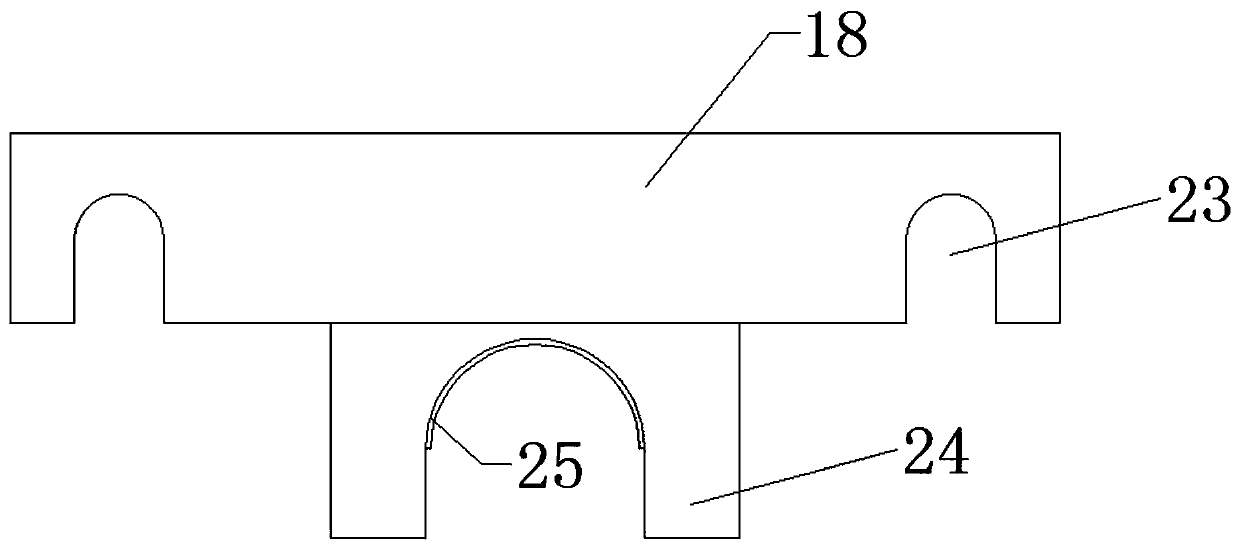

Pipe polishing equipment

InactiveCN112873029AIncrease the areaFast polishingPolishing machinesGrinding drivesEngineeringMechanical engineering

The invention belongs to the technical field of metal polishing, and particularly relates to pipe polishing equipment. The pipe polishing equipment comprises a feeding box, a feeding opening, an installation base, guide frames, an auxiliary frame and polishing mechanisms; the feeding box is arranged in a rectangular shape, and the installation base is placed at the right end of the feeding box; the installation base is arranged in a rectangular shape, and the guide frames are symmetrically and fixedly installed on the upper surfaces of the left end and the right end of the installation base; the auxiliary frame is arranged at the right side of the guide frame at the left side; the auxiliary frame is fixedly installed on the upper surface of the left end of the installation base, and the polishing mechanisms are arranged at the right side of the auxiliary frame; and the polishing mechanisms are fixedly installed on the upper surface of the middle portion of the installation base. The distance between two corresponding polishing plates is larger than the diameter of each pipe, so that the polishing plates sink inwards in the process of polishing the pipes through the polishing plates, and thus the contact areas of the polishing plates and the pipes are further increased, so that the polishing speed is greatly improved.

Owner:张书林

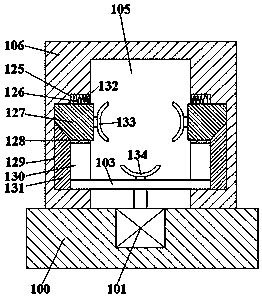

Device for glass sleeve inside polishing

InactiveCN108747791ASimple structureEasy to operateGrinding carriagesPolishing machinesEngineeringMechanical engineering

The invention discloses a device for glass sleeve inside polishing. The device for glass sleeve inside polishing comprises a base and a piece fixing machine body arranged on the end face of the top ofthe base. A polishing cavity is formed in the piece fixing machine body and penetrates through the left side and the right side of the piece fixing machine body. The front inner wall and the back inner wall of the polishing cavity are internally provided with symmetrical first guide sliding grooves in a communicating manner. The front inner wall and the back inner wall of the polishing cavity areinternally provided with symmetrical second guide sliding grooves in a communicating manner. The second guide sliding grooves are provided with third guide sliding grooves at the positions far away from the end inner walls of the polishing cavity in a communicating manner. The tops of the third guide sliding grooves communicate with the first guide sliding grooves. First guide sliding blocks areconnected into the first guide sliding grooves in a sliding and matched manner. The ends, close to the polishing cavity, of the first guide sliding blocks are provided with side arc clamping jaws. Thetops of the first guide sliding blocks are provided with elastic connection recovering device. The device for glass sleeve inside polishing is simple in structure, convenient to operate, large in polishing area, good in polishing effect and high in polishing efficiency and achieves close fit.

