Clothes treatment device with heat pump drying function

A clothes processing device and heat pump drying technology, which is applied to washing devices, household clothes dryers, washing machines with containers, etc., can solve the problems of low space utilization of washing machines, poor drying effect of washing machines, and inability to effectively control the height of the whole machine, etc. problem, achieve the effect of ensuring drying time and reducing space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] This embodiment carries out structural design and installation layout for the evaporator and condenser, so as to ensure that the evaporator and condenser can be installed in the space inside the shell, improve the space utilization rate inside the shell, and effectively control the height of the whole machine , the specific technical scheme is as follows:

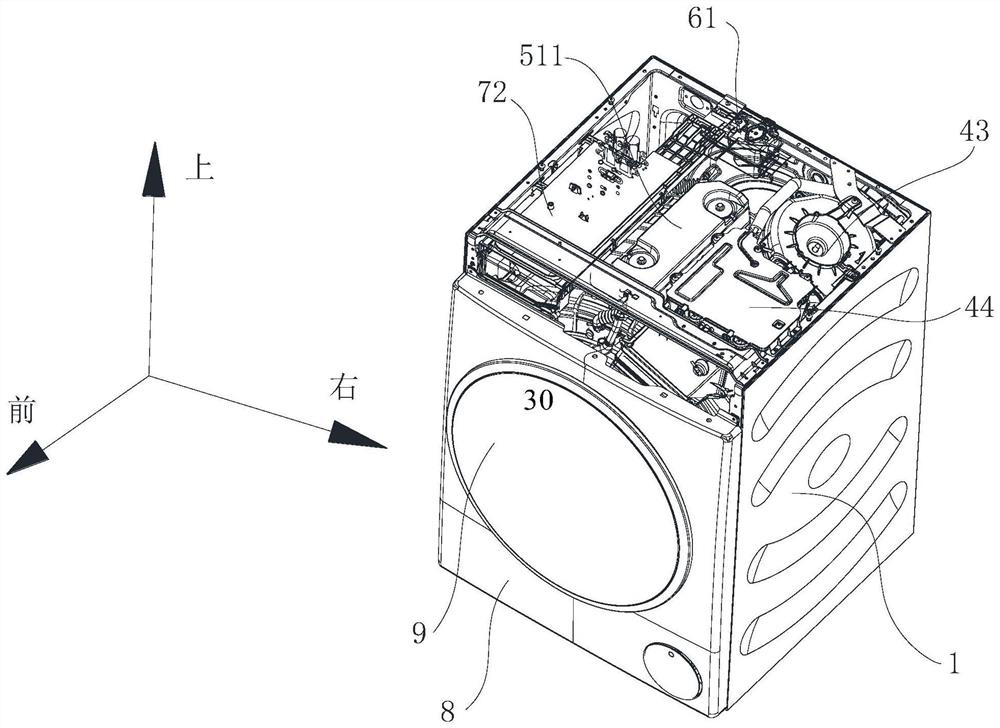

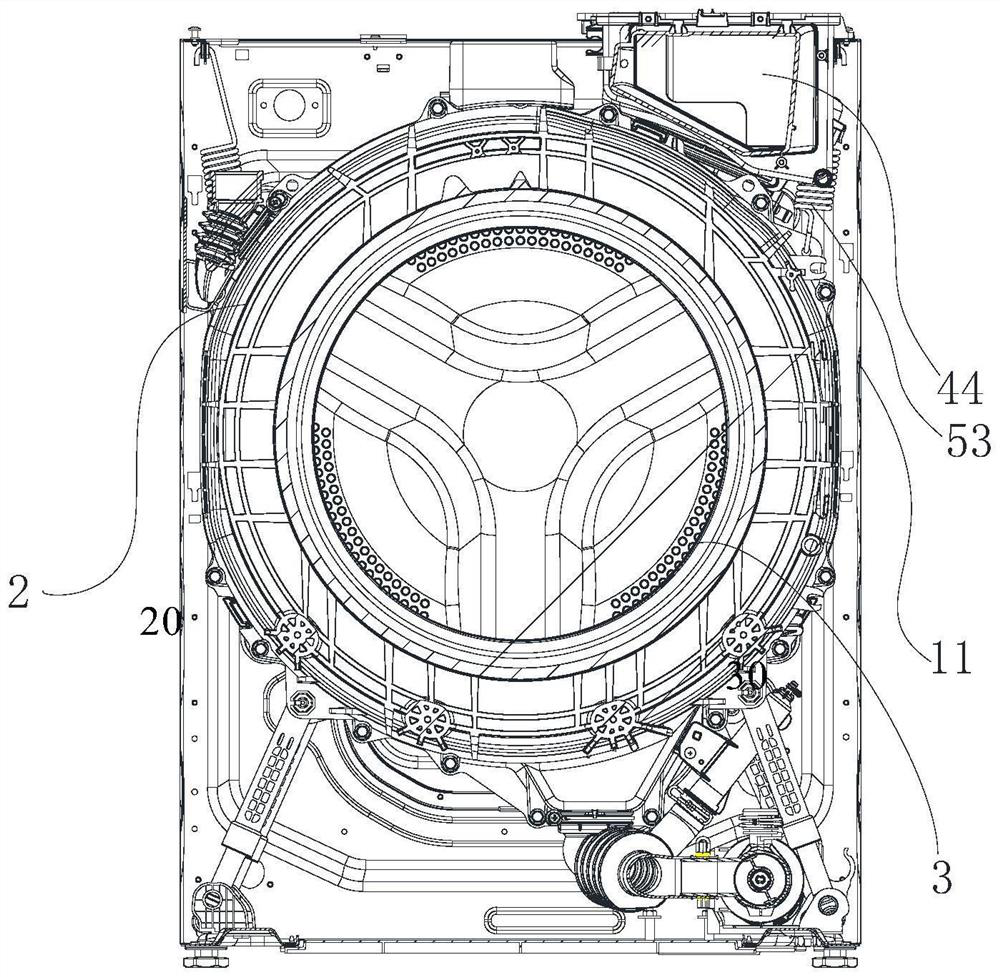

[0077] see Figure 1-Figure 9 As shown, a clothes treatment device with a heat pump drying function in this embodiment includes:

