Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Guaranteed drying time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

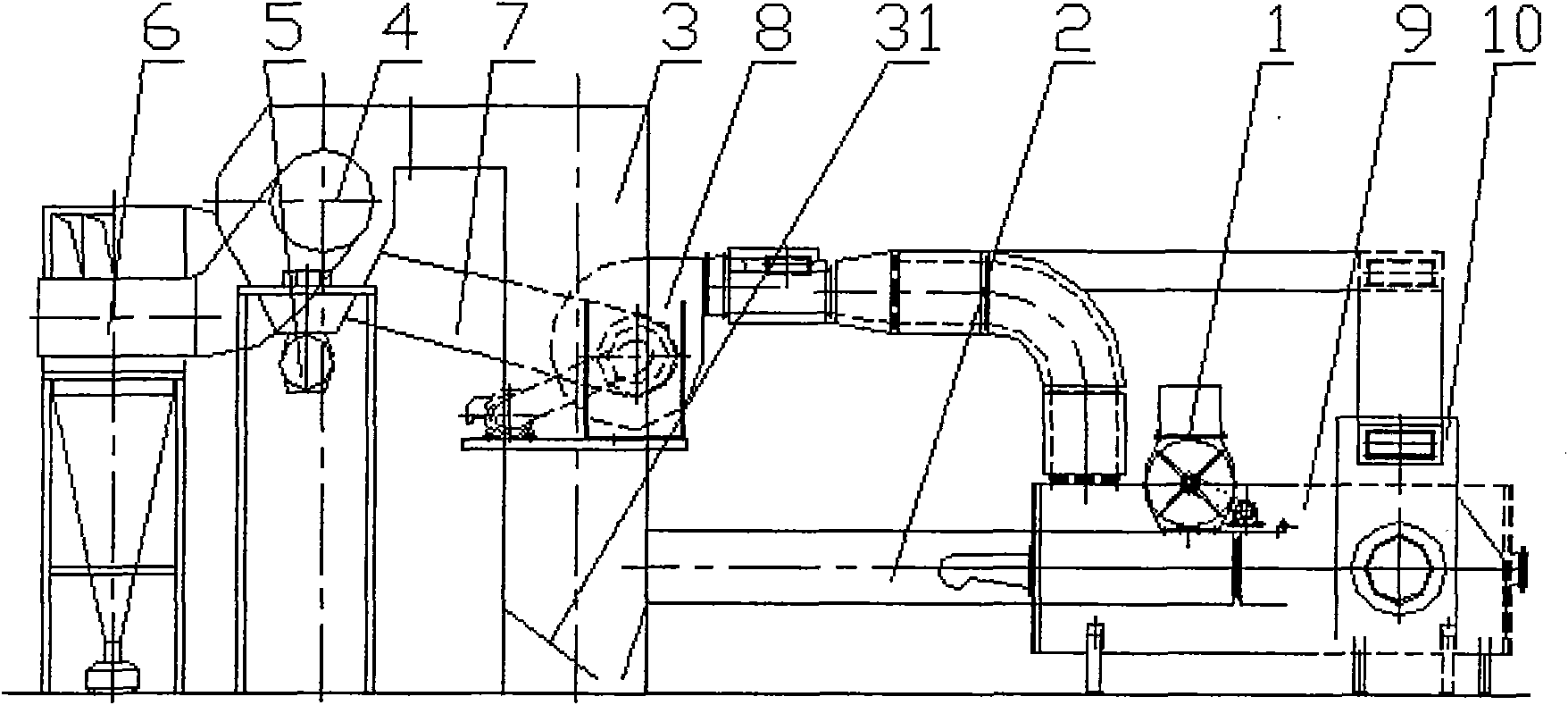

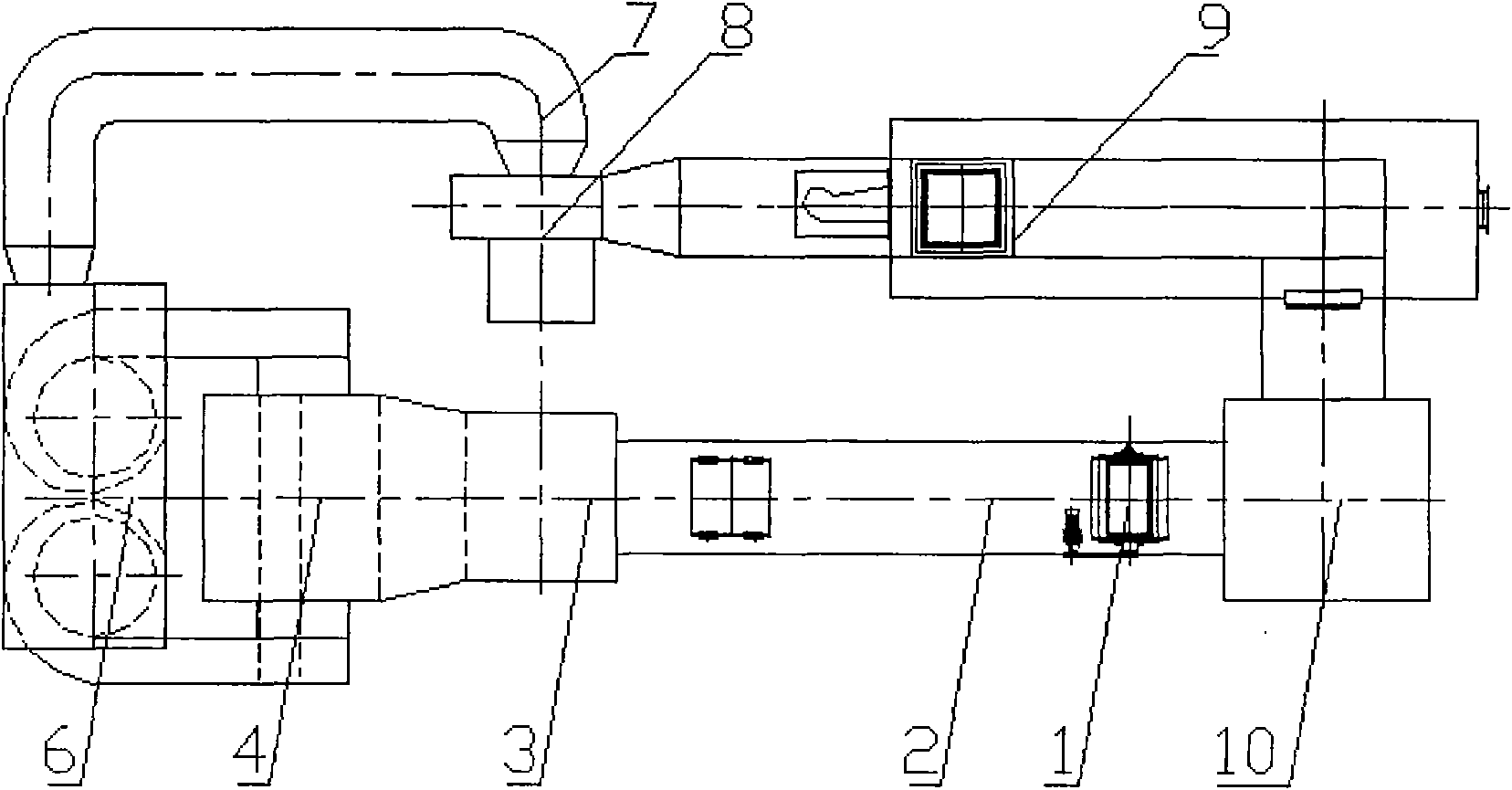

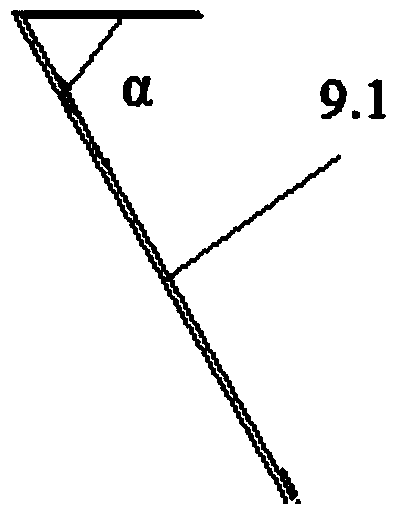

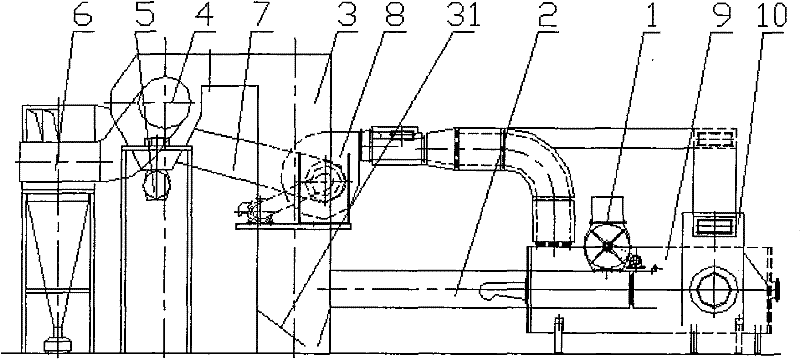

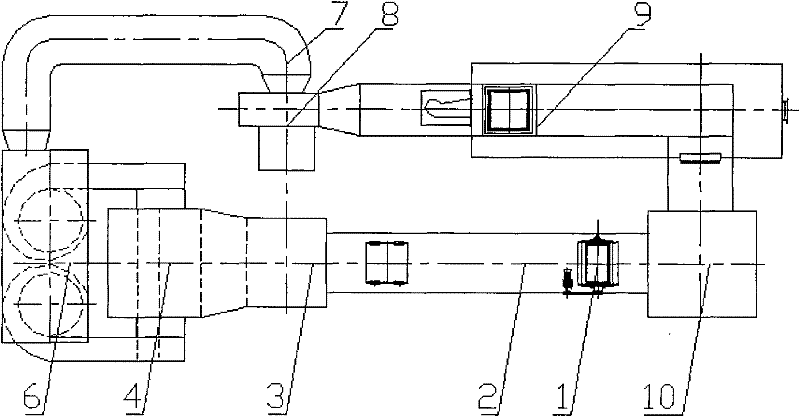

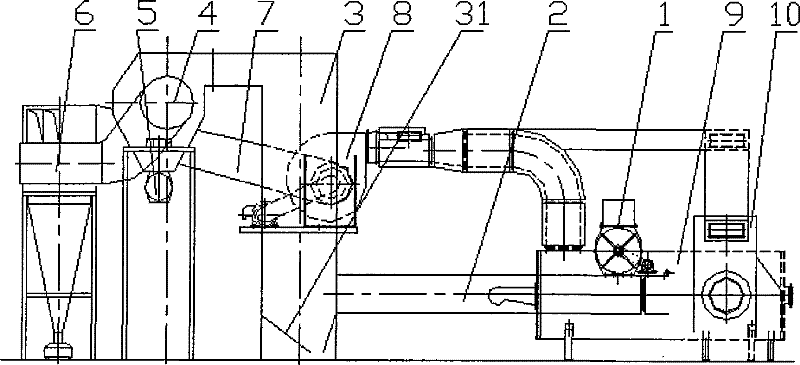

Tobacco material pneumatic drying process and equipment

ActiveCN101601500AShorten speedExtended drying timeTobacco preparationVolumetric Mass DensityEngineering

The invention provides a pneumatic drying method and equipment thereof for realizing large-flow tobacco material puffing drying treatment; the method comprises the following steps: puffed tobacco material is conveyed to a drying pipe for being dried by hot air flows, and then the tobacco material is separated from hot sir; the drying pipe is composed of a horizontal drying pipe and a vertical drying pipe of which the cross section is more than the cross section of the horizontal drying pipe; hot air with the temperature at 100-250 DEG C and air flow speed of10-50m / s of is sent in the horizontal drying pipe, wherein the air flow feeding direction is vertical to the material feeding direction; the material driven by hot air flows enters in the vertical drying pipe and is ascended in a suspension way, and the ascending speed of the material is reduced to 0.5-5m / s; meanwhile, sundries such as slivers with large density in the material can not be suspended and are separated pneumatically under the wind speed. By arranging the vertical drying pipe with large caliber, the speed of the material, moving upwards along the air flow direction, is reduced, on the premise of not increasing the drying route, the drying time of the material is prolonged, heat-transferring and mass transferring coefficient is improved, and the drying time of the material is improved.

Owner:ZHISI HLDG GRP

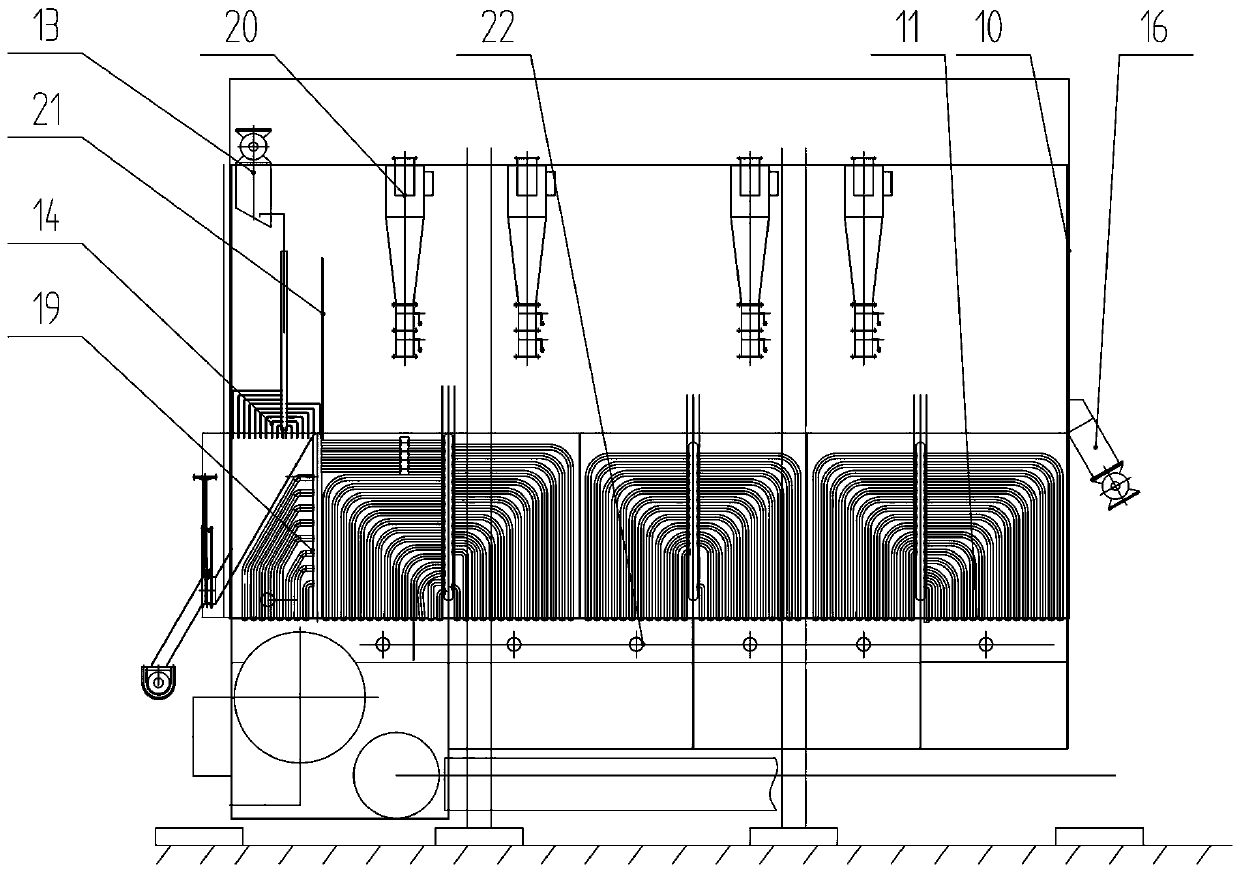

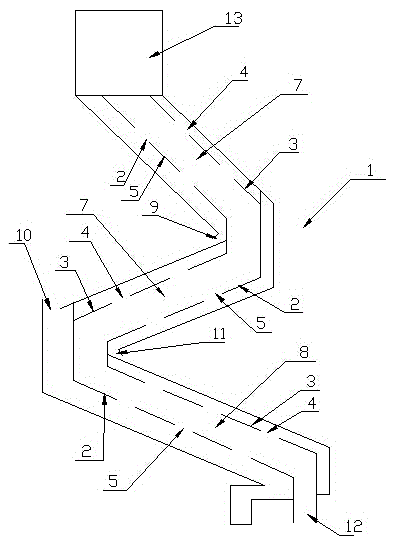

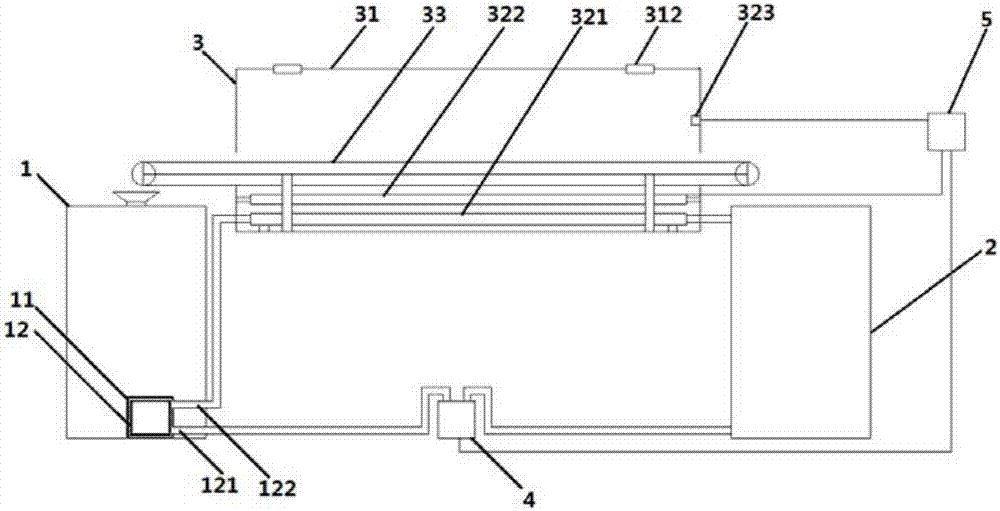

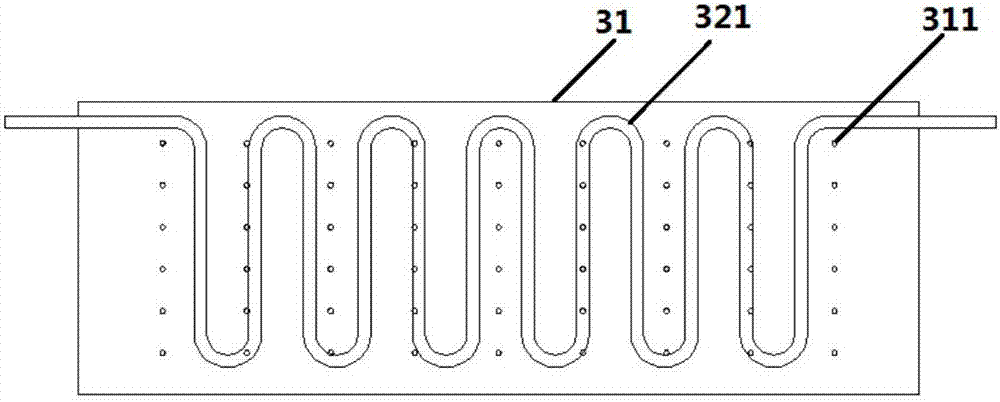

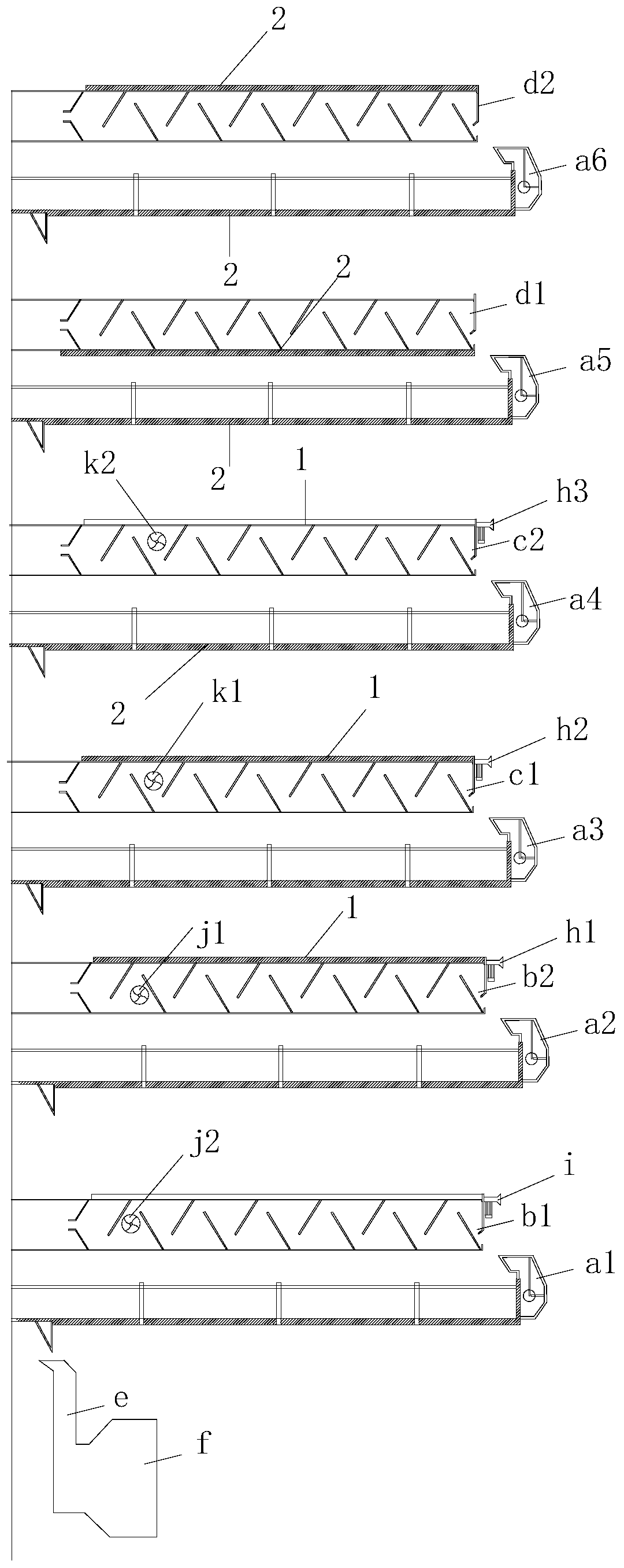

Aqueous synthetic leather production line

InactiveCN102765242ASimple structure layoutExtend oven lengthLamination plant layoutLamination ancillary operationsWinding machineConductor Coil

The invention discloses an aqueous synthetic leather production line. The aqueous synthetic leather production line is characterized by sequentially comprising, according to production procedures, a double-station release paper unwinding machine, a release paper joint table, a storage device, a first precision coating machine, a first drying oven, a double-roll cooling machine, a second precision coating machine, a first multi-layer fold back type drying oven, a multi-roll cooling machine, a stripping device, an edge cutting machine and a double-station winding machine, wherein the double-station winding machine comprises a product winding portion and a release paper winding portion. The aqueous synthetic leather production line is simple in arrangement and adaptive to aqueous synthetic leather production requirements, and mass production of aqueous synthetic leather can be realized. The drying oven is lengthened due to adoption of the 'fold back type drying oven', so that products can stay longer in the drying oven to adapt to drying and foaming characteristics of aqueous products. Further, production efficiency is improved, product quality can be guaranteed, occupied area is reduced, and cost reduction and efficiency improvement can be realized.