Owner:QUZHOU YANHANG BUSINESS CONSULTING CO LTD

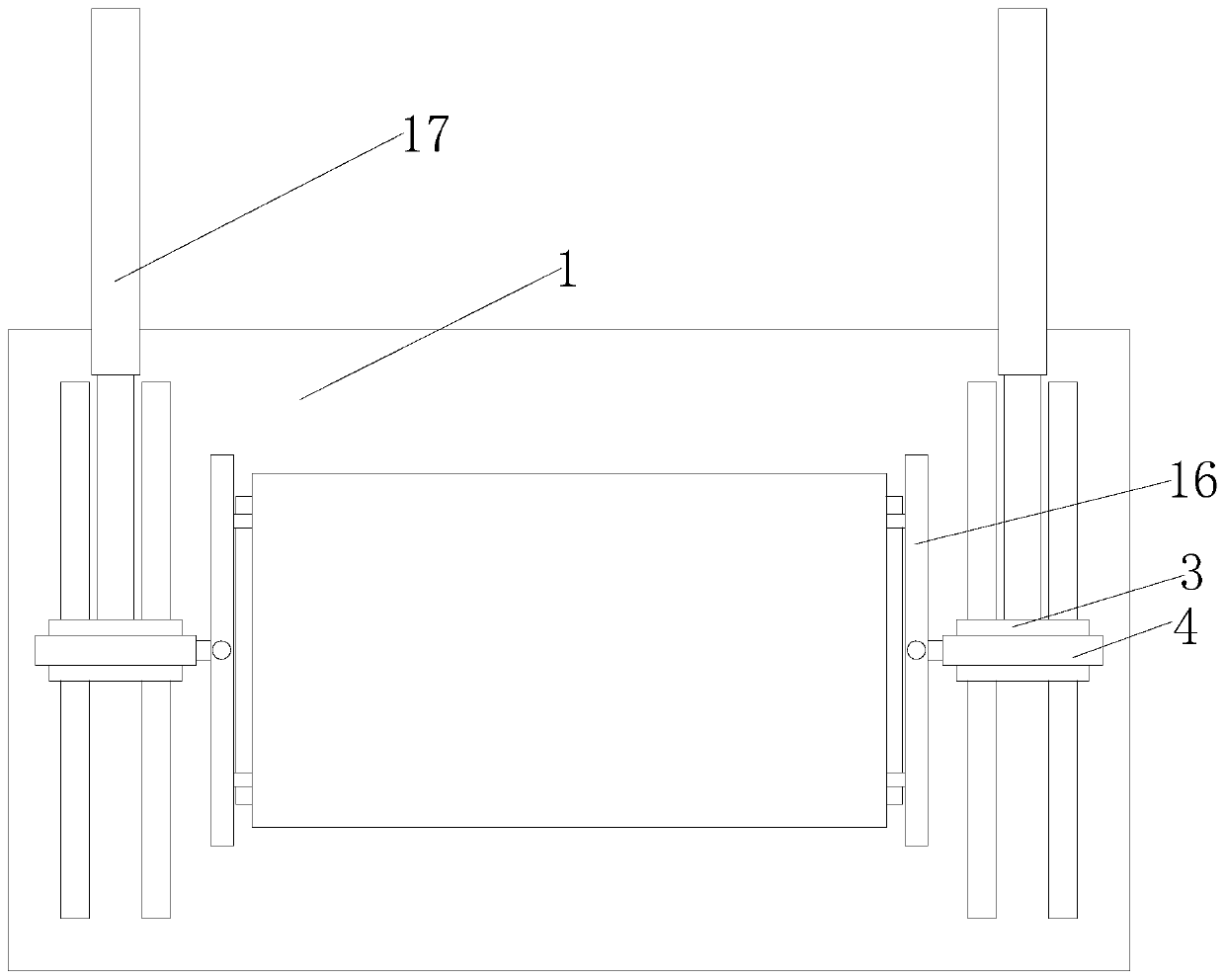

Automatic polishing device for external round corners of vertical face of tableware

PendingCN109434628AHigh degree of automationImprove efficiencyGrinding machinesGrinding/polishing safety devicesEngineeringMechanical engineering

The invention provides an automatic polishing device for external round corners of the vertical face of tableware, and belongs to the field of polishing equipment. The automatic polishing device comprises a base, a fixed assembly, a follow-up assembly, a lifting assembly and a transverse moving assembly; the fixed assembly is arranged at one end of the upper end face of the base, and the lifting assembly is arranged at the end, away from the fixed assembly, of the upper end face of the base and is slidably connected with the base; the transverse moving assembly slides relative to the lifting assembly, the sliding direction of the transverse moving assembly is perpendicular to the sliding direction of the lifting assembly, the lower end of the follow-up assembly is hinged to the lower middle part of the transverse moving assembly, the middle of the follow-up assembly is hinged to one end of a driving cylinder, the other end of the driving cylinder is hinged to the transverse moving assembly, and the driving cylinder is provided with an air release valve; and the follow-up assembly comprises a polishing wheel, and the polishing wheel and the fixed assembly are arranged correspondingly. According to the automatic polishing device, the round corners at the upper end of the vertical face of the tableware can be polished, the automatic degrees is high, the working efficiency is improved greatly, and the labor strength is lowered.

Owner:TIANJIN SHIDAI CHUANGYE TECH CO LTD

Improved polishing device

InactiveCN110281125AEasy to useIncrease the polishing areaPolishing machinesGrinding drivesEngineeringMechanical engineering

The invention discloses an improved polishing device. An equipment box is included. An installing frame is fixedly arranged on the top of the equipment box. Sliding installing bases are arranged on the two sides of the top of the equipment box in a sliding manner. Second electric telescopic rods are fixedly connected to the rear end faces of the sliding installing bases. According to the improved polishing device, through cooperative usage of the sliding installing bases, air cylinders, the installing frame, a second transverse adjusting device, a first electric telescopic rod, a movable base, a first threaded rod, a rotation motor, a limiting guide rod, a drive device, a grinding disc, a rotation shaft, a fixing block, adjusting boxes and the second electric telescopic rods, feeding and discharging are convenient, meanwhile, the grinding disc transversely moves left and right along with the movable base, and the material polishing area can be better increased; the second electric telescopic rods drive the sliding installing bases to move front and back, the material grinding area is adjusted, the material polishing area can be further better increased, and accordingly comprehensive polishing can be conducted on the single faces of the materials.

Owner:天津市友派智能科技有限公司

Hardware polishing equipment

InactiveCN108608301AFast polishingEven strengthGrinding carriagesPolishing machinesElectricityEngineering

The invention discloses hardware polishing equipment which comprises a base, an electricity box, a lifting rod, a fixed bar, a slide bar, a polishing stone and a plurality of motors, wherein the fixedbar is vertically arranged on the base; the lifting rod is movably connected to the fixed bar; the slide bar is arranged on one side of the fixed bar in parallel; a sliding base movably connected ismounted between the fixed bar and the slide bar, and the sliding base is fixedly connected to the lifting rod; the polishing stone is connected to the end part of the lifting rod; one side of the baseis connected to a movable rack; a rolling rack is arranged on the movable rack; and the rolling rack comprises a fixed seat, a supporting rack, a safety hood, a roller and a rolling shaft; the fixedseat is fixed to the base through a first bolt; two ends of the rolling shaft are arranged on the supporting rack; and the safety hood is connected to the edge of an arc-shaped side plate. A polishedarticle is loaded by using the roller, so that the polishing area of the polished article is larger, and the polishing speed is higher; when the roller rolls at a uniform speed, the force of the polishing stone for polishing the polished article is more uniform.

