Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Small quality error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thin wall cordierite carrier for ceramic honeycomb catalyst and method for preparing the same

InactiveCN1827217AEasy alignmentSmall expansion coefficientCatalyst carriersCeramicwarePorosityCordierite

The invention relates to the improvement on the ceramic beehive catalyst carrier, especially providing a ceramic beehive catalyst carrier with high mechanical strength and lower expansion parameter and preparing method. The invention is characterized in that: said beehive catalyst carrier is the alumina micro powder in 12-15%WT whose average particle diameter is less than 2 micron; the sheet kaolin and / or clay micro powder in 43-47% whose average particle diameter is less than 2 micron, the sheet steatite micro powder in 33-37% whose average particle diameter is 5-15 micron, and the fuse quartz in 6-12% whose average particle diameter is less than 2 micron to be mixed, molded and baked to attain the cordierite whose total amount is 92-96%, wherein, the Al203, MgO and SiO2 are each in 36-37%, 13.0-14.0% and 50-52%. The invention adds surface active agent in the mixture when in preparation. The prepared beehive cordierite total amount with 600 hole / square inch can reach 92-96%, the expansion parameter can reach 0.8X10-6 / Deg. C (800Deg. C to room temperature), and the factor of porosity can reach 39-40%. The invention can reduce the ignition temperature 25-40Deg. C, and reduce the tail gas discharge of nitrogen oxygen compound and carbon monoxide of vehicle 5-10% to meet the demand of Europe III standard.

Owner:JIANGSU PROVINCE YIXING NONMETALLIC CHEM MACHINERY FACTORY +1

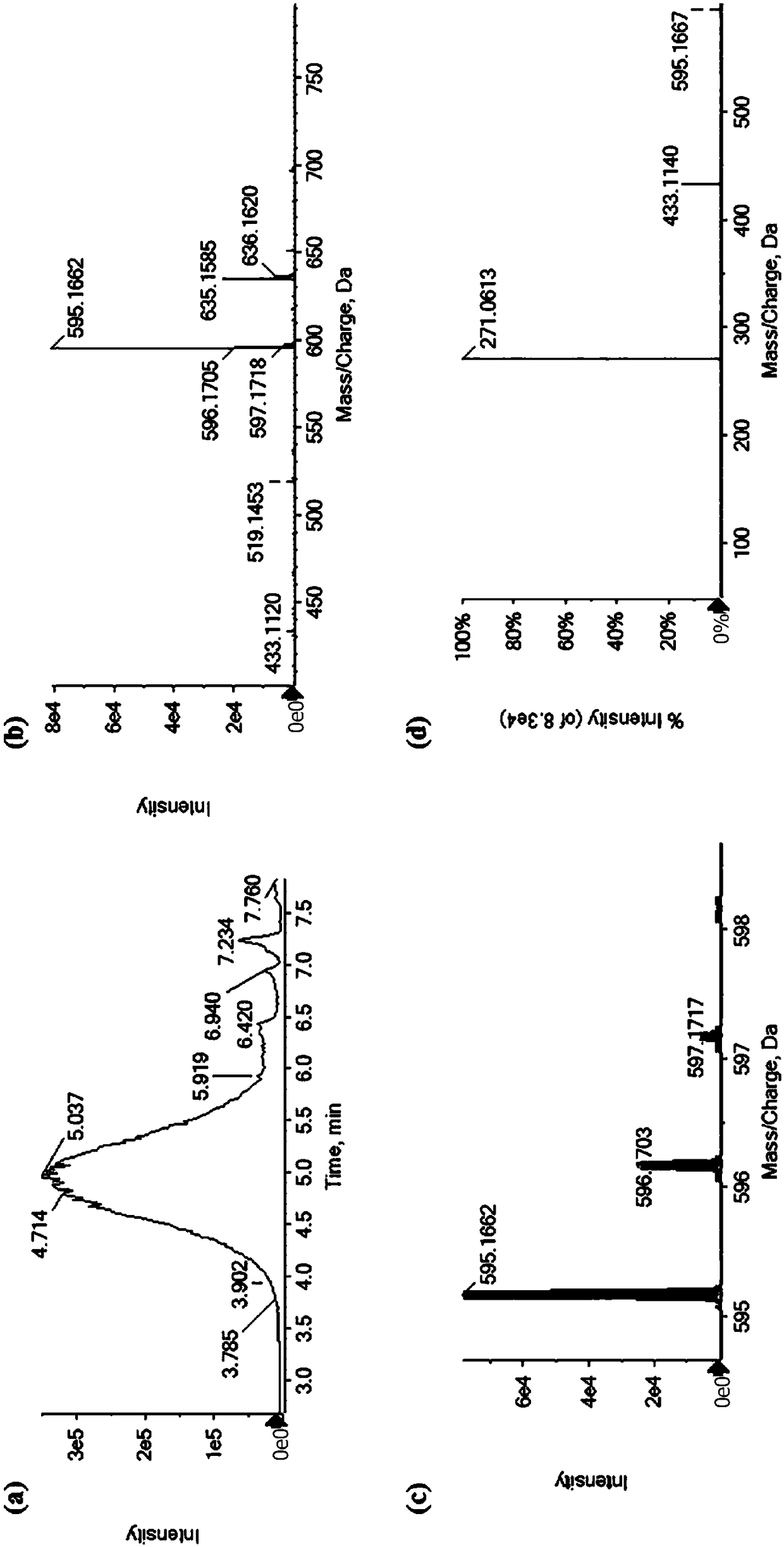

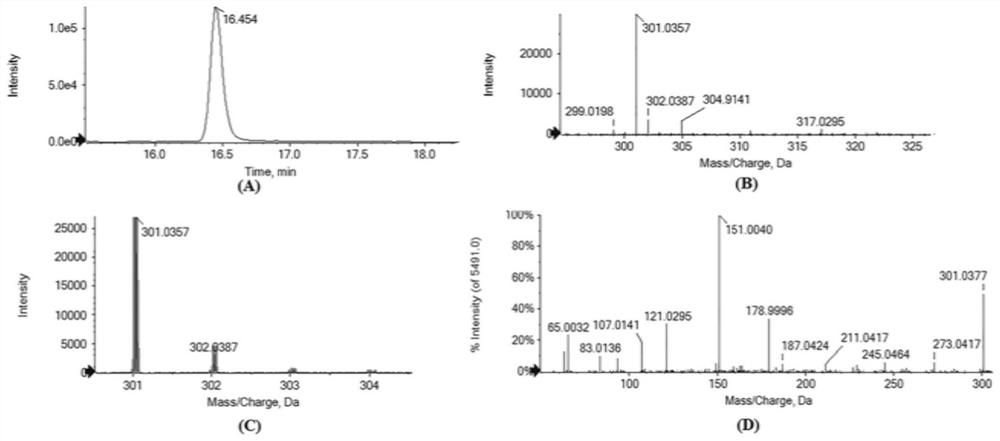

Method for detecting flavonoid components in peony leaves

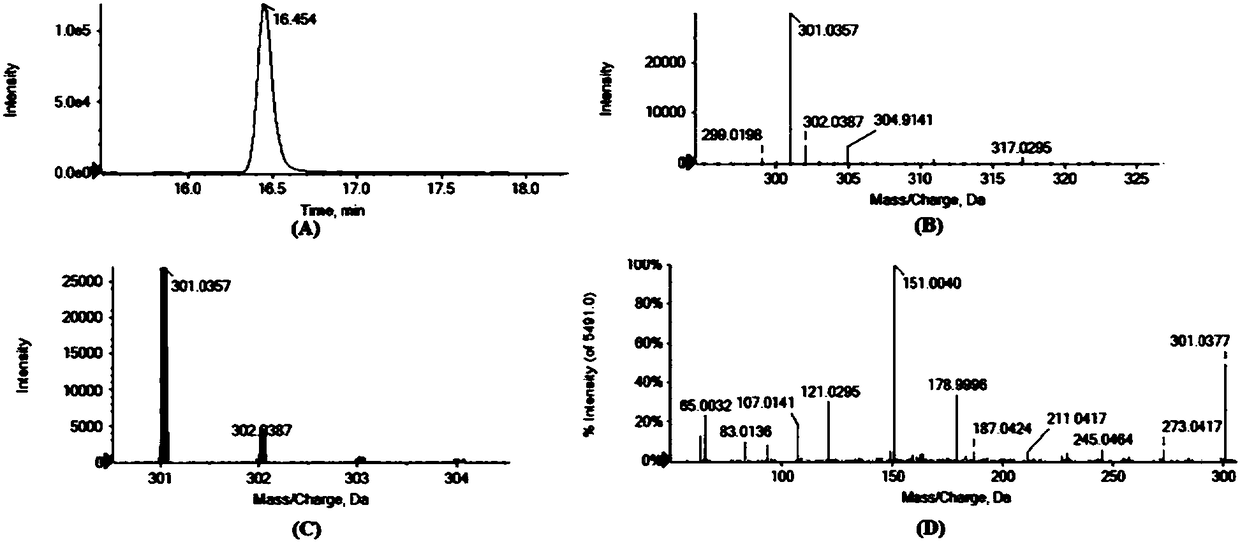

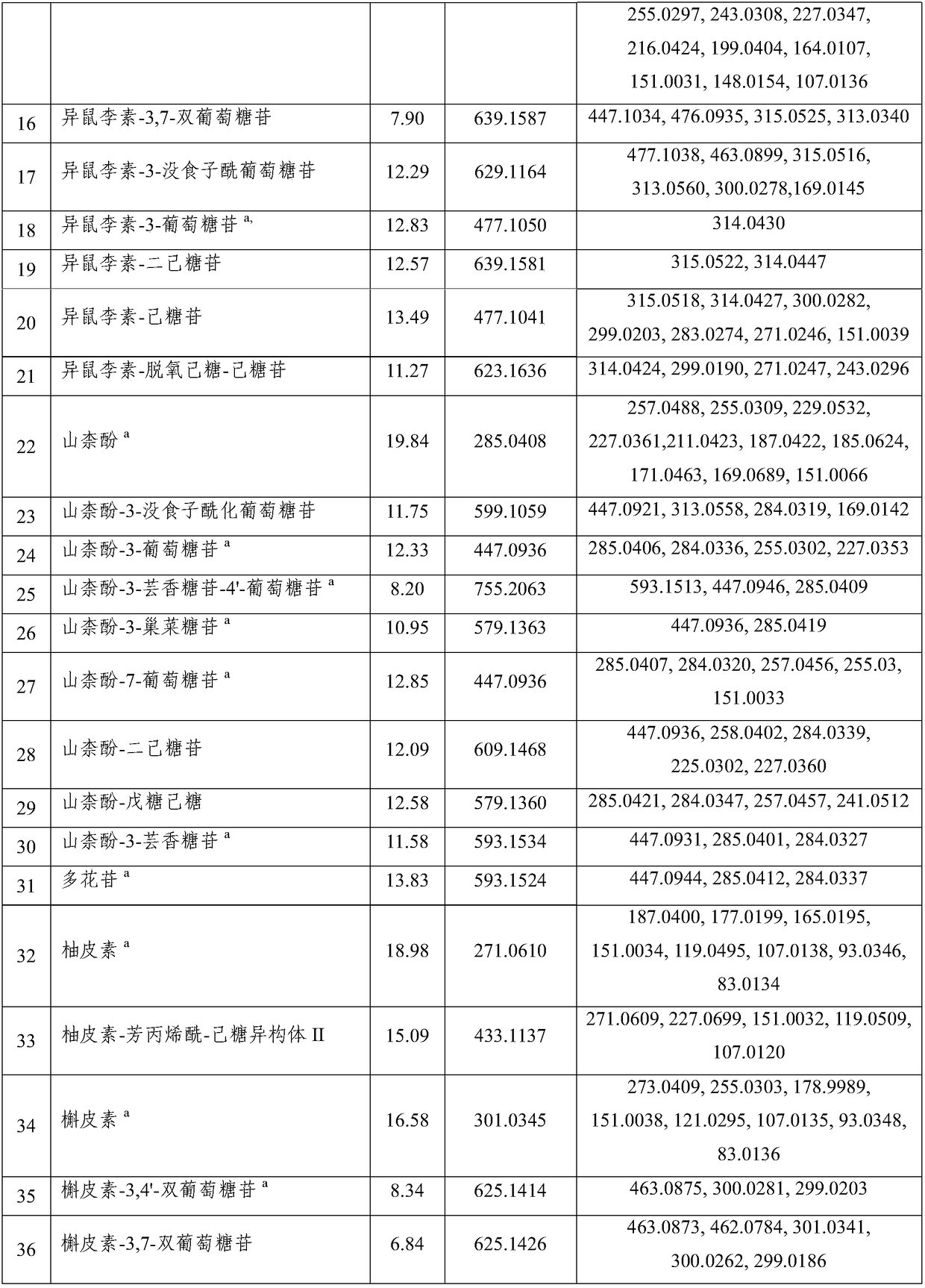

The invention relates to a method for detecting the flavonoid components in peony leaves. The method comprises the following steps of preparing a flavonoid extracting solution; setting chromatographicconditions, mass spectrum conditions and the detection wavelength of a diode array detector; adopting the super-efficient liquid chromatogram-diode array detector-triple quadrupole rod flight time tandem mass spectrum linkage technology for detecting the flavonoid extracting solution, and obtaining a detecting result; performing structure identification on flavonoid substances by analyzing the detecting result, and speculating the structure of the flavonoid compound. The method is simplified in operation steps, rapid in detection and high in accuracy and sensitivity, the micro content of theflavonoid components can be detected, the identification variety is comprehensive, 45 main flavone, flavonol, flavanone and flavanol compounds are identified in the peony leaves, a gap for flavonoid component identification in the peony leaves is filled up, and the method is of great significance in analysis of different varieties of peony leaf nutrient contents.

