Dust-free polishing device for metal products

A technology for polishing devices and metal products, which is applied in the direction of grinding/polishing safety devices, grinding drive devices, metal processing equipment, etc., and can solve problems such as extended working hours, small plate polishing area, and reduced plate polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

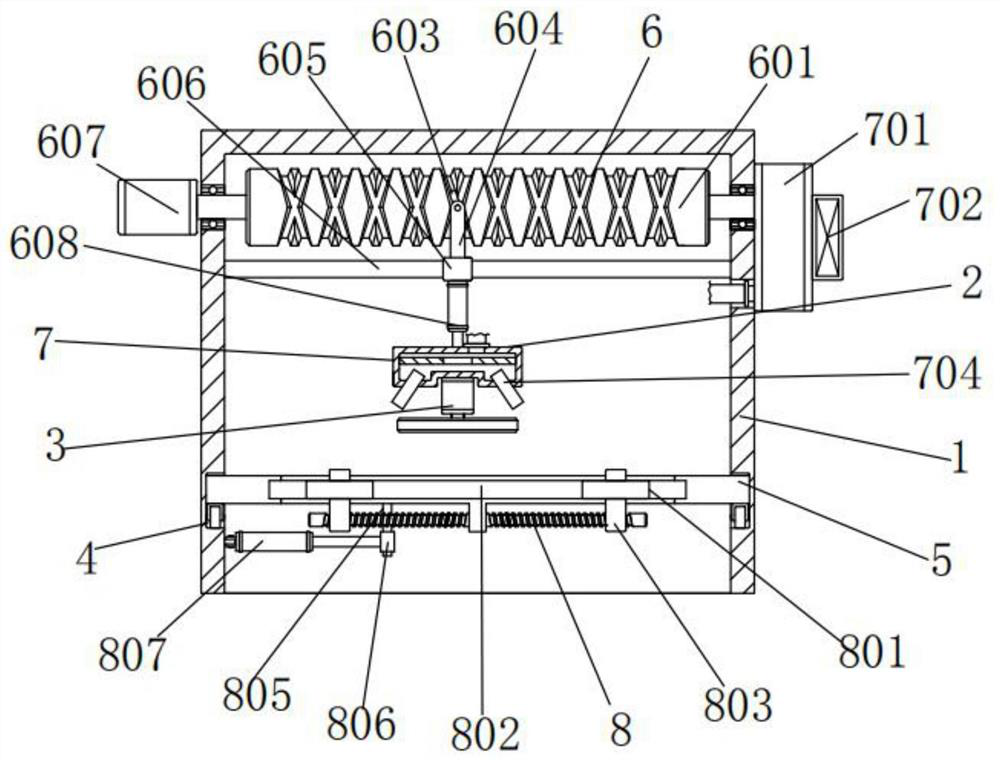

[0032] A dust-free polishing device for metal products, comprising a machine body 1, a box body 2 is provided inside the body body 1, and a polishing device 3 is provided at the bottom of the box body 2, and the polishing device 3 is made by fixing a high-speed motor and a polishing wheel, The polishing device 3 is installed on the bottom of the box body 2, and the bottom of the polishing device 3 is provided with a sliding seat 5, and the left and right sides of the sliding seat 5 are equipped with grooves 4, and the groove 4 plays a guiding role for the sliding seat 5. The groove 4 is processed on the left and right sides of the inner wall of the body 1, and a reciprocating assembly 6 is arranged above the inside of the body 1;