Owner:嘉善卡勒机车零部件有限公司

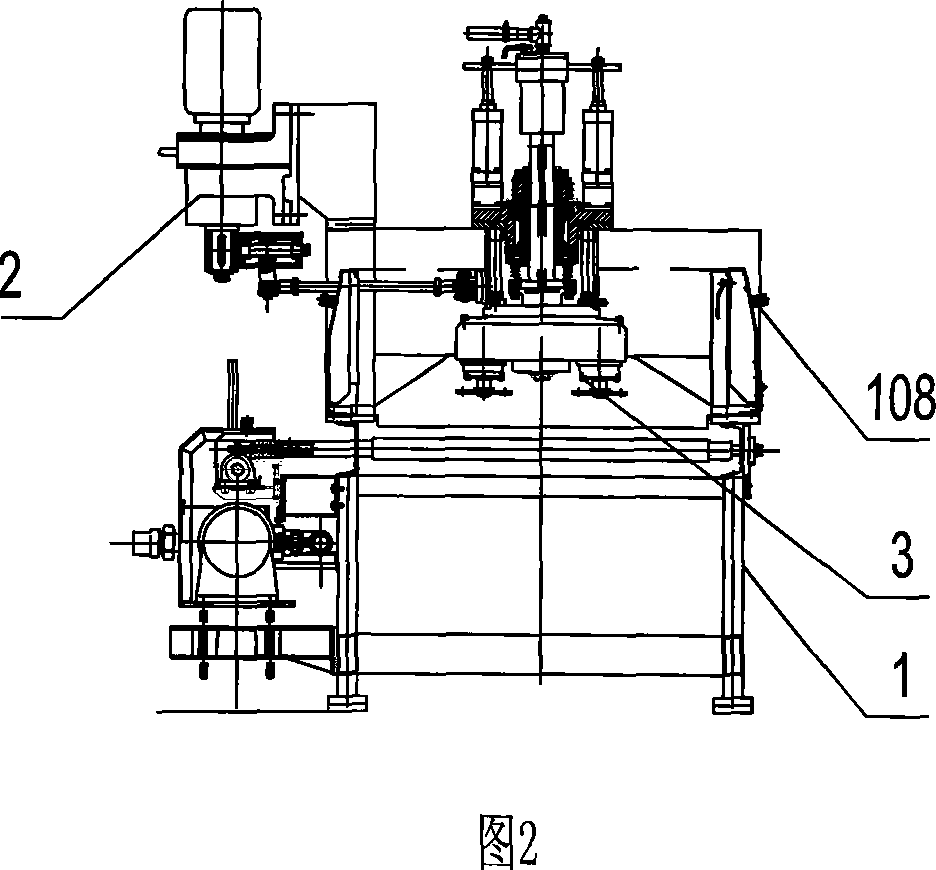

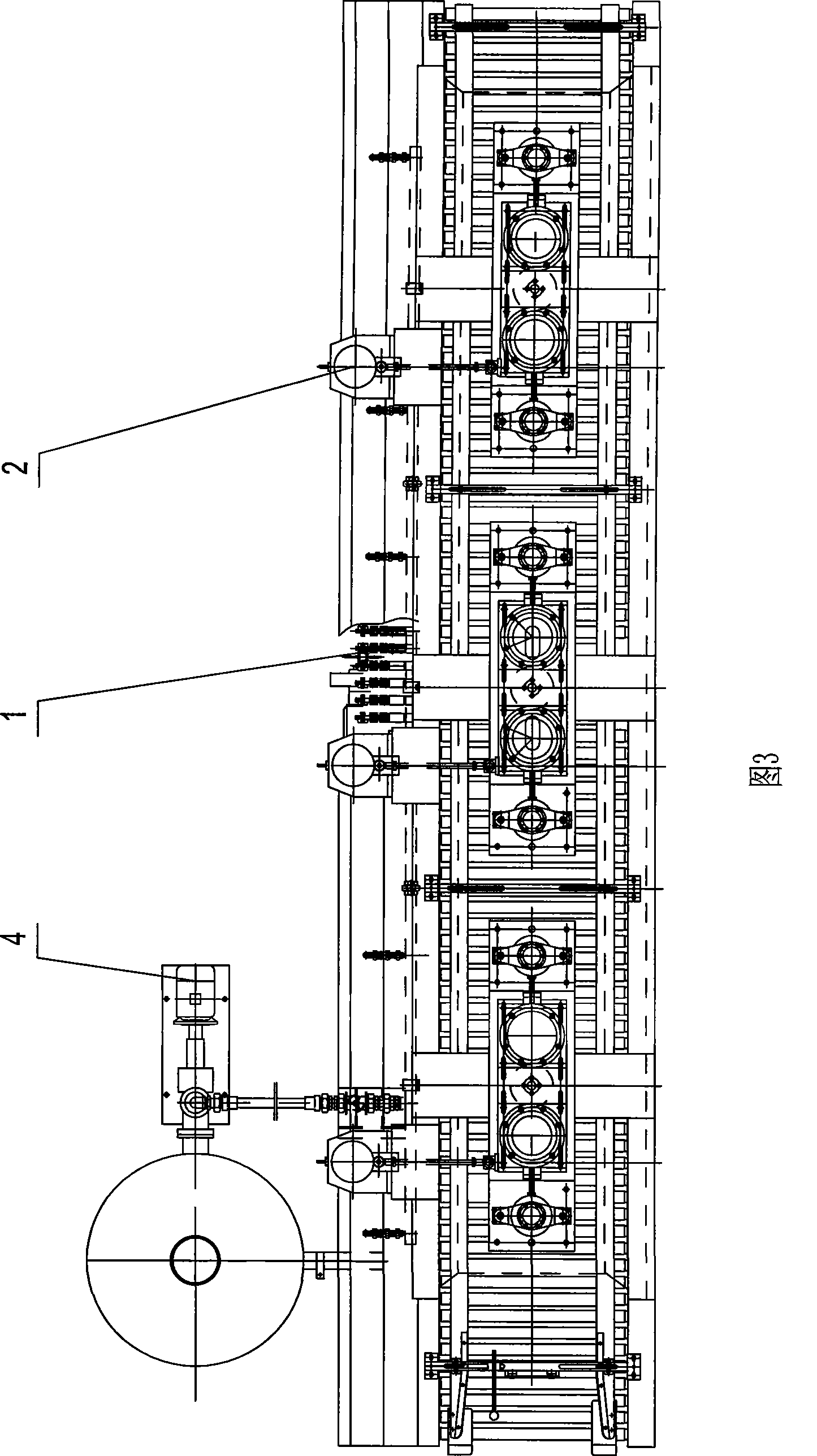

Glazing machine

ActiveCN101362312BImprove polishing efficiencyIncrease the polishing areaGrinding carriagesPolishing machinesEngineeringCeramic tiles

The invention discloses a glazing machine for glaze. The glazing machine comprises a ceramic tile delivery mechanism, and also a polishing device arranged along the extending direction of the delivery mechanism, wherein, the polishing device comprises a swing grinding bench device and a grinding head device arranged on the swing grinding bench device, and a cooling system is arranged on the grinding head device. The glaze surface glazing machine is utilized for the glaze polishing on the basis of fine polishing of a fine polishing machine. The cutting marks are eliminated to the largest extent, and the surface glossiness required by the market is reached; the polishing efficiency is high, the polishing surface is wide, the surface quality of the ceramic tile product can be effectively improved, therefore, the requirement of consumers on high quality tiles can be met.

