Mold for large belt wheel machining and manufacturing method thereof

A large pulley and mold technology, which is applied in the field of molds for processing large pulleys, can solve the problems that large pulleys cannot have draft angles and high inner surface smoothness, so as to improve the performance of cold and heat balance and improve the cooling effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

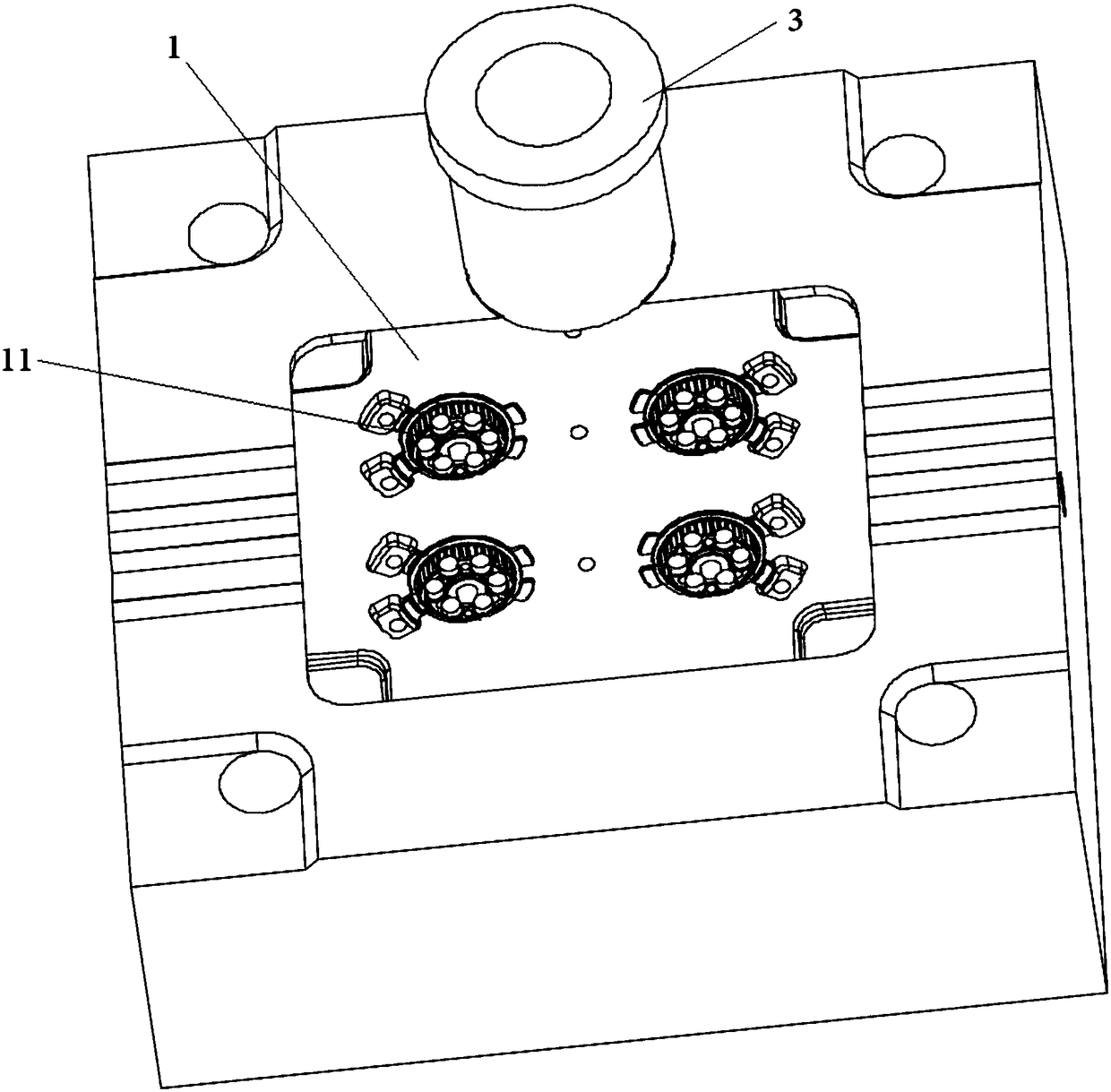

[0017] Below, combine figure 1 and 2 The mold for processing the large pulley of the present invention and its manufacturing method will be described in detail.

[0018] Such as figure 1 and 2 As shown, the mold for processing the large pulley of the present invention includes a fixed mold core 1 , a movable mold core 2 and a splitter cone 3 . The top of the fixed mold core 1 is provided with a casting cavity 11, and the side wall of the casting cavity 11 is provided with an alveolar structure. The movable mold core 2 is press-covered on the top of the fixed mold core 1 , and the bottom of the movable mold core 2 is provided with a casting cavity cover 21 corresponding to the position of the casting cavity 11 . The bottom of the movable mold core 2 is provided with a feed channel 22 , which communicates with the splitter cone 3 and the casting cavity cover 21 , that is, the feed channel 22 communicates with the casting cavity 11 and the splitter cone 3 . The roughness of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com