Owner:XINXIANG DINGXIN MACHINERY

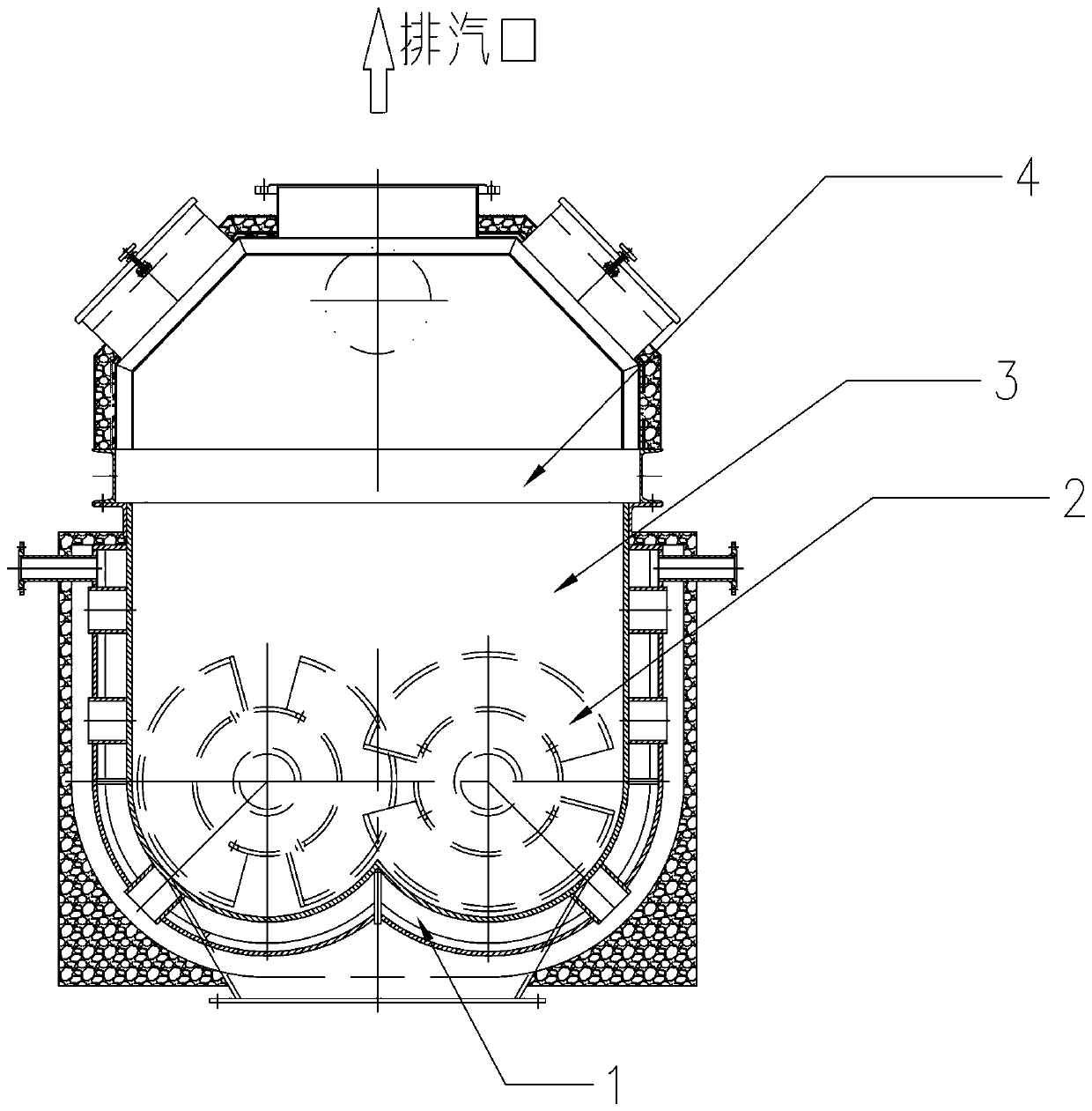

Production system for producing building plaster by using desulphurization gypsum and realization method of production system

The invention discloses a production system for producing building plaster by using desulphurization gypsum. The production system comprises a feeding system, a drying system, a calcining system, a dust removing system, a burning system and a material storing and packaging system, wherein the feeding system is used for feeding plaster materials; the drying system is used for drying the plaster materials; the calcimining system and the burning system are used for calcining the plaster materials into the building plaster; the material storing and packaging system is used for packaging the building plaster; the dust removing system is applied to all subsystems of the production system for removing dust in the production. The production system has the following advantages that the building plaster is prepared by a drying and calcining two-step method of a spiral dryer and a fluidized bed combustion boiler; the production system has remarkable advantages of low energy consumption, simple technology, stable quality of a product, easiness in control and the like.

Owner:山东海蓝阳光环境服务有限公司

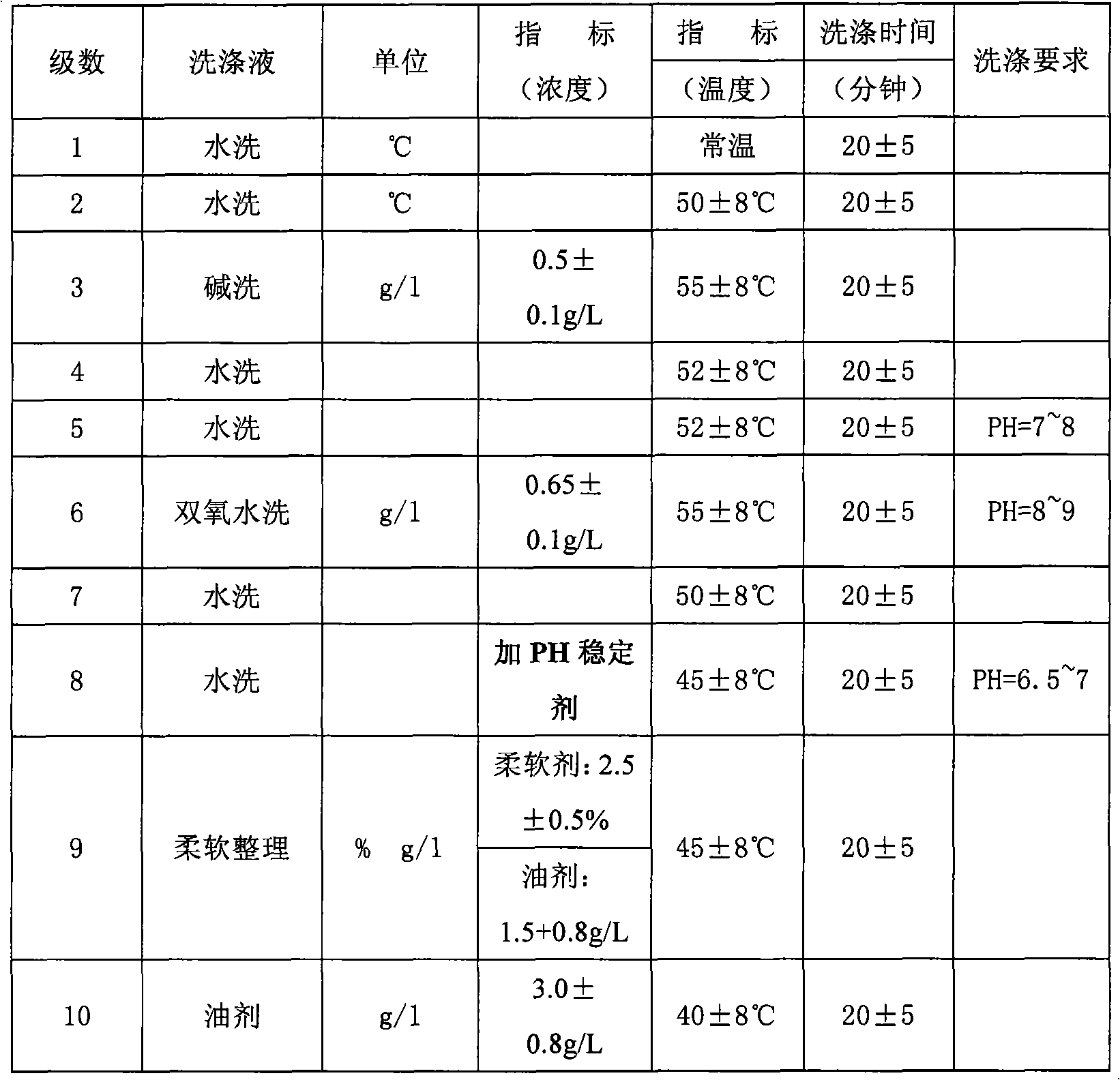

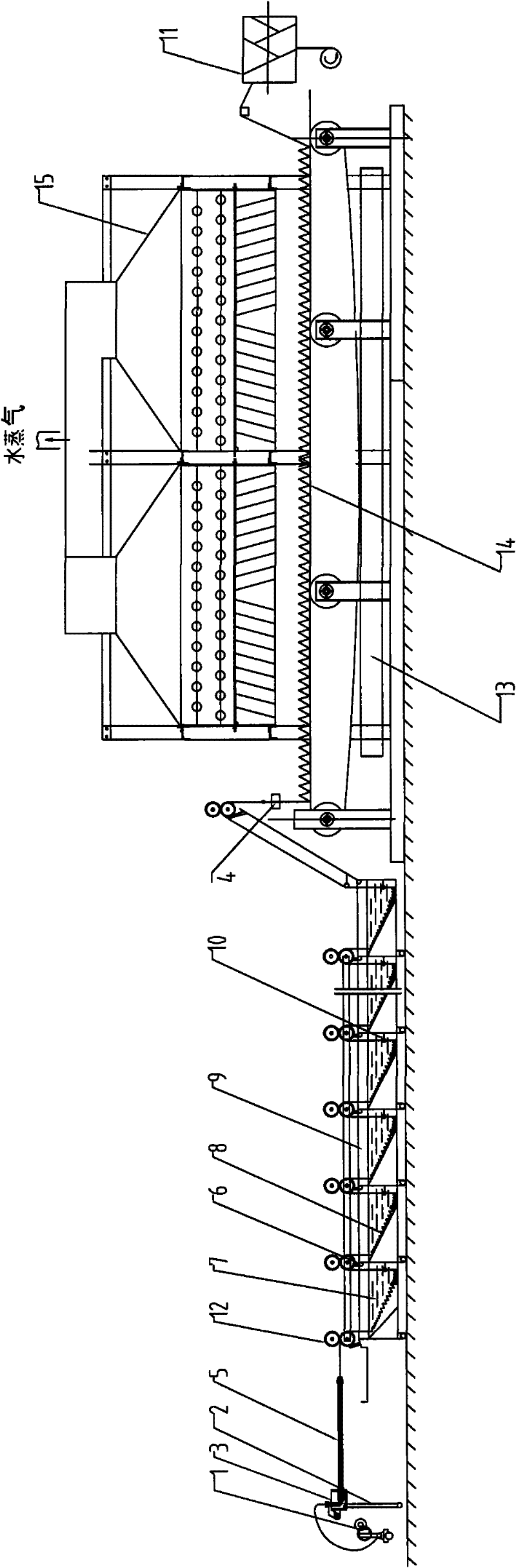

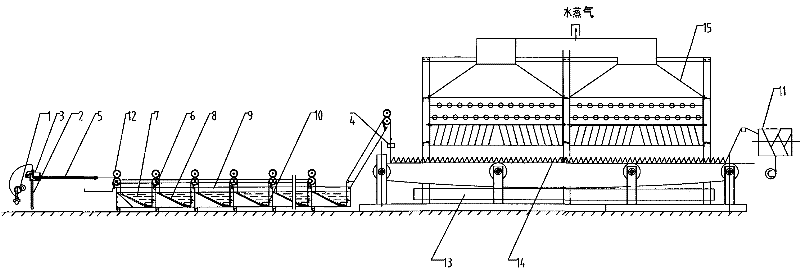

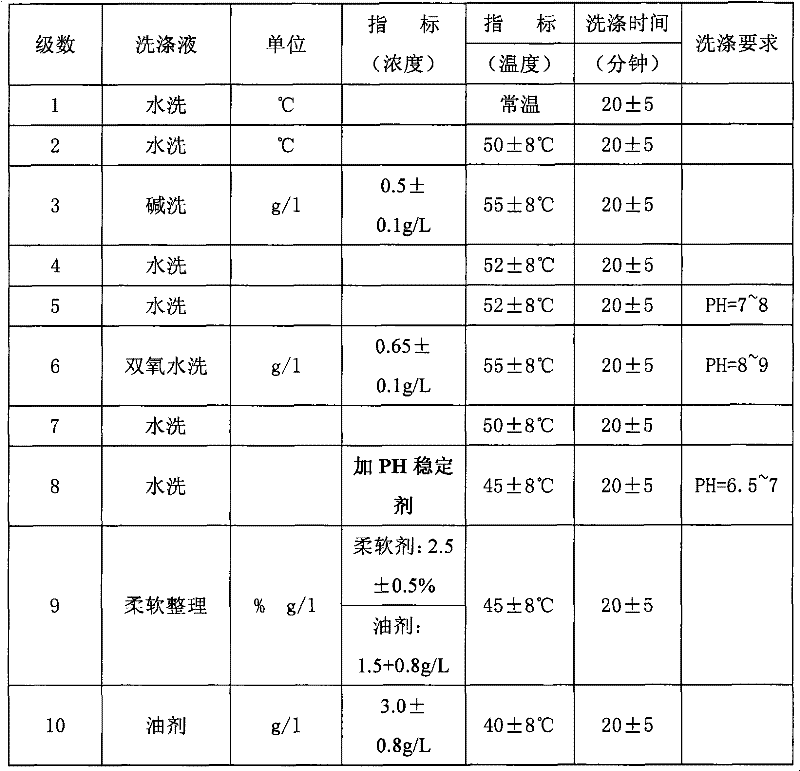

Continuous spinning process for viscose coarse denier flat filament

InactiveCN101775669AShort processReduce Process VariationsArtificial thread manufacturing machinesArtificial filament washing/dryingEngineeringUltimate tensile strength

The invention discloses a continuous spinning process for a viscose coarse denier flat filament, which comprises the following steps that: viscose measurement and forming, washing, drying and tube forming; the measured viscose reacts and is formed into filament strips in a glass forming tube; the filament strips formed in the glass forming tube are tractioned to a sink by a pressure roller of the multi-stage sink to be washed in a plurality of stages; the filament strips on the tail end of the multi-stage sink are tractioned to a steam dryer by the pressure roller; and the steam dryer dries the filament strips, and then forms the dried filament strips into a tube. The invention completes a plurality of procedures on a production line, optimizes the process, and achieves the purposes of shorter process, reduced process fluctuation, small quality difference between batches, reduced end breakage, higher yield, lower cost, higher quality and lower labor intensity.

Owner:YIBIN HIEST FIBER +1

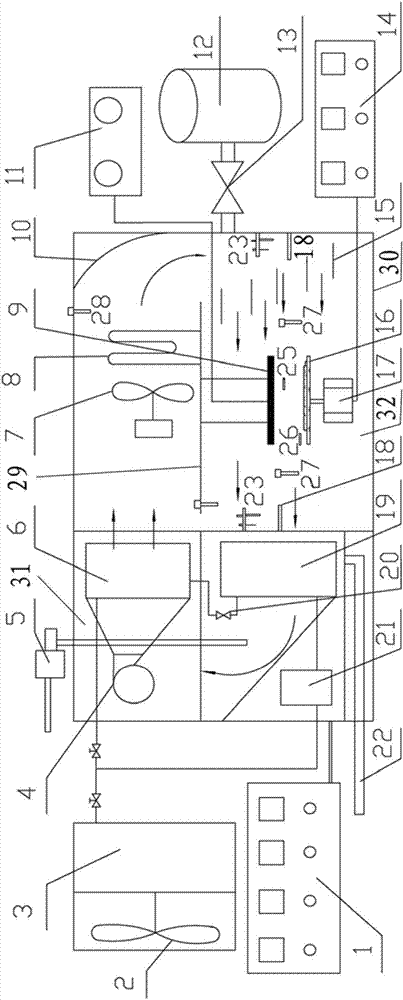

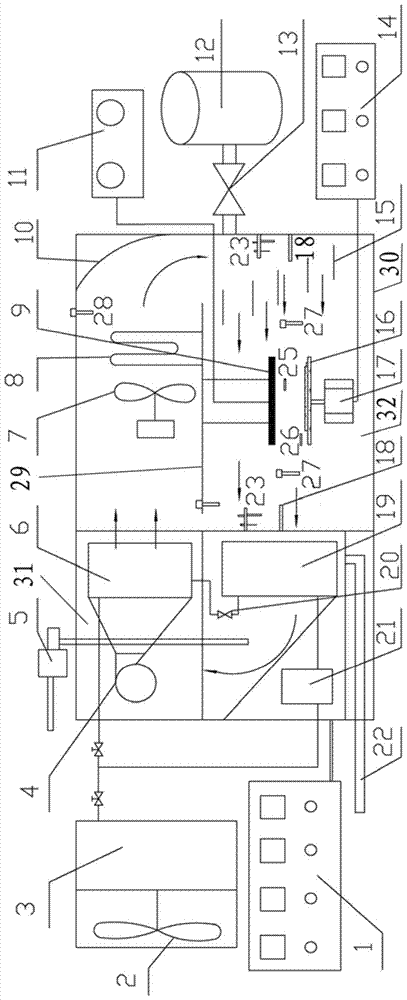

Ultrasonic-reinforced controlled atmosphere drying method and device

ActiveCN104322655AImproved heat conditionEnhance heat and mass transferFruits/vegetable preservation by dehydrationDrying timeLow oxygen

The invention discloses an ultrasonic-reinforced controlled atmosphere drying method and device. According to the method, when controlled atmosphere hot air is used for drying a material, the material is subjected to a direct contact ultrasonic treatment. With the ultrasonic-reinforced controlled atmosphere drying method provided by the invention, an oxidation reaction process during a drying process is effectively inhibited, such that effective components in the material are protected, color browning is effectively inhibited, and a problem that nutrients are prone to oxidative degradation under conventional hot air drying is solved. The direct contact ultrasonic treatment has a synergistic effect with controlled atmosphere drying under a low-oxygen environment. With the method, product quality is ensured, and ultrasonic energy is directly transferred into the material, such that water content migration rate of controlled atmosphere drying is effectively improved, and energy utilization rate and mass transfer reinforcement efficiency are improved. Therefore, drying efficiency is increased and drying time is shortened, and problems of low drying rate and poor product quality of conventional hot air drying are solved. The method and the device have a good application prospect.

