Preparation method of chemical material slurry plunger pump with composite coating, and product thereof

A composite coating and plunger pump technology, applied in the field of plunger pumps, can solve the problems of lack of corrosion resistance and wear resistance, corrosion strength enhancement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

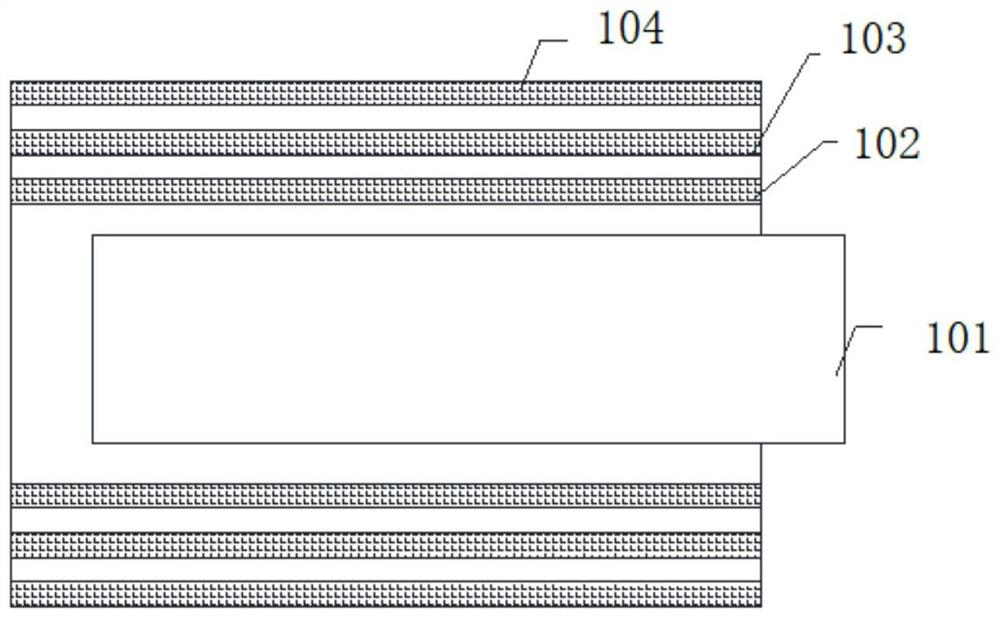

[0064] A chemical slurry plunger pump with a ceramic coating plunger, the process of which is:

[0065] 1. The part where the plunger substrate coating is located is undercut, leaving a coating thickness of 0.3mm, and the connection between the edge of the coating and the substrate should be chamfered at 45 degrees.

[0066] 2. The substrate is degreased and baked with an organic solvent. Sand blasting with No. 24 brown corundum sand, and the non-coating area is protected with a fixture. Sandblasting compressed air pressure 5kg, distance 15cm, sandblasting angle 80°. After sandblasting, the surface of the substrate is evenly roughened, reaching Sa3 level.

[0067] 3. After preheating the substrate to 100°C, use the SG100 spray gun 730 nozzle of the Thermach company in the United States to spray the nickel-chromium underlayer coating with a spraying current of 400A, a voltage of 38V, and a coating thickness of 0.1mm.

[0068] 4. Use the SG100 spray gun 720 subsonic nozzle of...

Embodiment 2

[0073] A preparation method of a chemical slurry plunger pump with a ceramic coating plunger, comprising the following preparation steps:

[0074] (1) The part where the plunger substrate coating is located is cut down to reserve a coating thickness of 0.25 mm, and the connection between the coating edge and the substrate is chamfered at 40 degrees;

[0075] (2) The substrate is degreased and baked with an organic solvent; then sandblasting, the compressed air pressure of sandblasting is 6kg, the distance of sandblasting is 12cm, and the angle of sandblasting is 85°; the non-coating area is protected by a fixture; thus the roughness can be increased ;

[0076] (3) The substrate is preheated to 90°C, sprayed with nickel-chromium primer, spraying current 350-450A, voltage 35V, coating thickness 0.08mm;

[0077] (4) Spraying chromium oxide coating, spraying current 500A, voltage 40V, coating thickness 0.2mm;

[0078] (5) Vacuum impregnation sealing is carried out to the coating...

Embodiment 3

[0082] A preparation method of a chemical slurry plunger pump with a ceramic coating plunger, comprising the following preparation steps:

[0083] (1) The part where the plunger substrate coating is located is cut down to reserve a coating thickness of 0.25-0.35mm, and the connection between the edge of the coating and the substrate is chamfered at 40-50 degrees;

[0084] (2) The substrate is degreased and baked with an organic solvent; then sandblasting is performed, with a compressed air pressure of 4kg, a sandblasting distance of 8cm, and a sandblasting angle of 75°; the non-coated area is protected by a fixture;

[0085] (3) The substrate is preheated to 110°C, and the nickel-chromium primer layer is sprayed, the spraying current is 450A, the voltage is 40V, and the coating thickness is 0.12mm;

[0086] (4) Spraying chromium oxide coating, spraying current 600A, voltage 50V, coating thickness 0.4mm;

[0087] (5) Vacuum impregnation sealing is carried out to the coating, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com