Owner:KEDA INDUSTRIAL GROUP CO LTD

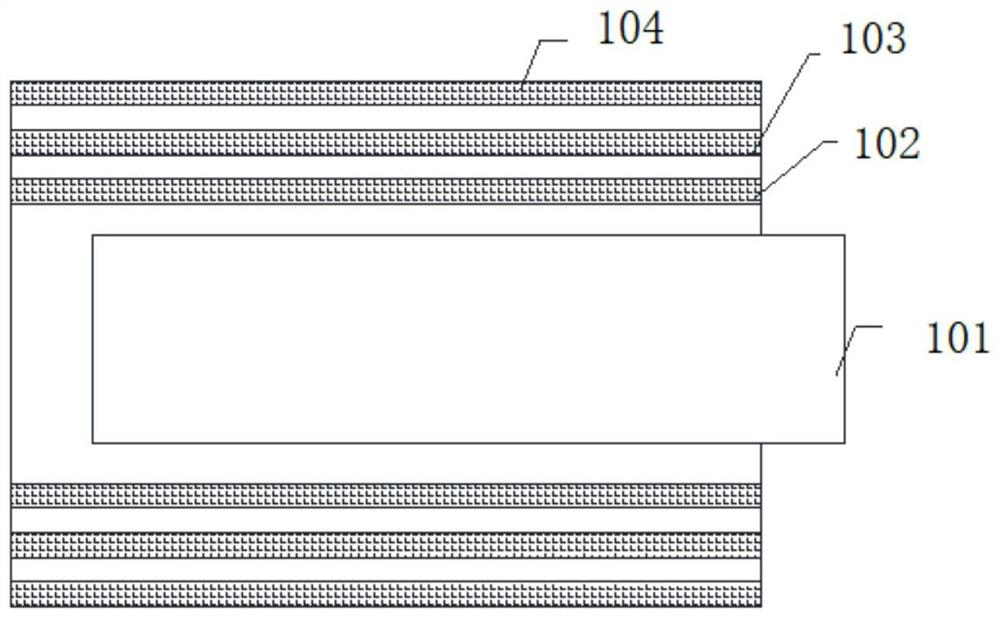

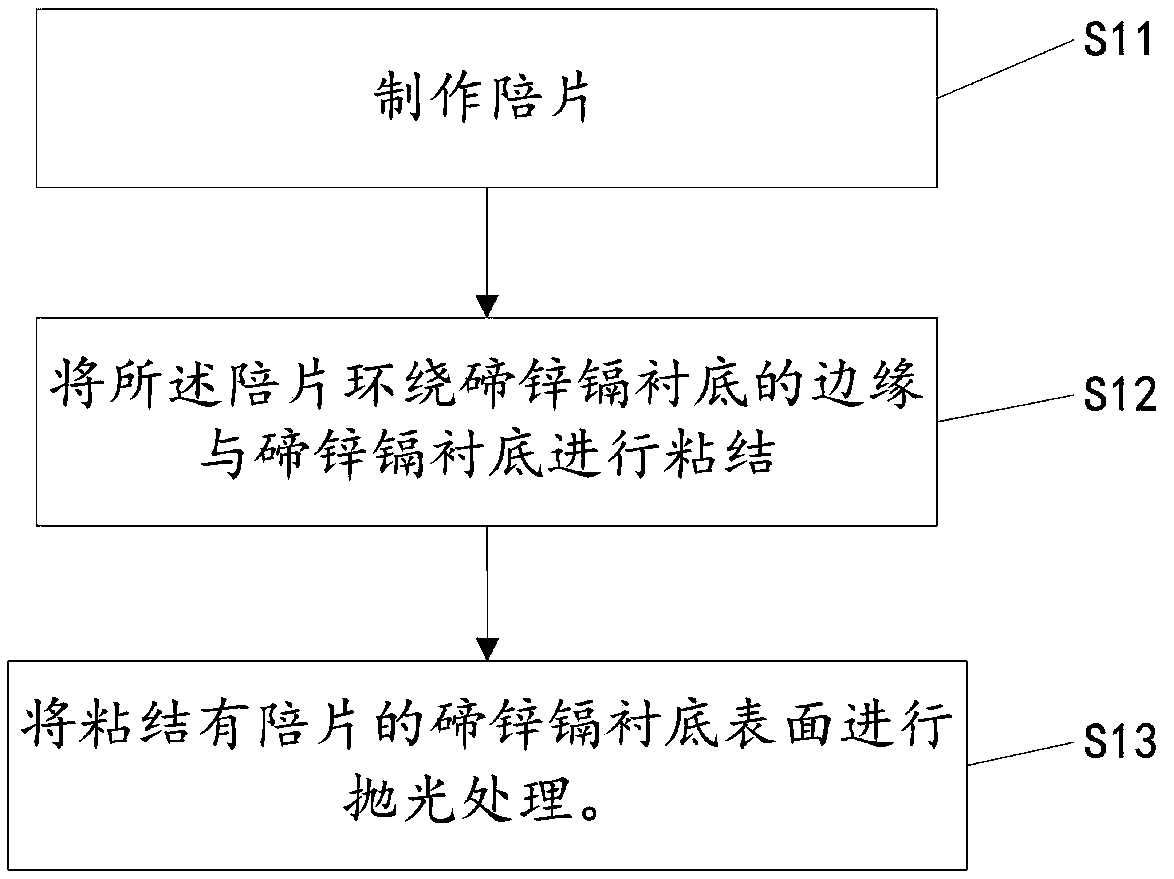

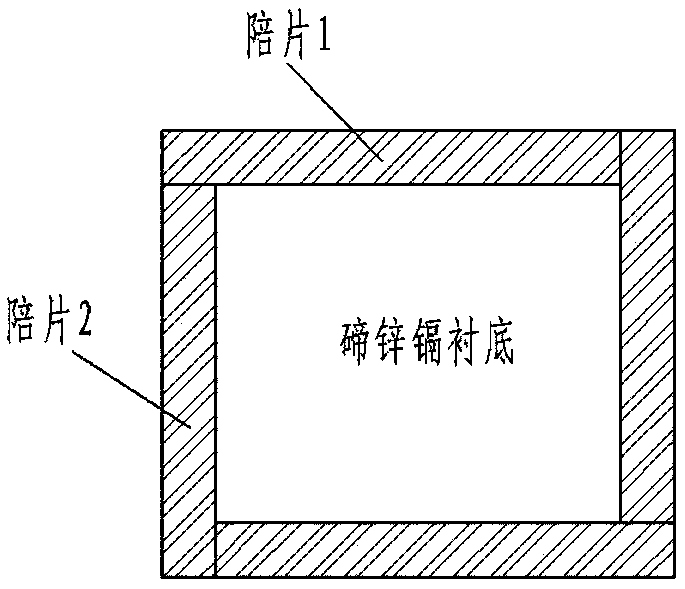

Method and device for processing surface of tellurium zinc cadmium substrate and component

ActiveCN109524504AHigh surface flatnessIncrease the polishing areaFinal product manufactureSemiconductor devicesTe elementOptoelectronics

The invention discloses a method and device for processing surface of a tellurium zinc cadmium substrate. The method comprises a step of preparing company sheets, a step of wrapping the edge of the tellurium zinc cadmium substrate with the sheets and bonding the sheet and the tellurium zinc cadmium substrate, and a step of polishing the surface of the tellurium zinc cadmium substrate to which thesheets are bonded. In the embodiment of the present invention, by adding the sheets to the periphery of the large area tellurium zinc cadmium substrate, the polishing area is increased, since the 'collapse' phenomenon inherent in the polishing process is serious in a certain area, usually about 5 mm, a 'collapsed' area generated during a wafer polishing process is controlled such that the 'collapsed' area is controlled within the area of the sheets, and the surface flatness of a tellurium zinc cadmium wafer is improved.