Owner:HENAN UNIV OF SCI & TECH

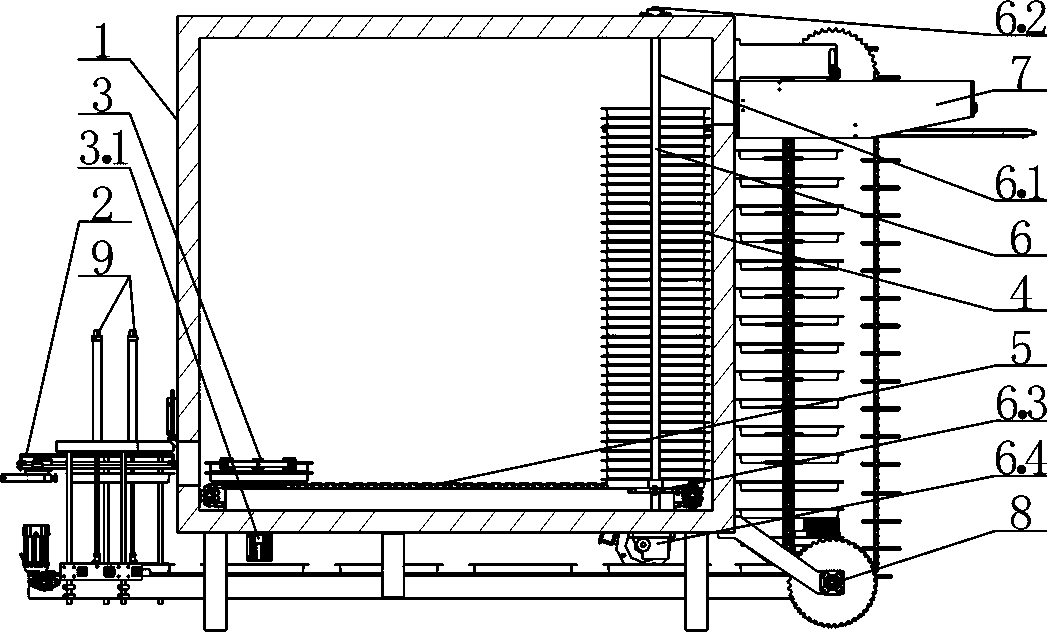

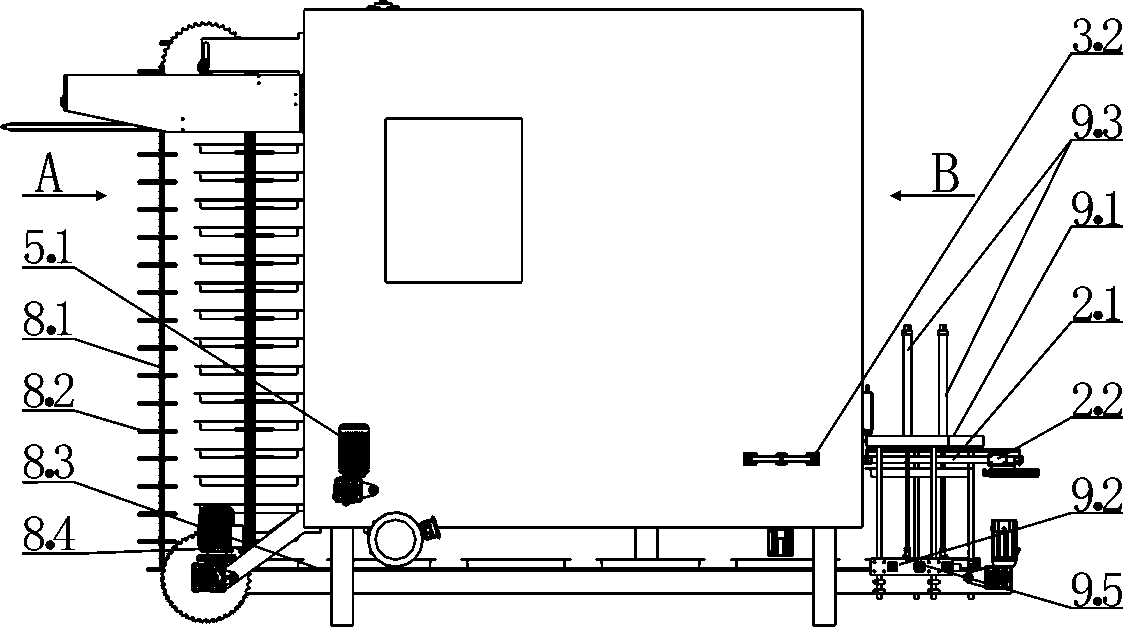

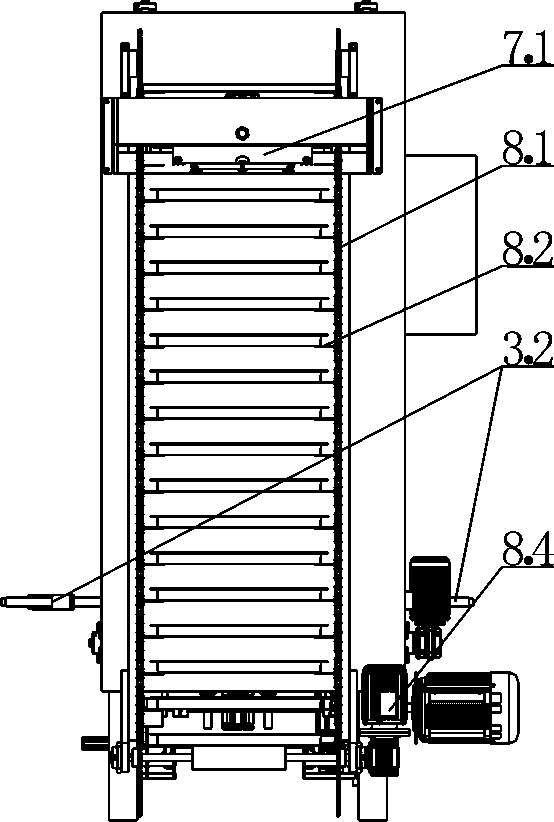

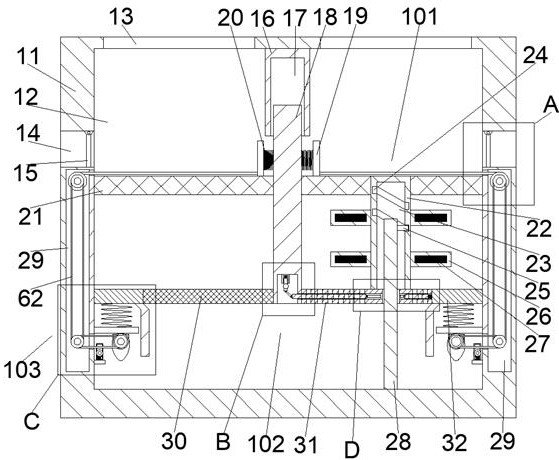

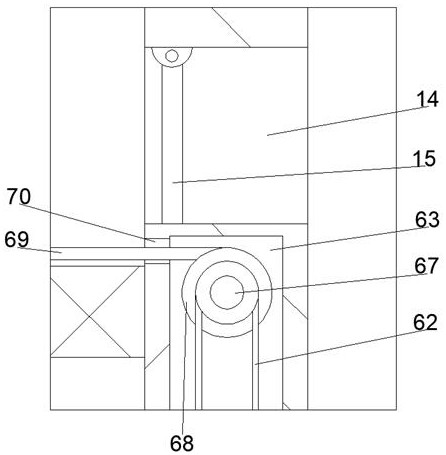

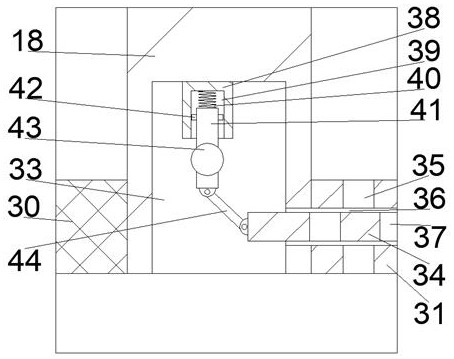

Full-automatic curing furnace for visual panel screen printing drying

PendingCN108839425AThe overall structure is compactSmall footprintScreen printersPrinting press partsContinuous productionEngineering

The invention relates to a full-automatic curing furnace for visual panel screen printing drying in the field of drying and curing heating furnaces. The full-automatic curing furnace comprises a feeding device used for pushing material trays to enter the furnace, a material supporting device used for supporting the material trays fed into the furnace one by one and stacking the material trays intoa material tray stack, a conveying device used for conveying the material tray stacks to the other side in the furnace from one side in the furnace, a lifting device used for lifting the material tray on the uppermost layer in the material tray stack to be correspondingly horizontal to a discharging opening, a discharging device used for taking out the material trays from the furnace, a materialtray conveying device used for conveying the taken-out material trays to the lower portion of the furnace tail and a material lifting device used for lifting the material trays to a furnace feeding opening after panels to be dried and cured are placed in the empty material trays. The curing furnace is small in occupied area and can carry out online continuous production, product quality stabilitycan be guaranteed, and the production efficiency can be improved.

Owner:LUOYANG TENGJIE FURNACE IND CO LTD

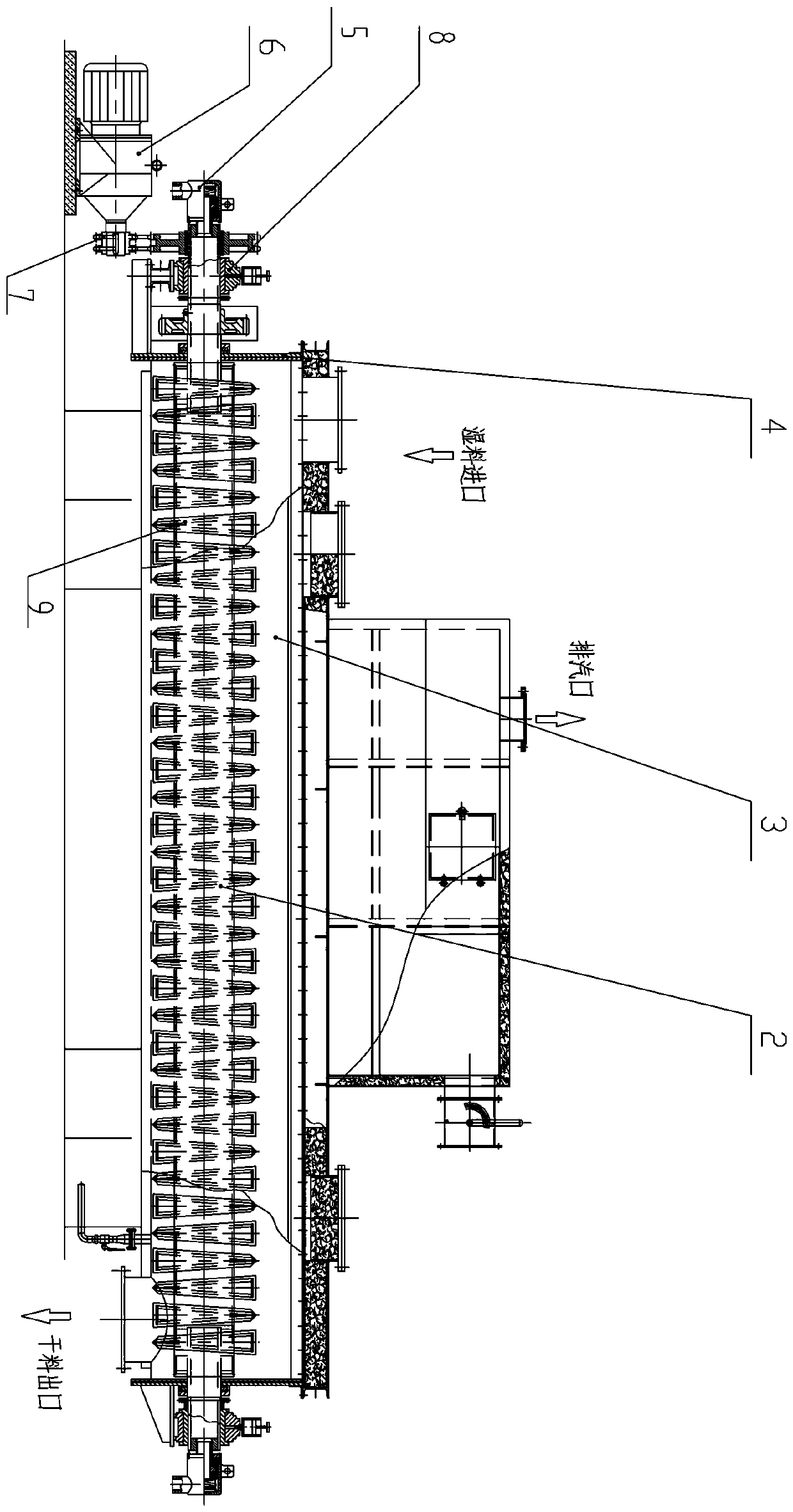

Mobile soil quick dryer suitable for sticky soil

PendingCN109269279ADry fastReduce moisture contentDrying gas arrangementsPreliminary solid treatment for dryingEngineeringMoisture

The invention discloses a mobile soil quick dryer suitable for sticky soil. The mobile soil quick dryer comprises a machine body and a walking assembly disposed at the bottom of the machine body, andfurther comprises an auger conveying assembly disposed in front of the machine body, a second drying assembly disposed at the rear of the machine body and a first drying assembly disposed on the upperportion of the machine body. A first pulverizing device is disposed between the first drying assembly and the machine body, a second pulverizing device and a circuitous soil conveying assembly are disposed in the machine body, and the auger conveying assembly is located between the pulling direction of the machine body and an inlet of the first drying assembly. The mobile soil quick dryer is suitable for an area where the soil is sticky, the rainy season is long, and the mechanized rotary tillage ridging is difficult, and is particularly suitable for the seeding of seeds having the soil moisture requirement. The oil quick dryer achieves secondary quick drying of sticky and wet soil through two procedures, quickly evaporates the soil moisture to about 20%-25% of the content and has practical value for farming during the farming season, and the whole device is movable and convenient to use.

Owner:CHENGDU ACAD OF AGRI & FORESTRY SCI

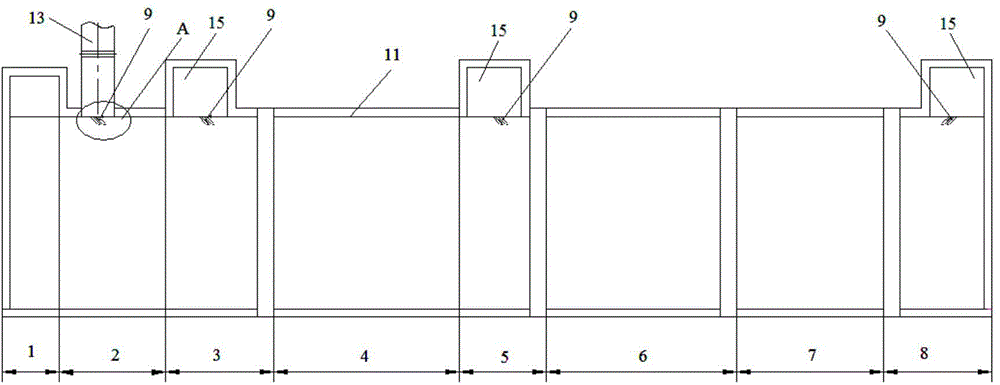

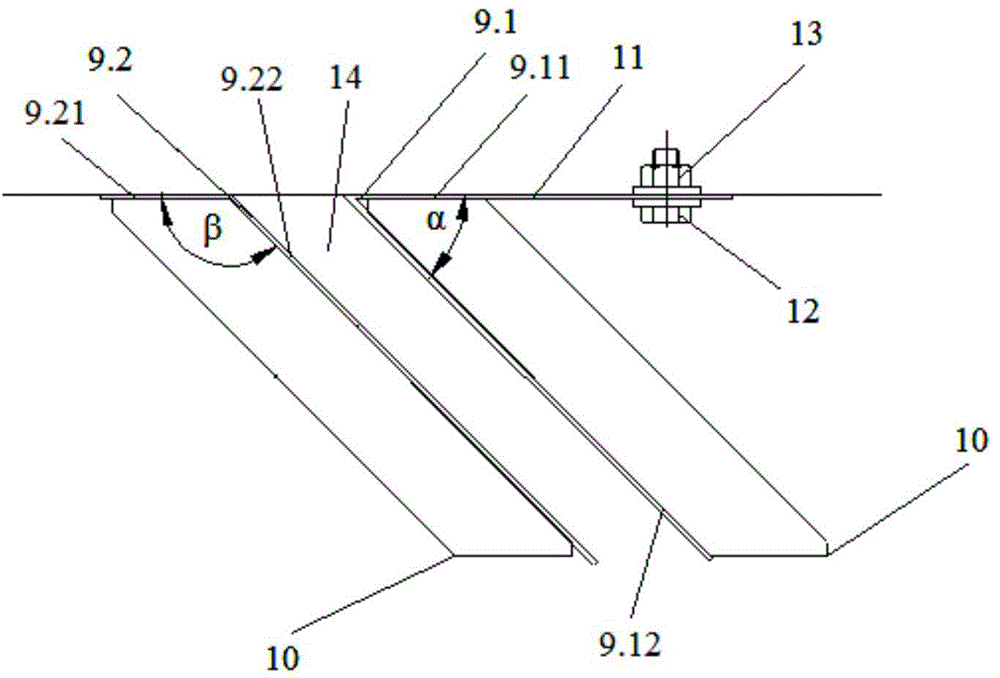

Straight-through drying oven with air curtain system

ActiveCN103673573APrevent spilloverGuaranteed non-proliferationDrying solid materialsEngineeringMechanical engineering

The invention relates to a straight-through drying oven with an air curtain system. The straight-through drying oven comprises an inlet hood region, a fresh air curtain region, an inlet air curtain region, a preheating region, an internal air curtain region, a heating region, an outlet air curtain region, and an outlet hood region, wherein the regions are communicated with one another sequentially from front to rear. Each of the fresh air curtain region, the inlet air curtain region, the internal air curtain region and the outlet air curtain region is provided with an air curtain guide plate. Each air guide plate comprises a first angle plate and a second angle plate. A first top plate of the first angle plate and a second top plate of the second angle plate are both mounted a top wall plate of the drying oven. A gap between a first sloping plate of the first angle plate and a second sloping plate of the second angle plate forms an air passage. The air curtain guide plates in the inlet air curtain region and the outlet air curtain region prevent smoke inside the drying oven from overflowing. The air curtain guide plate in the internal air curtain region separates different temperature areas, so that temperature disturbance amongst different temperature areas is prevented effectively.

Owner:武汉东研智慧设计研究院有限公司

Drying device for suaeda salsa seed purification

InactiveCN104964545AKeep dryExtended storage timeSeed preservation by dryingDrying machinesEngineeringImpurity

The invention provides a drying device for suaeda salsa seed purification. The drying device comprises a drying pipeline, an upper partition plate and a lower partition plate are arranged in the drying pipeline symmetrically and are a drying plate located in the upper middle in the pipeline and a draining plate located in the lower middle in the pipeline respectively, a ventilation opening is formed in the drying plate, draining holes are formed in the draining plate, and the diameter of the draining holes is smaller than the particle size of suaeda salsa seeds. The drying device can further dry the seeds after washing and impurity removal are carried out on the seeds, the seeds are cleaner, which is beneficial for further developing and using the seeds in the later period, components good for the human body are extracted and used for food processing, the seeds washed with water can be dried, the drying effect is good, and the storage time is long.

