Full-automatic curing furnace for visual panel screen printing drying

A technology of drying furnace and curing furnace, applied in screen printing, screen printing machine, printing, etc., can solve problems such as inability to wire and connect process equipment, reduce production efficiency, and temperature instability, and achieve energy saving Effects of waste and heat pollution, reduction of floor space, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention can be explained in more detail by the following examples, and the purpose of disclosing the present invention is intended to protect all changes and improvements within the scope of the present invention, and the present invention is not limited to the following examples:

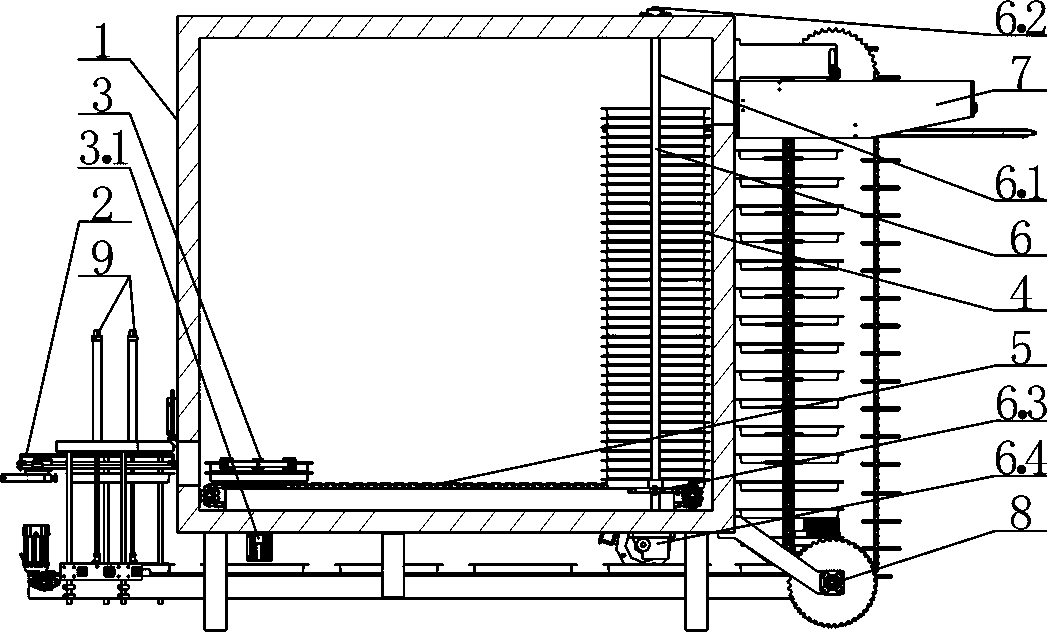

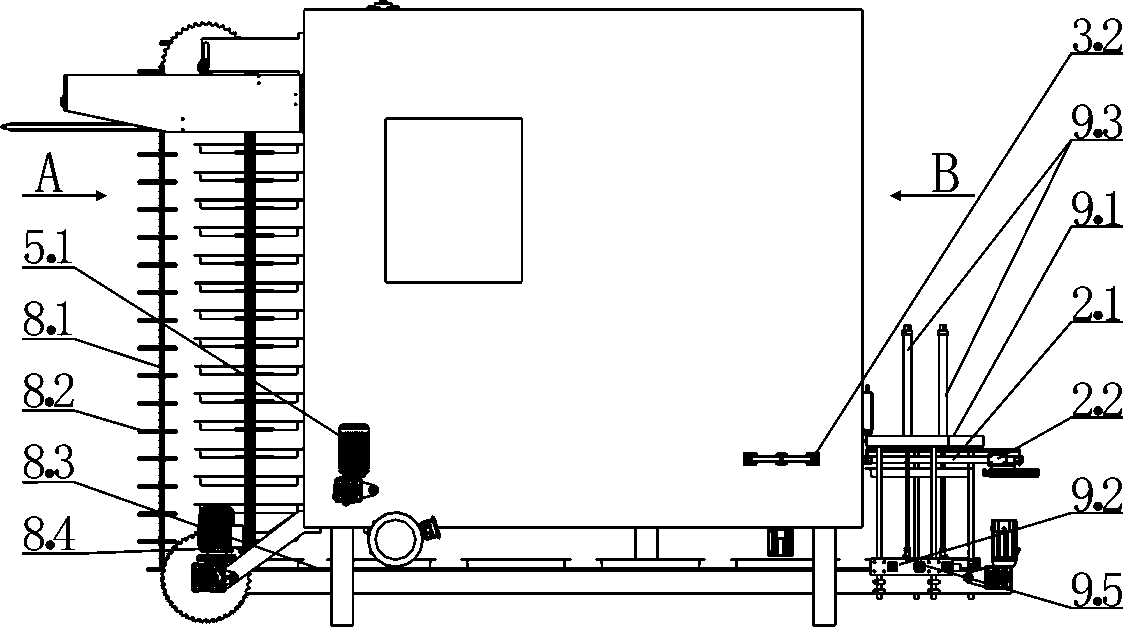

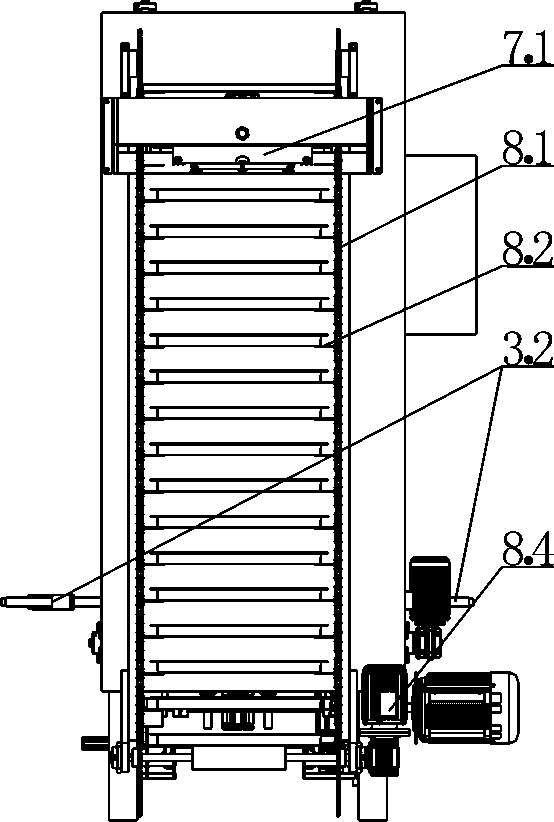

[0028] combined with Figure 1~4 The fully automatic curing furnace for screen printing and drying of visible panels, the curing furnace includes a heating and drying furnace 1, a feeding device 2, a supporting device 3, a lifting device 6, a discharging device 7, and a feeding tray Conveyor 8 and material lifting device 9; the lower part of the head end face of the heating and drying furnace 1 is provided with a feed port, and a horizontally corresponding feed port is provided outside the heating and drying furnace 1 for pushing the tray into the The feeding device 2 of the furnace, that is, the feeding device 2 can smoothly push the tray on which the panel to be dried and sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com