Glazing machine

A glaze and frame technology, which is applied to surface polishing machine tools, machine tools suitable for grinding workpiece planes, grinding frames, etc. It can eliminate cutting marks, improve surface gloss and improve grinding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

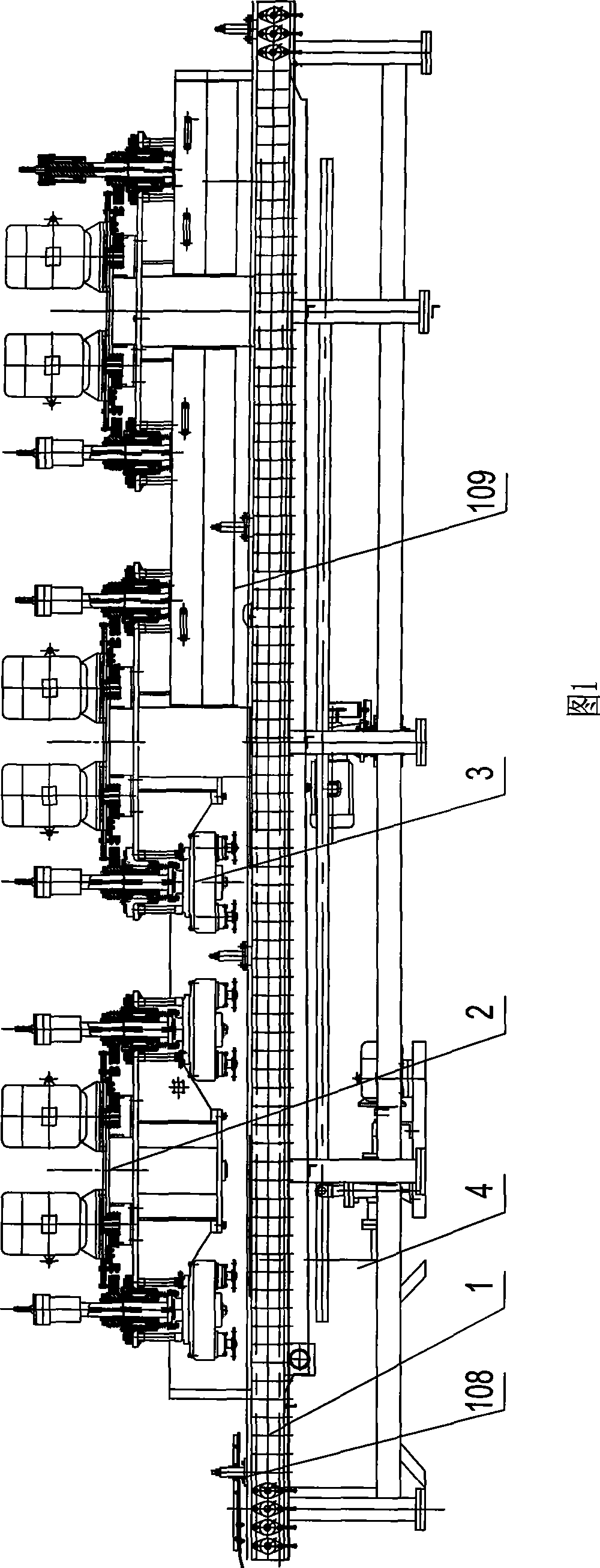

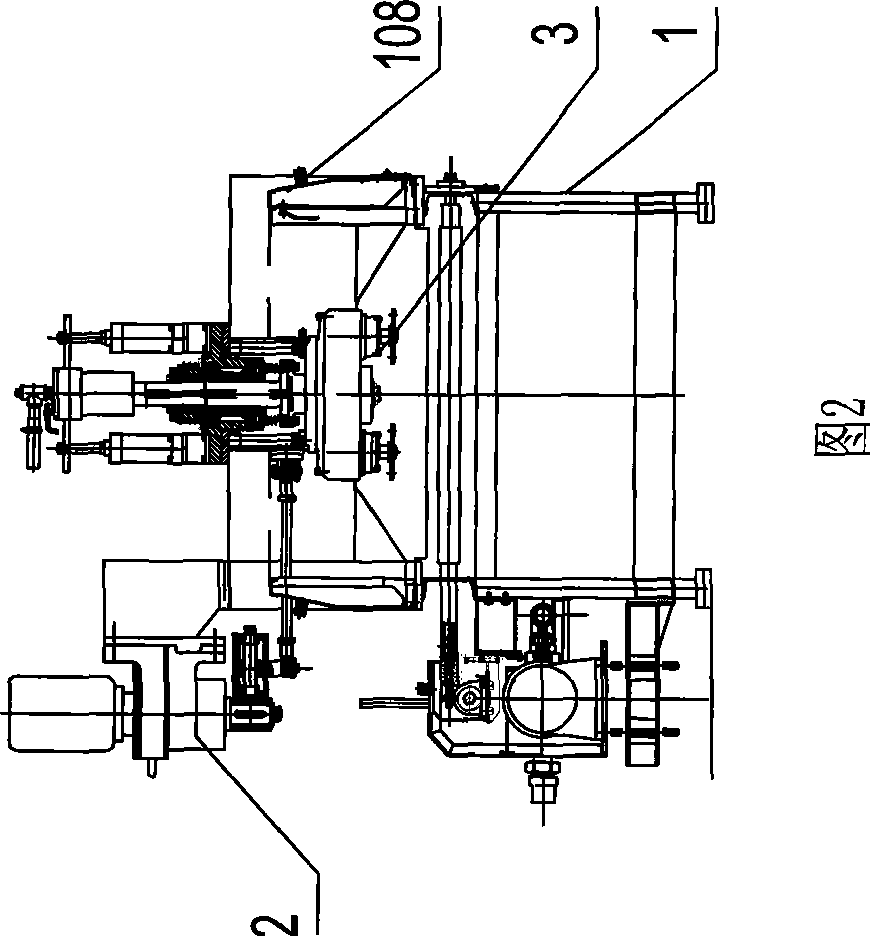

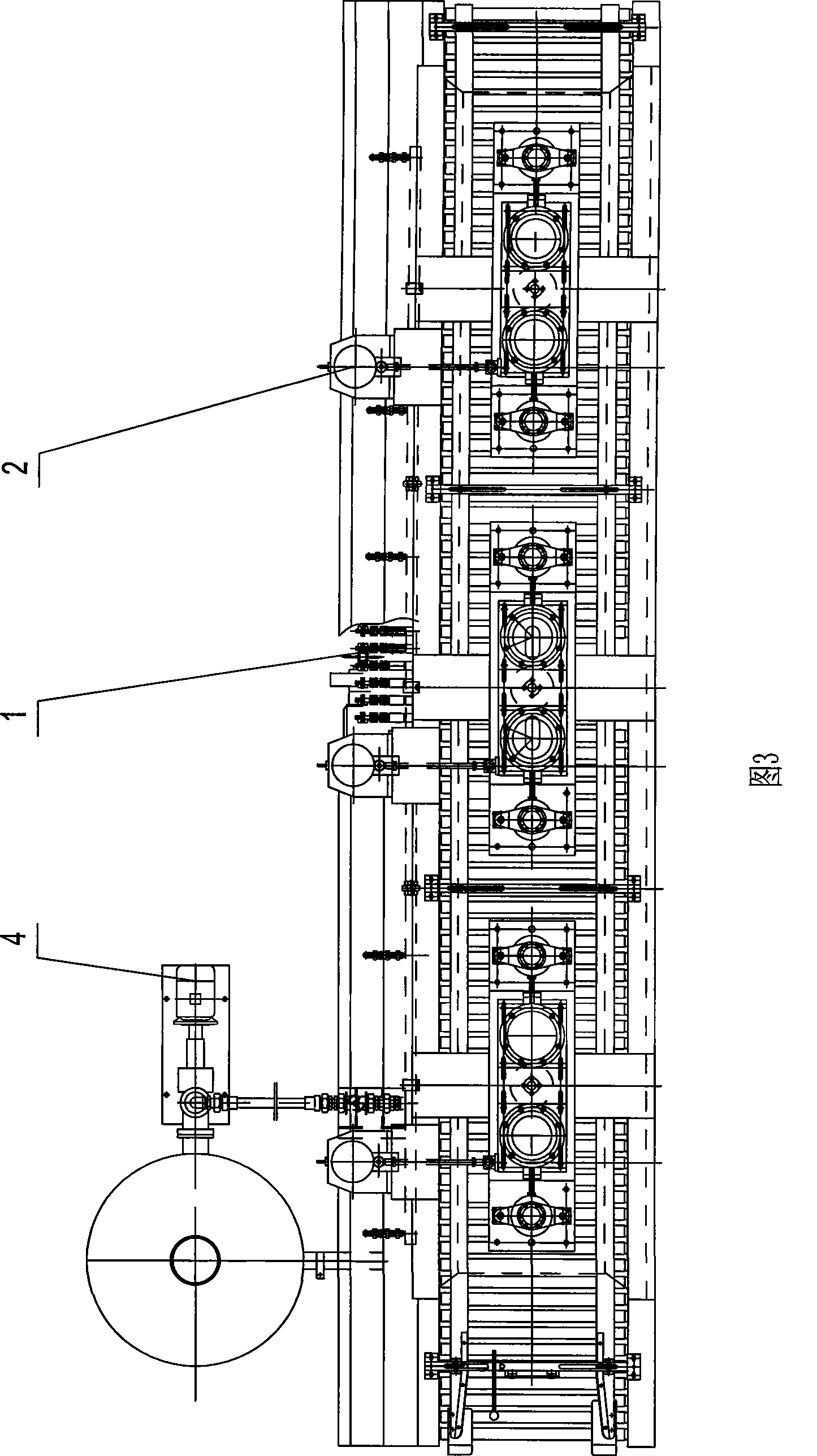

[0031] As shown in FIGS. 1-3 , a glaze polishing machine of the present invention includes a tile conveying device 1 and a polishing device arranged along the extending direction of the conveying device 1 . The polishing device includes a swinging grinding table device 2, a rotating grinding table placed on the swinging grinding table device 2, and a grinding head device 3 distributed on the rotating grinding table, and a cooling system 4 is also provided on the grinding head device 3 . In the present invention, three sets of oscillating grinding table devices 2 and grinding head devices 3 are provided along the axial extension direction of the conveying device 1. Generally, in order to achieve better polishing and grinding effects, the oscillating grinding table device 2 and the grinding head device 3 There can also be more groups.

[0032] As shown in Fig. 4 and Fig. 5, the conveying device 1 includes a support foot 101 and a crossbeam 102 placed on the support foot 101, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com