Owner:WEIFANG YOURONG IND

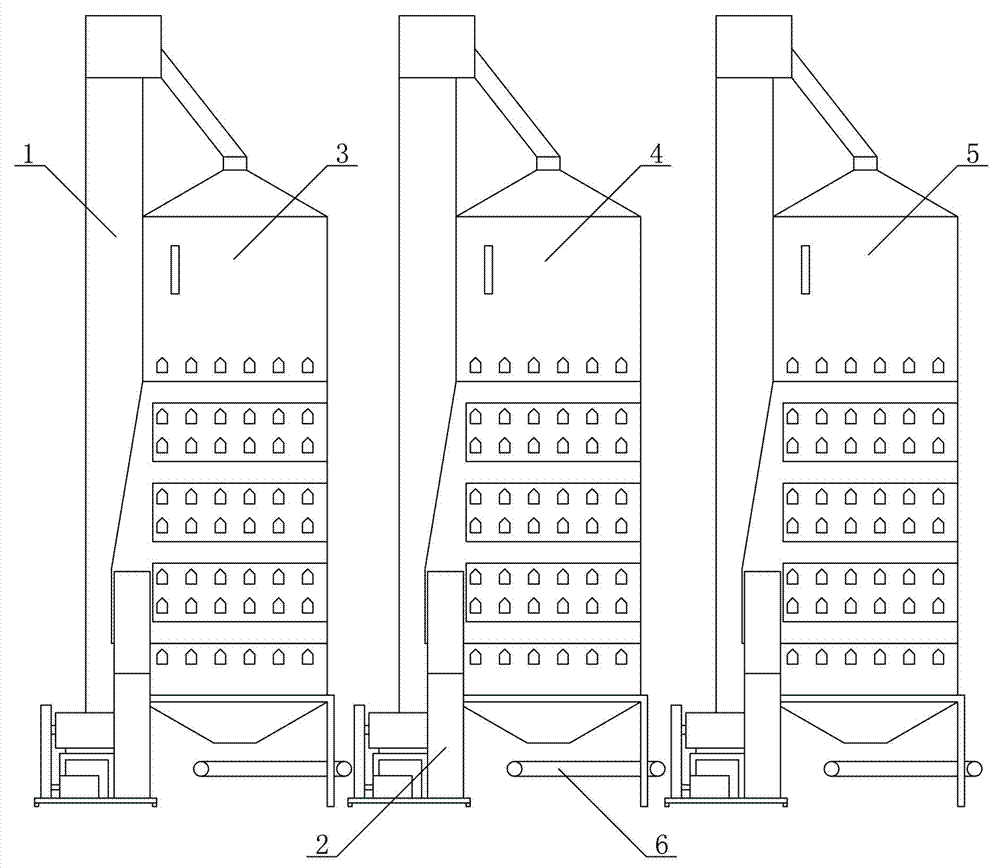

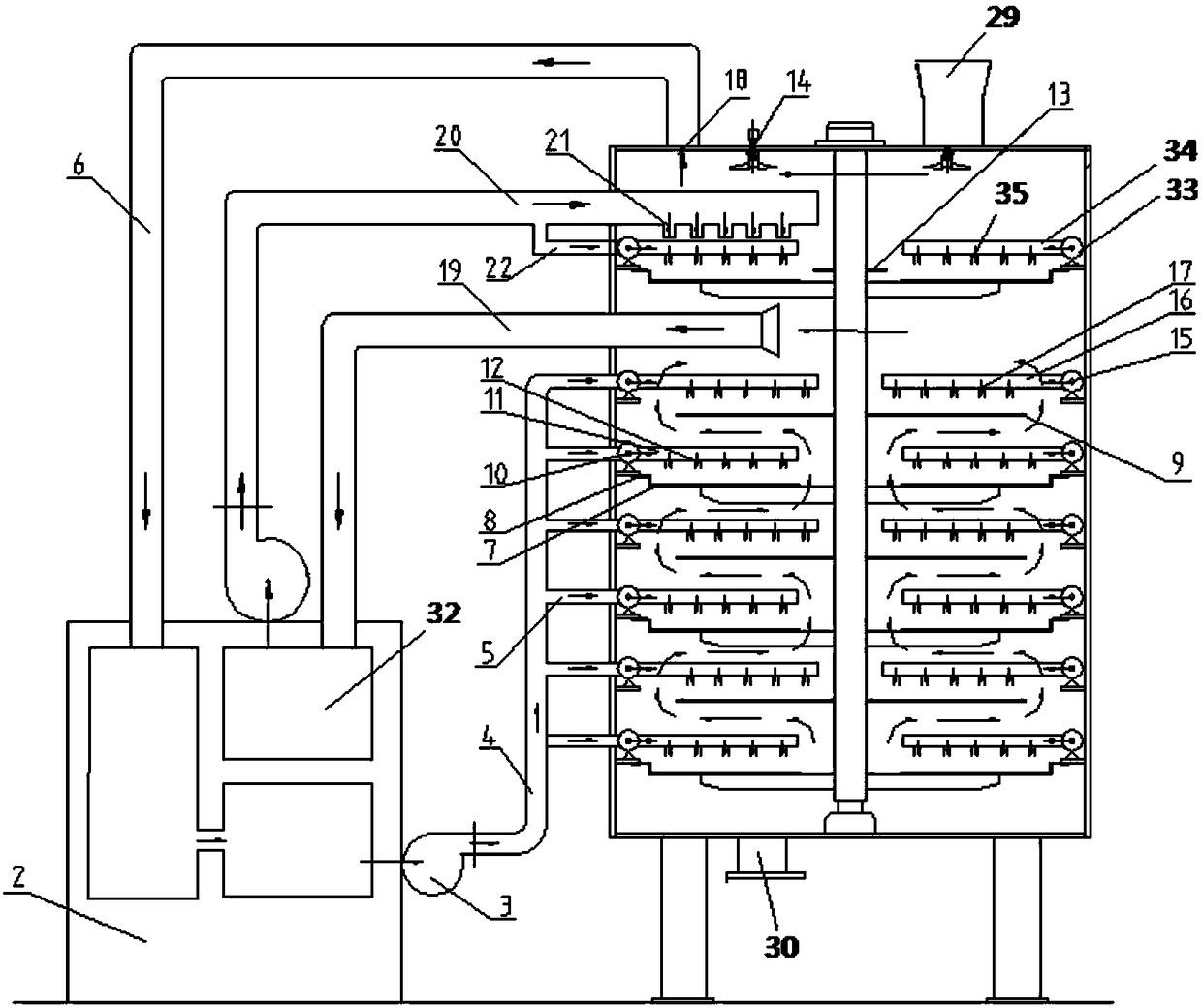

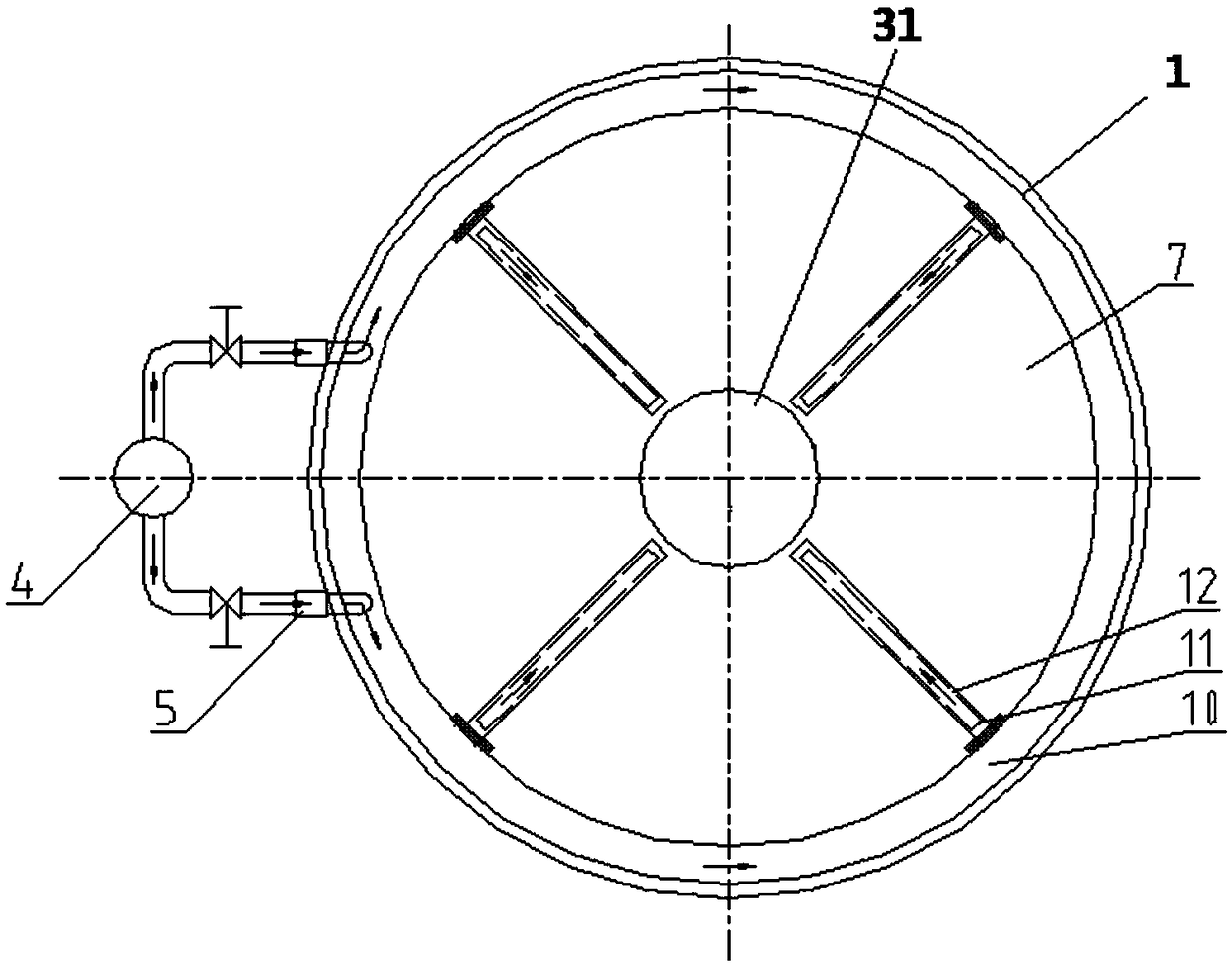

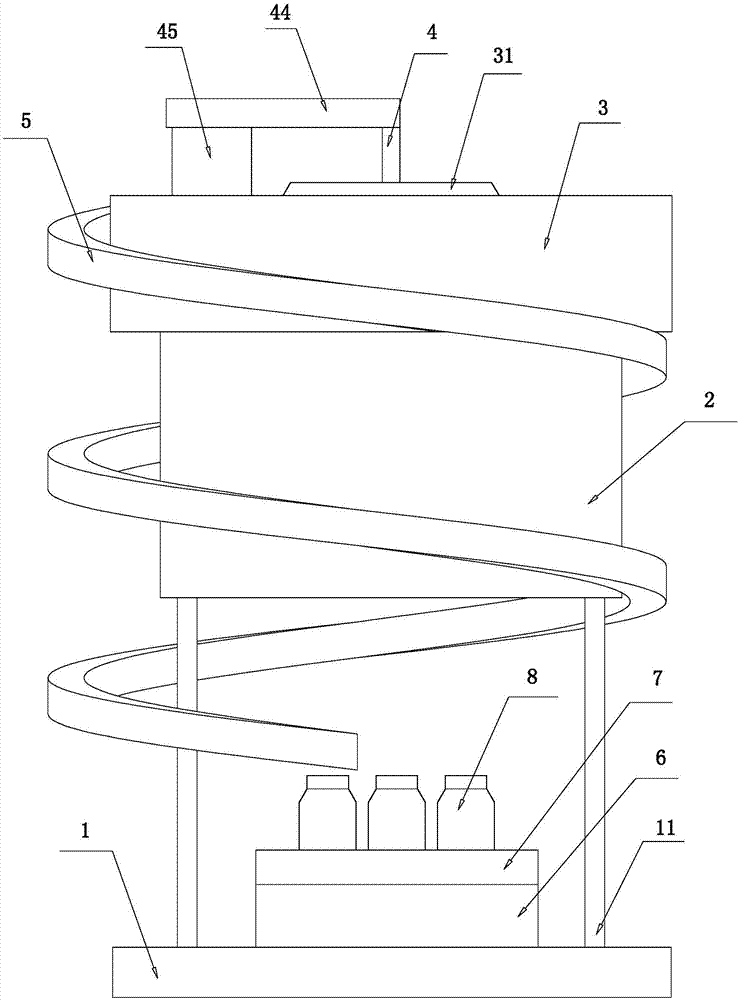

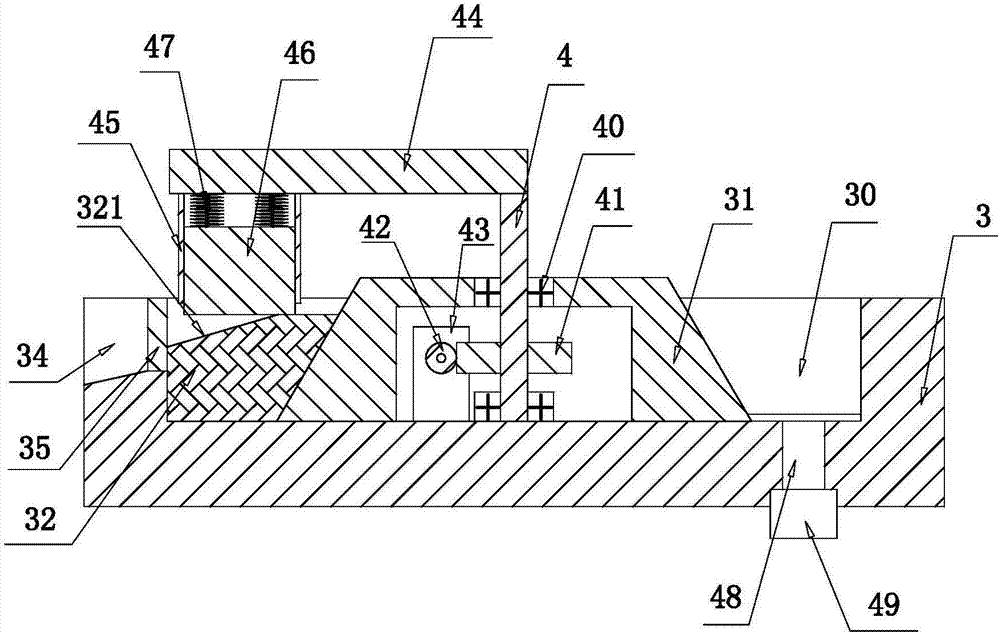

Multiple-tower continuous dryer

InactiveCN103478246AGuaranteed drying timeWon't burn outSeed preservation by dryingProcess engineeringDrying time

The invention provides a multiple-tower continuous dryer, comprising at least two stages of drying tower mechanisms and a hot air generating and conveying mechanism for providing drying gas for each drying tower mechanism. Each stage of drying tower mechanism comprises a drying tower and an elevator for conveying grains to the corresponding drying tower; and a grain input terminal of a lower stage of elevator is arranged corresponding to the grain output terminal of an upper stage of elevator, so as to conveniently convey the dried grains in an upper stage of drying tower to a lower stage of drying tower. The multiple-tower continuous dryer has the advantages of scientific design, sufficient drying time, low cost, grading temperature supply, good drying effect and high drying efficiency.

Owner:李保安

3D printing precoated sand and preparation method thereof

InactiveCN108296477AEnsure mixing qualityGuaranteed dimensional accuracyAdditive manufacturing apparatusFoundry mouldsNitrile rubberChemical composition

The invention relates to precoated sand and a preparation method thereof, in particular to 3D printing precoated sand and a preparation method thereof. The 3D printing precoated sand is prepared fromthe following raw materials in parts by weight: 80-90 parts of silica sand, 50-60 parts of graphite powder, 10-15 parts of lignin, 1.2-1.6 parts of sodium hexametaphosphate, 3-5 parts of pyrethroids compound, 3-5 parts of nitrile rubber, 3-5 parts of maltose, 10-20 parts of silica sol and 20-25 parts of phenolic resin. The 3D printing precoated sand provided by the invention is excellent in mechanical property, high in curing speed and good in high-temperature resistance, and addition of chemical components is reduced. The preparation method of the 3D printing precoated sand provided by the invention is simple to operate, and the process parameters are strictly controlled, so that the product quality of the precoated sand is finally guaranteed.

Owner:LIUZHOU LIUJING TECH CO LTD

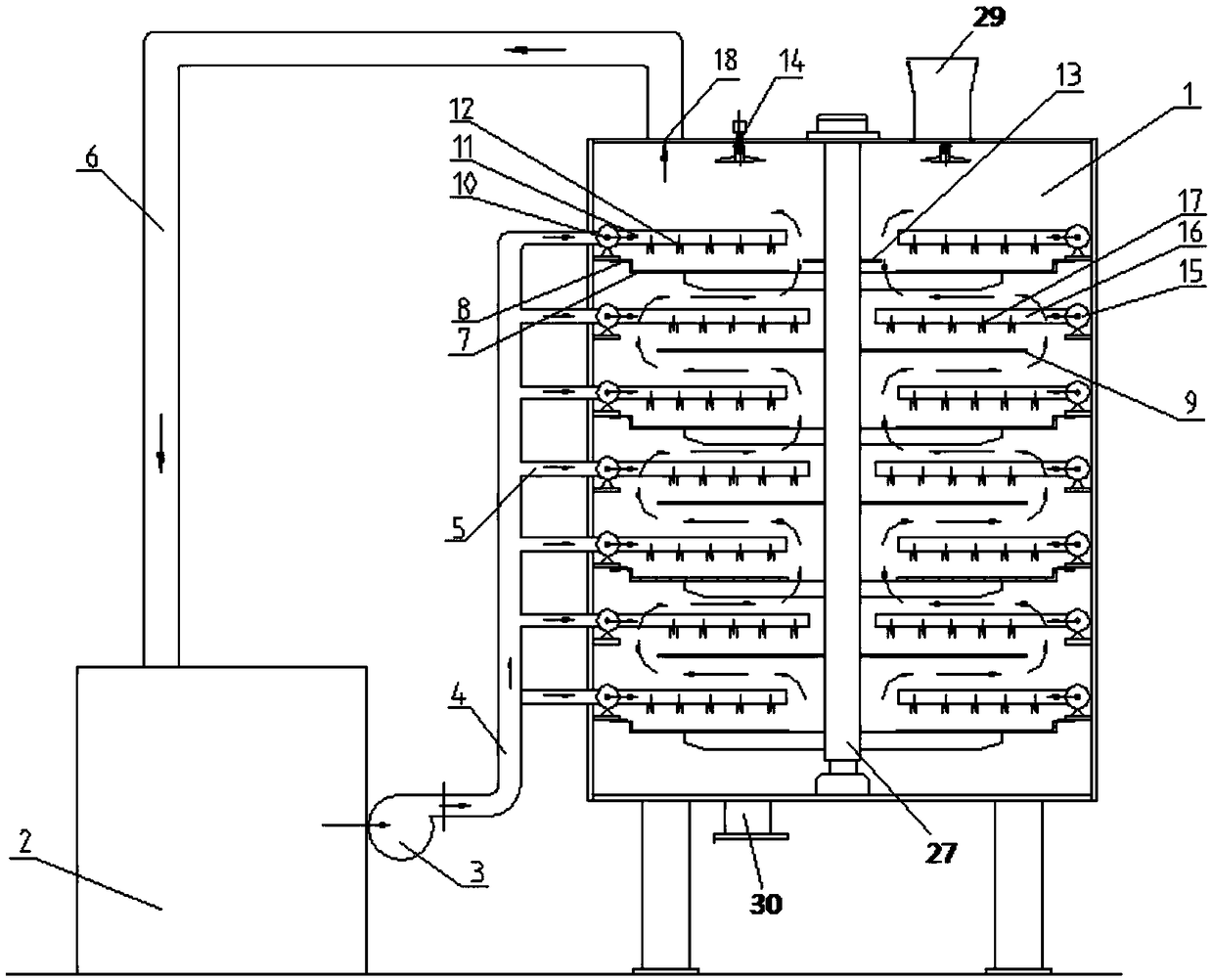

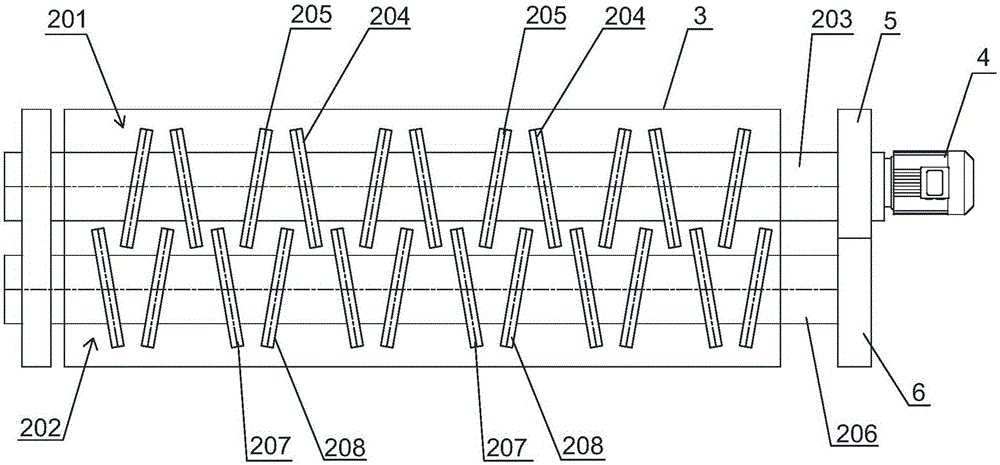

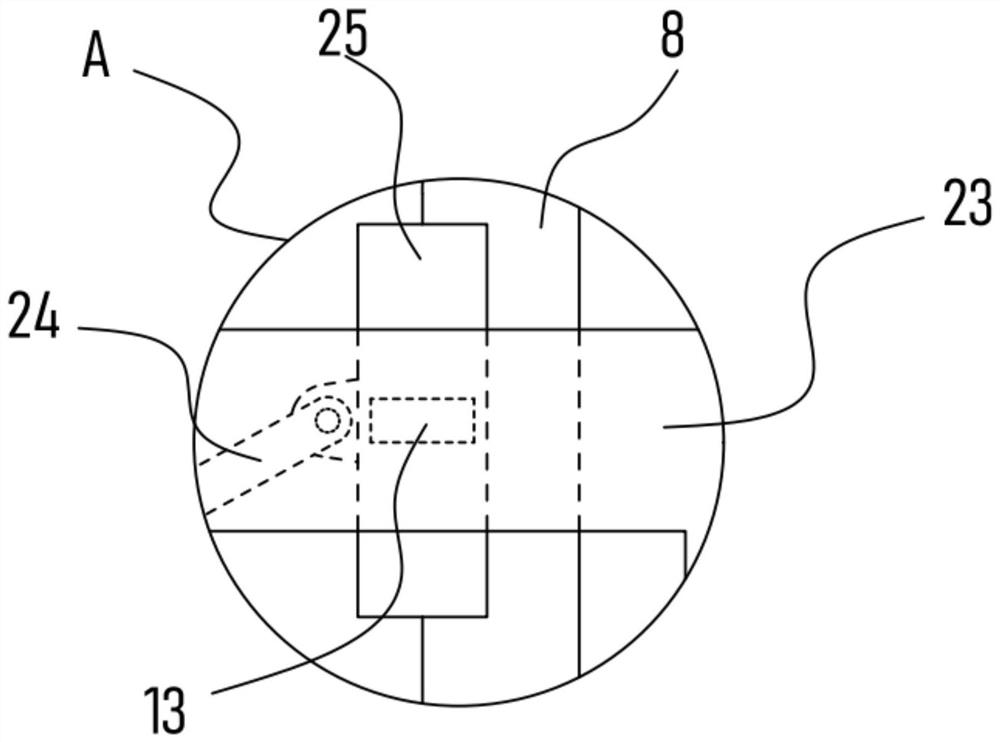

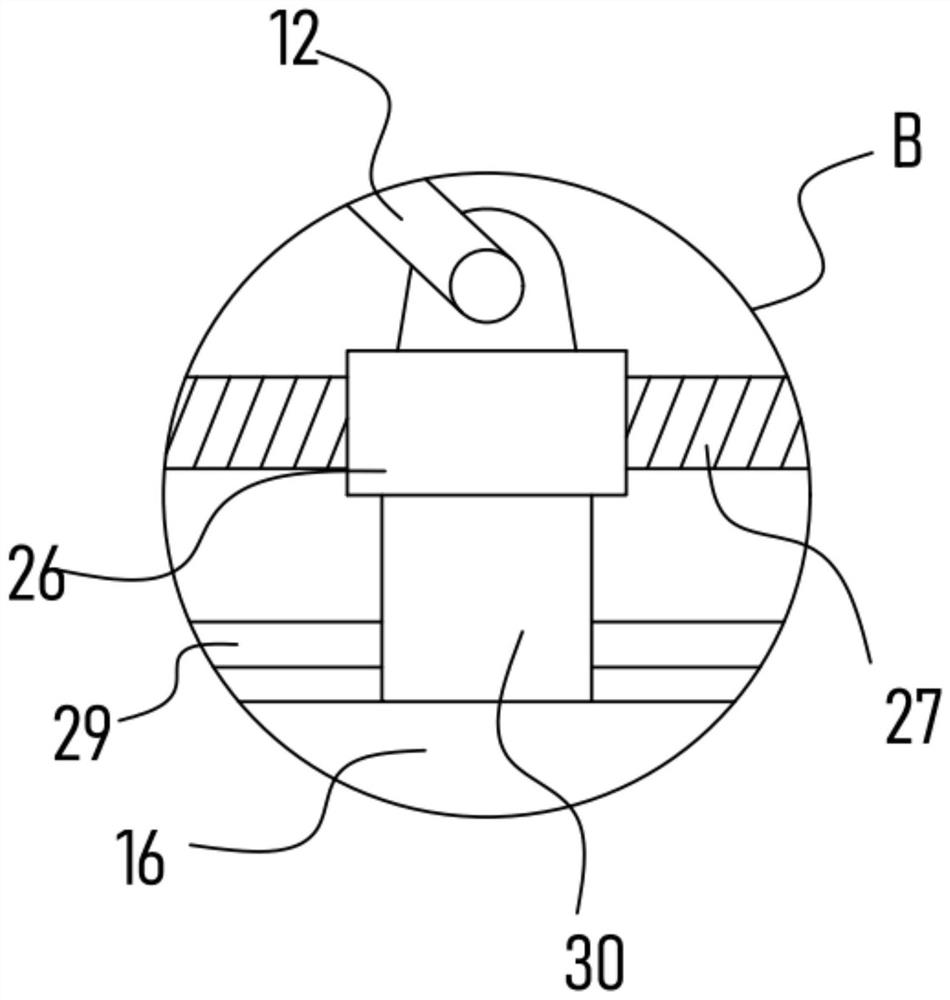

Air distribution structure of low-temperature rotational-flow rotary-disc material drying machine

PendingCN109297285AReduce air volumeGuaranteed drying timeDrying gas arrangementsDrying chambers/containersRotational flowMechanical engineering

The invention discloses an air distribution structure of a low-temperature rotational-flow rotary-disc material drying machine. The air distribution structure of the low-temperature rotational-flow rotary-disc material drying machine comprises a drying chamber and a heat pump; large material discs and small material discs are disposed in a staggered mode along a center shaft in the drying chamber;and the large material discs and the small material discs rotate synchronously with the center shaft. The air distribution structure of the low-temperature rotational-flow rotary-disc material dryingmachine is characterized in that air distribution rings are disposed in the positions, corresponding to the upper portions of the large material discs and the small material discs, on the inner wallof the drying chamber correspondingly; the air distribution rings communicate with an air outlet of the heat pump; air distribution mechanisms are disposed on the air distribution rings; and downwardair distribution openings are formed in the air distribution mechanisms. Hot air directly blows wet materials through air distribution pipes by means of the air distribution rings in the drying chamber, and accurate demand control over the hot air quantity and hot air speed can be performed according to the humidity; and the hot air and the wet materials of the certain layers are subjected to heatexchange, and then the hot air enters the positions between the large material discs and the small material discs of the next groups from through holes of the large material discs or gaps between thesmall material discs and the side wall of the drying chamber.