Owner:INST OF VEGETABLE & FLOWERS CHINESE ACAD OF AGRI SCI +1

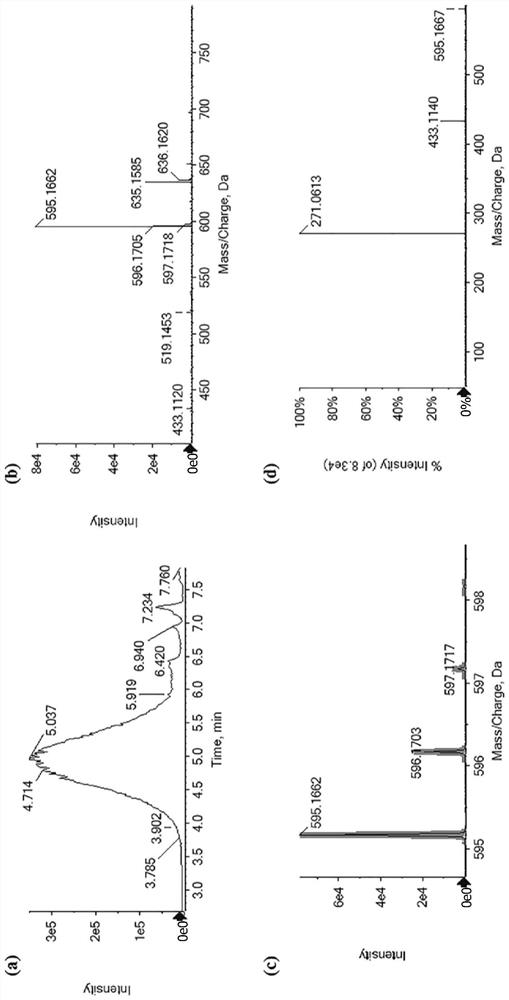

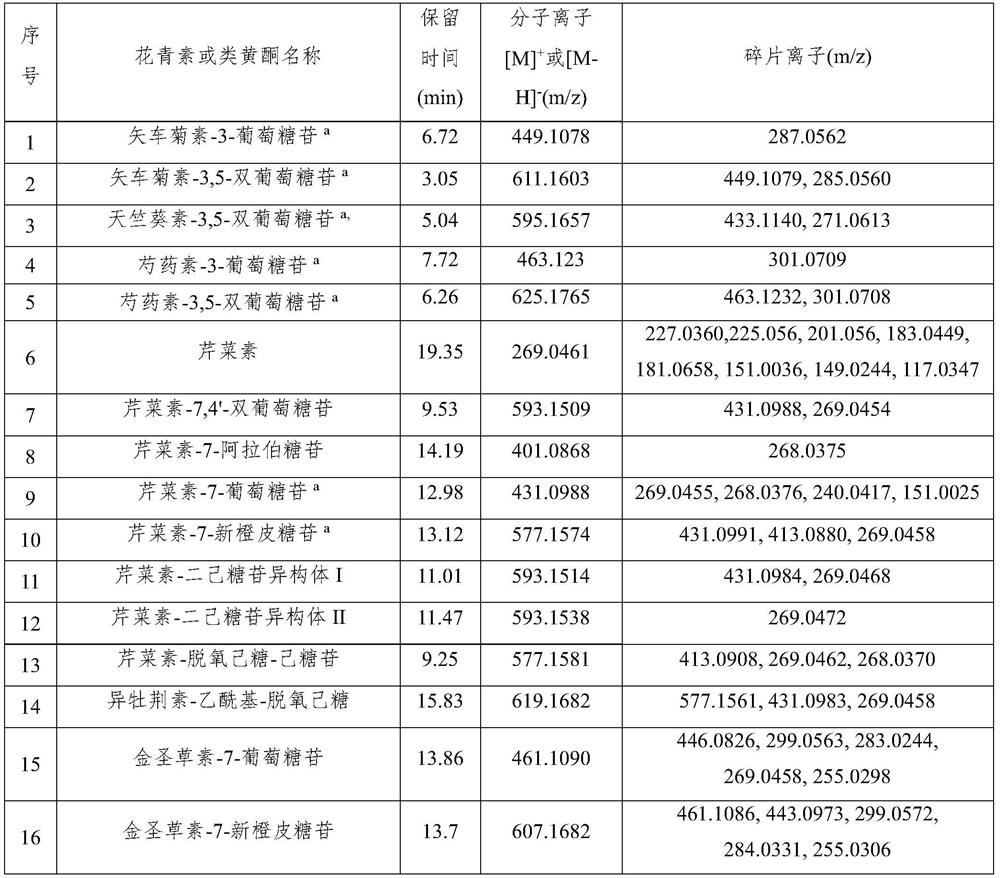

Method for detecting flavonoids component in peony petals

The invention relates to a method for detecting a flavonoids component in peony petals. The method comprises the following steps: preparing a flavonoids extracting solution; setting a chromatographiccondition, a mass spectrum condition and a detection wavelength of a diode array detector; detecting the flavonoids extracting solution by adopting an ultra performance liquid chromatograph-diode array detector-triple quadrupole flight time tandem mass spectrometry and obtaining a detection result; carrying out structure identification on a flavonoids substance through analyzing the detection result; reckoning the structure of the flavonoids component. The method provided by the invention has the advantages of simple operation steps, rapid detection speed and high accuracy and sensitivity andcan be used for detecting the flavonoids component with the extremely less content; identification species are comprehensive and 67 types of main flavone, flavonol, flavanone and flavanol compounds and 5 types of main anthocyanin compounds are totally identified from the peony petals; the blank of identifying the flavonoids component in the peony petals is filled up and the method has important meanings on in analysis of nutrient components of the peony petals with different varieties.

