Hardware polishing equipment

A technology for hardware and equipment, applied in the field of hardware polishing equipment, can solve the problems of inconvenient operation, heavy weight, uneven polishing surface, etc., and achieve the effects of reducing defects, fast polishing, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

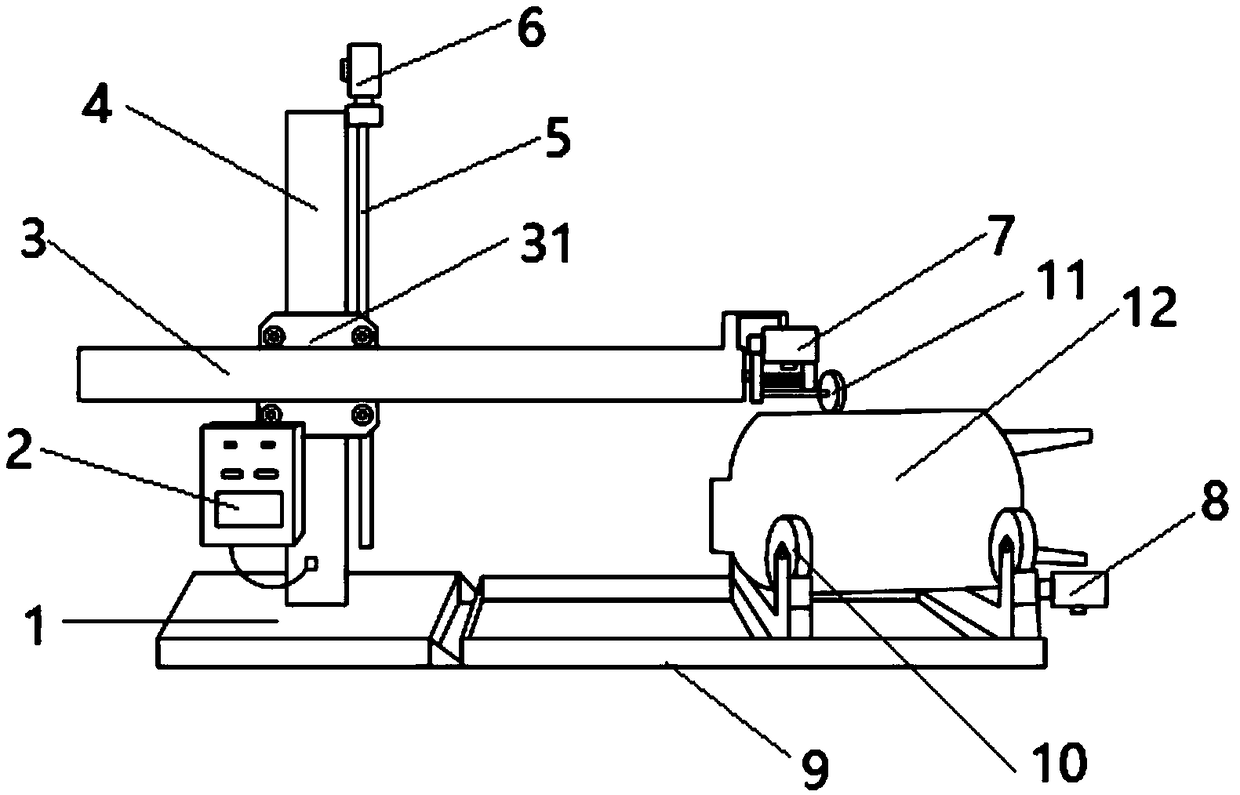

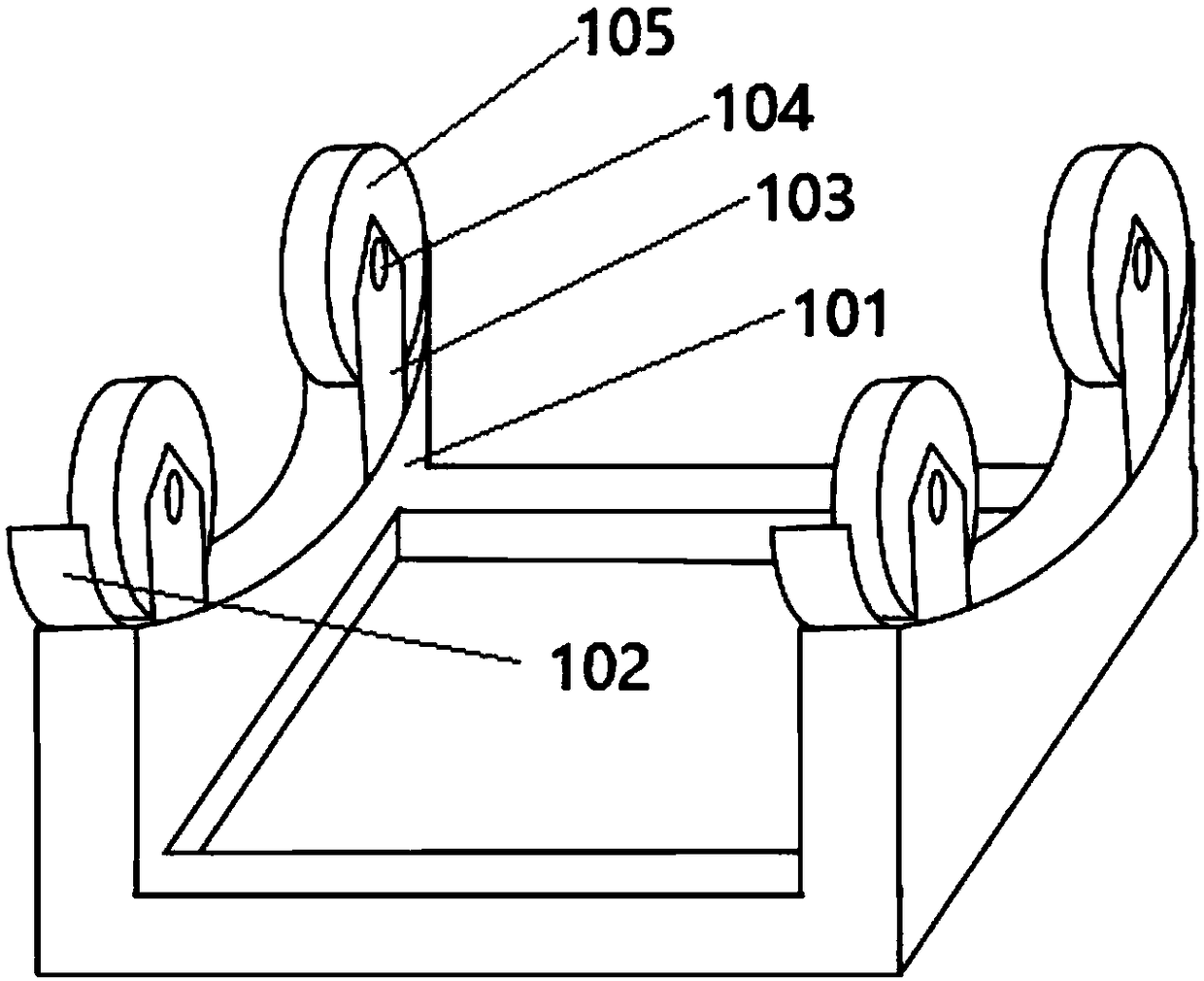

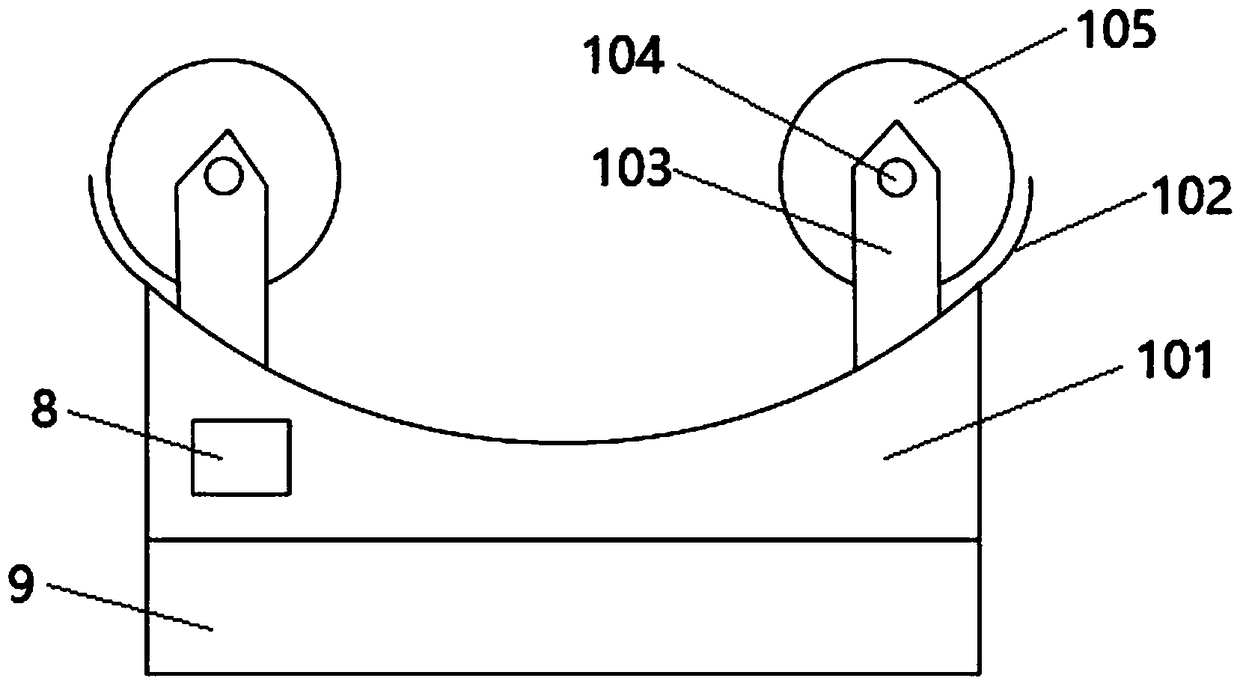

[0021] see Figure 1 to Figure 3 , a hardware polishing device according to the present invention, comprising a base 1, an electric box 2, a lifting rod 3, a fixed rod 4, a sliding rod 5, a polishing stone 11 and several motors, and the fixed rod 4 is vertically arranged on the base 1 Above, the lifting rod 3 is movably connected to the fixed rod 4, and the lifting rod 3 and the fixed rod 4 are perpendicular to each other; the sliding rod 5 is arranged on one side of the fixed rod 4 in parallel, and a The sliding base 31 is movably connected, and the sliding base 31 is fixedly connected with the lifting rod 3 , and the end of the lifting rod 3 is connected with the polishing stone 11 .

[0022] One side of described base 1 connects movable frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com