Owner:北京水木益华环保科技有限公司

Continuous spinning process for viscose coarse denier flat filament

InactiveCN101775669BShort processReduce Process VariationsArtificial thread manufacturing machinesArtificial filament washing/dryingProduction lineEngineering

Owner:YIBIN HIEST FIBER +1

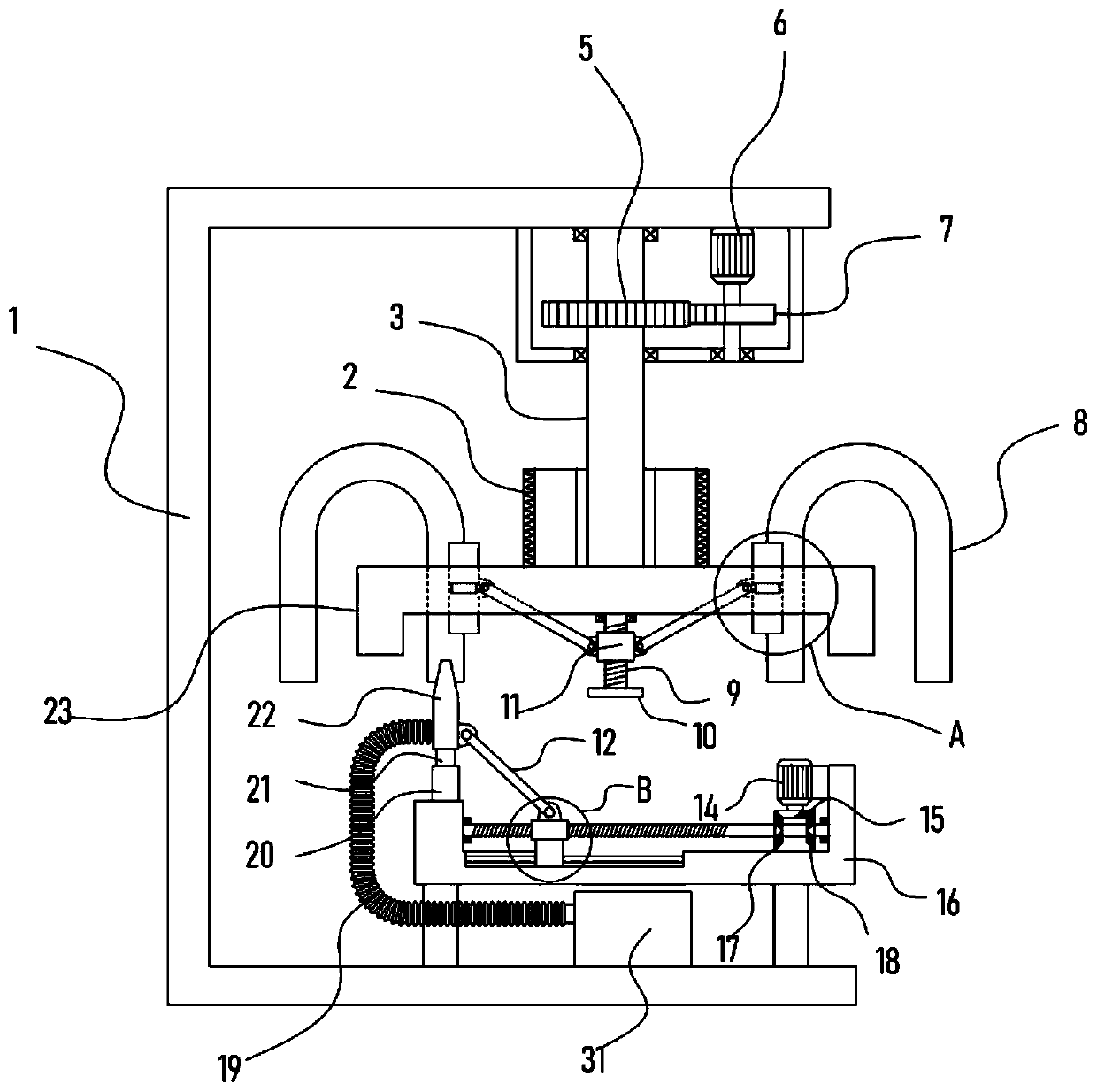

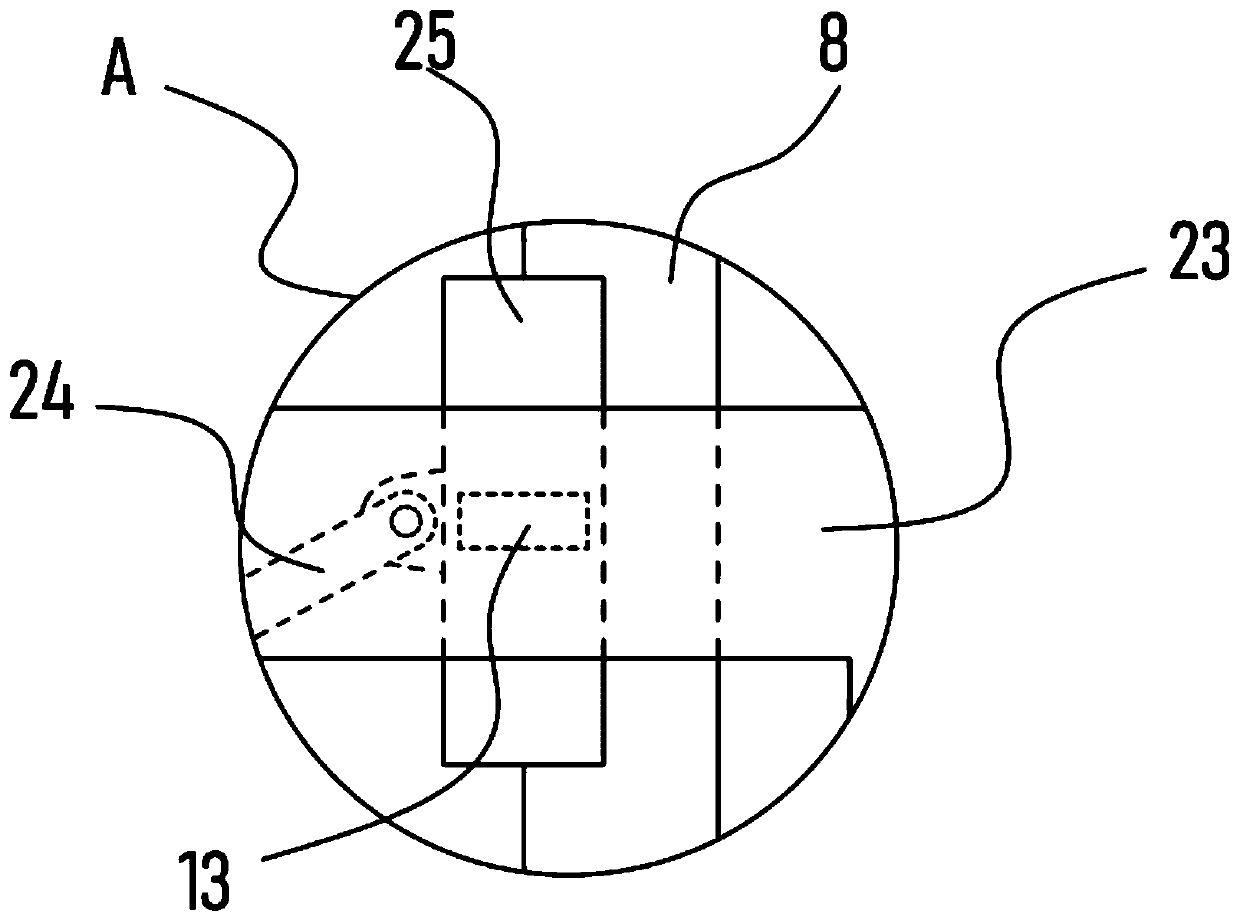

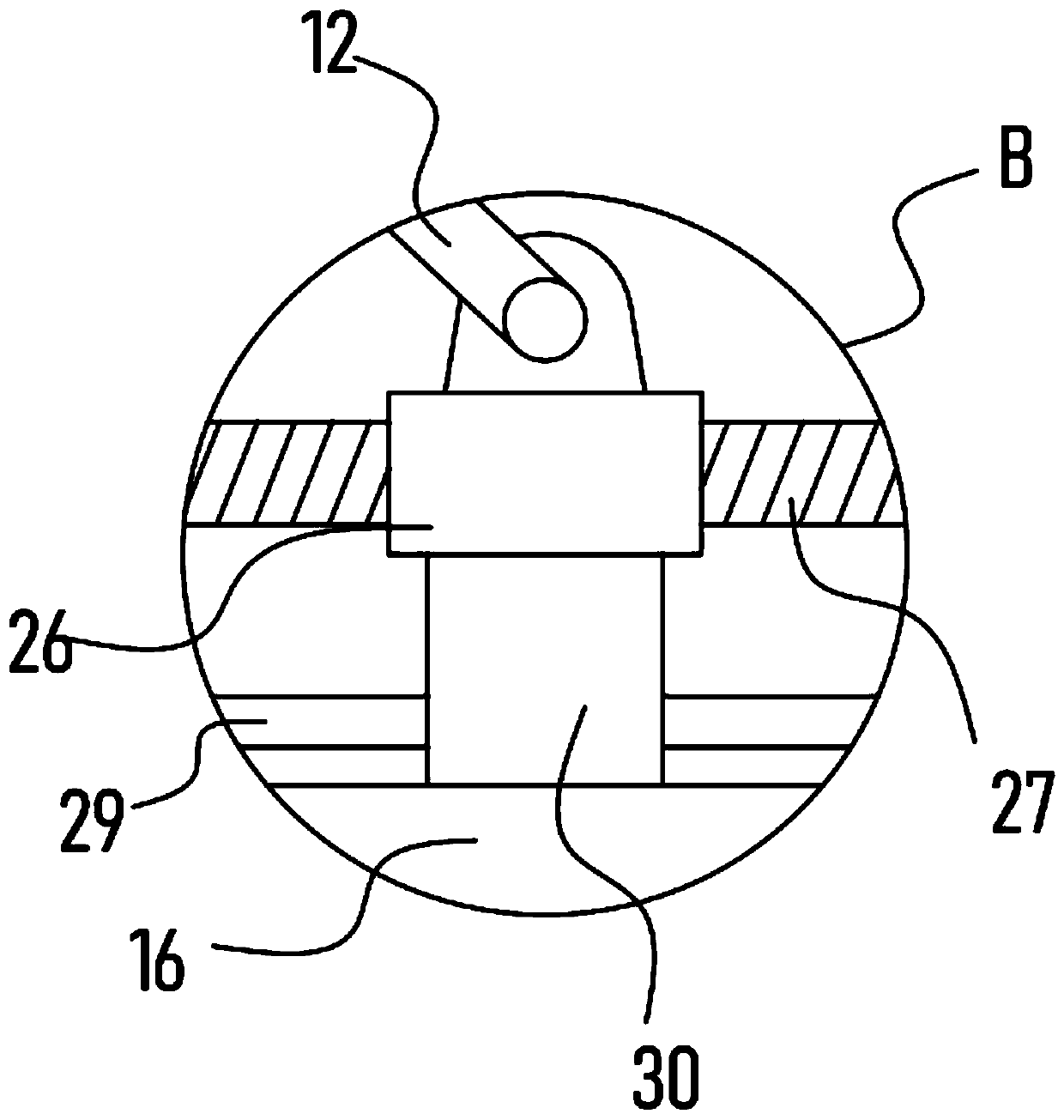

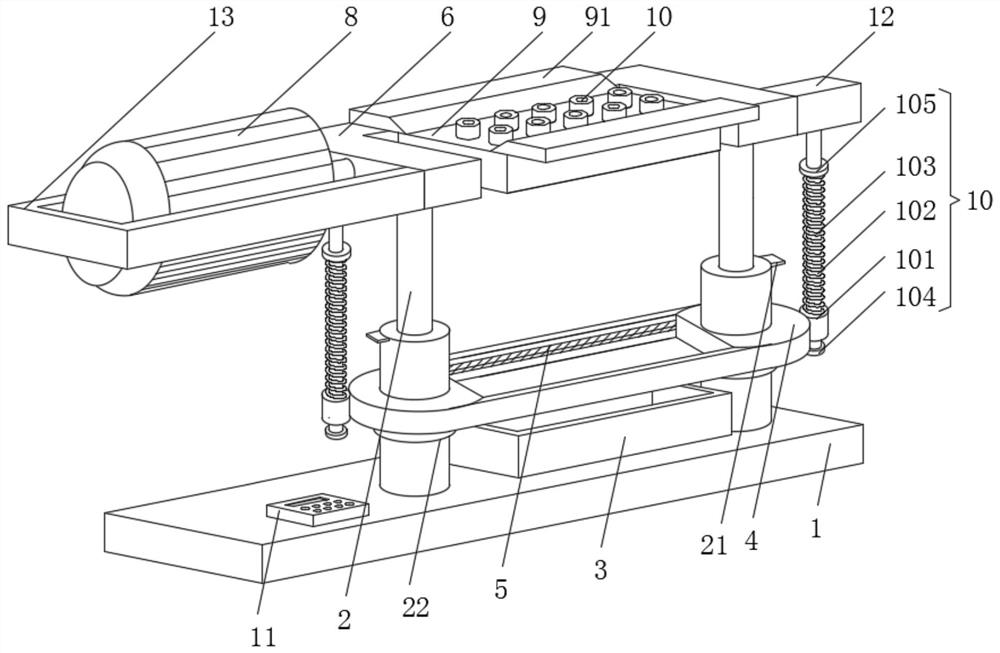

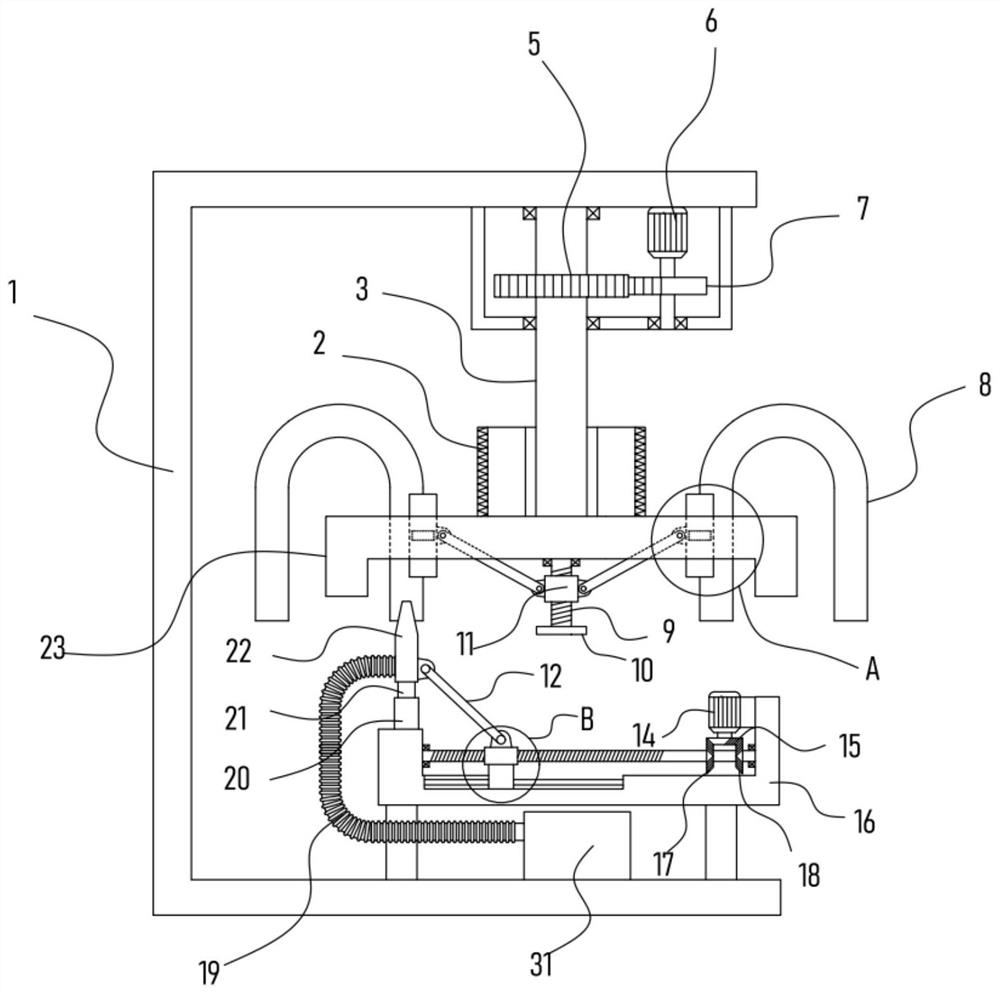

Drying device for U-shaped quartz tubes

ActiveCN111486683AFull drying effectStrong targetingDrying gas arrangementsDrying chambers/containersRotational axisEngineering

The invention discloses a drying device for U-shaped quartz tubes, and relates to the technical field of quartz tube processing. The drying device comprises a fixing frame; a bracket is fixed on the fixing frame; a rotating shaft pivotally connected to the fixing frame is vertically and fixedly installed on a rotating disc, and a locking mechanism for fixing the U-shaped quartz tubes is arranged on the rotating disc; an air blower is fixed on the fixing frame, and a nozzle vertically corresponding to the openings of the U-shaped quartz tubes is connected to the outlet end of the air blower through a corrugated pipe; and a servo motor II is fixed on the bracket, and the servo motor II is in driving connection with a lifting mechanism for driving the nozzle to ascend or descend. According tothe drying device, the multiple U-shaped quartz tubes can be clamped and fixed on the rotating disc through an arranged clamping mechanism, the rotating shaft can be driven by an arranged driving mechanism to drive the rotating disc to rotate stepwise, then, the nozzle can be aligned with the openings of the U-shaped quartz tubes on the rotating disc one by one to achieve the effect of sufficiently drying the U-shaped quartz tubes one by one, and the drying process has high pertinence; and besides, the drying time is guaranteed, and the drying process is efficient and sufficient.

Owner:新沂市赛立科石英制品有限公司

Injection molding machine drying cabinet

Owner:安徽鹭江电子工业制造有限公司

Grading and selecting device of dried fruits

InactiveCN107156883ARealize washingPlay the role of dryingSolid materialFood treatmentWater leakageEngineering

The present invention discloses a grading and selecting device of dried fruits. The grading and selecting device is used to realize a pre-treatment of the dried fruits before researches. A support tray is arranged at a top part of a shell body, a fixing table is arranged in an inner cavity of the support tray and two cushion blocks are arranged between the fixing table and support tray; a washing tank is formed among the fixing table, support tray and cushion blocks, a water nozzle is arranged one of the cushion blocks and connected with a water pump via a water inlet pipe, the water pump is used to extract water in a water tank, and a water return pipe is arranged between the water tank and a water leakage pipe; a rotary shaft is rotably arranged on the fixing table, a cross bar is fixed on the rotary shaft, fixing plates are fixed on the cross bar, and a movable plate is slidly arranged in an inner cavity of the fixing plates; a drying pipe is arranged at outside of the shell body, a bottom seat is fixed on a top part of a base seat, a rotary plate is rotably arranged on the base seat, a rotary plate driving unit used for driving a rotation of the rotary plate is arranged on the bottom seat, a plurality of blind holes arranged uniformly at a top part of the rotary plate along a circumferential direction, and sub-packaging bottles are placed in the blind holes. The device can effectively realize water washing, drying and sub-packaging of the dried fruits.