Owner:城发投资集团有限公司 +1

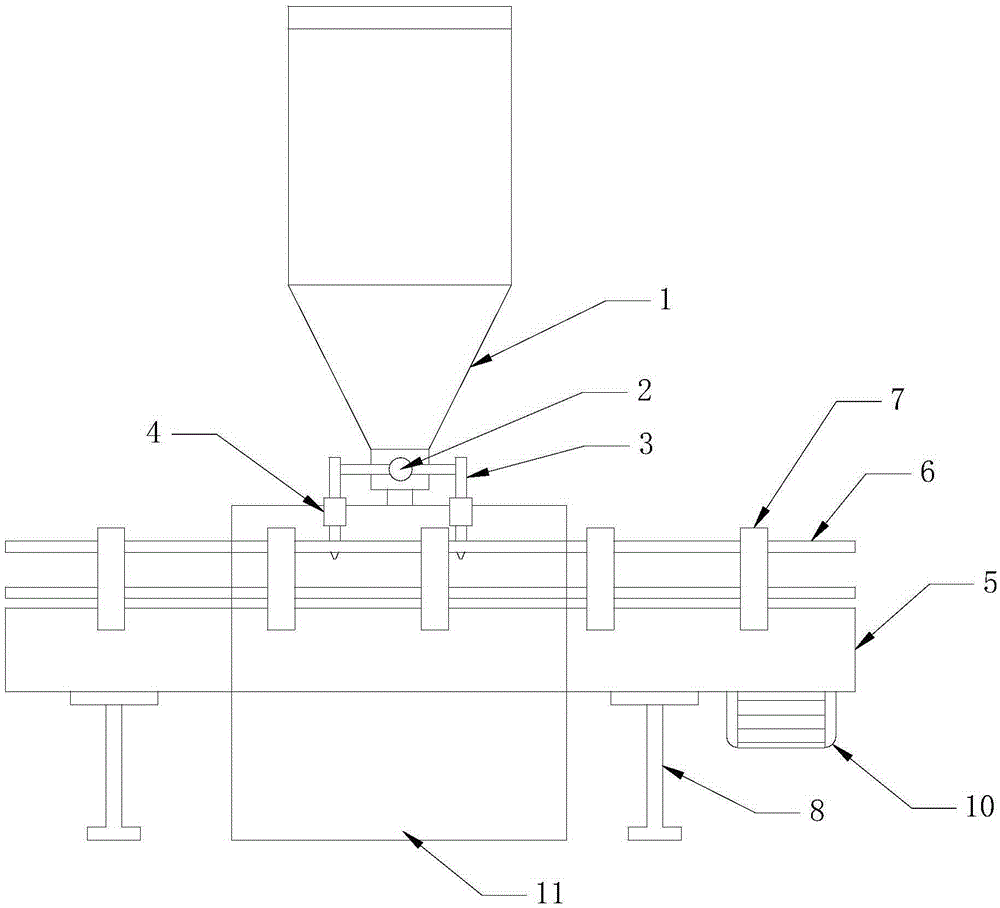

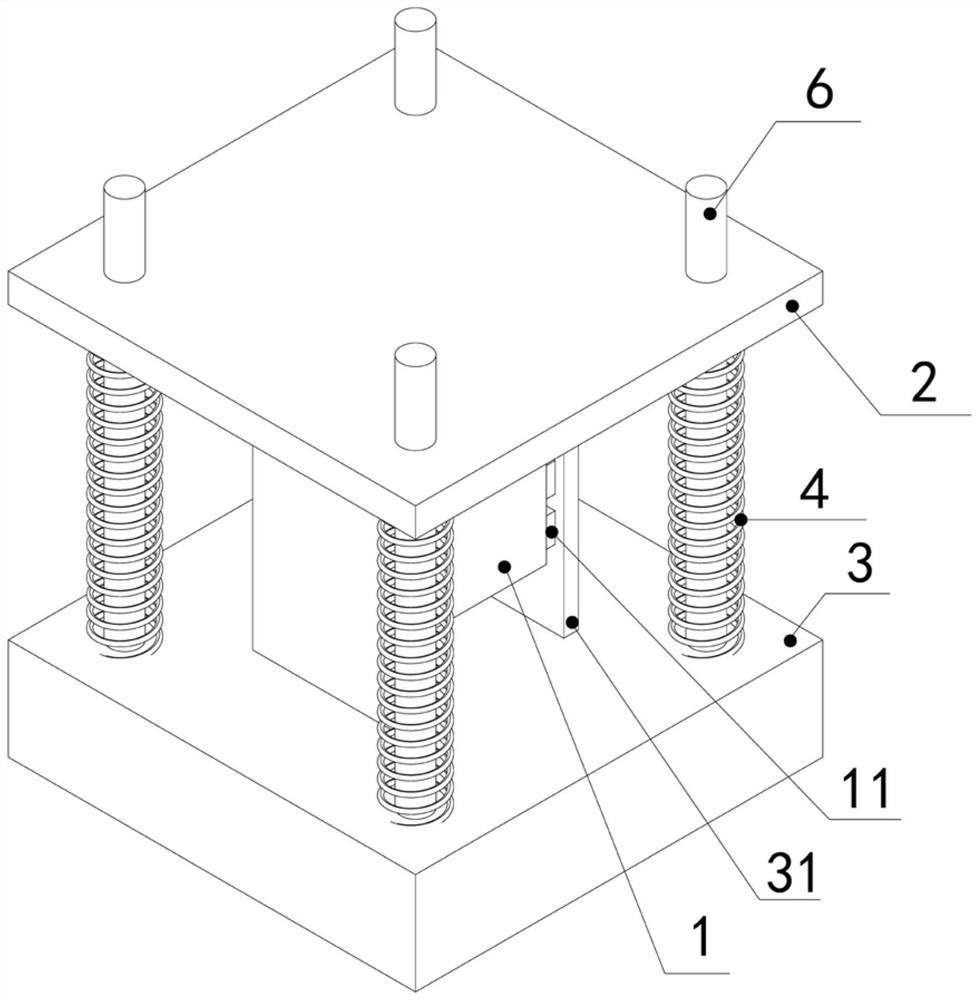

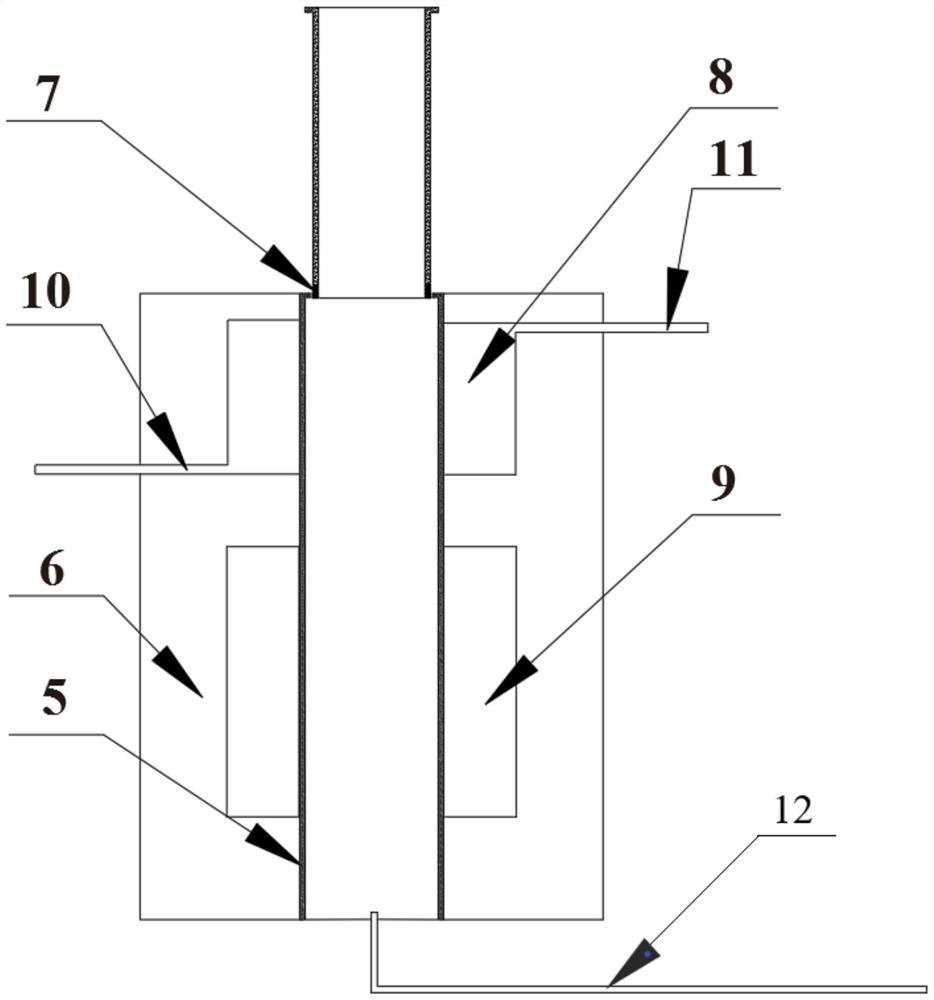

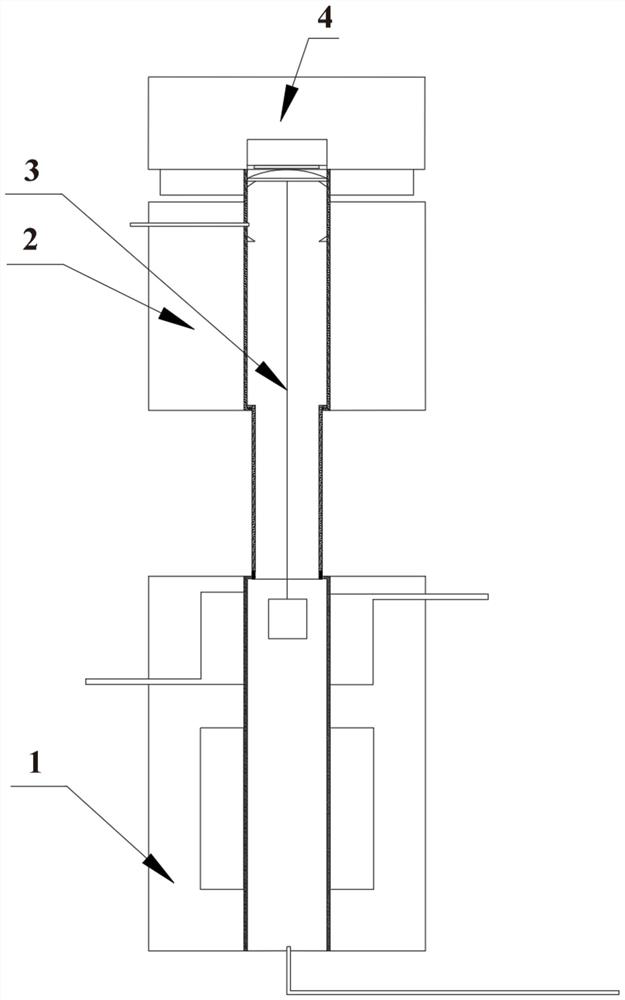

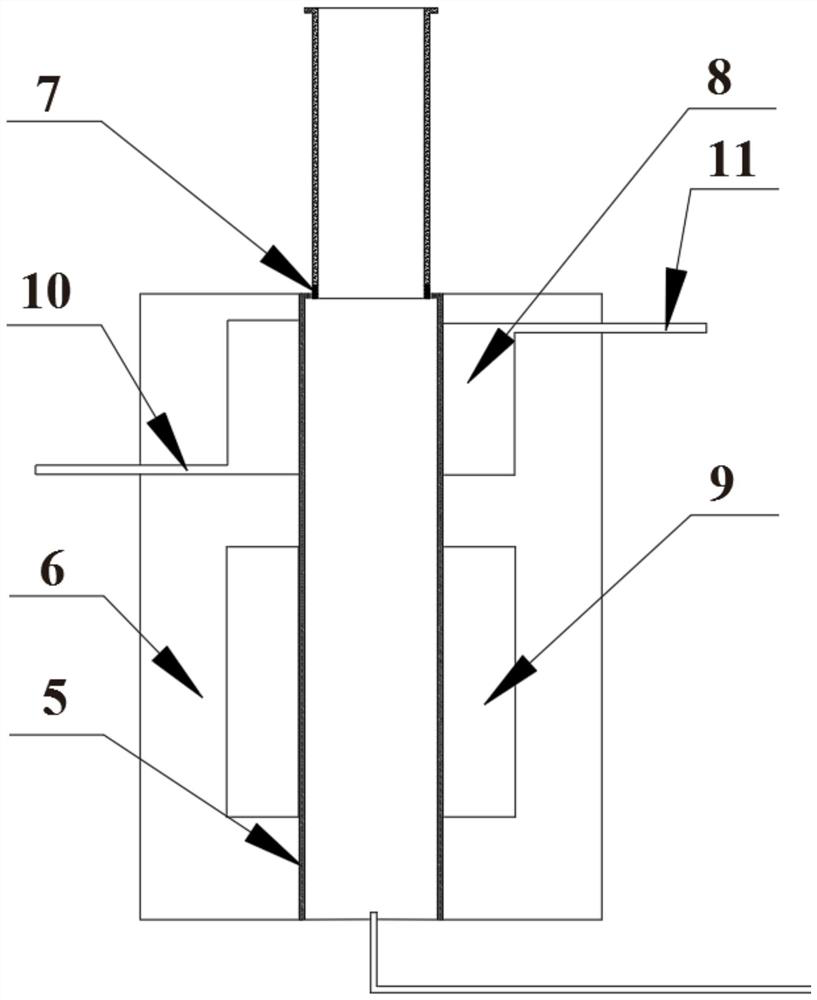

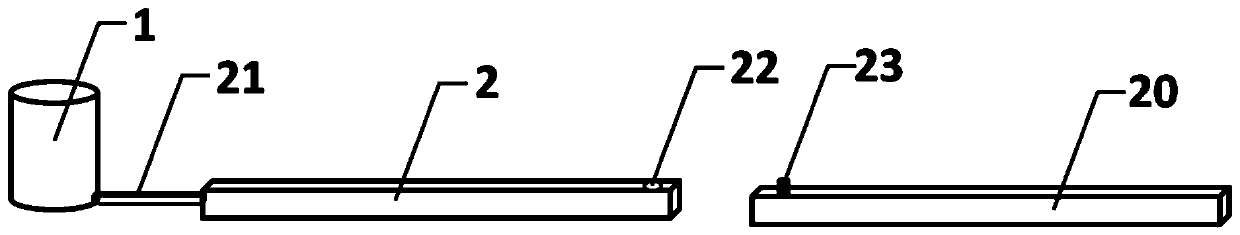

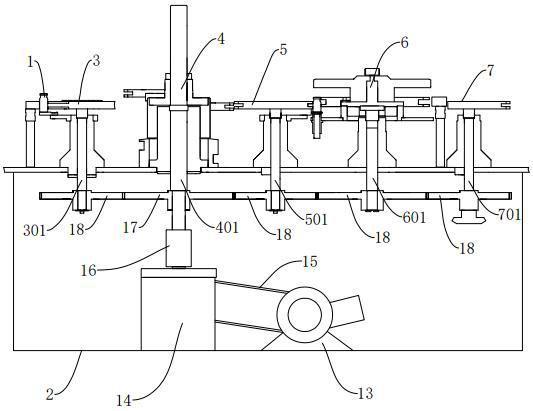

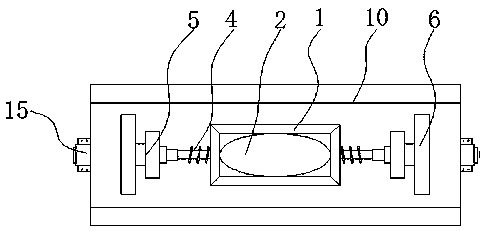

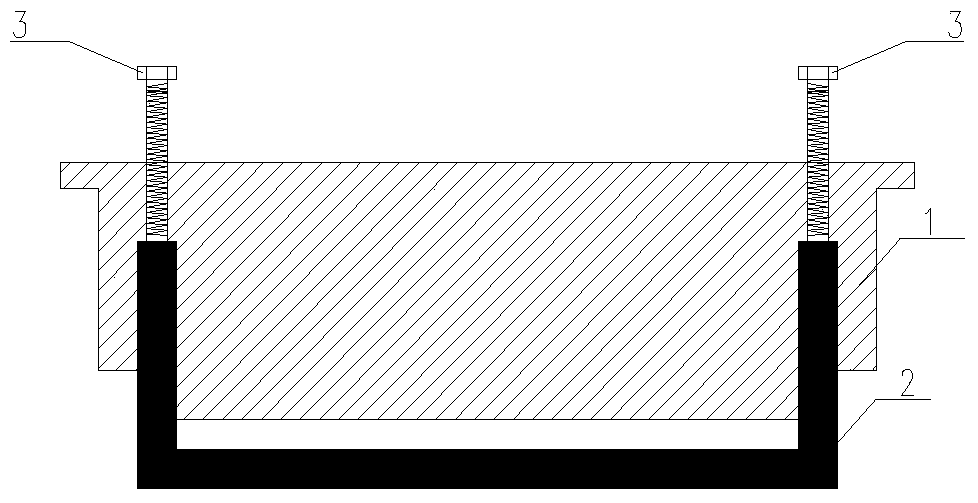

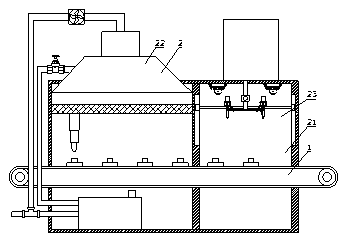

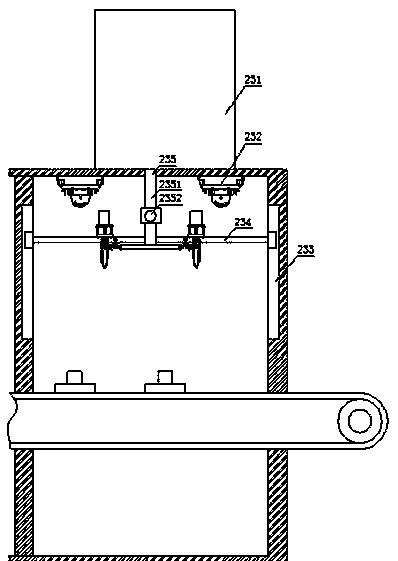

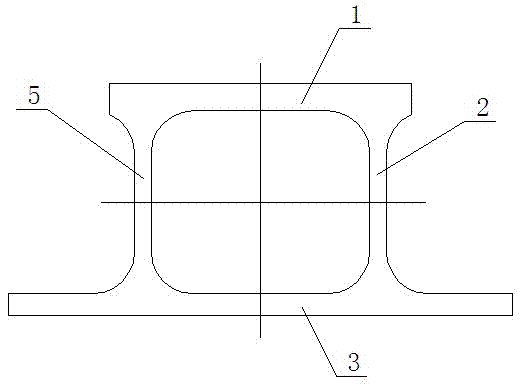

Device and method for accurate compression molding of test piece during similar material confecting process

ActiveCN103196738ASmall quality errorReduce the differencePreparing sample for investigationCompression moldingControl system

The invention relates to a device and a method for accurate compression molding of a test piece during a similar material confecting process. The device comprises a material molding mold and an accurate compression control system, wherein the material molding mold is detachable so as to facilitate the coating of a release agent in early period and de-molding of the test piece in later period; and the accurate compression control system can display the pressure and set the pressure to be applied to compress the test piece. By adopting the accurate compression system of the test piece during the similar material confecting process for a geo-mechanics model test, the problem that the pressure exertion and the material dosage cannot be controlled during the test piece confecting process in a traditional manual mode; and the pressure exertion can be controlled accurately during the manufacturing process of the similar material test piece, and therefore the quality error of the test piece is reduced, the difference of mechanical parameter caused by the manufacturing of various test pieces is reduced, and the obtained experimental data can well guide the confecting of similar materials.

Owner:SHANDONG UNIV

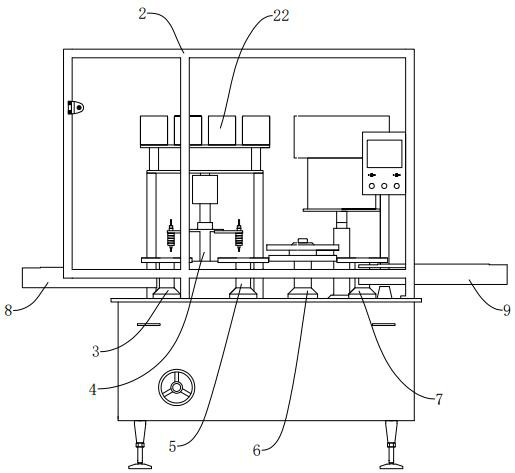

Paste filling machine

The invention provides a paste filling machine. The paste filling machine comprises a paste material box, a filling mechanism, a conveying mechanism, a motor and an electric control cabinet, wherein the paste material box is arranged on the electric control cabinet; the filling mechanism is arranged at one side of the paste material box; the conveying mechanism is arranged below the filling mechanism; the filling mechanism comprises a regulating cylinder, a plurality of filling heads and regulating valves; one end of the regulating cylinder is connected with the paste material box by a pipeline; the corresponding other end of the regulating cylinder is connected with the filling heads; each filling head is provided with one regulating valve; the conveying mechanism comprises a bottle body conveying rolling path, poles, a pole frame and a rolling path base; the poles are arranged on the two sides of the bottle body conveying rolling path; the poles are fixed on the bottle body conveying rolling path by the pole frame; the rolling path base is arranged below the bottle body conveying rolling path. The paste filling machine disclosed by the invention is provided with the poles and the pole frame for preventing a bottle body from falling off or being flicked away, so that a tidy work environment is guaranteed and waste of resources is reduced.

