Circular arc radius adjustable disc type air bag polishing head

A technology of arc radius and airbag polishing, which is applied in the direction of grinding/polishing equipment, grinding heads, and parts of grinding machine tools, which can solve the problems of poor dynamic balance and achieve the effect of ensuring smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

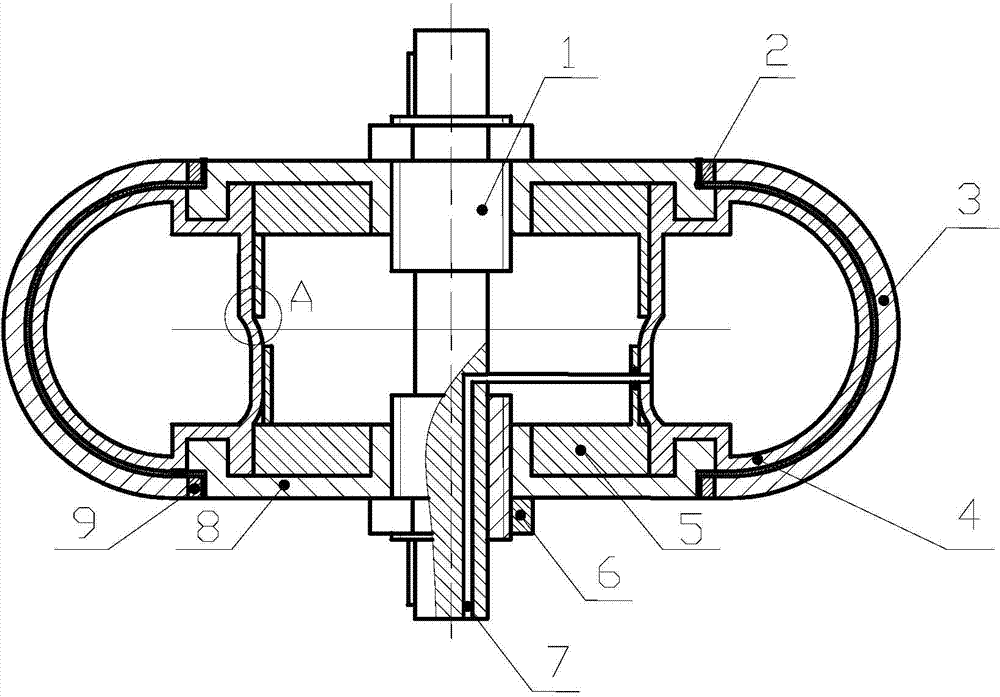

[0022] see Figure 1~4 , the embodiment of the present invention is provided with adjusting screw rod 1, annular airbag bracket 2, annular elastic outer layer 3, annular elastic inner layer 4, elastic inner layer fixing sleeve 5, adjusting flange 8, airbag bracket fixing sleeve 9 and polishing material layer ( not shown in the figure).

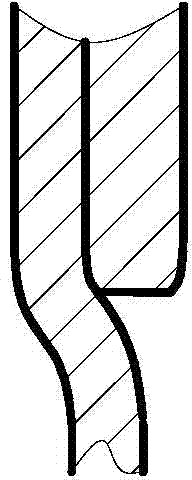

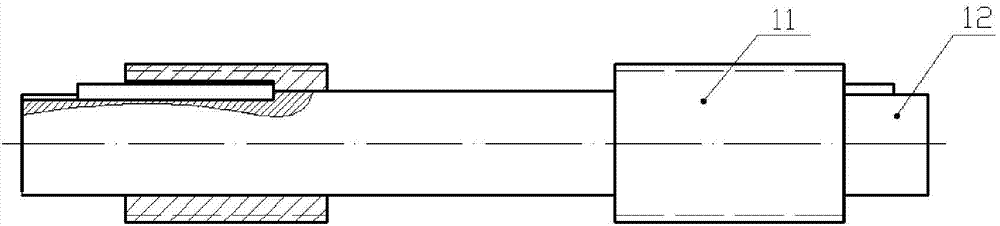

[0023] The adjusting screw 1 is provided with an adjusting screw sleeve 11 and a main shaft connecting rod 12, the annular elastic inner layer 4 is bonded to the elastic inner layer fixing sleeve 5, the elastic inner layer fixing sleeve 5 is provided with a support plate, and the support plate is provided with a groove Holes and slots are used to pass through the inflation hose to prevent the airbag from being over-inflated and deformed too much; The airbag bracket 2 is fixed on the adjusting flange 8 and closely ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com