Owner:SHANDONG CROP GERMPLASM CENT

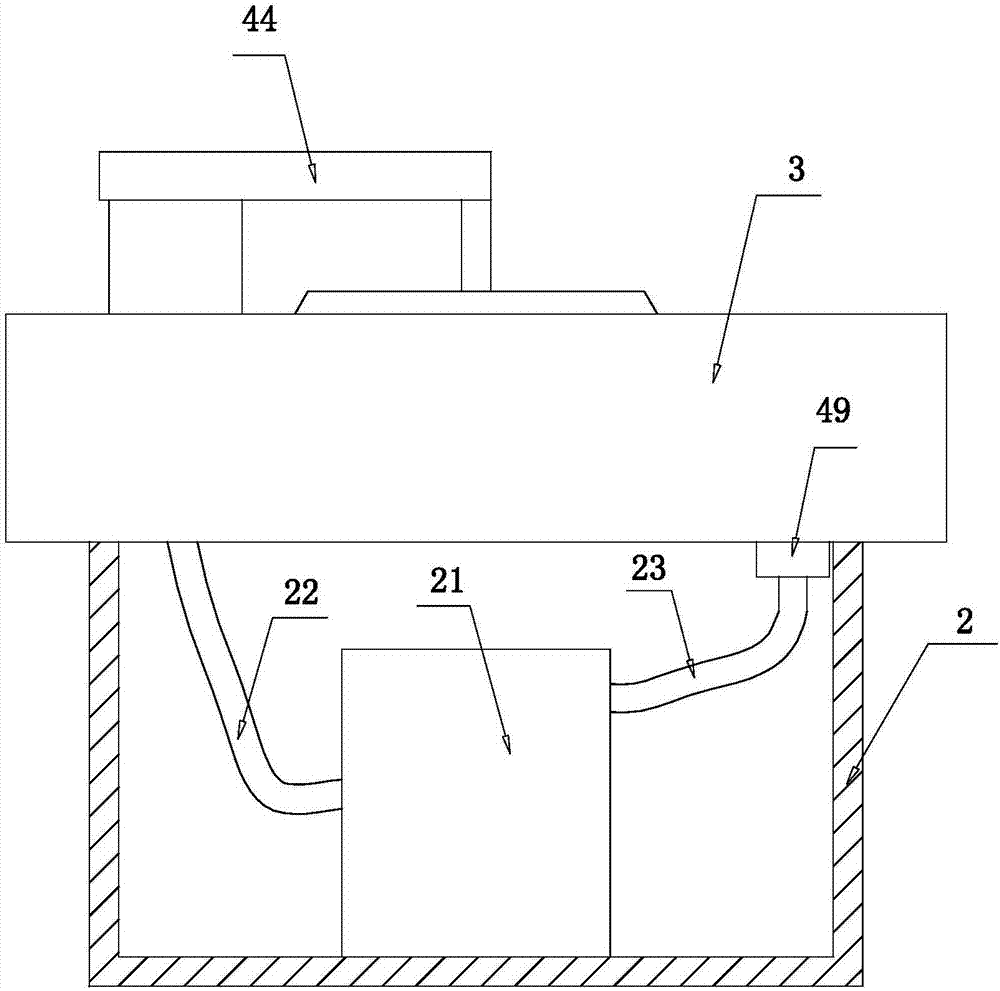

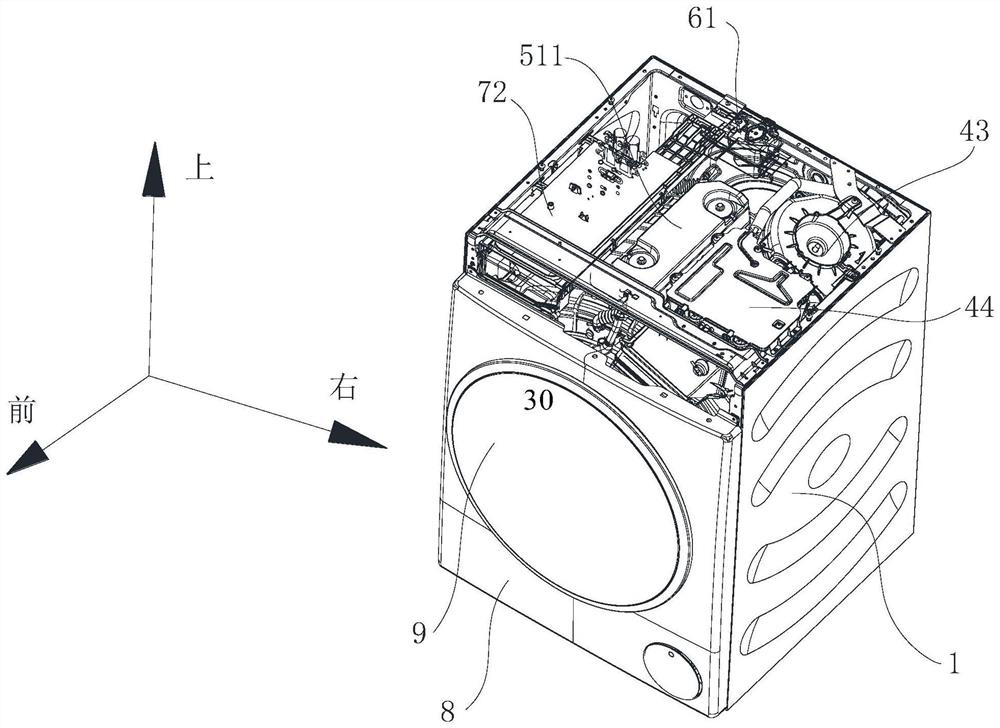

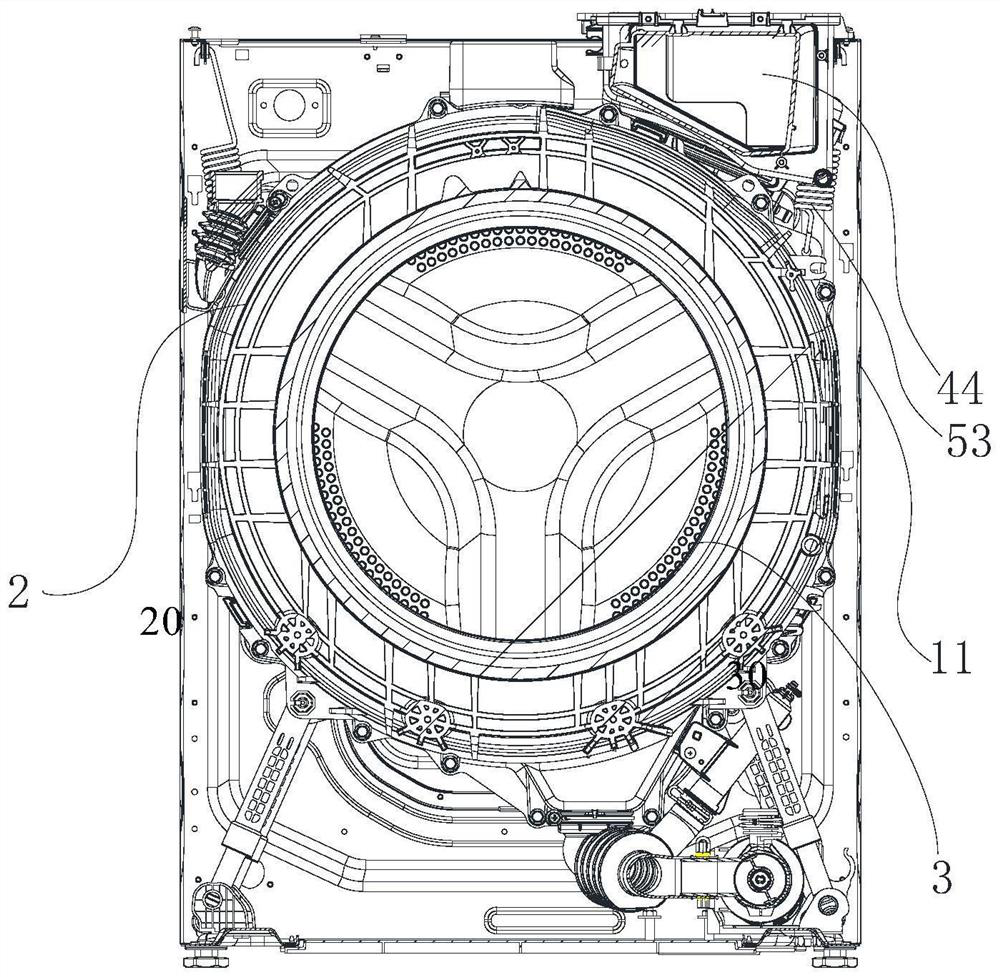

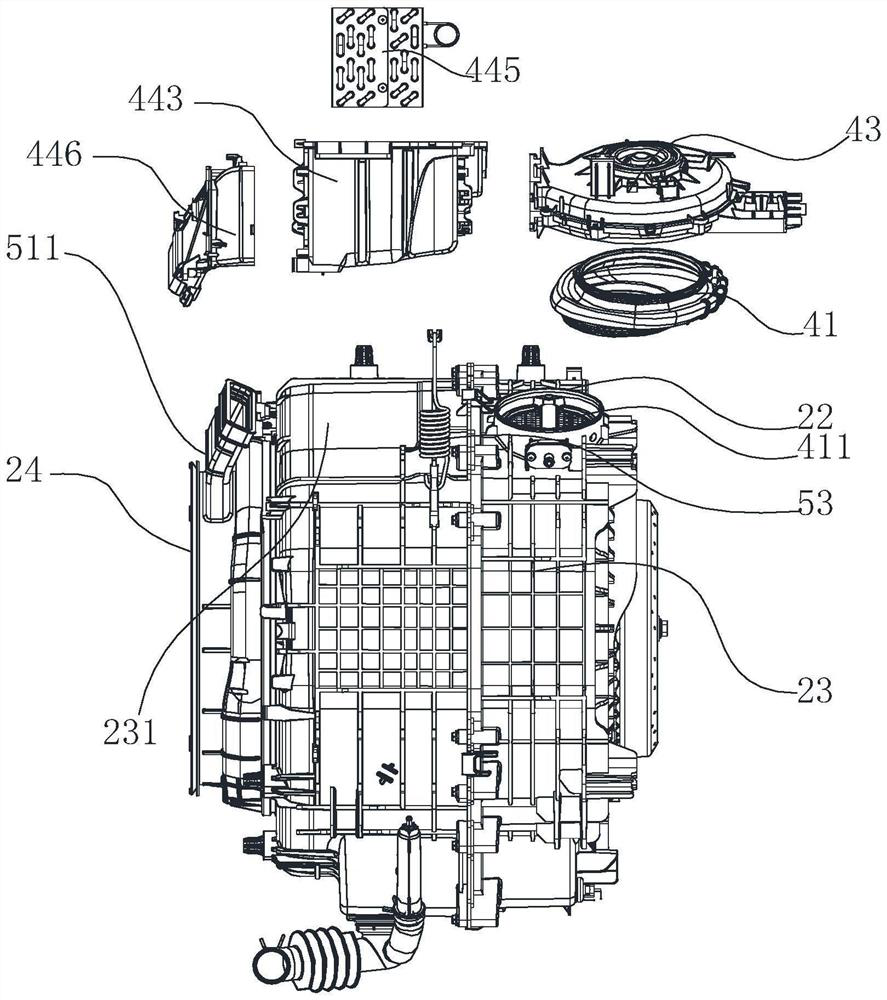

Clothes treatment device with heat pump drying function

PendingCN114059264AEffective height controlIncrease the use of spaceWashing machine with receptaclesTextiles and paperInterior spaceHeat pump

The present invention discloses a clothes treatment having a heat pump drying function. The device comprises: a shell forming an internal space; an outer cylinder arranged in the inner space of the shell; and a heat pump module comprising a two-device assembly, wherein the two-device assembly comprises an evaporator and a condenser, the evaporator and / or the condenser are / is arranged in the upper left space or the upper right space of the inner cylinder and the outer barrel of the shell, and the heat exchange main body of the evaporator and / or the condenser is provided with an outer contour matched with the upper left space or the upper right space where the heat exchange main body is located. The shape of the heat exchange main body of the evaporator and / or the condenser is matched with the space between the shell and the outer cylinder, that is, the overall structure of the evaporator and / or the condenser is adaptively designed according to the mounting space and is not a regular rectangle any more, the mounting space in the shell can be fully utilized, the height of the whole machine can be controlled, and heat exchange efficiency can be guaranteed.

Owner:GREE ELECTRIC APPLIANCES INC

Three-dimensional dynamic turn-back flow preheating, drying and calcining system

PendingCN110879008ACalcined evenlyReduce manufacturing costFurnace typesHandling discharged materialHot blastExhaust gas

The invention discloses a three-dimensional dynamic turn-back flow preheating, drying and calcining system. A first preheater is arranged on the side edge of a first elevator, a second preheater is arranged on the side edge of a second elevator, a first calcinator is arranged on the side edge of a third elevator, a second calcinator is arranged on the side edge of a fourth elevator, a first cooleris arranged on the side edge of a fifth elevator, a second cooler is arranged on the side edge of a sixth elevator, a feeding port of the first elevator is connected to a stock bin through an auger,a first high-temperature heating source is arranged on a middle machine body of the first calcinator, a second tail gas hot air outlet is formed in the rear end of the first calcinator, a second high-temperature heating source is arranged on a middle machine body of the second calcinator, and a third tail gas hot air outlet is formed in the rear end of the second calcinator. A three-dimensional inclined plate turn-back flowing process is adopted, so that the preheating, drying and calcining time of the materials can be ensured. Meanwhile, no power exists in the turn-back flow process, the natural flow process can guarantee uniform material calcination, the production cost is saved, and automatic production can be achieved.