Owner:金旺唐盛元成(天津)健康科技有限公司

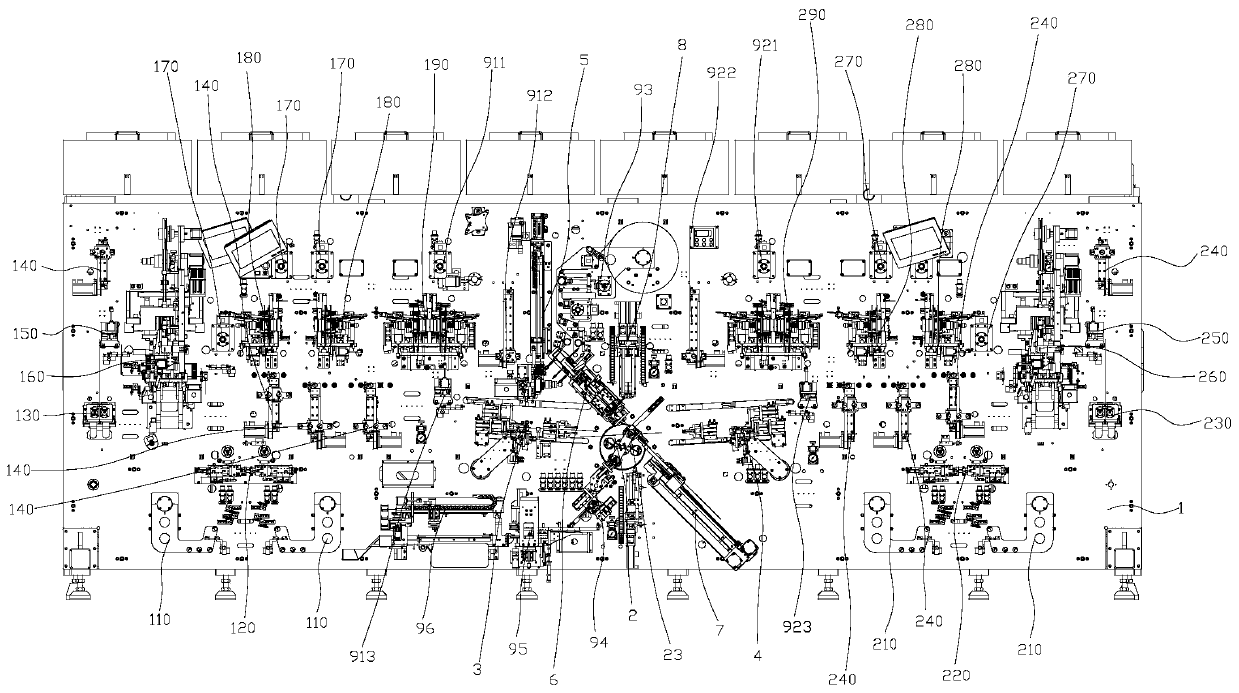

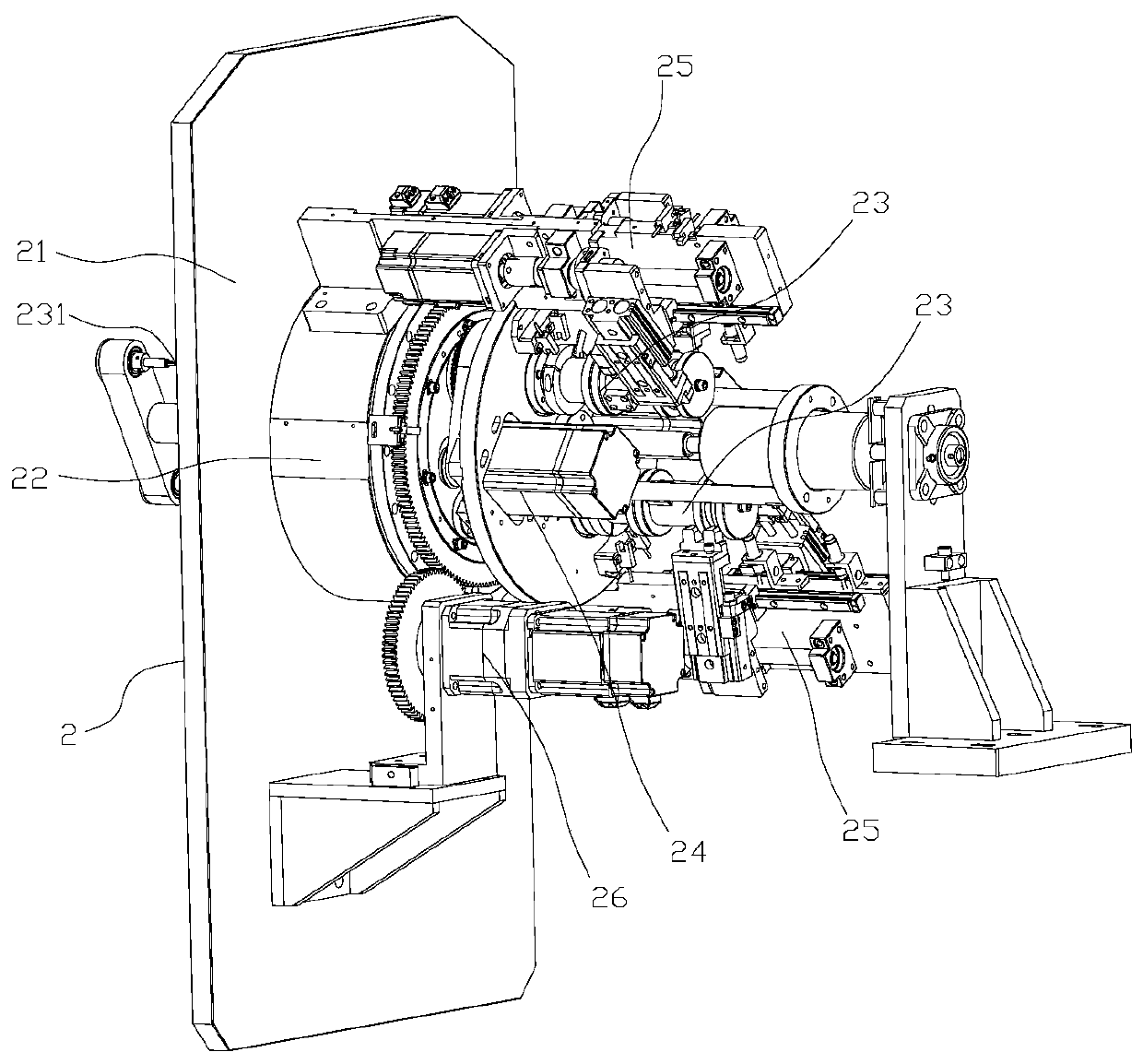

Piece producing and winding integrated device

PendingCN110589591ASmall footprintLow costFinal product manufactureSecondary cellsEngineeringPole piece

The invention discloses a piece producing and winding integrated device. The device comprises a piece producing mechanism and a winding mechanism which are installed on a wallboard. The piece producing mechanism comprises a positive pole piece producing mechanism and a negative pole piece producing mechanism, the positive pole piece producing mechanism and the negative pole piece producing mechanism complete piece producing work on a positive pole piece and a negative pole piece, the winding mechanism winds the positive pole piece, the negative pole piece and a diaphragm into a battery cell product, and furthermore, cold pressing and discharging are performed on the battery cell. The piece producing and winding integrated device has the advantages of being high in automatic degree, high inproduction efficiency, good in battery cell production quality, large in battery cell capacity, low in labor cost, small in occupied space and the like which are not achieved in the prior art.

Owner:深圳市万德自动化科技有限公司

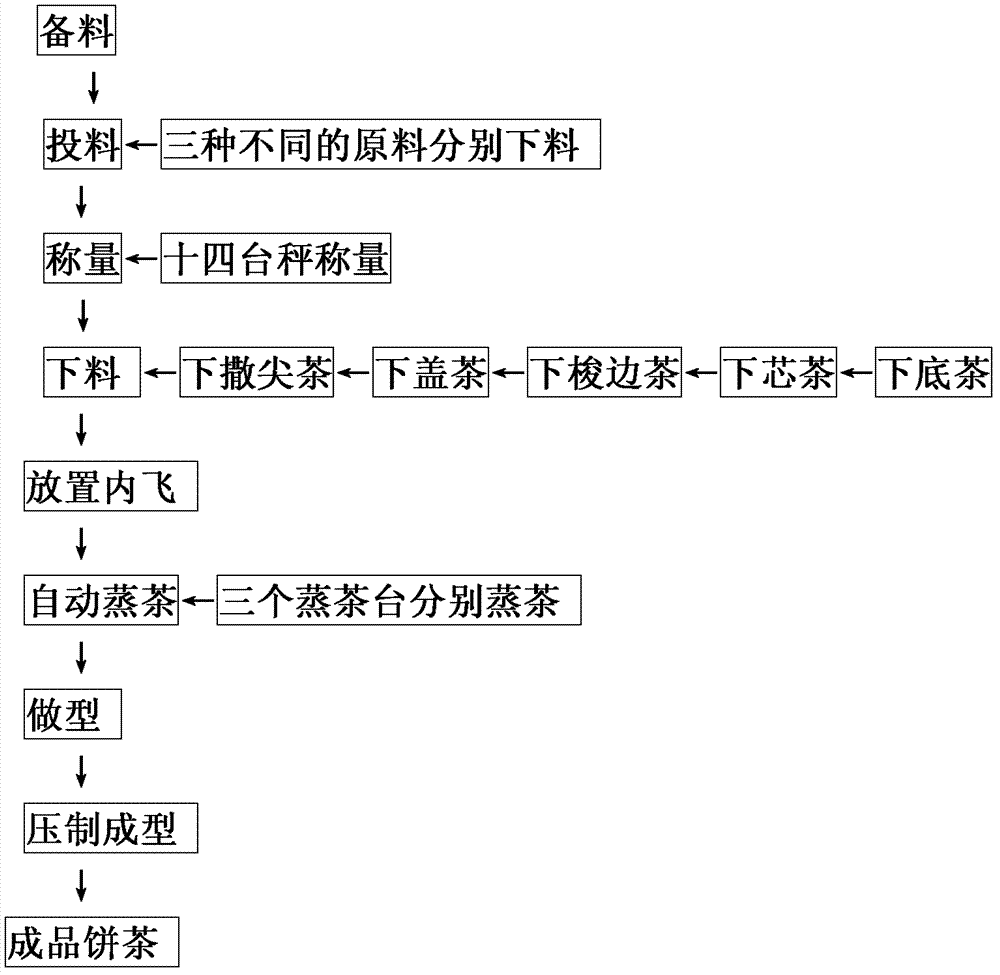

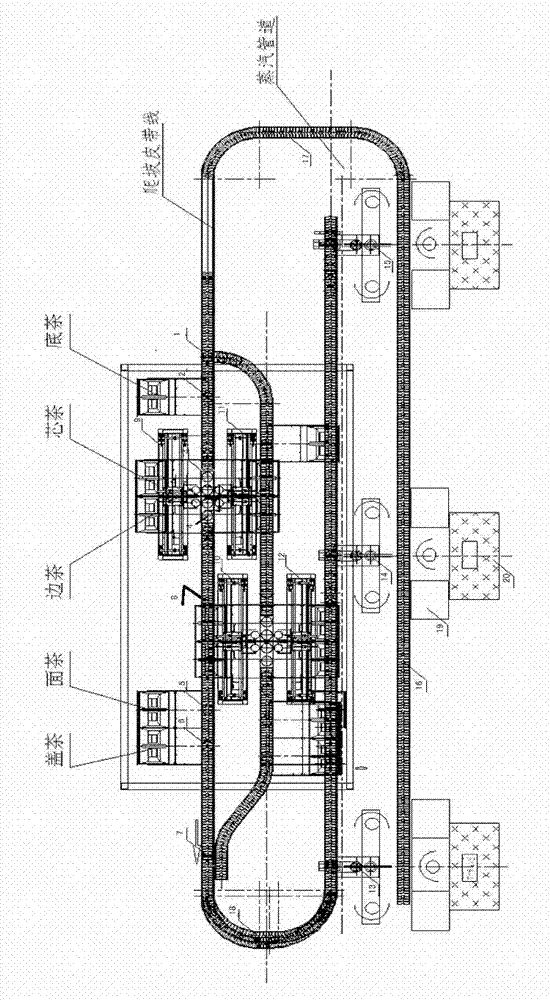

Pu'er tea cake flow line forming method

ActiveCN102550713BImprove product qualityReduce manual labor intensityPre-extraction tea treatmentCompression moldingEngineering

The invention relates to a pu'er tea cake forming process, in particular relates to a flow line and an automatic weighting device which are important parts for pu'er tea cake forming and processing and belongs to the field of foods. Tea leaves are fed by a feed device and are weighted, automatic weighting of bottom scattering tea, core tea, edge tea, surface tea and top scattering tea is finished, after the feeding is finished, an inner marker is placed, and automatic steaming, forming and compression molding are carried out, so that the pu'er tea can be molded by compression. The pu'er tea cake forming technology can be used for realizing local mechanization of the processing process, reducing the error caused by manual weighting, improving the integral quality of tea cakes, reducing theamount of labor used, reducing the labor intensity of workers, and providing a foundation for further mechanical improvement of tea cake formation processing.