Owner:11TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Dust-free polishing device for metal products

PendingCN112247797AIncrease the polishing areaImprove polishing efficiencyGrinding carriagesPolishing machinesPolishingTransverse groove

The invention discloses a dust-free polishing device for metal products. The dust-free polishing device for the metal products comprises a machine body, a box body is arranged in the machine body, grooves are machined in the left side and the right side of the inner wall of the machine body, and a reciprocating assembly is arranged on the upper portion in the machine body. According to the dust-free polishing device for the metal products, a polishing device body can transversely slide in a reciprocating mode through clearance fit between a sliding groove and a sliding block, clearance fit between a lantern ring and a transverse rod and rotation of a round roller, then the polishing area of plates is enlarged, the polishing efficiency of the plates is improved, and the working time is saved; plates of different sizes can be fixed through threaded connection of a stud and a supporting block and clearance fit of a sliding plate and a transverse groove, the fixing position is always located in the middle of a sliding base, and therefore the use applicability is improved, the plates are more stable in the polishing process, and the polishing precision is guaranteed; and through annulardistribution of supporting pipes and corresponding arrangement of the supporting pipes and the polishing device body, annular dust collection can be conducted on the polishing position during polishing, and then dust-free polishing is achieved.

Owner:深圳市誉豪金属制品有限公司

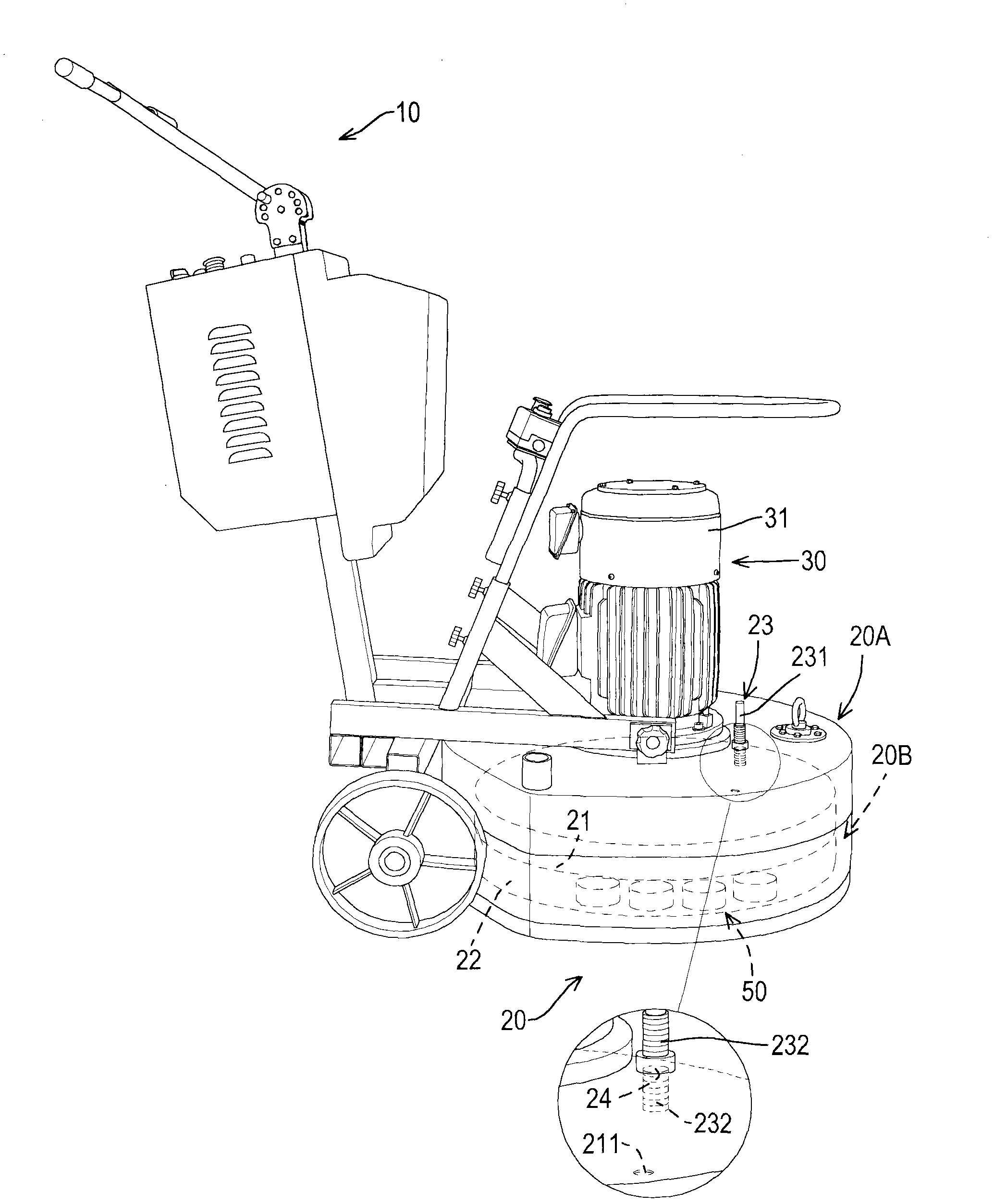

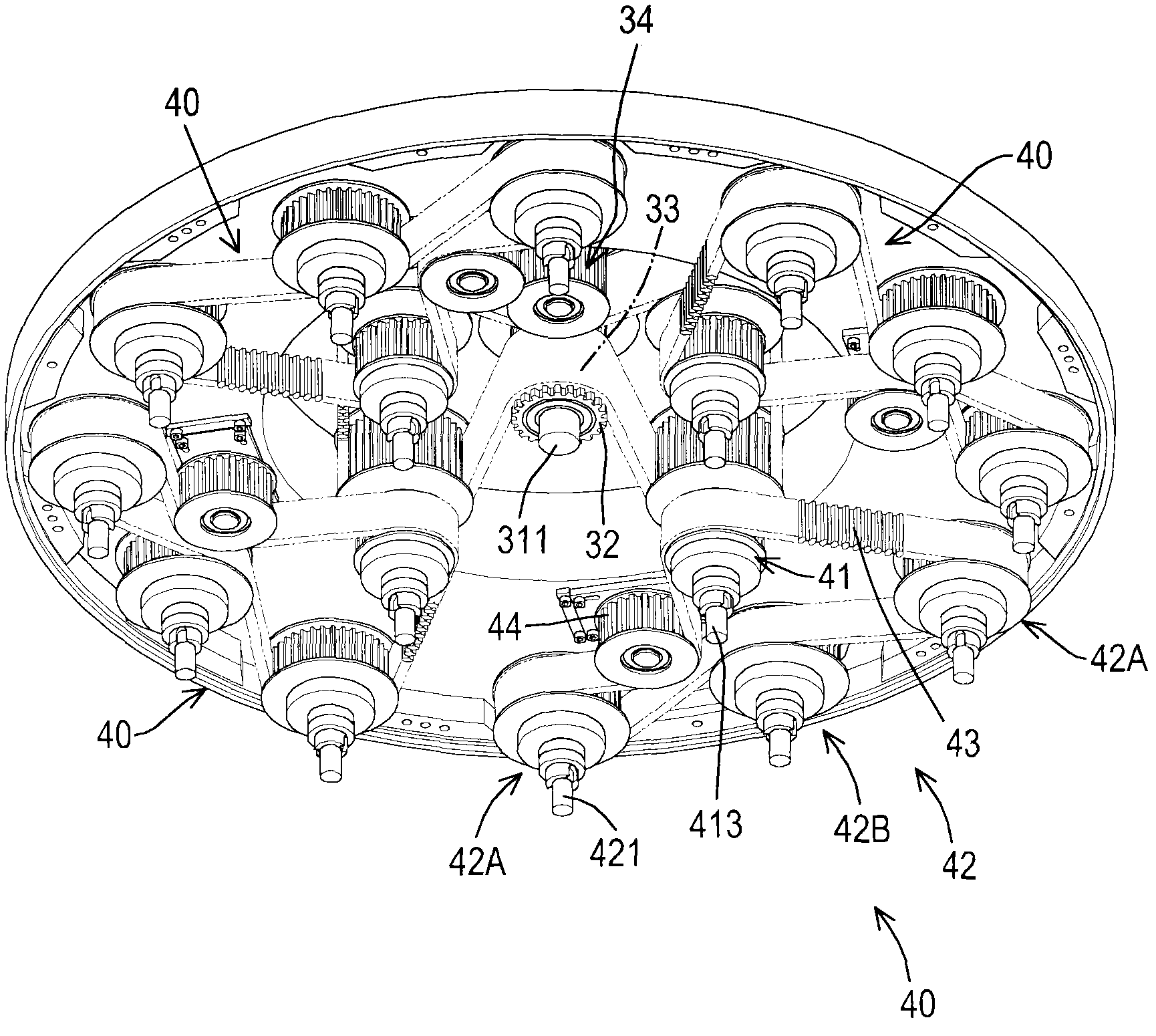

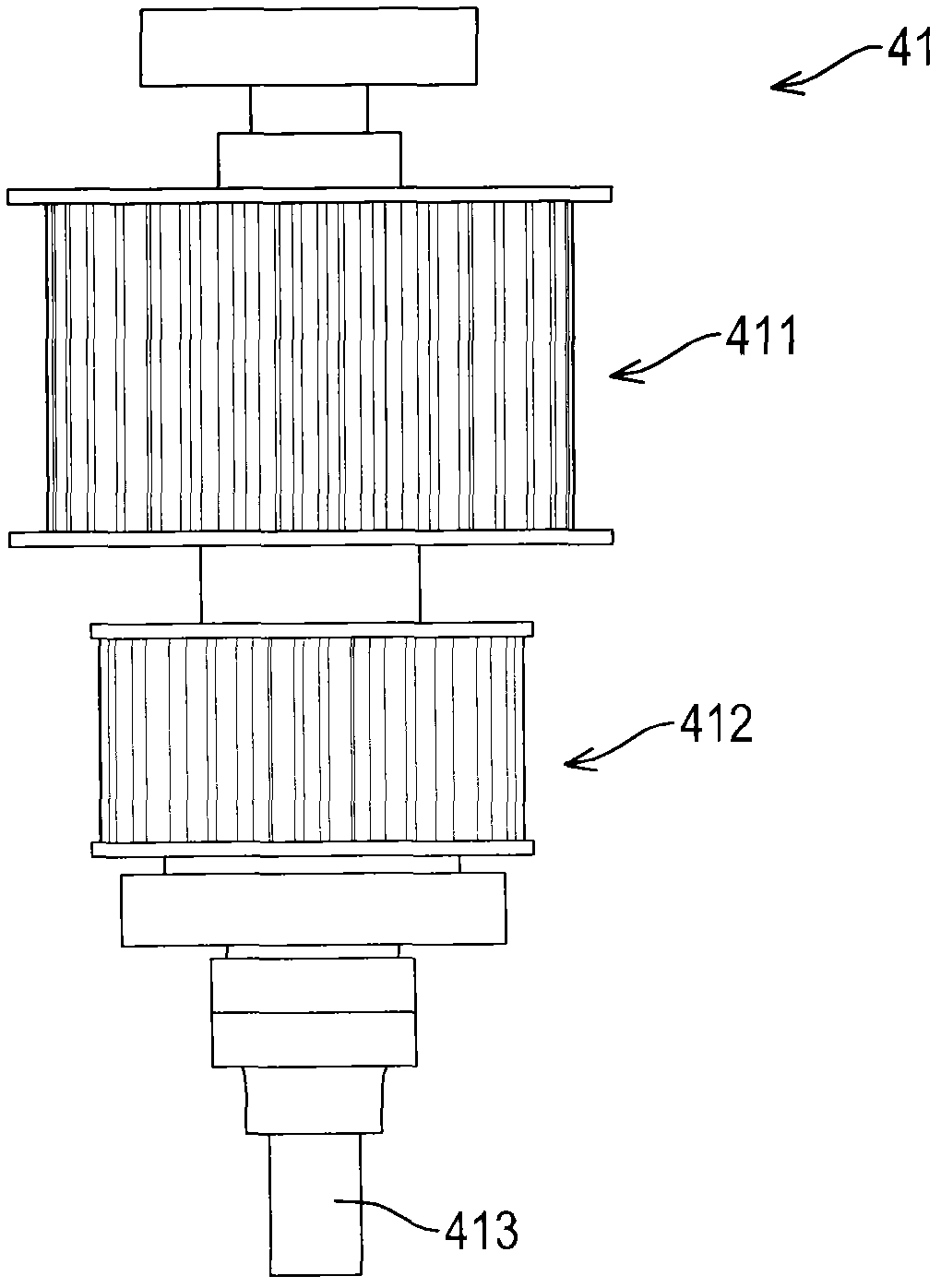

Drive device of polisher