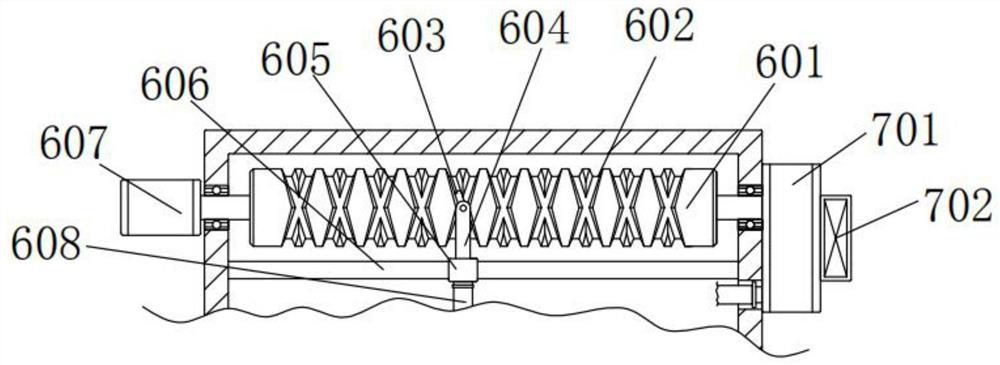

[0033] The reciprocating assembly 6 includes a round roller 601, a chute 602, a slide block 603, a vertical bar 604, a collar 605, a cross bar 606, a motor 607 and a first air cylinder 608. The outer wall of the round roller 601 is matched with the i...

Embodiment 2

[0035] As an option, see Figure 1-3 , a metal product dust-free polishing device, the inside and outside of the box body 2 are provided with a dust collection assembly 7, the dust collection assembly 7 includes a dust collection box 701, a fan 702, a partition 703 and a branch pipe 704, the left end of the dust collection box 701 is connected to the body The right end of 1 is fixedly connected, and the right end of the dust collection box 701 is equipped with a fan 702. The model of the fan 702 is HG-HF-150P. The left side of the partition is provided with a partition 703, and the central round hole of the partition 703 makes the diversion of the branch pipe 704 more uniform. , the branch pipes 704 are equidistantly distributed in a ring, and the position of the branch pipes 704 is set corresponding to the position of the polishing device 3, so that the design can realize precise dust removal;

[0036] The solution in this embodiment can be selectively used in combination wi...

Embodiment 3

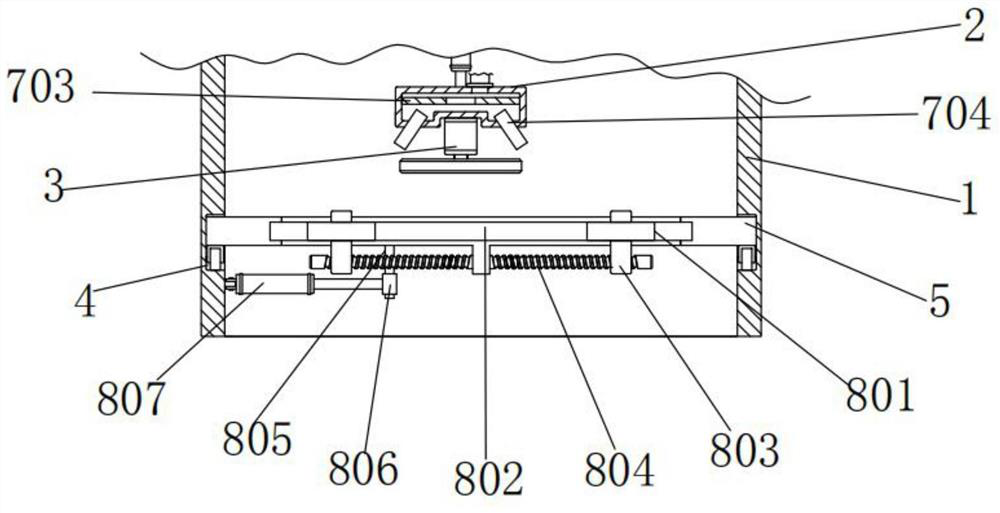

[0038] As an option, see figure 1 , 3 , 4 and 6, metal product dust-free polishing device, the upper and lower sides of the slide seat 5 are provided with a fixed assembly 8, the fixed assembly 8 includes a slide plate 801, a transverse groove 802, a support block 803, a double-ended stud 804, and a short rod 805 , the circular ring 806 and the second cylinder 807, the outer wall gap of the slide plate 801 is matched with a transverse groove 802, the transverse groove 802 is processed inside the slide seat 5, the upper and lower ends of the slide plate 801 are provided with support blocks 803, and the support blocks on the same side The inner ends of 803 are respectively fixedly connected to the upper and lower ends of the slide plate 801, and the support block 803 above protrudes from the top of the slide seat 5, so that the design is convenient for fixing the sheet metal, and the inside of the support block 803 below is provided with double-ended screws. Column 804, the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com