Self-balancing PE ball core polishing machine

A polishing machine, self-balancing technology, applied in surface polishing machine tools, grinding/polishing equipment, grinding racks, etc., can solve PE ball core vibration, difficult to control polishing pressure, surface roughness of PE ball core polishing accuracy Problems such as failure to achieve the expected effect, to achieve the effect of low cost, guaranteed polishing accuracy, and conducive to large-scale promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

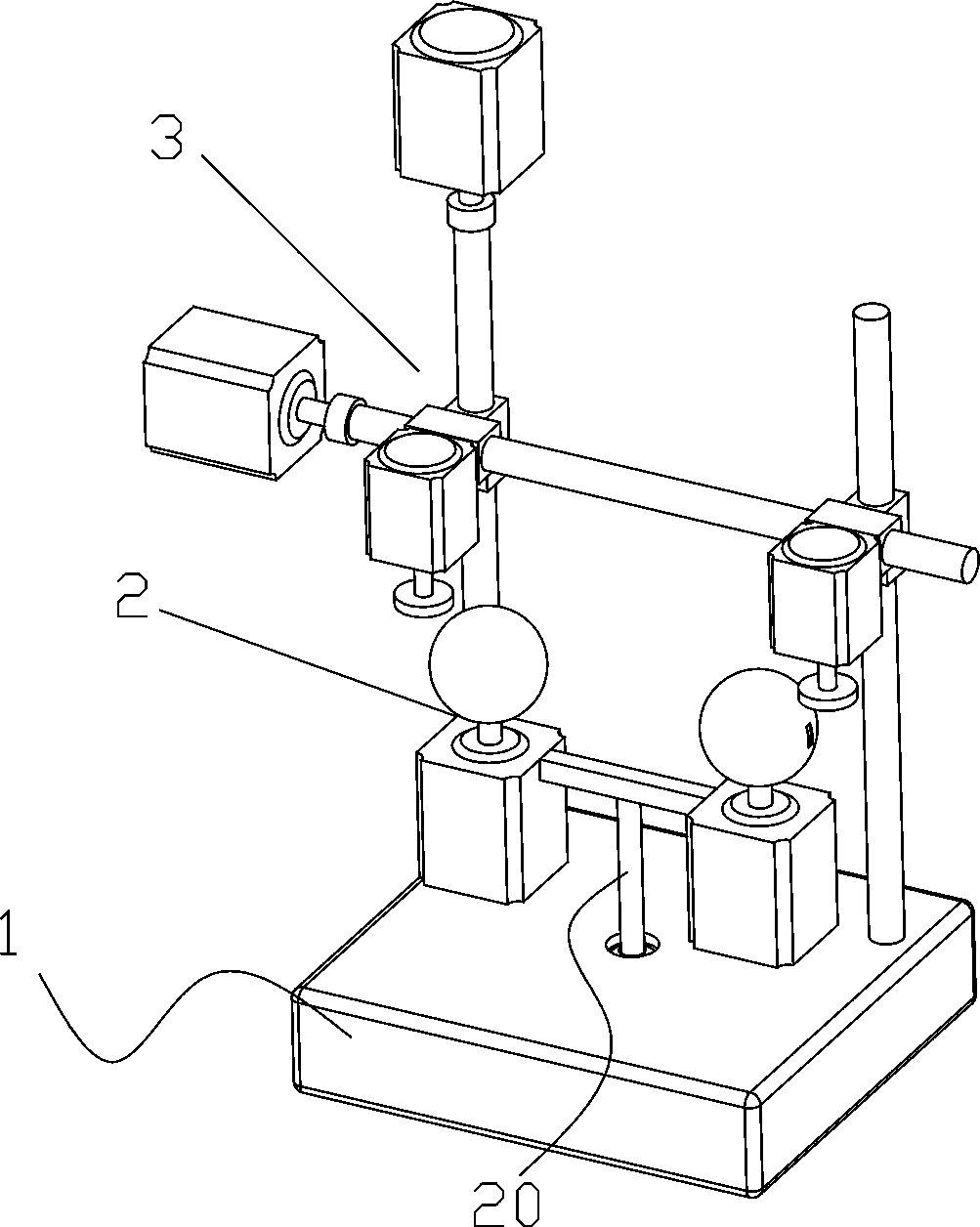

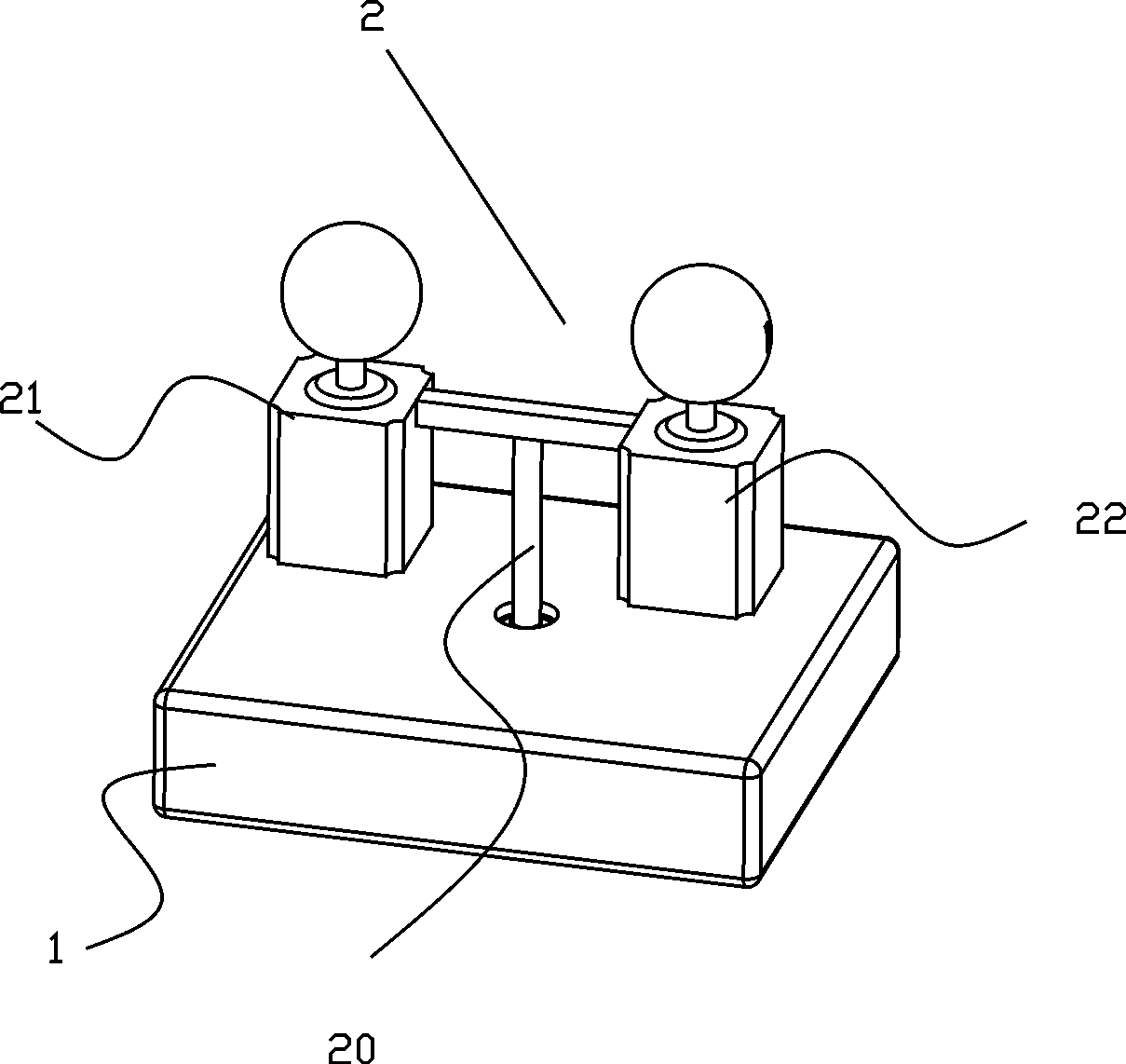

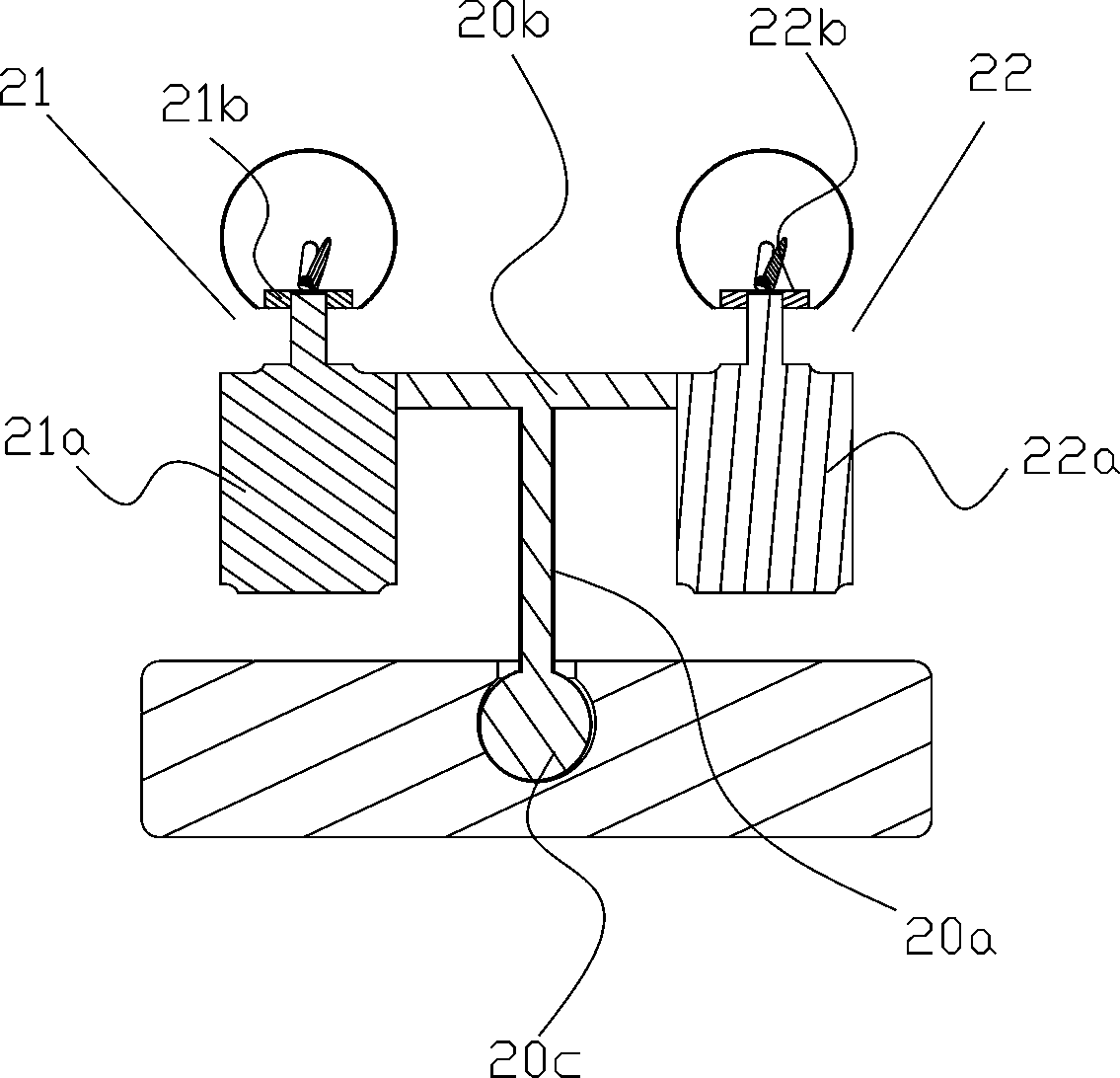

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail: Figure 1 to Figure 5 As shown, the present invention discloses a self-balancing PE ball core polishing machine, including: a base 1, on which a PE ball core clamping device 2 and a polishing wheel feeding device 3 are arranged, and the PE ball The core clamping device 2 comprises a bow support 20, which comprises a longitudinal bar 20a, a cross bar 20b is arranged at the end of the longitudinal bar 20a, a spherical part 20c is arranged at the tail of the longitudinal bar 20a, and the spherical part 20c Cooperating with the spherical groove provided on the base 1, the first clamping mechanism 21 and the second clamping mechanism 22 are fixed on the cross bars on both sides of the bow support 20; The vibratory force received by the ball core can cancel each other out. When the two PE ball cores are installed on the first clamping mechanism 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com