The invention discloses a drive device of a polisher. The drive device comprises a shell, a drive unit arranged in the shell, a plurality of transmission units positioned in the shell and a plurality of polishing units, wherein the drive unit comprises a motor, a driving wheel connected with the motor and a drive rotation belt meshed with the driving wheel; each transmission unit comprises a transmission wheel meshed with the drive rotation belt, a plurality of driven wheels and a transmission belt; transmission belts of the transmission units are meshed with transmission wheels and a plurality of driven wheels of the corresponding transmission units; and a plurality of polishing units are respectively connected with a plurality of transmission units. By the drive device, a plurality of driven wheels are driven by the double-layer belts, so that load of the motor can be effectively reduced, the service lives of the belts are prolonged, and the drive device has extremely high practicality.

Owner:CHA ENTERPRISE

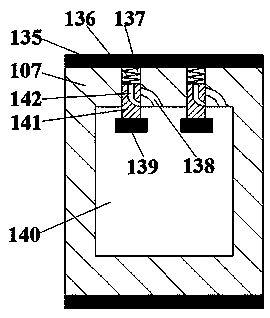

Device and method for internal polishing and clamping of ceramics

ActiveCN111687736BEasy to fixImprove clamping efficiencyPolishing machinesDispersed particle filtrationPolishingWorking environment

The invention discloses a ceramic internal polishing clamping device and method, belonging to the technical field of ceramic polishing clamping, comprising a bottom box, a dust accumulation tank is provided in the bottom box, an ash suction component is fixed in the dust accumulation tank, and the bottom box Fix the platen above the inner ash accumulation tank, install the clamping device above the fixed platen, set the polishing assembly above the clamping device, and fix the polishing assembly on the support frame plate installed at the side end of the bottom box. The ceramic internal polishing clamping device and method of the present invention can improve the clamping efficiency, facilitate the fixing of polished parts of different lengths, facilitate manipulation, improve the convenience of use, increase the stability of the clamping groove, prevent the slipping of the polished parts, and improve the The stability of polishing is suitable for polishing a variety of polishing parts, increasing the overall adaptability, increasing the polishing area, avoiding manual polishing, preventing dust from rising, affecting the staff, improving the quality of the working environment, and reducing damage to the human body.

