Single-sphere double-R watch cover secondary material reworking process and polishing device

A polishing device and watch technology, applied in the polishing field, can solve problems such as poor control of thickness, difficulty in meeting polishing requirements, scratches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

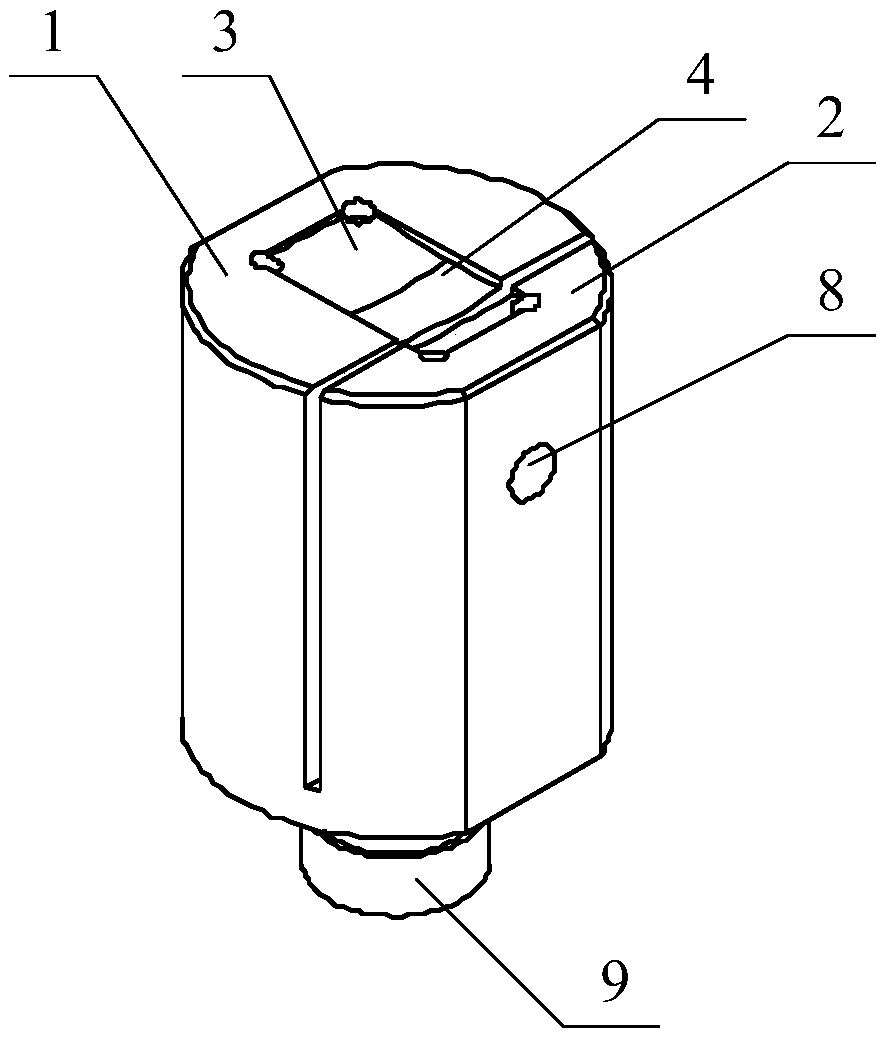

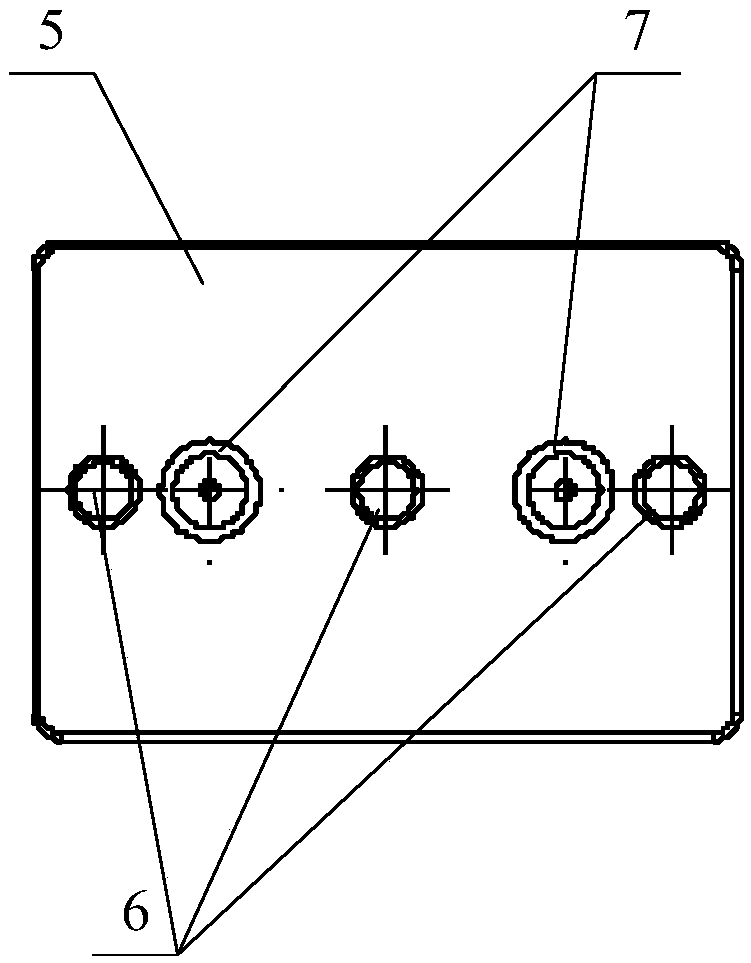

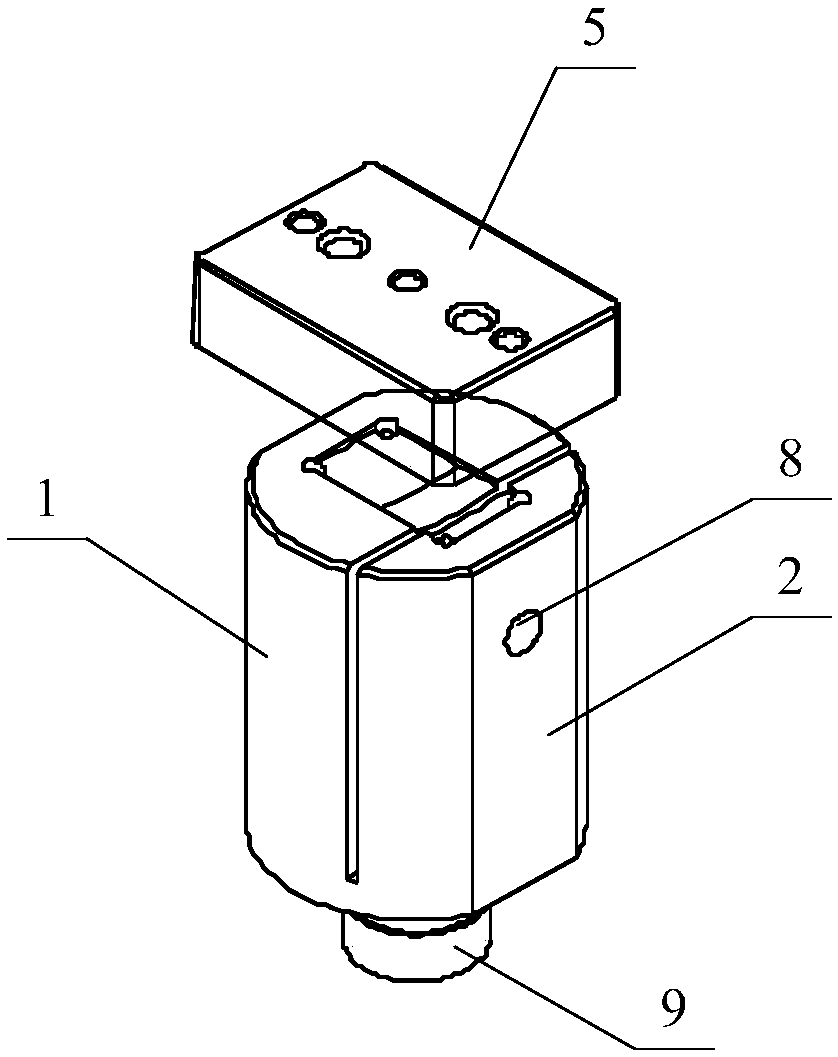

[0031] The core of this specific embodiment is to provide a single-ball double R watch cover 2-material rework process, which can rework and polish the single-ball double R watch cover with 2 materials to ensure its polishing accuracy and solve the current problems in this field.

[0032] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solutions of the invention described in the claims.

[0033] The single ball double R watch cover 2 material rework process proposed by the present invention comprises the steps of: placing the watch cover to be polished in the cavity structure of the polishing device, making the spherical surface of the watch cover stick to the inner wall of the cavity structure close; adjust t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com