Polishing machine for automobile engine crankshaft

A technology for automobile engines and polishing machines, which is applied to surface polishing machine tools, grinding/polishing equipment, grinding racks, etc. It can solve the problems of inability to complete fast polishing at one time, incomplete control of precision, and low efficiency of manual polishing, etc. Problems, to achieve the effect of polishing is not easy to deform, improve efficiency, and ensure polishing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

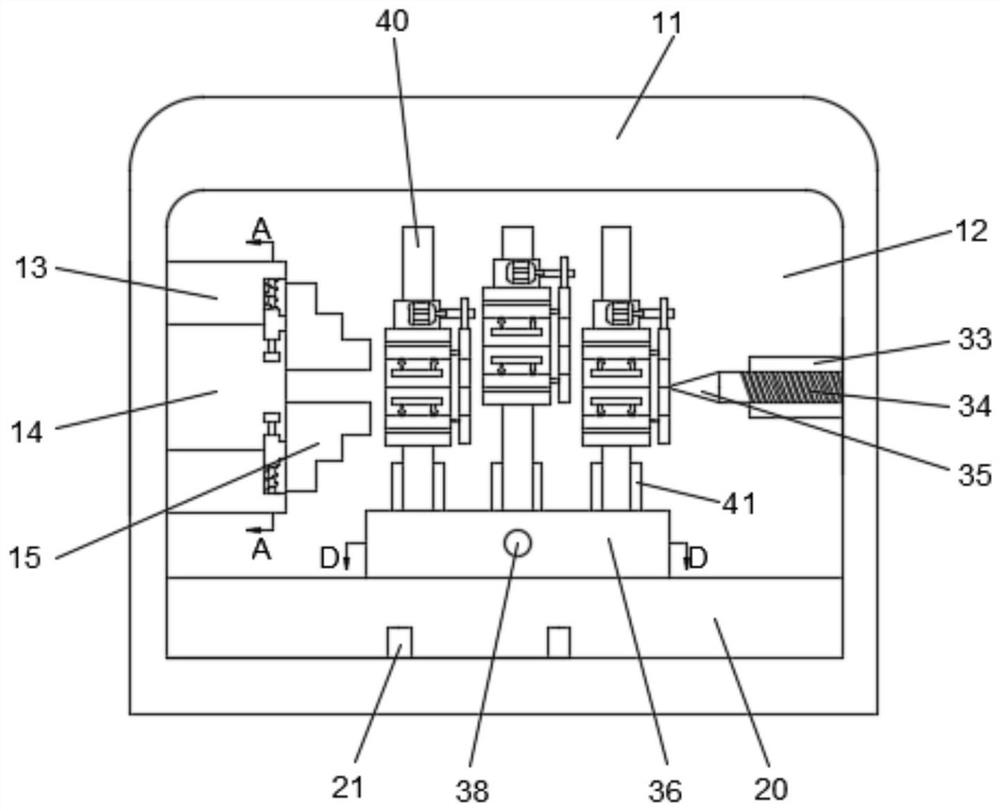

[0028] In the description of the present invention, it should be understood that the terms "upper", "lower", "front", "rear", "left", "right", "vertical", "horizontal", "top", The orientation or positional relationship indicated by "bottom", "inside", "outside", etc. is based on the attached figure 2 The orientation or positional relationship shown is only a simplified description for the convenience of describing the present invention, rather than indicating or implying that the indicated device or element must have a specific orientation, be constructed and operated in a specific orientation, and therefore should not be construed as a reference to the present invention. limits:

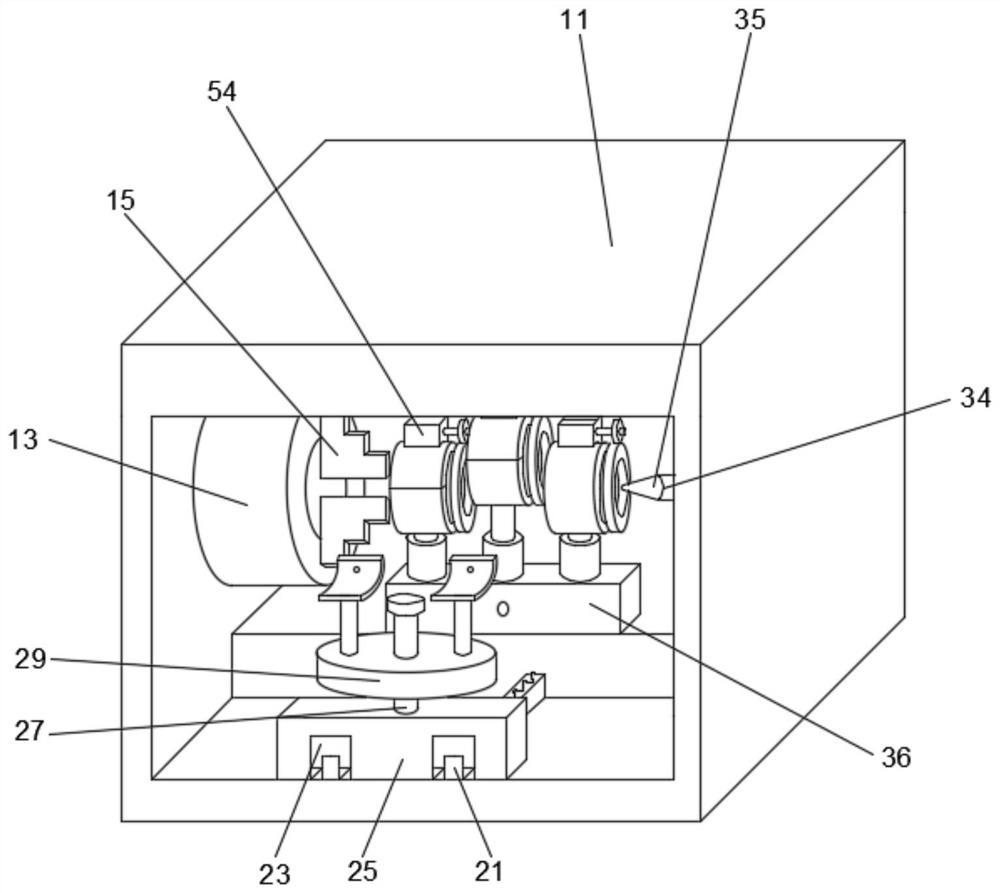

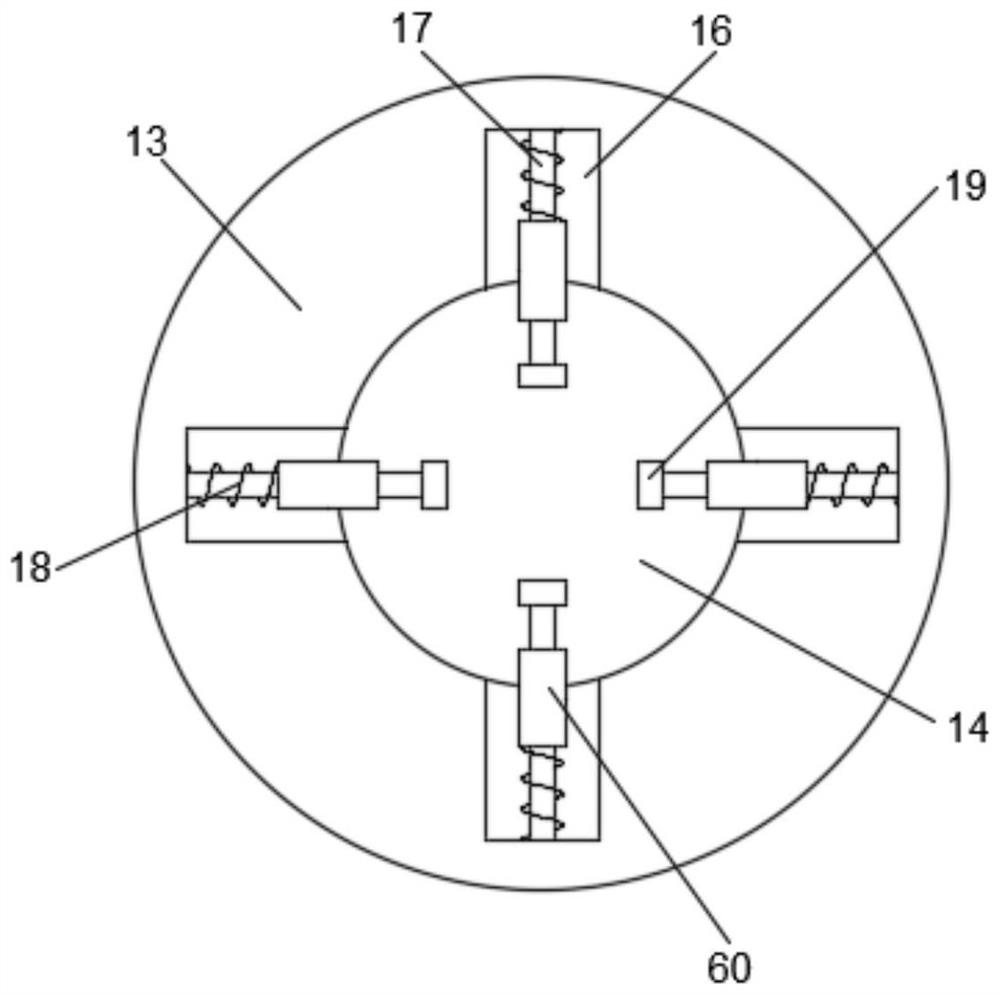

[0029] Refer to the attached Figure 1-Figure 8 , according to an embodiment of the present invention, an automobile engine crankshaft polishing machine includes a main box body 11, a polishing cavity 12 is arranged in the main box body 11, and a telescopic clamping column is arranged on the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com