Owner:安徽雪城超细碳酸钙有限公司

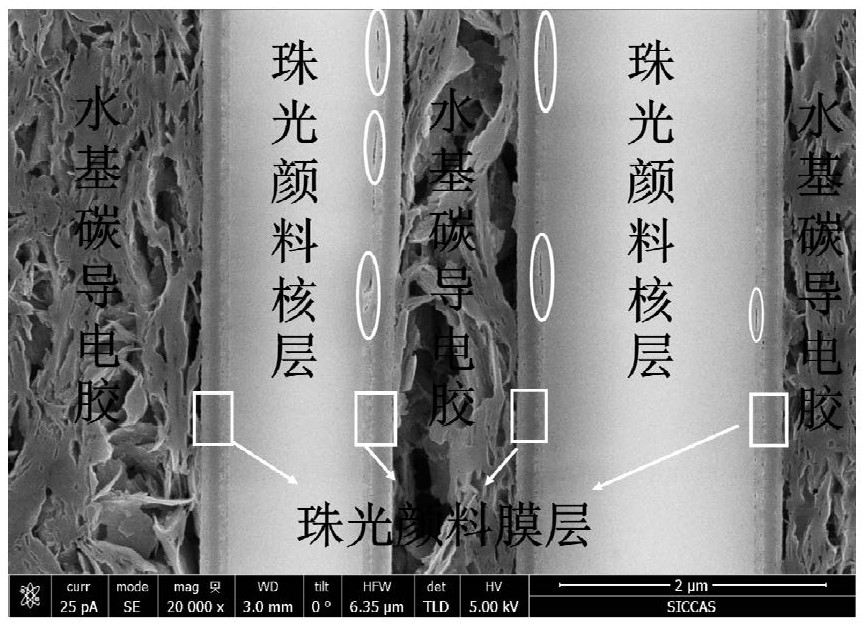

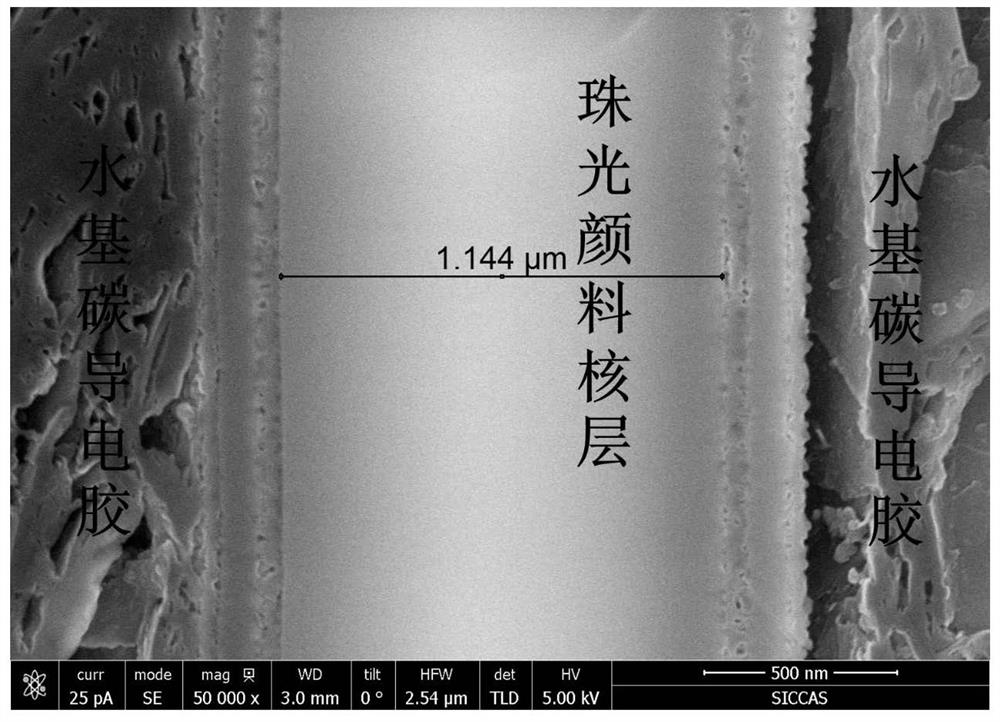

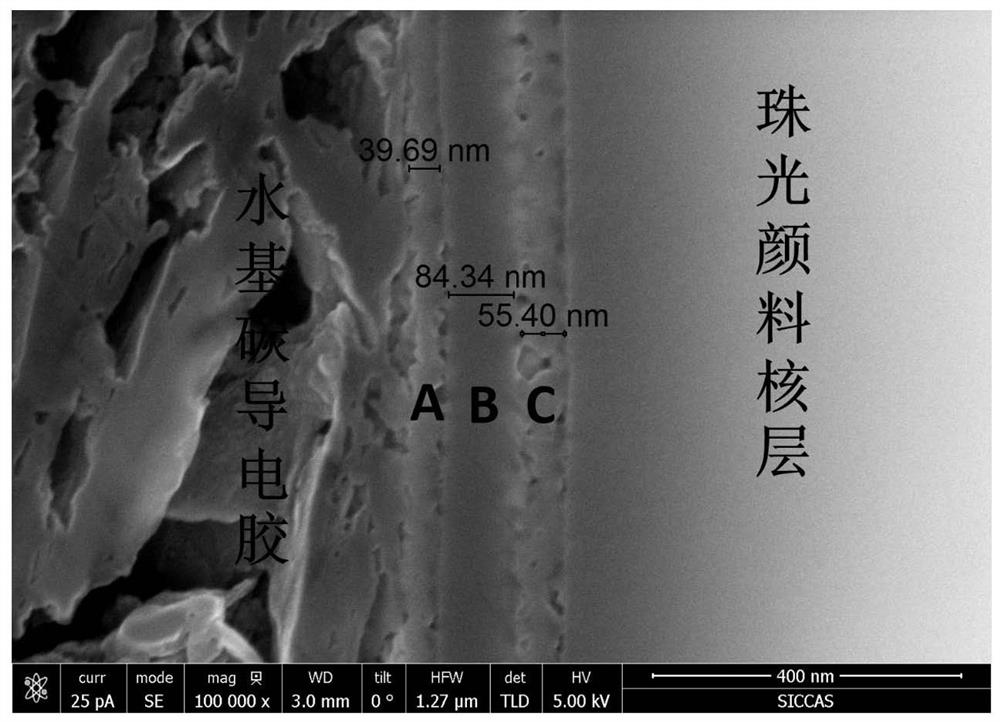

A preparation method and measurement method of a pearlescent pigment cross-section sample for scanning electron microscope determination

ActiveCN109030530BImprove reliabilityIncrease authenticityMaterial analysis using wave/particle radiationPhotopigmentIon beam