Owner:MENGHAI TEA IND

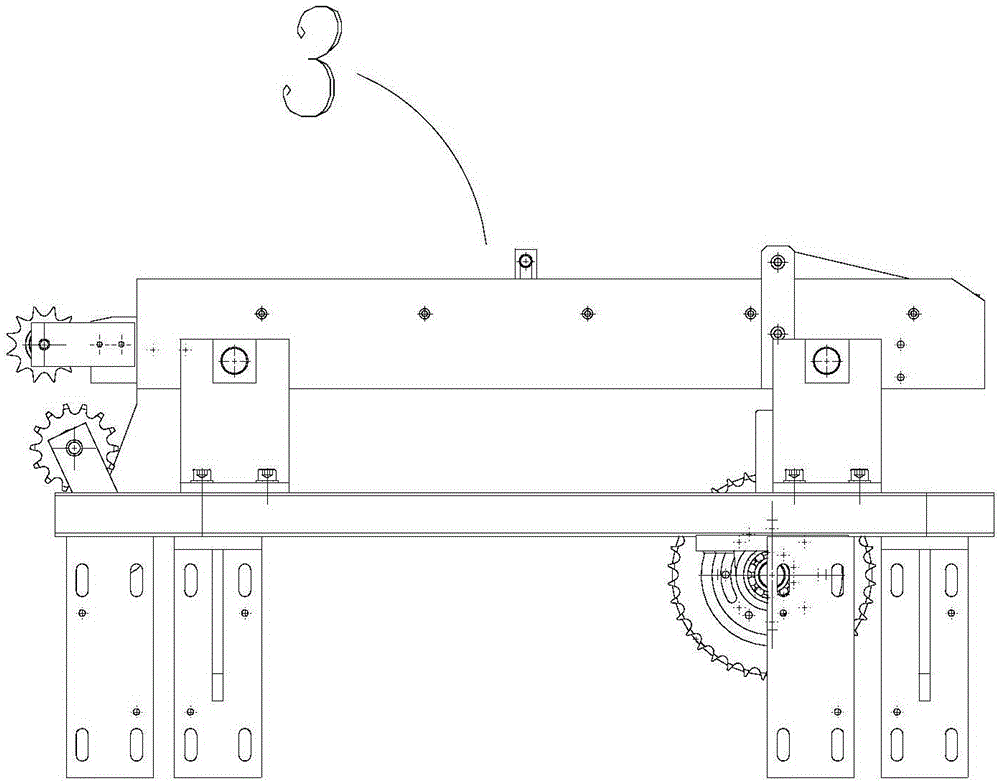

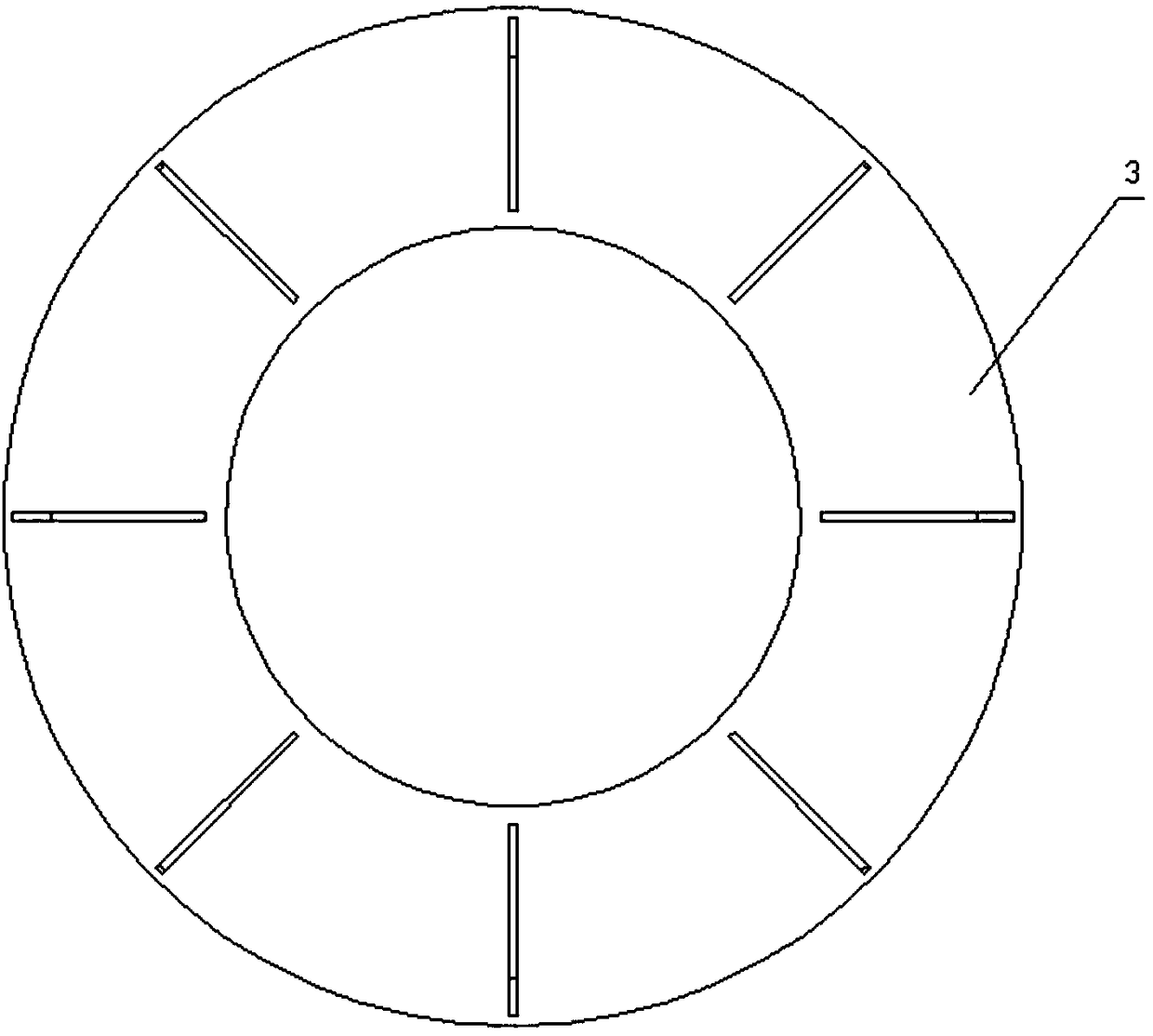

Medium-large-density battery piece wrapping machine

InactiveCN105070955AHigh precisionSmall quality errorFinal product manufactureLead-acid accumulators constructionEngineeringMechanical engineering

The invention discloses a medium-large-density battery piece wrapping machine. The machine comprises a main frame mechanism, partition paper uncoiling mechanisms, a conveying mechanism, a feeding mechanism, a transmission mechanism, a paper feeding piece wrapping mechanism, a piece stacking mechanism, a collecting mechanism, an output mechanism and a negative pressure mechanism. The conveying mechanism is composed of a first conveying mechanism body and a second conveying mechanism body. The partition paper uncoiling mechanisms are installed on the left side of the main frame mechanism. Each partition paper uncoiling mechanism is connected with a motor. The first conveying mechanism body, the second conveying mechanism body, the piece stacking mechanism and the collecting mechanism are sequentially installed in the main frame mechanism from left to right. The paper feeding piece wrapping mechanism is located over the joint of the first conveying mechanism body and the second conveying mechanism body. The output mechanism is installed at the right end of the main frame mechanism. The medium-large-density battery piece wrapping machine is reasonable in structure. The medium-large-density battery piece wrapping machine is wholly arranged linearly, so that the space occupying coefficient is high. A mechanical linkage mode is adopted, so that piece wrapping efficiency is high. The piece wrapping efficiency and quality of batteries are improved while labor cost is reduced.

Owner:CHANGXING JINGSHENG HYDRAULIC MACHINERY

Shape cutting process for octahedral arc-shaped sealing head of tank container of railroad through transport vehicle

The invention provides a shape cutting process for an octahedral arc-shaped sealing head of a tank container of a railroad through transport vehicle. The shape cutting process comprises the followingsteps: (1) manufacturing a shape cutting support frame for a sealing head manipulator; (2) adhering a sealing head arc surface and a shape positioning arc surface; (3) drawing running track positionsof the manipulator; (4) programming and cutting; (5) shielding a nonworking region; (6) cutting; (7) grinding; and (8) measuring the dimensions. The shape cutting process provided by the invention canguarantee that the sealing head stops moving after the sealing head is positioned once; after numerical control programming of a cutter, a cutting gun stably runs according to a preset track, so quality errors caused by multi-time positioning are prevented, and the sealing head is guaranteed to be absolutely qualified. The shape cutting process guarantees stable shape cutting quality, zero rejection rate and relatively high universality.

Owner:大连中车集装箱有限公司

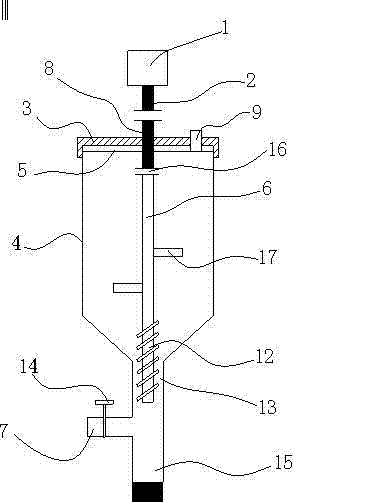

Uniform adjustable powder feeding device

InactiveCN102114972BOvercome stuckMaintain up and down pressure consistencyPackagingDrive shaftEngineering

The invention provides a uniform adjustable powder feeding device which comprises an speed-adjusting motor, an speed-adjusting motor transmission shaft, a feed tank cover, a feed tank, a feeding shaft and an air inlet pipe, wherein the feed tank cover is arranged on the feed tank, a vacuum sealing washer is arranged between the feed tank and the feed tank cover, a vacuum dynamic seal device is arranged in the middle of the feed tank cover, a loading port is formed at an edge of the feed tank cover, the upper end of a rotating shaft of the vacuum dynamic seal device is connected with the speed-adjusting motor transmission shaft, the lower end of the rotating shaft of the vacuum dynamic seal device is connected with the upper end of the feeding shaft, the feeding shaft is perpendicularly mounted, a spiral shaft is arranged at the lower part of the feeding shaft, the spiral shaft is inserted into a feed pipe at the bottom of the feed tank, the feeing shaft is a hollow shaft, a gap is formed at the junction of the upper end of the feeding shaft and the rotating shaft of the vacuum dynamic seal device, the lower part of the feed pipe is communicated with an air / powder discharge pipe, the air inlet pipe is connected with the middle part of the feed pipe and the middle part of the air / powder discharge pipe, and a valve is arranged on the air inlet pipe. The uniform adjustable powder feeding device solves the problem that the spiral shaft is choked by using the cooperative action of gravity force and spiral force, and improves the powder feeding accuracy in case of no pressure fluctuation by adopting the hollow spiral shaft.