[0078] Housing 1, which forms an inner space;

[0079] The outer cylinder 2 is arranged in the inner space of the housing 1;

[0080] The heat pump module includes a two-device assembly, the two-device assembly includes an evaporator 441 and a condenser 442, and the evaporator 441 and / or the condenser 442 are arranged in the upper left or upper right space of the inner and outer cylinder 2 of the housing 1 In the square space, the heat exchange body of the evaporator 441 and / or the con...

Embodiment 2

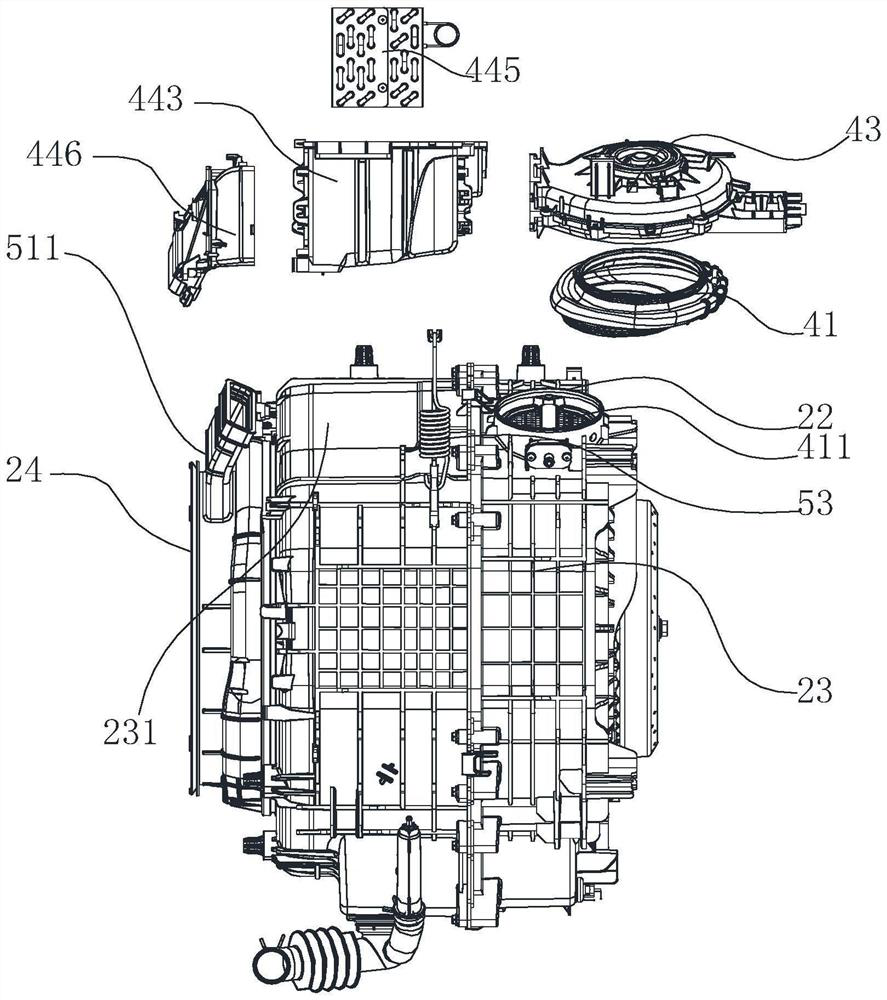

[0099] In this embodiment, a specific structural design is carried out for the two-device box in the first embodiment, so as to realize the installation of the two-device components, optimize the circulation of the drying airflow, and the like.

[0100] see Figure 1-Figure 3 , Figure 10-Figure 13 As shown, a clothes treatment device with a heat pump drying function in this embodiment includes:

[0101] Outer cylinder 2;

[0102] A housing 1, the outer cylinder 2 is arranged in the inner space of the housing 1;

[0103] and a heat pump module, including a two-device box and a two-device module 445 integrated with a condenser 442 and an evaporator 441 arranged in a two-device box 447. The two-device box 447 has an air inlet 4431 for the two-device box. The air inlets 4431 of the two device boxes are arranged obliquely relative to the horizontal direction.

[0104] Specifically, the air inlet 4431 forms an acute angle with the horizontal direction; the air inlet 4431 of the...

Embodiment 3

[0125] This embodiment specifically optimizes the design for the assembly and structural improvement of the fan assembly of the heat pump module, better utilizes the space inside the housing for assembly, improves the space utilization rate in the housing, ensures drying efficiency, and simplifies the installation process at the same time. The specific plan is as follows:

[0126] see Figure 1-Figure 3 , Figure 14-Figure 18 As shown, in this embodiment, a clothes treatment device with a heat pump drying function includes:

[0127] The outer cylinder 2 has an air outlet 22 on the top;

[0128] A housing 1, the outer cylinder 2 is arranged in the inner space of the housing 1;

[0129] And the heat pump module, including an evaporator, a condenser, a heat exchange air duct and a fan assembly 43 arranged in the space between the top of the outer cylinder 2 and the housing 1, the evaporator and the condenser are arranged in the heat exchange air duct, the The fan air inlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com