Owner:营口仁和昌顺耐火材料有限公司

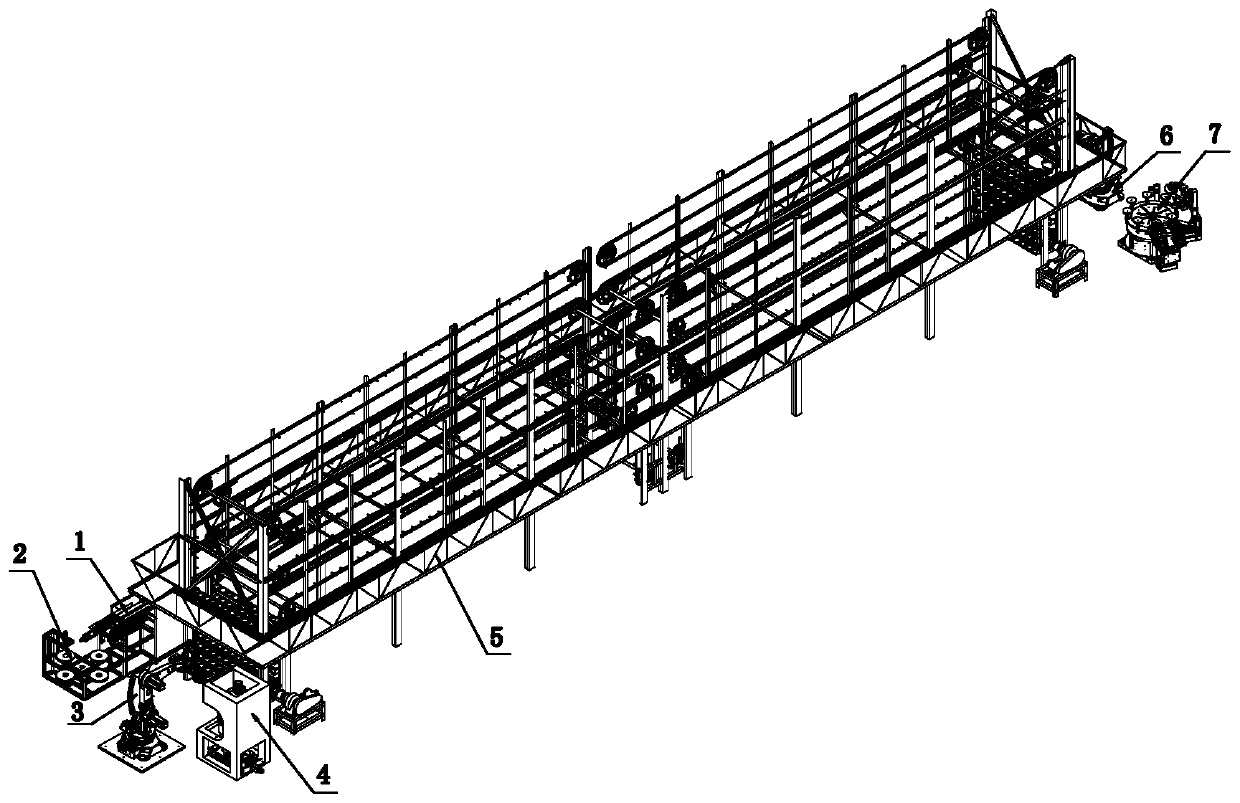

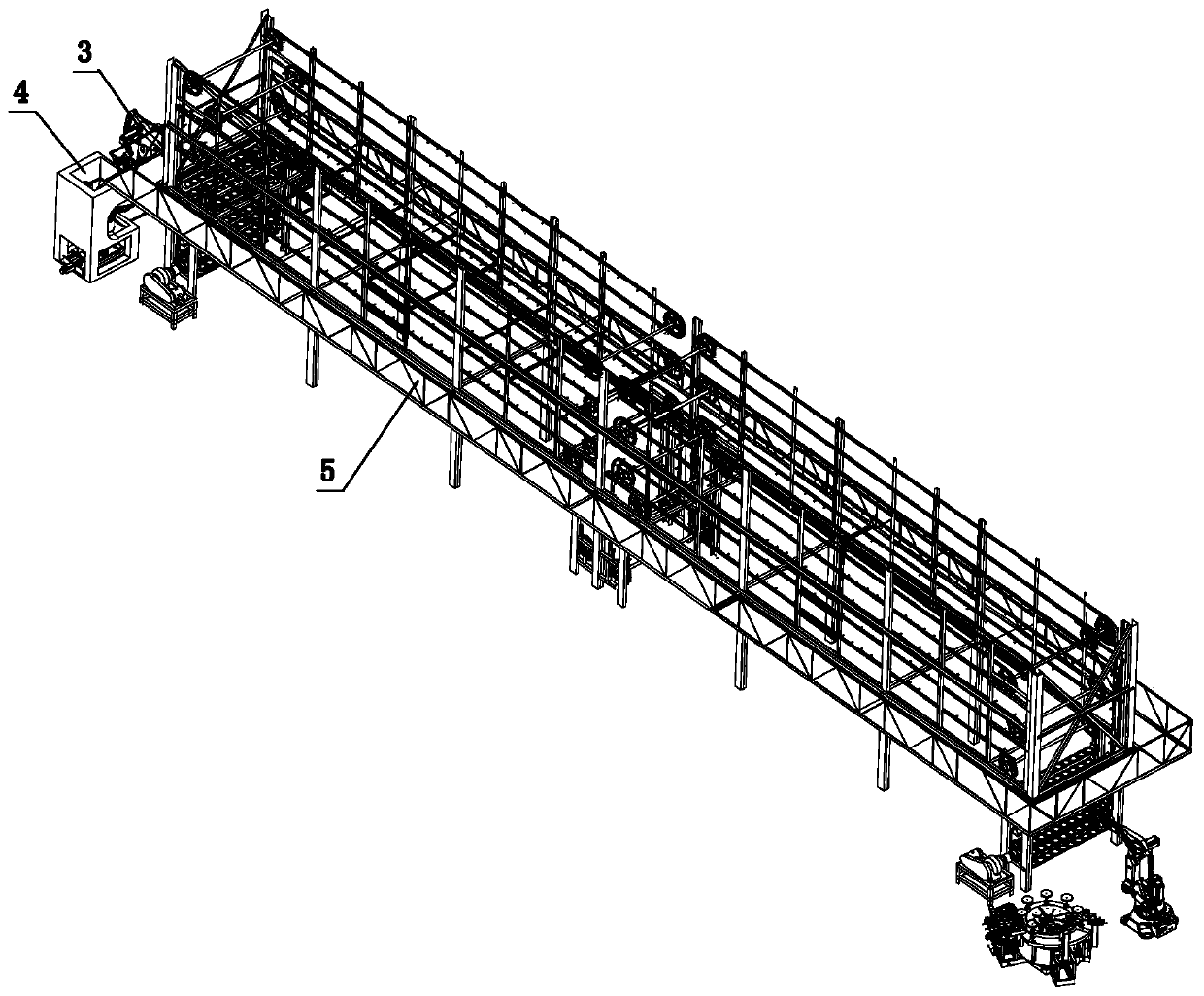

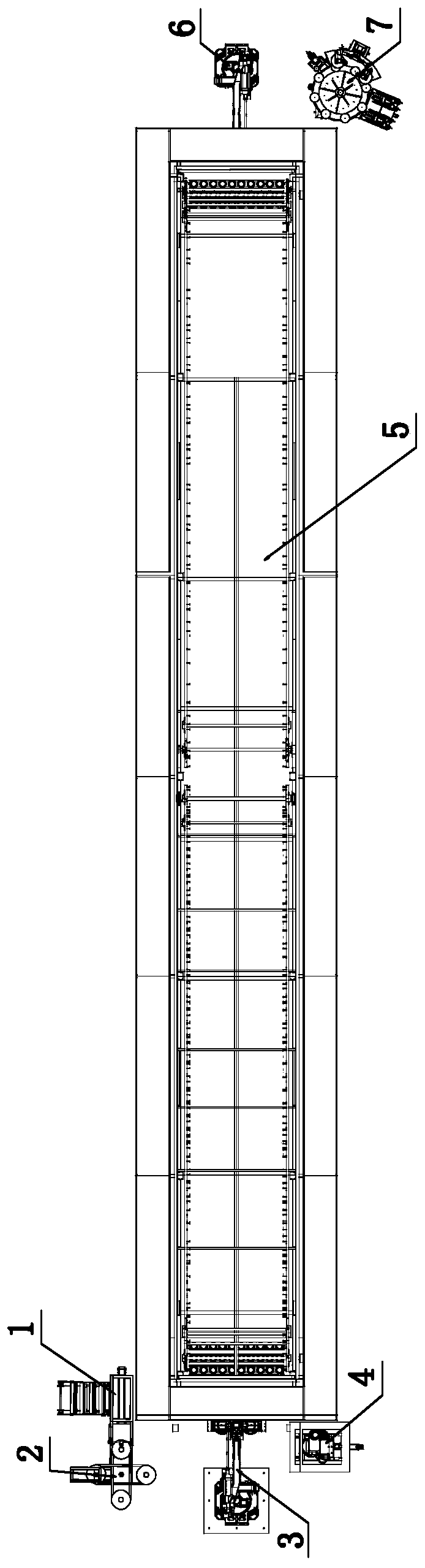

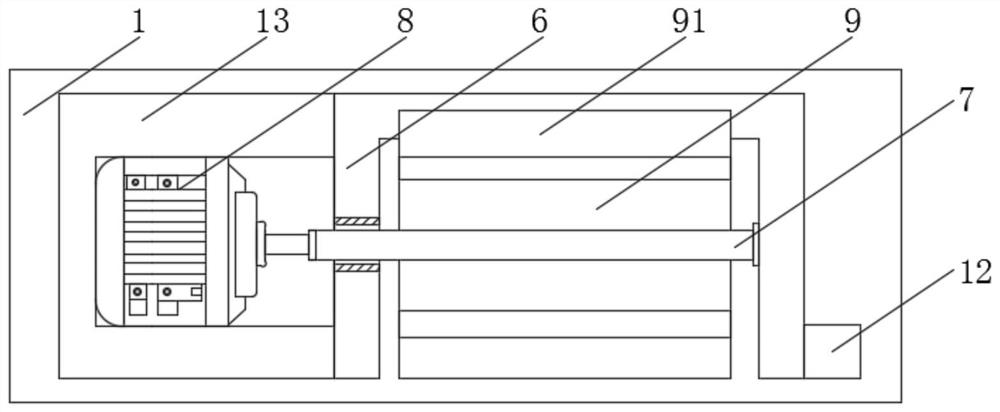

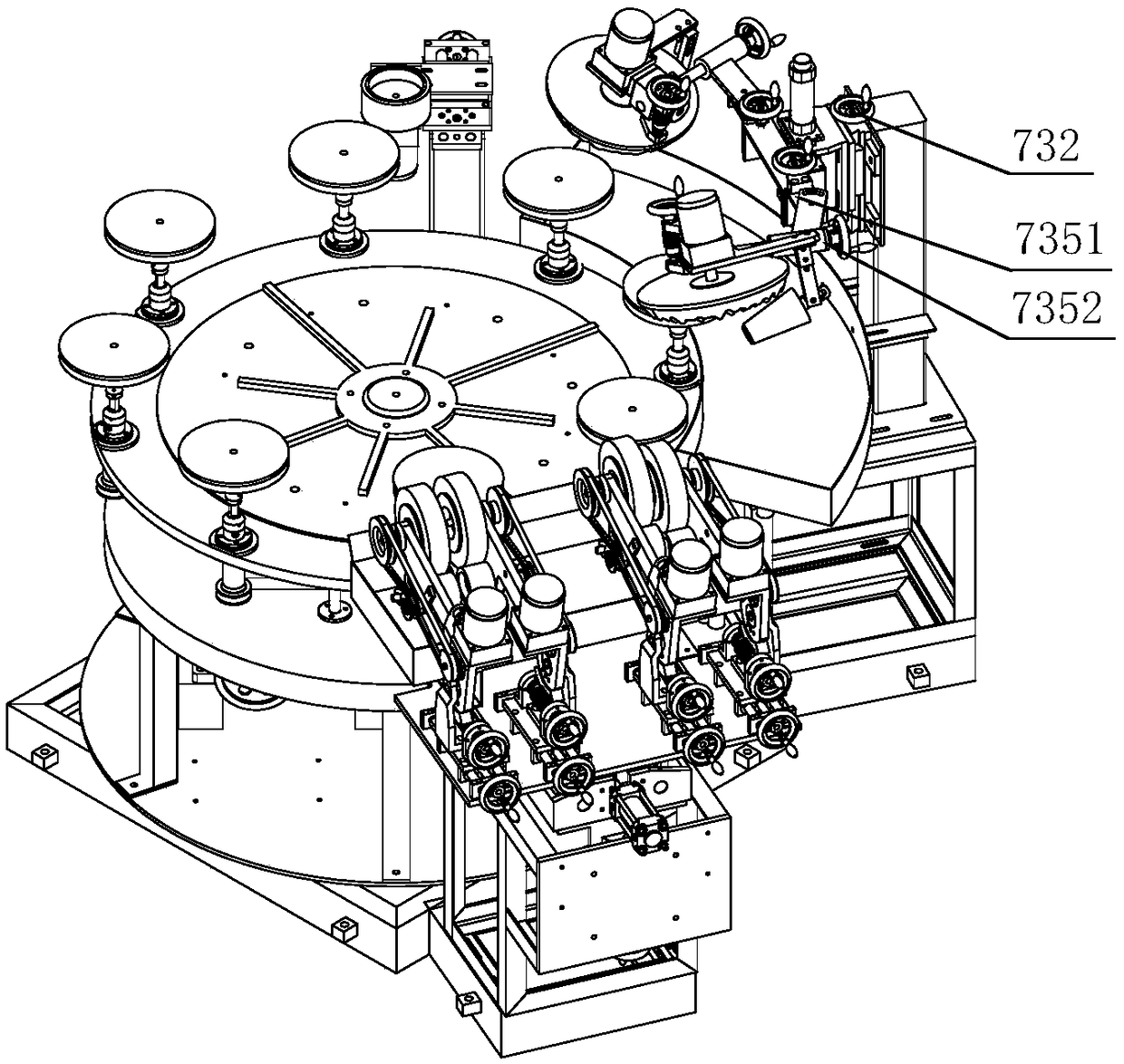

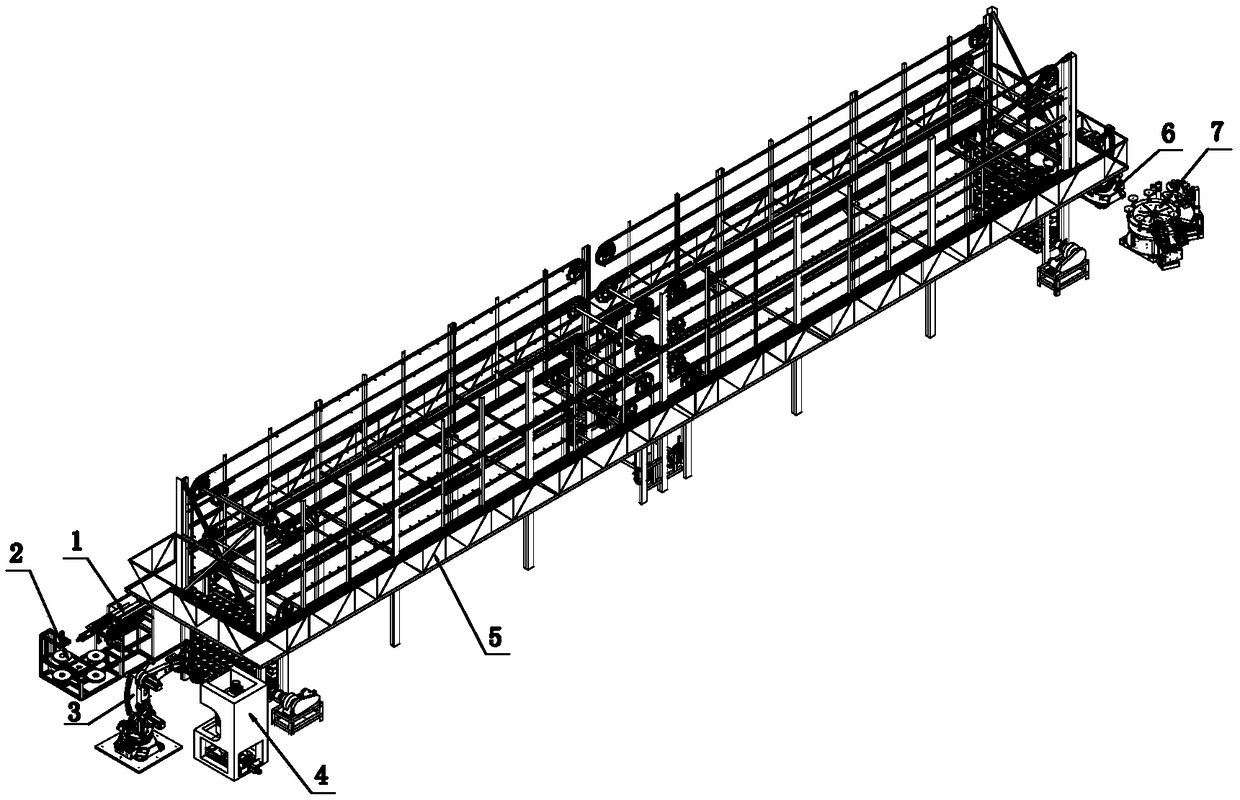

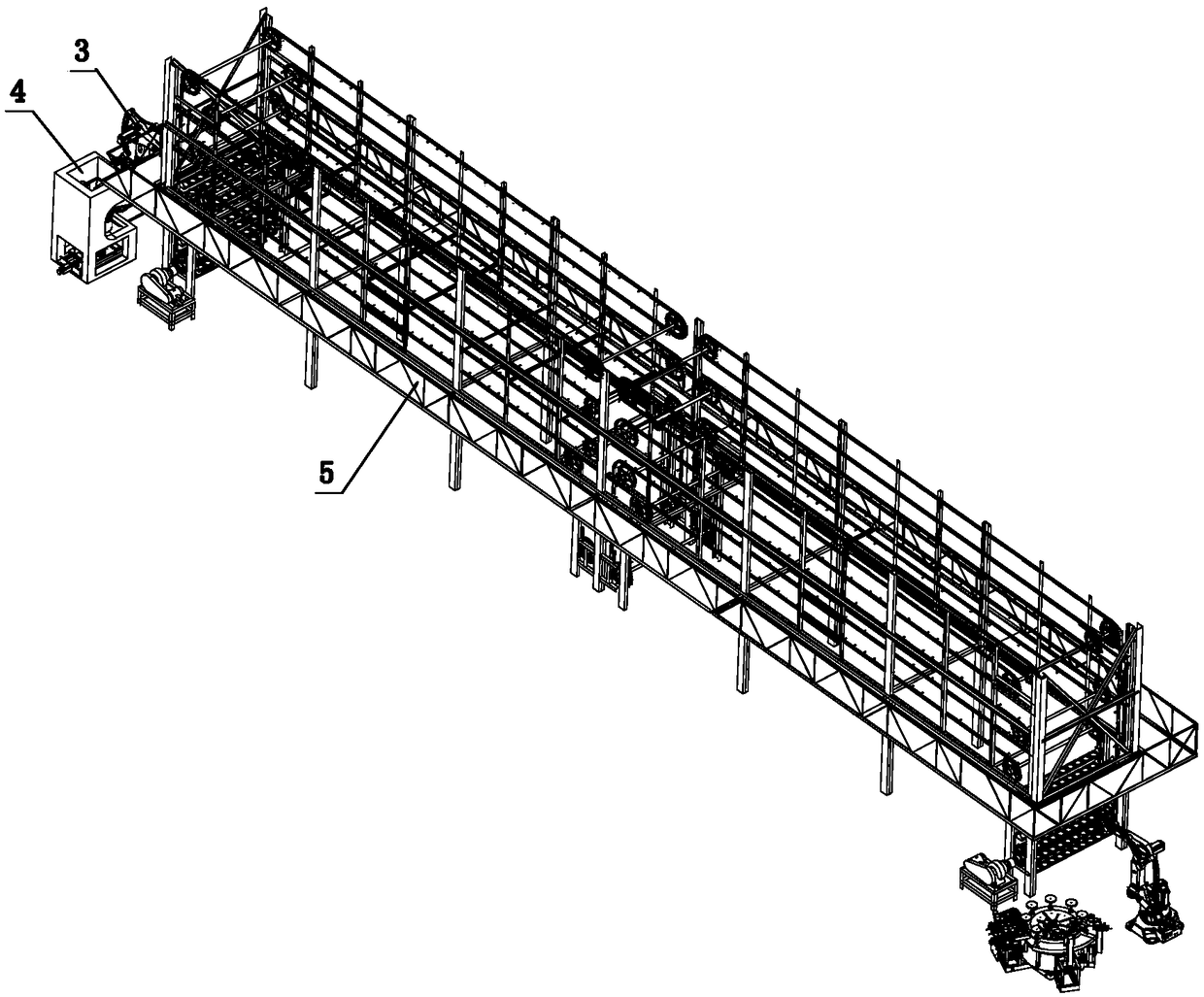

An Intelligent Robot Flexible Production System

ActiveCN109227889BReduce labor intensityImprove working environmentCeramic shaping apparatusRobot handMolding machine

The invention provides an intelligent robot flexible production system. The system comprises a mud cutting machine, a rotary disc mechanism, a mold delivery manipulator, a rolling pressing forming machine, a chain-type dried production line, a finished product delivery manipulator and an edge washing machine; materials are delivered to a discharging port to be cut by a mud cutting assembly by themud cutting machine, a mold with mud blocks is delivered to the rolling pressing forming machine by the mold delivery manipulator, the mold which is rolled and pressed is delivered and placed on the chain-type dried production line by the mold delivery manipulator, the dried finished product is sucked out from the mold by the finished product manipulator through a suction plate mechanism and delivered to the edge washing machine, and edge washing and grinding is conducted on the finished product by the edge washing machine. By means of the system, automatic mold taking and placing, automatic mud delivery, automatic mud cutting, automatic mud feeding, automatic rolling pressing can be achieved, so that manual operation is completely replaced, the labor intensity of workers is reduced, the operation cost is reduced, and the production efficiency is improved.

Owner:斯罗米克智能机器(唐山)有限公司

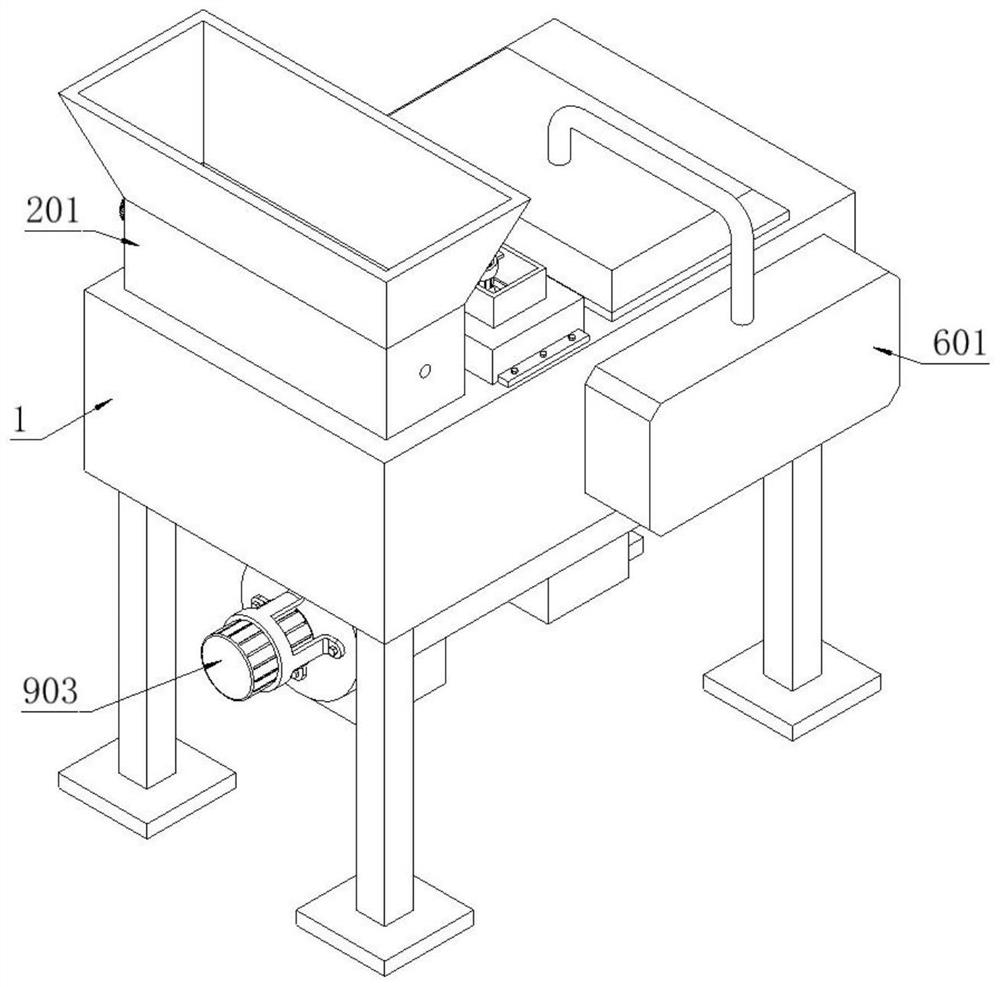

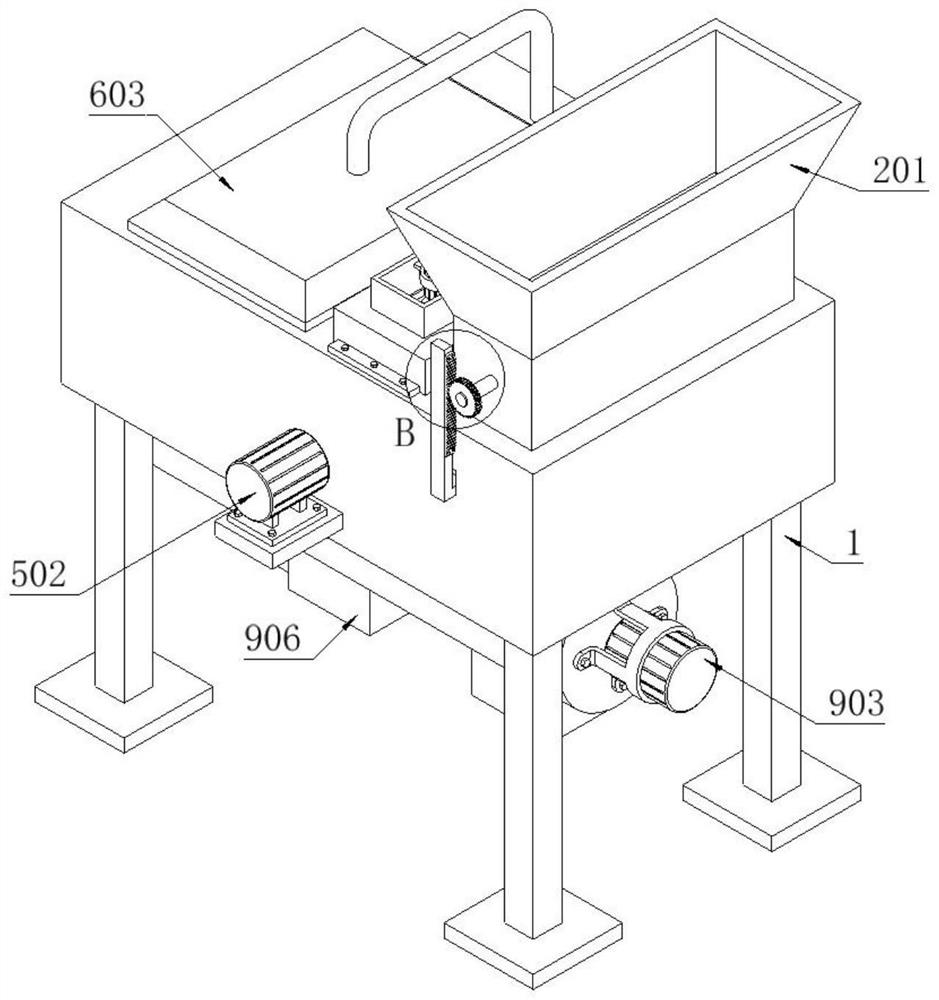

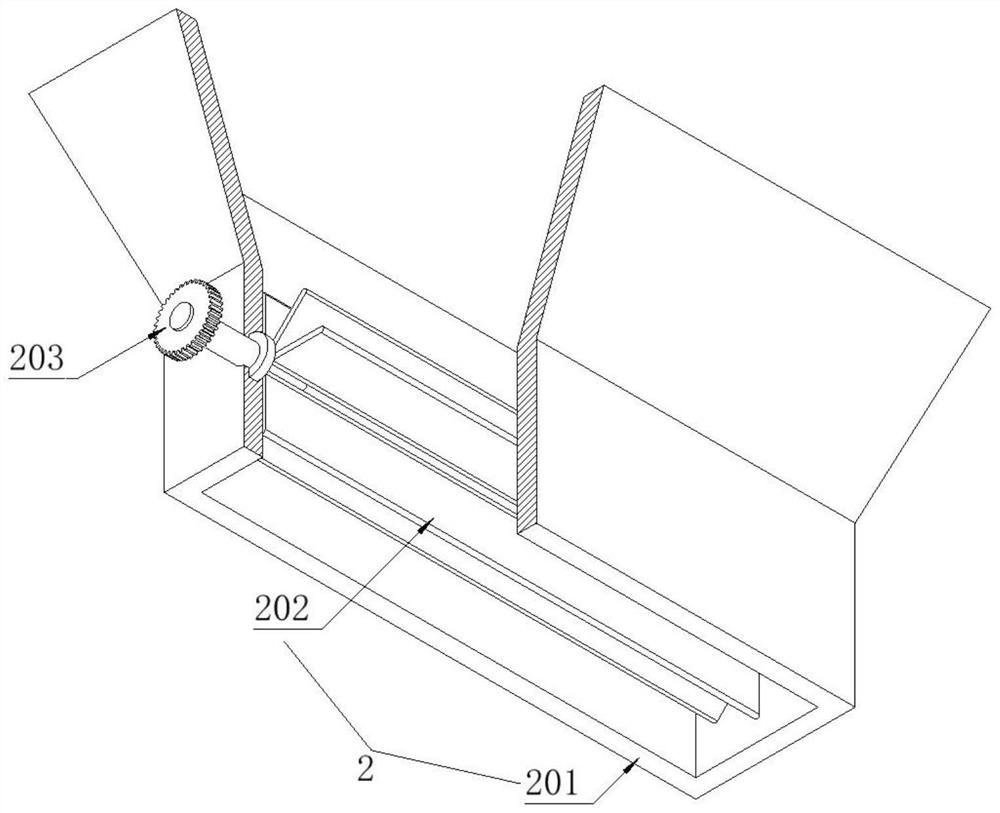

Separation equipment based on traditional Chinese medicine raw material classification

InactiveCN113976442AAvoid cloggingImprove separation qualitySievingGas current separationMechanical engineeringChinese herbology

The invention provides separation equipment based on traditional Chinese medicine raw material classification. The equipment comprises a body. A feeding device is mounted at the top of the body, a vibrating device is mounted in the body, a connecting device is mounted on the rear side of the vibrating device, and a driving mechanism is mounted on the body. An adsorption device and a heating device are installed on the body, the heating device is located on the left side of the adsorption device, and a flow guide mechanism is installed in the heating device. A classification mechanism is installed at the bottom of the body. According to the separation equipment, when three driving blocks rotate, the flow guide plate is driven to reciprocate up and down, at the moment, the flow guide plate vibrates slightly, impurities such as wood chips, grass roots and tree roots are prevented from remaining at the bottom of traditional Chinese medicine raw materials, and the separation quality is improved; and when the flow guide plate reciprocates up and down, a material blocking frame is driven to rotate in a reciprocating mode, the same amount of traditional Chinese medicine raw materials in a feeding hopper fall to the top of the flow guide plate at the moment, it is guaranteed that the feeding quantity is the same every time, and blocking among the traditional Chinese medicine raw materials is avoided.