Owner:CENT SOUTH UNIV

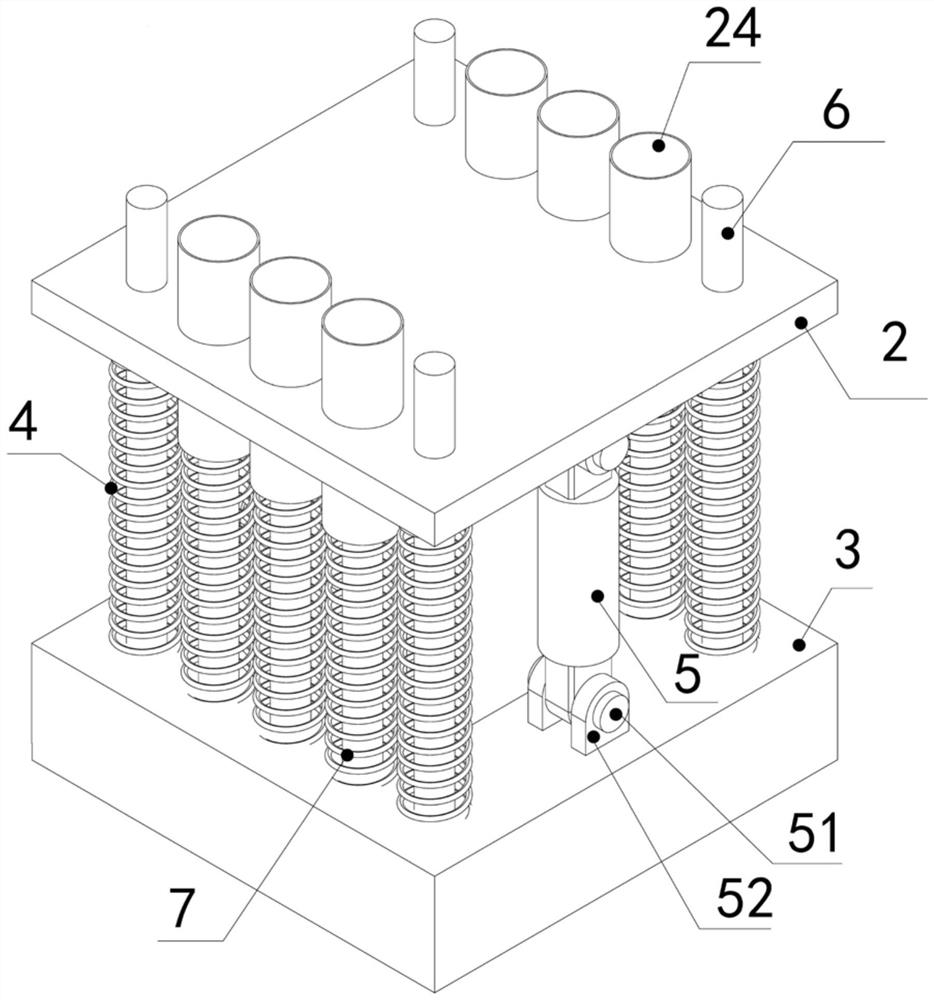

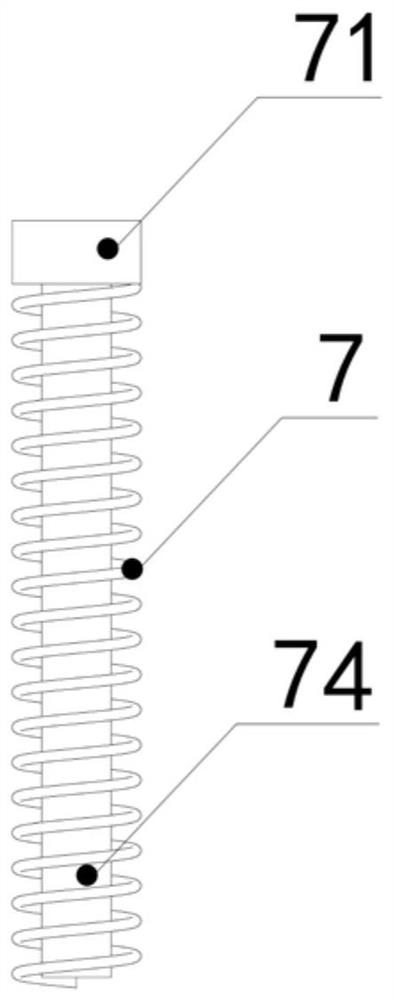

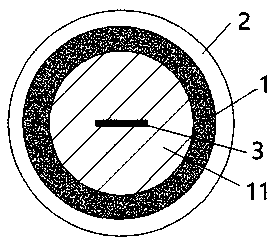

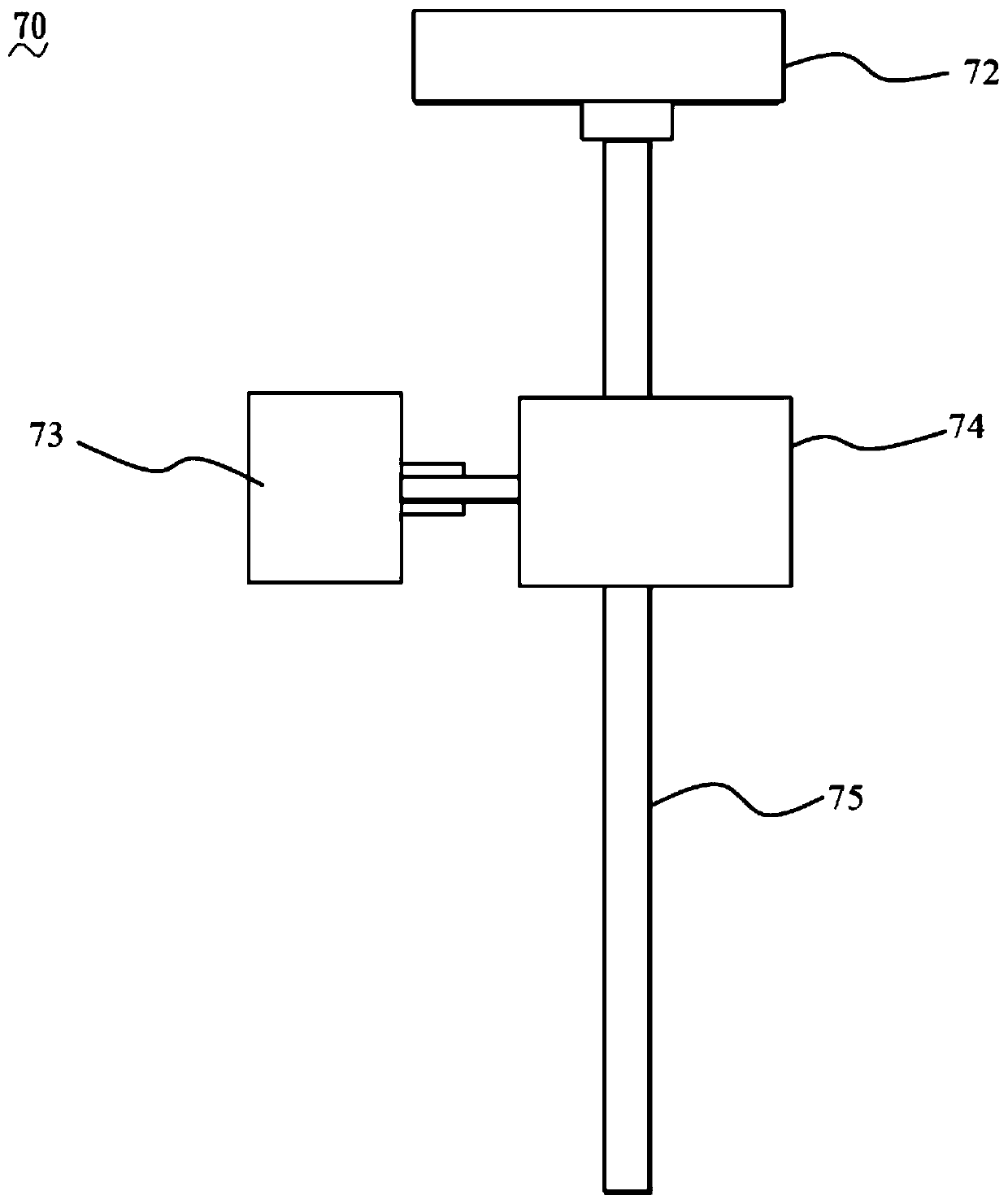

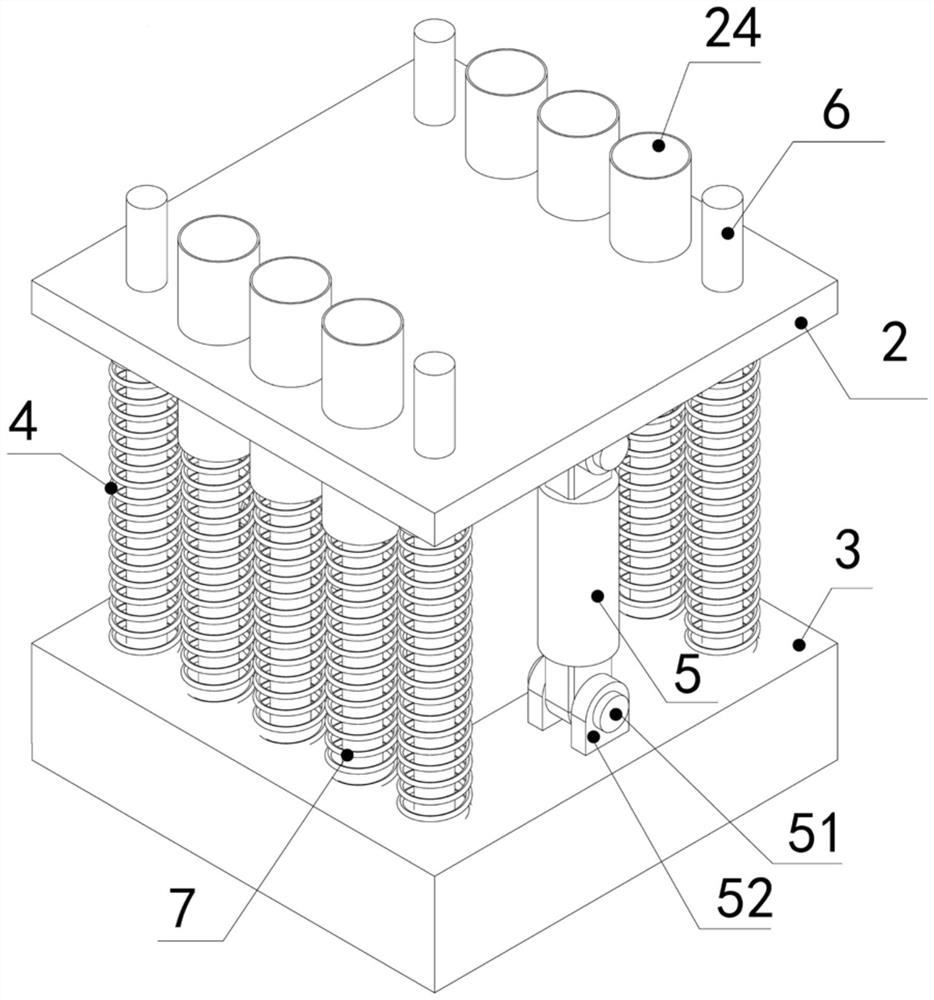

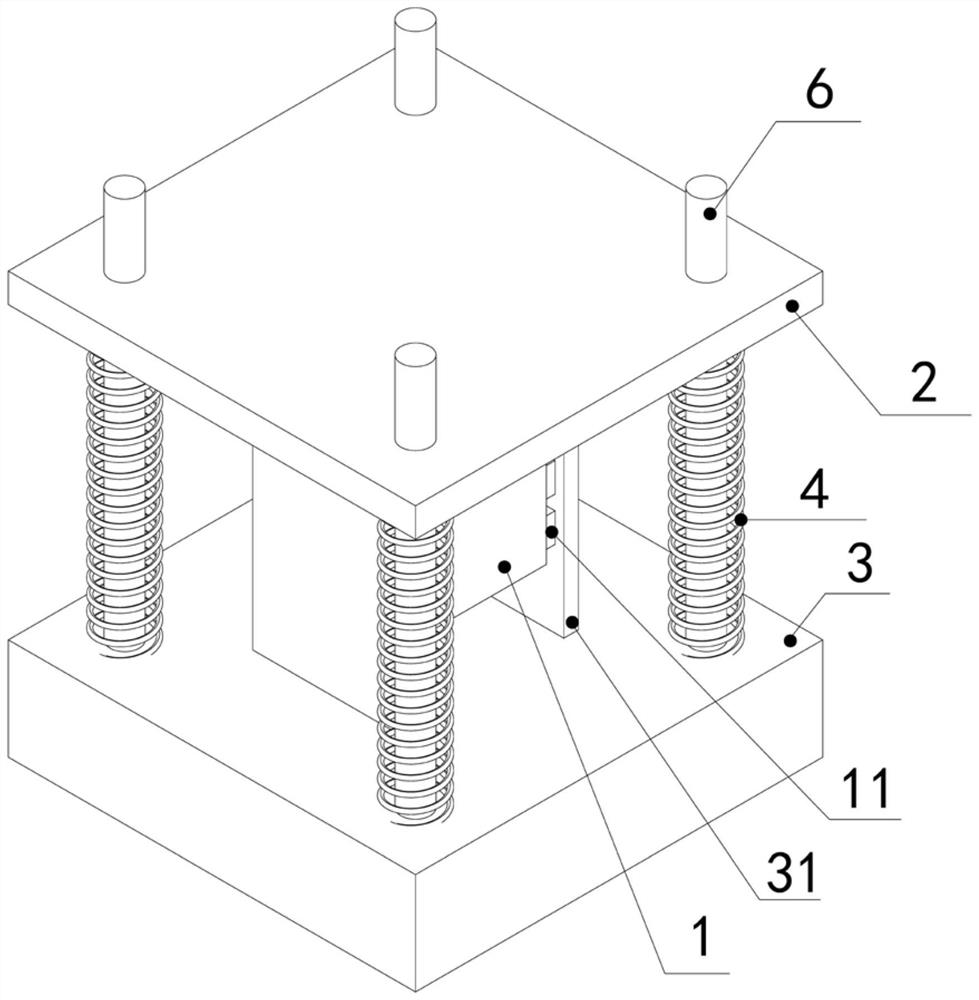

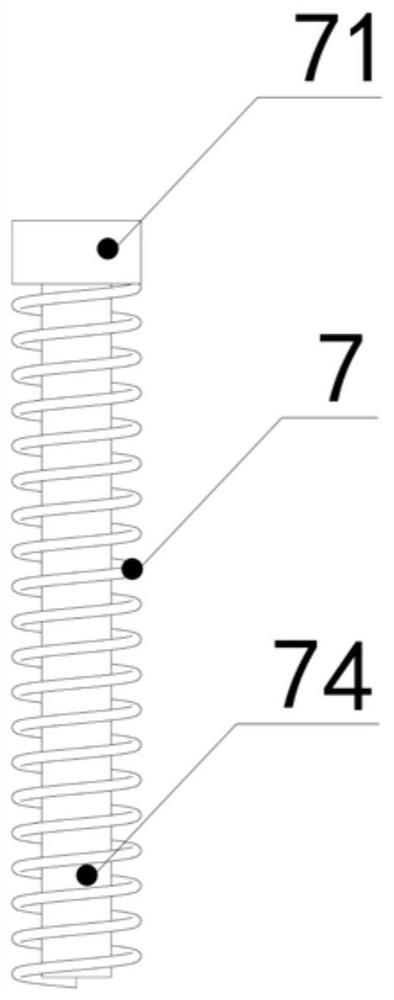

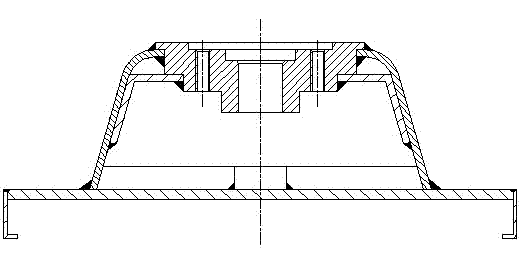

Tuned mass damper with variable stiffness, variable mass and variable damping and design method thereof

ActiveCN113638515AControlling Multi-Order VibrationImprove adaptabilityProtective buildings/sheltersShock proofingEngineeringTuned mass damper

The invention discloses a tuned mass damper with variable stiffness, variable mass and variable damping and a design method thereof. The damper comprises a mass system, a support and a damping system; the mass system comprises a mass block; the damper is characterized in that a plurality of guide rods are arranged on the support; the mass system can slide along the guide rods; the damping system is arranged on the support; the guide rods are sleeved with first springs; one end of each first spring is connected with the mass system; the other end of each first spring is connected with the support; a plurality of second springs are further arranged on the support; the second springs are connected with sliding blocks; locking structures are connected between the mass system and the sliding blocks; and the sliding blocks and the mass system can be connected or disconnected by locking or disconnecting the locking structures. By the adoption of the tuned mass damper with the variable stiffness, the variable mass and the variable damping, multi-order vibration of a structure can be controlled, the damper can adapt to natural vibration frequency in a wide range, and corresponding optimal damping can be set according to vibration of a main structure in different states, so that the adaptability and the restraining effect are greatly improved, and the device has wide application prospects.

Owner:HUNAN UNIV

Method for rapidly testing moisture content of sized and dried carbon fibers

PendingCN114113463AAffect stabilityFast testChemical analysis using titrationMaterial heat developmentFiberCarbon fibers

The invention belongs to the technical field of detection methods, and particularly relates to a method for rapidly testing the moisture content of sized and dried carbon fibers. According to the method, the final moisture content of the fiber is comprehensively judged by adopting solvent digestion in combination with a trace moisture testing method and a thermal weight loss step. The method is high in testing speed, and overcomes the difficulties of long testing time and high testing environment requirements of a drying method for testing the moisture content of the fiber; by adopting the method, the total mass of the original fiber sample only needs to be tested once, and the subsequent mass test is not involved, so that the mass error caused by the fact that the fiber is light, crisp and easy to drift out of an experimental container in the experimental process can be avoided.