The invention provides a method for preparing and measuring a pearlescent pigment section sample for scanning electron microscope measurement. The preparation method includes: mixing liquid carbon conductive adhesive and pearlescent pigment and coating it on one side of a silicon chip, drying Obtain an initial sample fixed with a pearlescent pigment coating layer, the pearlescent pigment is coated with at least one continuous film layer and the thickness of the film layer is more than 2 nm; the obtained initial sample is subjected to ion beam cross-sectional polishing to obtain a cross-sectional sample of the pearlescent pigment , The parameters of the ion beam section polishing include: the ion beam accelerating voltage is 3-7 kV; the sample polishing time can be 120-480 minutes; the current is 1.5-3mA.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Automobile part polishing machine

InactiveCN113231947AReduce wear rateIncrease the polishing areaGrinding carriagesPolishing machinesAutomotive engineeringPolishing

The invention belongs to the technical field of automobile production devices, and discloses an automobile part polishing machine which comprises a base, a fixing assembly, a polishing assembly, a second rotating power component and a plurality of groups of rotating shafts, wherein the fixing assembly is fixedly mounted on the base, and used for supporting and fixing an automobile part; the polishing assembly is arranged on the base, is used for polishing the automobile part, and comprises a mounting component; the second rotating power component is fixedly mounted on the mounting component; and the rotating shafts are rotatably mounted on the mounting component. The automobile part polishing device has the beneficial effects that dust at a polishing position and residues generated by polishing can be blown away, and a polishing component can be cooled, so that the abrasion speed of the polishing component can be effectively reduced; both an unpolished area and a polished area can be cleaned, so that the polishing quality can be improved and the workload of subsequent dust treatment on the automobile part can be reduced; and the automobile part can be subjected to fine polishing and rough polishing simultaneously, so that the polishing component need not be replaced, and the polishing speed and efficiency can be improved.

Owner:江苏润杨精密制造有限公司

Method and apparatus for polishing large-scale diamond membrane

InactiveCN100390331CNo pollution in the processImprove polishing efficiencyAfter-treatment detailsPlasma techniqueHigh frequency powerMicrowave

A method and an equipment for extended diamond film polishing. It includes such steps as follows: produce electron cyclotron resonance plasm by microwave stimulating; high-frequency power was coupled to ion in plasm by ion convoluted vibrating, so that the kintic temperature of ion was increased to 10-40eV; control ion movement by derivative electrode and graded magnetic field so that etching reaction may occur between specific carbon atom that to be wiped off and the ion as the ion moves to the surface of diamond film; Volatile gas generated and polishing completed. The equipment consists of four parts: plasma generating unit, ion heating up unit, ion movement controlling unit and etching reaction and polishing unit. Advantages are high polishing efficiency, large polishing dimension, high precision and non pollution of diamond film surface.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

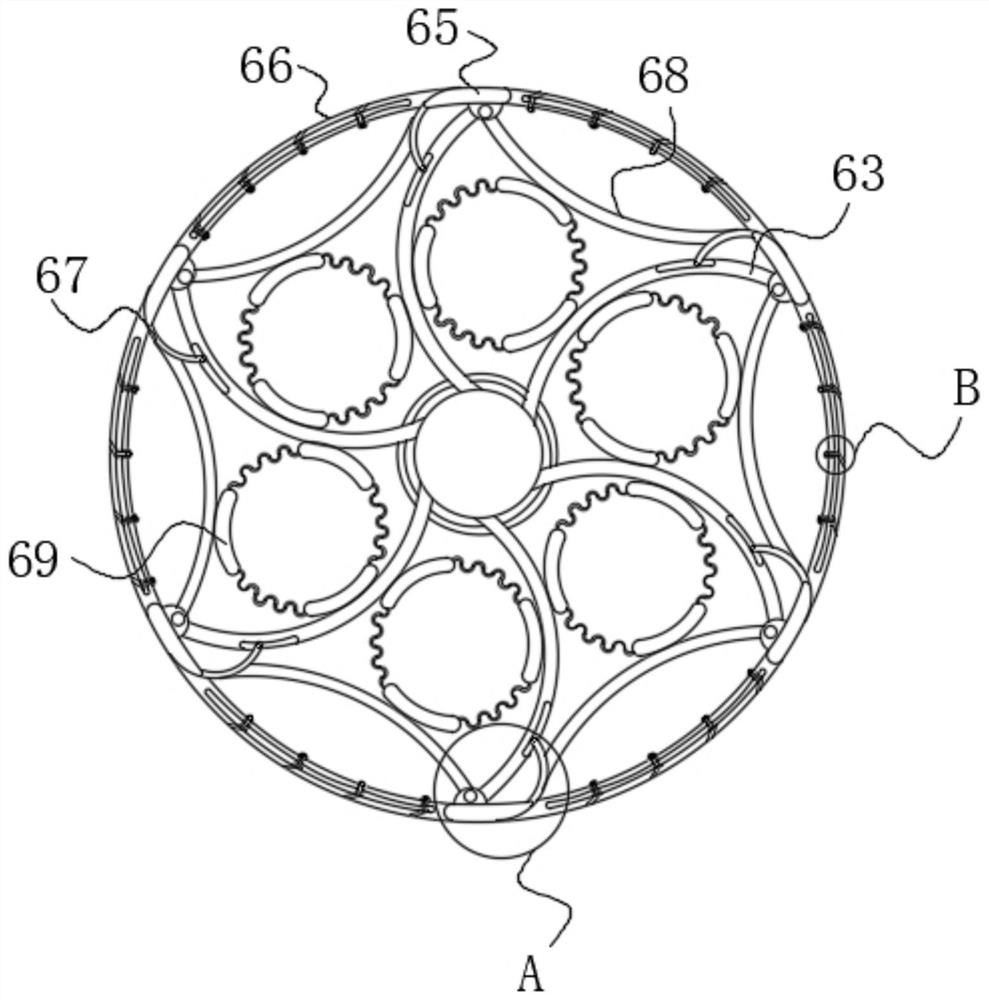

Method for efficiently polishing wood

InactiveCN113601371AIncrease the number ofProtection securityPolishing machinesGrinding drivesGear driveReciprocating motion

The invention discloses a method for efficiently polishing wood. The method involves a machine body shell suitable for the method, wherein a machine body cavity is formed in the machine body shell, a polishing mechanism is arranged in the machine body cavity, and the polishing mechanism comprises a planet box fixedly connected to the inner wall of the machine body cavity. According to the method, a gear drive principle and a belt drive principle are used, a group of planetary gear structures is used firstly, the polishing area can be enlarged, two groups of different rotating speeds can be divided, rough polishing is carried out on the outer side at a low rotating speed firstly, then fine polishing is carried out on the interior at a high rotating speed, in addition, the number of polishing blocks on a polishing disc can be increased under the action of centrifugal force during polishing, and polishing particles do reciprocating motion, so that the polishing efficiency is improved, the polishing effect is guaranteed, and wood chips generated during polishing can be collected through the method, so that the wood chips are prevented from being sucked into a human body to harm the body health, the safety of workers is protected, and meanwhile resources can further be saved.

Owner:厦门绘眸贸易有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com