Owner:江西仟方智能科技有限公司

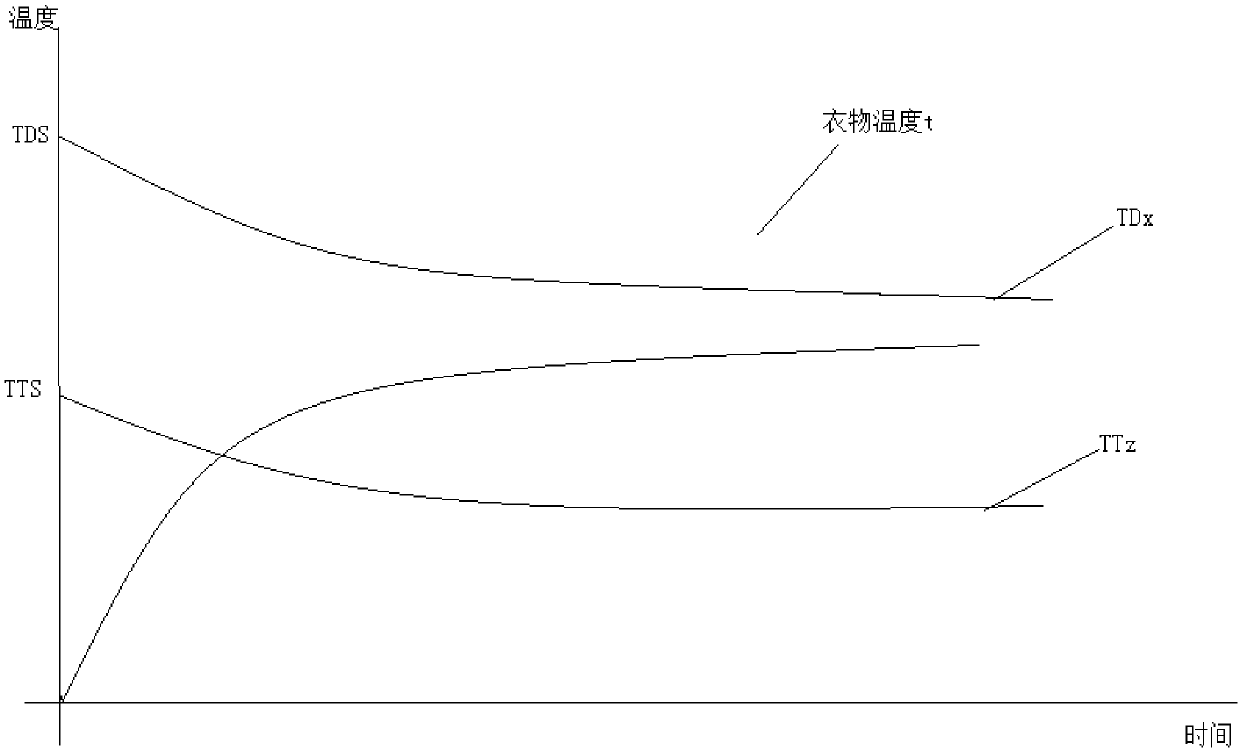

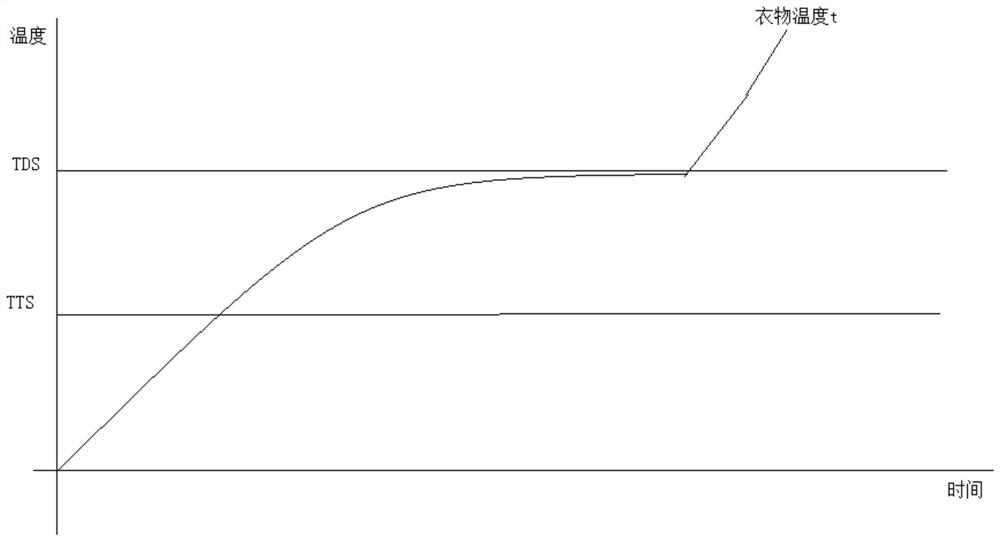

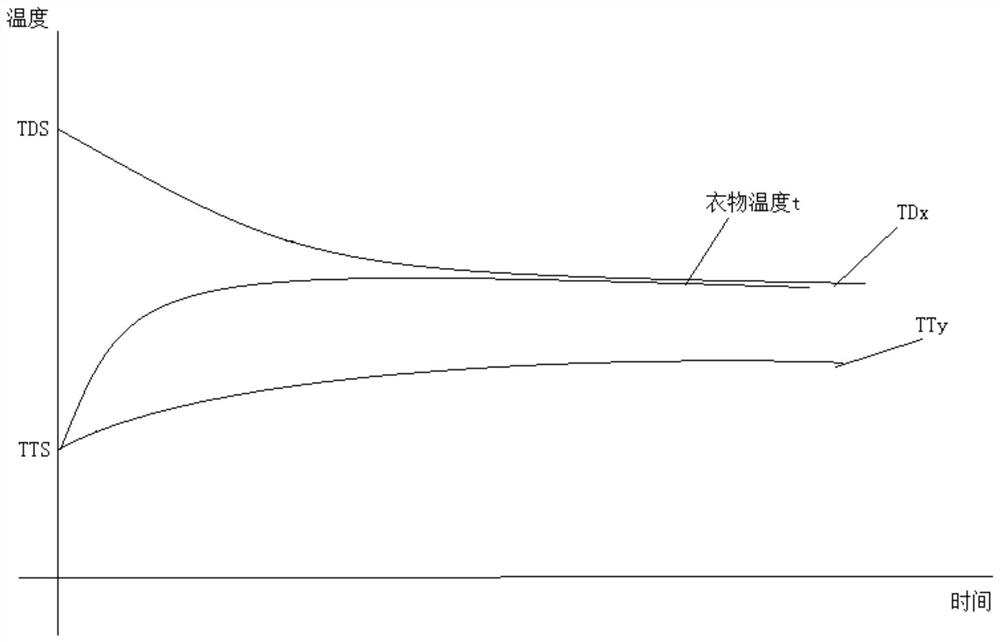

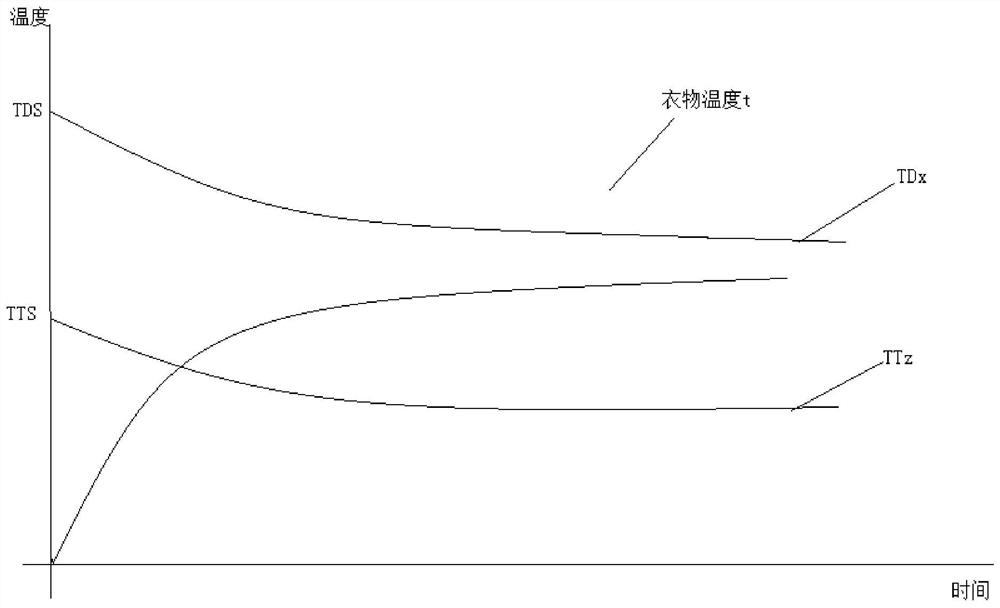

Clothes drying and treatment device temperature control method and clothes drying and treatment device

ActiveCN110438779AIncrease temperatureExtend warm-up timeTextiles and paperLaundry driersTemperature controlProcess engineering

The invention discloses a clothes drying and treatment device temperature control method and a clothes drying and treatment device. A heating device of the clothes drying and treatment device performson / off operation in a temperature interval, when the temperature in a cylinder reaches an upper limit value TDx of the temperature interval under the action of the heating device, the heating deviceis disconnected, and the heating device stops heating; and the upper limit value TDx of the temperature interval decreases as the number x of times the heating device is turned off increases. A high initial turn-off temperature for the heating device is adopted, the temperature in the cylinder is rapidly increased to reach a clothes drying temperature, so that the preheating time is shortened; andsubsequent control parameters for controlling on-off of the heating device is multiplied with a certain coefficient, the coefficient is related to the on-off times, and effects of gradually reducingthe off-temperature of the clothes dryer along with increasing of on-off times, and correspondingly adjusting the on-temperature along with the turn-on times of the heating device are achieved, and the contradiction between high temperature required at the initial stage of the clothes dryer and low temperature required at the later stage of the clothes drying process is effectively balanced.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

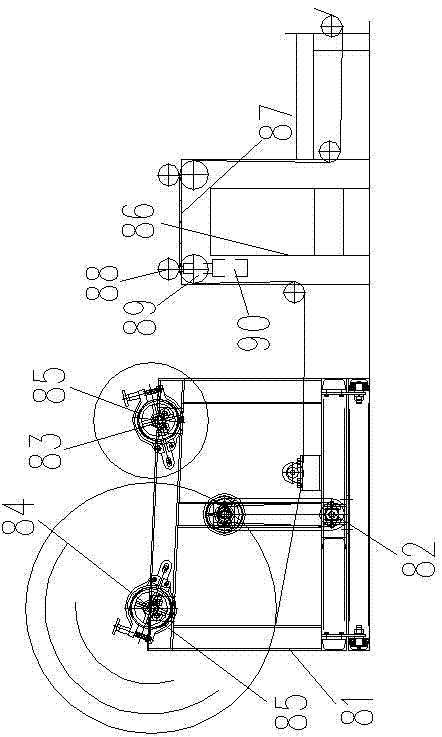

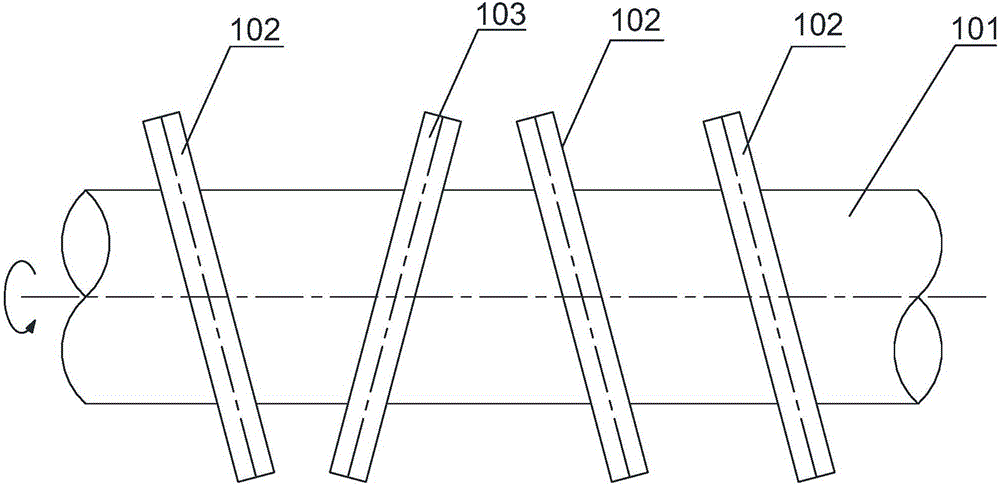

Paddle shaft provided with reverse blade of steam dryer

InactiveCN106813495AGuaranteed drying timeGood for strangulationRotary stirring mixersTransportation and packagingEngineeringDrying time

The invention discloses a paddle shaft provided with a reverse blade of a steam dryer. The paddle shaft comprises a shaft body, wherein blades are arranged on the shaft body; the blades comprise front blades which are used for pushing materials forwards when the shaft body rotates clockwise and the reverse blade which is used for reversely pushing the materials when the shaft body rotates clockwise. According to the paddle shaft disclosed by the invention, the reverse blade is arranged on the shaft body, so that wet materials are reversely pushed when the shaft body normally rotates, and therefore, dispersing of materials and cleaning of blades are facilitated while drying time of the materials can be guaranteed. The two paddle shafts are separately the first paddle shaft and the second paddle shaft, which are arranged in a dryer case in parallel, and the blades on the first paddle shaft extend to a gap between adjacent blades on the second paddle shaft. According to the paddle shaft disclosed by the invention, the blades on adjacent two shaft bodies are arranged in a crossed mode positively and negatively, so that the materials can be continuously extruded, rubbed and stirred between the two blades, and therefore, contact areas between the materials and the blades are increased.

Owner:青岛福荣华鑫环保能源科技有限公司

Glue sealing device for semiconductor diode

ActiveCN112216618AAvoid bendingDry evenlySemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention discloses a glue sealing device for a semiconductor diode, which belongs to the field of semiconductor manufacturing and comprises a base, two electric push rods are fixedly connected tothe top of the base, and a glue sealing groove body is fixedly connected to the top of the base. Lantern rings slidably connected with the two electric push rods are arranged on the outer sides of the two electric push rods in a sleeving mode, integrally-formed heating plates are fixedly connected to the front faces and the back faces of the two lantern rings, integrally-formed I-shaped frames are fixedly connected to the tops of the two electric push rods, and the tops of the two electric push rods are fixedly connected to the bottom ends of the two electric push rods; the top of the base isfixedly connected to the bottom of the glue sealing groove body, the outer sides of the two electric push rods are slidably connected to the inner sides of the two lantern rings correspondingly, andthe front faces and the back faces of the two lantern rings are fixedly connected to the opposite sides of the two heating plates correspondingly, so that the device has the advantages that lead bending is avoided, gluing is uniform, and drying is rapid and uniform.

Owner:抚州华成半导体科技股份有限公司

Intelligent robot flexible production system

ActiveCN109227889AReduce labor intensityImprove working environmentCeramic shaping apparatusProduction lineEngineering

The invention provides an intelligent robot flexible production system. The system comprises a mud cutting machine, a rotary disc mechanism, a mold delivery manipulator, a rolling pressing forming machine, a chain-type dried production line, a finished product delivery manipulator and an edge washing machine; materials are delivered to a discharging port to be cut by a mud cutting assembly by themud cutting machine, a mold with mud blocks is delivered to the rolling pressing forming machine by the mold delivery manipulator, the mold which is rolled and pressed is delivered and placed on the chain-type dried production line by the mold delivery manipulator, the dried finished product is sucked out from the mold by the finished product manipulator through a suction plate mechanism and delivered to the edge washing machine, and edge washing and grinding is conducted on the finished product by the edge washing machine. By means of the system, automatic mold taking and placing, automatic mud delivery, automatic mud cutting, automatic mud feeding, automatic rolling pressing can be achieved, so that manual operation is completely replaced, the labor intensity of workers is reduced, the operation cost is reduced, and the production efficiency is improved.

Owner:斯罗米克智能机器(唐山)有限公司

A U-shaped quartz tube drying device

ActiveCN111486683BFull drying effectStrong targetingDrying gas arrangementsDrying chambers/containersRotational axisEngineering

The invention discloses a U-shaped quartz tube drying device, which relates to the technical field of quartz tube processing. The turntable is provided with a locking mechanism for fixing the U-shaped quartz tube, and a blower is fixed on the fixed frame, and the outlet end of the blower is connected with a nozzle vertically corresponding to the mouth of the U-shaped quartz tube through a corrugated tube. The servo motor II is fixed, and the servo motor II is driven and connected with a lifting mechanism for driving the nozzle lifting mechanism; the present invention can clamp and fix a plurality of U-shaped quartz tubes on the turntable through the set clamping mechanism, and the set driving mechanism It can drive the rotating shaft to drive the turntable to rotate step by step, so that the nozzles can be aligned with the U-shaped quartz tube nozzles on the turntable one by one, and the U-shaped quartz tubes can be fully dried one by one. The drying process is highly targeted, and the drying The time is guaranteed and the drying process is efficient and sufficient.

Owner:新沂市赛立科石英制品有限公司

Tobacco material pneumatic drying process and equipment

ActiveCN101601500BImprove the effect of puffing and dryingReach drying timeTobacco preparationThermodynamicsDrying time

Owner:ZHISI HLDG GRP

A temperature control method of a dry clothes treatment device and a dry clothes treatment device

ActiveCN110438779BIncrease temperatureExtend warm-up timeTextiles and paperLaundry driersTemperature controlHot Temperature

The invention discloses a method for controlling the temperature of a dry clothes treatment device and a dry clothes treatment device. The heating device of the dry clothes treatment device performs an on / off operation within a temperature range. When the upper limit TDx of the temperature range is reached, the heating device is disconnected, and the heating device stops heating; the upper limit TDx of the temperature range decreases as the number x of disconnection of the heating device increases. The present invention adopts a relatively high initial disconnection temperature for the heating device, and quickly raises the temperature in the cylinder to the drying temperature to speed up the preheating time, and multiplies a certain coefficient in the subsequent control parameters for controlling the on-off of the heating device. This coefficient is related to the number of on-off times, realizing the effect that the off-temperature of the dryer gradually decreases with the increase of the number of on-off times, and the on-off temperature is adjusted accordingly with the number of on-off times of the heating device, which effectively balances the dryer. The contradiction between the need for high temperature at the beginning and the need for low temperature later in the drying process.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

Method and device for ultrasonically enhanced controlled atmosphere drying

ActiveCN104322655BImproved heat conditionEnhance heat and mass transferFruits/vegetable preservation by dehydrationModified atmosphereEnvironmental engineering

The invention discloses a method and device for ultrasonically enhanced controlled atmosphere drying. The method includes performing direct contact ultrasonic treatment on the material while the controlled atmosphere hot air is drying the material. The ultrasonic enhanced modified atmosphere drying method of the present invention effectively inhibits the oxidation reaction process in the drying process, protects the active ingredients in the material, effectively inhibits the browning of the color and luster, and solves the problem that nutrients are easily oxidized and degraded in conventional hot air drying; directly The synergistic effect of contact ultrasonic and modified atmosphere drying in low oxygen environment, under the premise of ensuring product quality, ultrasonic energy is directly transmitted into the material, effectively improving the moisture migration rate of controlled atmosphere drying, improving energy utilization and mass transfer Strengthen the efficiency, thereby improving the drying efficiency, shortening the drying time, and solving the problems of low drying rate and low product quality of conventional hot air drying, and has broad application prospects.

Owner:HENAN UNIV OF SCI & TECH

Straight-through drying oven with air curtain system

ActiveCN103673573BPrevent spilloverGuaranteed non-proliferationDrying solid materialsFresh airMechanical engineering

The invention relates to a straight-through drying oven with an air curtain system. The straight-through drying oven comprises an inlet hood region, a fresh air curtain region, an inlet air curtain region, a preheating region, an internal air curtain region, a heating region, an outlet air curtain region, and an outlet hood region, wherein the regions are communicated with one another sequentially from front to rear. Each of the fresh air curtain region, the inlet air curtain region, the internal air curtain region and the outlet air curtain region is provided with an air curtain guide plate. Each air guide plate comprises a first angle plate and a second angle plate. A first top plate of the first angle plate and a second top plate of the second angle plate are both mounted a top wall plate of the drying oven. A gap between a first sloping plate of the first angle plate and a second sloping plate of the second angle plate forms an air passage. The air curtain guide plates in the inlet air curtain region and the outlet air curtain region prevent smoke inside the drying oven from overflowing. The air curtain guide plate in the internal air curtain region separates different temperature areas, so that temperature disturbance amongst different temperature areas is prevented effectively.

Owner:武汉东研智慧设计研究院有限公司

Sandy soil screening equipment capable of distinguishing dryness and wetness

InactiveCN112317323AEfficient mixing and dehumidificationGuaranteed drying timeSievingGas current separationDry sandEngineering

The invention discloses sandy soil screening equipment capable of distinguishing dryness and wetness. The sandy soil screening equipment comprises a main box body, a screening cavity is formed in themain box body, the upper wall of the screening cavity is provided with feeding ports in a communicating mode, the feeding ports are provided with upward openings and are in bilateral symmetry, and theupper wall of the screening cavity is fixedly connected with a telescopic block located between the left feeding port and the right feeding port. A telescopic cavity with a downward opening is formedin the telescopic block, the left wall and the right wall of the screening cavity are in up-down sliding connection with a primary filter plate, and the telescopic cavity is in up-down sliding connection with a sliding block fixedly connected with the primary filter plate. The left wall and the right wall of the screening cavity are in up-down sliding connection with filter plate fixing plates. The upper end faces of the filter plate fixing plates are rotationally connected with guide slippers which extend upward to be rotationally connected with the upper end face of the primary filter plate. According to the sandy soil screening equipment capable of distinguishing dryness and wetness, dry sand and wet sand are separately screened, so that efficient screening can be conducted, and efficient stirring and dehumidification are conducted on the wet sand in the screening process.

Owner:福州经济技术开发区兆网亿智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com