Owner:辽宁诺科碳材料有限公司

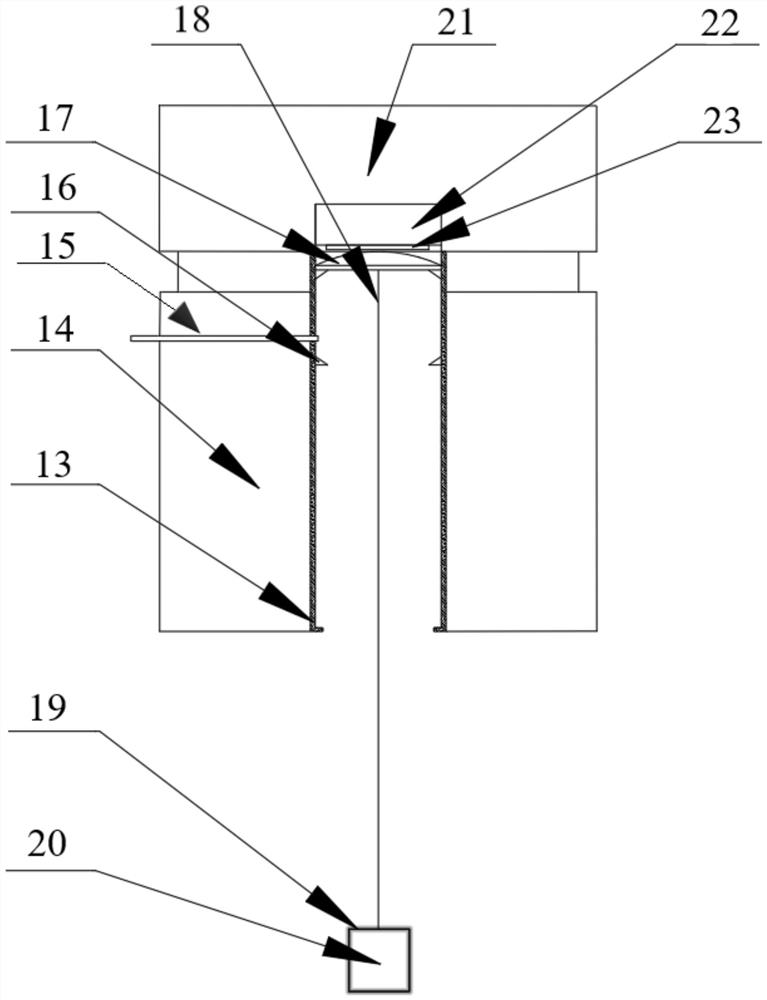

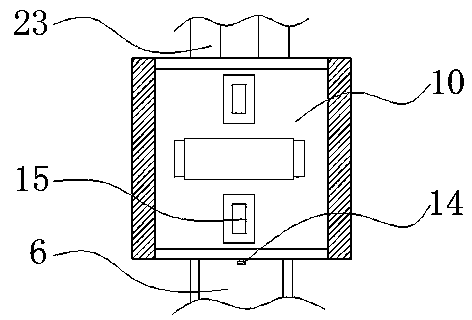

A thermal analysis device and application of extremely rapid temperature rise-variable atmosphere-weight real-time

ActiveCN112986327BBreak through the limitations caused by corrosionRealize measurementNuclear energy generationMaterial heat developmentCombustionHeat analysis

Owner:SHANXI UNIV

Rapid heating-atmosphere variable-weight real-time thermal analysis device and application

ActiveCN112986327ABreak through the limitations caused by corrosionRealize measurementNuclear energy generationMaterial heat developmentCombustionHeat analysis

The invention provides a rapid heating-atmosphere variable-weight real-time thermal analysis device and application. The thermal analysis device comprises a furnace body reaction device, a fixed protection device, a sample weighing device and an electric control device, wherein a pressure sensor is used for replacing a traditional thermobalance in the sample weighing device; so that measurement of the macroscopic sample amount (g-kg level) is achieved in combination with a movable furnace body, and mass errors caused by vibration generated by moving a measured object are avoided; meanwhile, the limitation caused by the fact that the thermobalance is prone to being corroded is overcome by adopting a corrosion-resistant material; so that any combination of various combustion atmospheres and top-speed temperature rise can be realized, and the application range is greatly widened; therefore, the thermal burst amount of the sample can be accurately measured, and an effective way is provided for the research of the later thermal burst behavior.

Owner:SHANXI UNIV

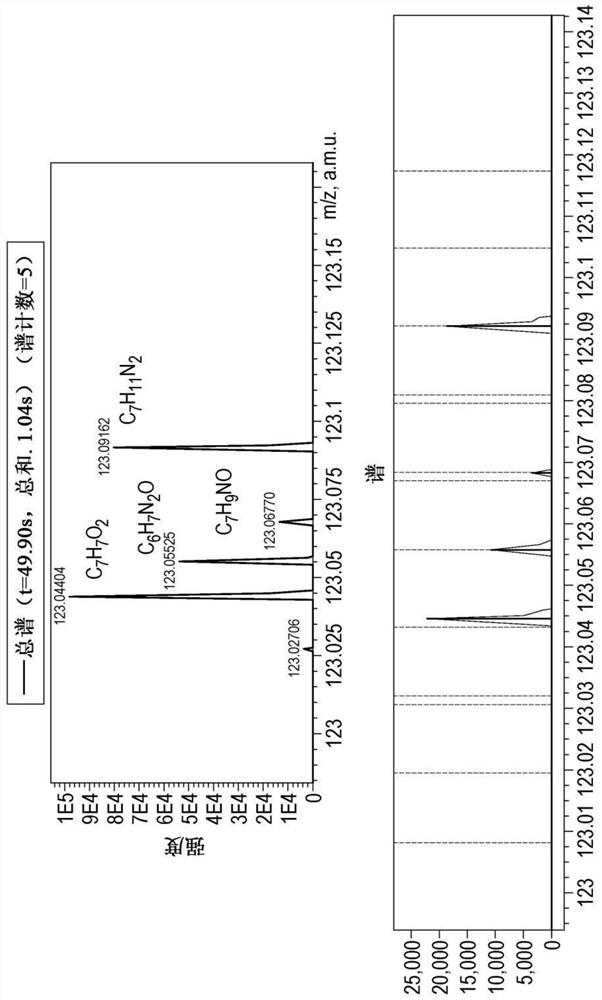

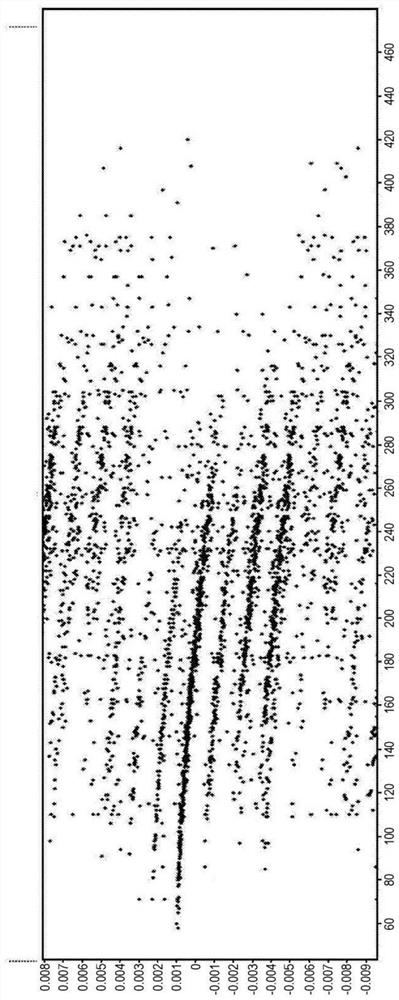

Self-calibration of high resolution mass spectrum

A method of self-calibrating a mass spectrometer or mass spectral data is disclosed. At least some first observed mass to charge ratios are matched with or against a comprehensive reference set of possible or predicted elemental compositions having known precise mass to charge ratios. One or more calibration parameters of a calibration routine are then adjusted so as to optimize the match between one or more of the first observed mass to charge ratios and the corresponding known precise mass to charge ratios of one or more possible or predicted elemental compositions contained within the reference set.

Owner:MICROMASS UK LTD

Cutting mechanism for resistant folding feet

The invention discloses a cutting mechanism for resistant folding feet. The cutting mechanism comprises a substrate and a cutter, wherein the cutter is connected with the substrate through a fixing block, a slot is formed in one side of the upper surface of the substrate, the slot is deployed just below the cutter and the fixing block is arranged adjacent to the inner side of the slot on the substrate. The cutting mechanism provided by the invention has the beneficial effects that the cutting mechanism is suitable for a transistor foot folding mechanism in small scale production; firstly, a machine is low in cost, convenient to operate, and can operate without cultivation; and secondly, the quality errors caused by the manual operation of an operator can be prevented, the stability of products can be improved, and the product quality can be improved.

Owner:张国勇

Quantitative sample weighing spoon

The invention discloses a quantitative sample weighing spoon, comprising a handle and a bowl, and belongs to the technical field of auxiliary tools for physiochemical detection. The bowl is a hollow cylinder, the top of the bowl is opened, the bottom of the bowl is sealed and is connected with the handle, the part of the handle close to the bowl is provided with a thin handle, the end of the handle far away from the bowl is provided with a round hole, one end of the extension of the handle is provided with the round hole, and the other end is provided with a cylindrical protrusion; the cylindrical protrusion at one end of the extension of the handle may be tightly connected with the round hole in the handle so that the handle is extended. Compared with the prior art, the quantitative sample weighing spoon has the advantages that the spoon herein is convenient to use, the length of the handle is increasable, and applications under special conditions can be guaranteed; the spoon is suitable for quantitatively weighing a solid sample, the sample can be poured completely into a specified container at a time, and splashing of the sample is effectively avoided; the sample can be sub-packaged quickly, time for the sample to be exposed in air is shortened, a change in the character of the sample is effectively avoided, working efficiency is improved, and the reliability of results is improved.

Owner:INST OF COTTON RES CHINESE ACAD OF AGRI SCI

A rotary pharmaceutical packaging machine

ActiveCN113845080BImprove infusion efficiencyAchieve continuous infusionFilling using suctionSynchronising machinesEngineeringPharmaceutical packaging

The invention relates to a rotary medicine packaging machine, which sequentially includes a bottle feeding mechanism, a continuous infusion mechanism, a transition mechanism, a stopper mechanism and a bottle discharging mechanism along the bottle conveying direction, the continuous infusion mechanism is fixed on the frame, and the continuous infusion mechanism One end of the mechanism is connected to the bottle feeding mechanism, and the other end is connected to the transition mechanism. The continuous infusion mechanism includes a main shaft, on which there are distributing parts, infusion parts and lifting parts, and an infusion pump is arranged on the top of the frame. The distribution part and the infusion part are connected through the infusion pipeline. There is a pump body control valve at the bottom of the frame. The pump body control valve is electrically connected to the infusion pump. The lower end of the infusion part conflicts with the lifting part. The frame is provided with a control cam, and the infusion part is provided with an infusion cut-off mechanism. The invention can realize the effect of continuous and high-efficiency packaging of bottle bodies.

Owner:山东蓬能机械科技有限公司

A method for detecting flavonoids in peony petals

The invention relates to a method for detecting a flavonoids component in peony petals. The method comprises the following steps: preparing a flavonoids extracting solution; setting a chromatographiccondition, a mass spectrum condition and a detection wavelength of a diode array detector; detecting the flavonoids extracting solution by adopting an ultra performance liquid chromatograph-diode array detector-triple quadrupole flight time tandem mass spectrometry and obtaining a detection result; carrying out structure identification on a flavonoids substance through analyzing the detection result; reckoning the structure of the flavonoids component. The method provided by the invention has the advantages of simple operation steps, rapid detection speed and high accuracy and sensitivity andcan be used for detecting the flavonoids component with the extremely less content; identification species are comprehensive and 67 types of main flavone, flavonol, flavanone and flavanol compounds and 5 types of main anthocyanin compounds are totally identified from the peony petals; the blank of identifying the flavonoids component in the peony petals is filled up and the method has important meanings on in analysis of nutrient components of the peony petals with different varieties.

Owner:城发投资集团有限公司 +1

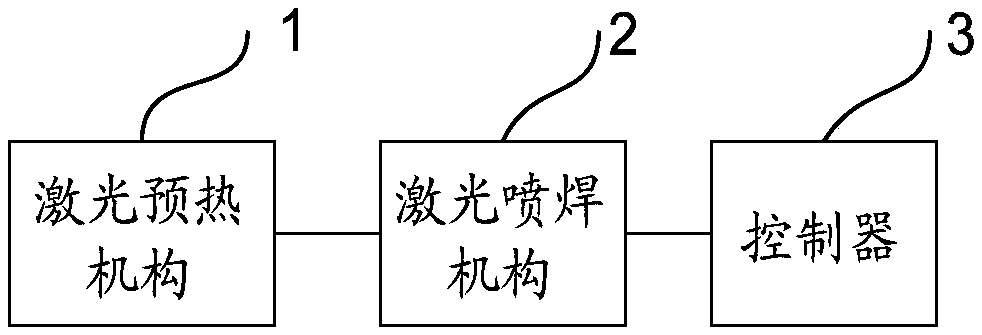

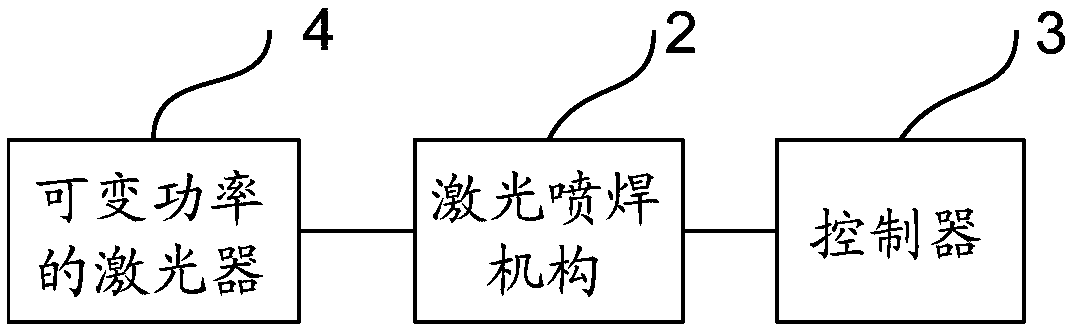

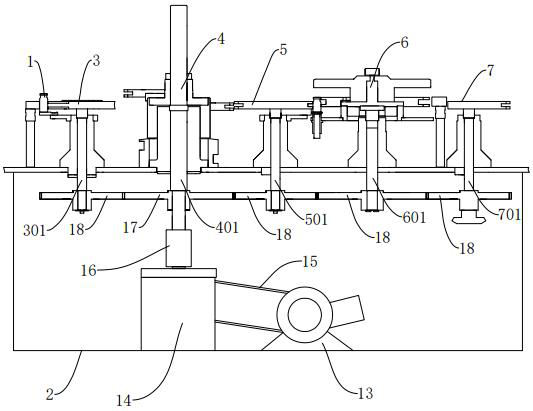

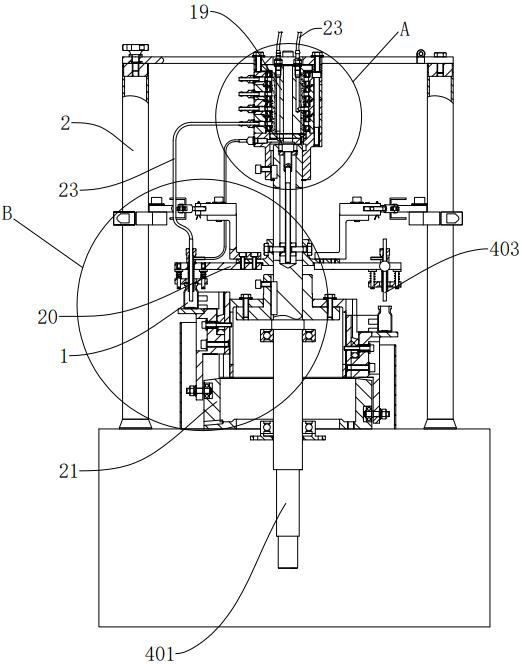

Motor reverser and voltage-sensitive resistor laser welding device and method

The invention discloses a motor reverser and voltage-sensitive resistor laser welding device and method, the laser welding method is suitable for the technical field of laser welding. The motor reverser and the voltage -sensitive resistor laser welding device comprise a laser preheating mechanism for heating the commutator terminal and a laser welding mechanism for jetting the welding ball to theterminal of the pre-heating commutator, and a controller for coordinating the working of the laser preheating mechanism and the laser welding mechanism. During use, the laser preheating mechanism is used for heating the terminals on the commutator with high heat conduction, and then injecting molten welding balls into the terminal and the voltage -sensitive resistor bonding pad, due to the fact that the terminal of the commutator is preheated, the temperature of the welding ball can be reduced, and the terminal can be soaked with the terminal, the voltage -sensitive resistor bonding pad cannotbe separated from the ceramic base, the welding process difficulty is lowered, meanwhile, due to the fact that the mass error of each ball is small, the welding spots are evenly distributed, so thatthe quality of each welding spot can be prevented from being unbalanced due to the fact that the quality of each welding spot is not uniform, and the service life is prolonged.

Owner:SHENZHEN ANEWBEST ELECTRONICS TECH

Rotary medicament packaging machine

ActiveCN113845080AImprove infusion efficiencyAchieve continuous infusionFilling using suctionSynchronising machinesControl valvesBottle

The invention relates to a rotary medicament packaging machine which sequentially comprises a bottle feeding mechanism, a continuous liquid conveying mechanism, a transition mechanism, a plug pressing mechanism and a bottle discharging mechanism in the bottle conveying direction. The continuous infusion mechanism is fixed onto a rack; one end of the continuous liquid conveying mechanism is connected with the bottle feeding mechanism, and the other end of the continuous liquid conveying mechanism is connected with the transition mechanism; the continuous liquid conveying mechanism comprises a main shaft; a distribution part, a liquid conveying part and a lifting part are arranged on the main shaft; a liquid conveying pump is arranged at the top of the rack and communicated with the distribution part through a liquid conveying pipeline; the distribution part is communicated with the liquid conveying part through a liquid conveying pipeline; a pump body control valve is arranged at the bottom of the rack and electrically connected with the liquid conveying pump; the lower end of the liquid conveying part abuts against the lifting part; a control cam is arranged on the rack; and the liquid conveying part is provided with a liquid conveying cut-off mechanism. The rotary medicament packaging machine provided by the invention can achieve the effect of continuously and efficiently packaging bottle bodies.

Owner:山东蓬能机械科技有限公司

Manipulator with detecting function in bolt transmission

The invention discloses a manipulator with a detecting function in bolt transmission, and relates to the technical field of powder packing. The manipulator comprises a fixed block and a connecting block; a feed hole is mounted under the fixed block; an ejector block is mounted on the inner side of the fixed block; a spring is mounted on the right side of the ejector block; and a straight rod is arranged on the right side of the spring. In the manipulator with the detecting function in bolt transmission, through arrangement of the fixed block, the feed hole, the ejector block, the spring, the straight rod, a connecting rod, a fixed screw, the connecting block and an electromagnetic block, users can effectively fix bolts through the fixed block; the bolts are put in the device through the feed hole; then, the users can shift the straight rod to the inner side to drive the ejector block to fix the bolts on the fixed blocks through the spring, so that the users are convenient to transmit and fix the bolts; the users can mount and fix the connecting rod through the fixed screw, so that the users are convenient to mount the device in the previous stage; and the electromagnetic block canabsorb the bolts in operation.

Owner:DONGGUAN UNIV OF TECH

A method for detecting flavonoid components in peony leaves

The invention relates to a method for detecting the flavonoid components in peony leaves. The method comprises the following steps of preparing a flavonoid extracting solution; setting chromatographicconditions, mass spectrum conditions and the detection wavelength of a diode array detector; adopting the super-efficient liquid chromatogram-diode array detector-triple quadrupole rod flight time tandem mass spectrum linkage technology for detecting the flavonoid extracting solution, and obtaining a detecting result; performing structure identification on flavonoid substances by analyzing the detecting result, and speculating the structure of the flavonoid compound. The method is simplified in operation steps, rapid in detection and high in accuracy and sensitivity, the micro content of theflavonoid components can be detected, the identification variety is comprehensive, 45 main flavone, flavonol, flavanone and flavanol compounds are identified in the peony leaves, a gap for flavonoid component identification in the peony leaves is filled up, and the method is of great significance in analysis of different varieties of peony leaf nutrient contents.

Owner:INST OF VEGETABLE & FLOWERS CHINESE ACAD OF AGRI SCI +1

Substation power grid comprehensive grounding lead-out wire construction method

InactiveCN111446660AOvercome construction flawsGuaranteed reliabilityCable installation apparatusEpoxyGrounding grid

The invention discloses a substation power grid comprehensive grounding lead-out wire construction method. The method comprises the steps of firstly, manufacturing a sleeve and a water stop ring, welding the water stop ring to the outer ring of the sleeve, brushing two layers of zinc-rich paint at a weld joint, and brushing a layer of antirust paint; penetrating a grounding lead-out wire into thesleeve, arranging an insulating fixing ring between the grounding lead-out wire and the sleeve, respectively pouring epoxy resin fillers from two ends of the sleeve; after the epoxy resin fillers arecompletely solidified, arranging the bottom end of the sleeve on a civil engineering cushion layer; welding the grounding lead-out wire at the bottom end of the sleeve to a grounding grid; locating the water stop ring at the position of a civil engineering bottom plate; and enabling the top end of the sleeve extends out of a concrete backfill layer located above the civil engineering bottom plateto complete construction of the grounding lead-out wire. According to the method, the defects of traditional grounding lead-out wire construction are overcome; the construction period is effectively shortened; quality errors possibly occurring in construction operation are reduced; and the reliability of grounding lead-out wire arrangement and a traction substation grounding system is ensured.

Owner:SHANGHAI BAOYE GRP CORP

Automatic activating and laminating all-in-one machine for waterproof film

PendingCN111493436AImprove work efficiencySmall quality errorClothes making applicancesManufacturing engineeringManual handling

The invention relates to the technical field of mechanical equipment, in particular to an automatic activating and laminating all-in-one machine for a waterproof film, which comprises a rack, a feeding mechanism, a material supporting mechanism, an activating mechanism and a shoe last, the feeding mechanism is installed on the rack, the feeding mechanism comprises a material containing assembly and a material taking assembly, and the material taking assembly is located above the material containing assembly; the material supporting mechanism comprises a material supporting lifting driver installed on the rack and a material supporting plate connected with the material supporting lifting driver, the material supporting lifting driver is used for driving the material supporting plate to ascend or descend, and the material supporting plate is close to the material taking assembly and used for bearing materials conveyed by the material taking assembly; the activation mechanism is installedon the rack and used for activating the materials borne by the material supporting mechanism; and the shoe last is arranged on the rack and is positioned above the retainer plate. Manual operation isnot needed in the process, so that the working efficiency is improved, the quality error caused by manual operation is reduced, and the product quality is improved.

Owner:广东汇齐新材料有限公司

A medium and large density battery packing machine

InactiveCN105070955BHigh precisionSmall quality errorFinal product manufactureLead-acid accumulators constructionEngineeringMechanical engineering

The invention discloses a medium and large-density battery wrapping machine, which comprises a main frame mechanism, a partition paper unwinding mechanism, a conveying mechanism, a material feeding mechanism, a transmission mechanism, a paper feeding and wrapping mechanism, a stacking mechanism, a material receiving mechanism, an output mechanism and negative pressure mechanism, the conveying mechanism is composed of a first conveying mechanism and a second conveying mechanism, a number of separator paper unwinding mechanisms are installed on the left side of the main frame mechanism, and each separator paper unwinding mechanism is connected with a motor Connected, the inside of the main frame mechanism is sequentially installed with a first conveying mechanism, a second conveying mechanism, a stacking mechanism and a receiving mechanism from left to right, and the paper feeding and wrapping mechanism is located between the first conveying mechanism and the second conveying mechanism. Directly above the mechanism junction, the output mechanism is installed on the right end of the main frame mechanism. The invention discloses a medium-to-large-density battery wrapping machine, which has a reasonable structure, an overall linear layout, a high space occupation factor, adopts a mechanical linkage method, has high wrapping accuracy, reduces labor costs, and improves battery wrapping efficiency and quality.

Owner:CHANGXING JINGSHENG HYDRAULIC MACHINERY

A tuned mass damper with variable stiffness, variable mass and variable damping and its design method

ActiveCN113638515BControlling Multi-Order VibrationImprove adaptabilityProtective buildings/sheltersShock proofingEngineeringTuned mass damper

Owner:HUNAN UNIV

A method for making remolded soil samples

ActiveCN105571926BSmall quality errorEffective height controlPreparing sample for investigationHydraulic equipmentDensity difference

The invention provides a method for manufacturing a remolding soil test specimen in the technical field of geotechnical tests. A darby tray and a specimen making device are used. The darby tray is a rectangular tray, and an adjustable darby is attached to the upper part of the rectangular tray. The specimen making device consists of a concave press rod, a pad block and a transparent sleeve with scales. By using a one-step feeding mode, the characteristic of uniform loading of the existing servo hydraulic equipment in a laboratory is used; the problems of nonuniform and instable specimen making pressure, easy layering of the soil specimen and upper and lower density difference are solved; the visual scale characteristic of the specimen making device is used; the precise control on the test specimen volume is achieved; and further, the dry density is precisely controlled on the premise of precisely controlling the moisture content. The method is applicable to the preparation of cylindrical remolding soil test specimens, and has the characteristics that the system errors are small; the structure is simple; the laboratory equipment is integrally utilized; the multi-time repeated utilization can be realized, and the like.

Owner:ANHUI UNIV OF SCI & TECH

Filling machine for heparin sodium cream

PendingCN110642203AAvoid pollutionImprove qualitySnap-on cap applicationCapping machinery safety/controlDust controlHeparin sodium

The invention discloses a filling machine for heparin sodium cream. The machine comprises a conveying structure and a filling device. Through an air storage tank, an exhaust opening, a pipeline, a lifting rod and a nozzle, blowing dust removal is carried out on a medicine tube placed on a filling box inner cavity positioning structure, through a dust suction cover, a pipeline and a dust suction fan, sucking is carried out, the heparin sodium cream is prevented from being polluted in the filling process, an ultraviolet sterilization lamp arranged on the top of a filling box inner cavity carriesout sterilizing and disinfecting on the heparin sodium cream during filling, the quality of the heparin sodium cream is improved, the size of the shape of the lower end of the piston is matched withthe size of the shape of the lower end of the filling pipe head inner cavity, under the action of a driving air cylinder, cream in the filling pipe head is extruded, the pollution caused by deterioration of cream remaining in the filling head can be avoided, the quality of the heparin sodium cream is further improved, waste is avoided, resources are saved, production cost is reduced, due to a sliding structure, different heights and sizes of medicine tubes can be filled, and device practicability is improved.

Owner:JIANGSU JIUHUI FOOD PROD CO LTD

Needle plate girder of high-speed needling machine

InactiveCN103243485AGood bending and torsion resistanceHigh strengthNeedling machinesEngineeringPlate girder

A needle plate girder of a high-speed needling machine relates to the technical field of non-woven production and comprises a top side plate, a bottom side plate, a left side plate and a right side plate, wherein at least one reinforced rib is arranged between the left side plate and the right side plate, the upper end of each reinforced rib is fixedly connected with the top side plate, and the lower end of each reinforced rib is fixedly connected with the bottom side plate. The at least one reinforced rib is arranged in the middle so that the needle plate girder is improved in strength and is led to be small in volume. Counter-acting forces of felting needles are uniformly distributed on the plurality of reinforced ribs so that bending deformation is small when the contact surface of the needle plate girder and a needle plate works. Each needle is evenly and uniformly stressed so that the needling needle track effect of a whole breadth directional cloth cover is good and high-quality cloth can be produced.

Owner:JIANGSU YIZHENG HAIRUN TEXTILES MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com