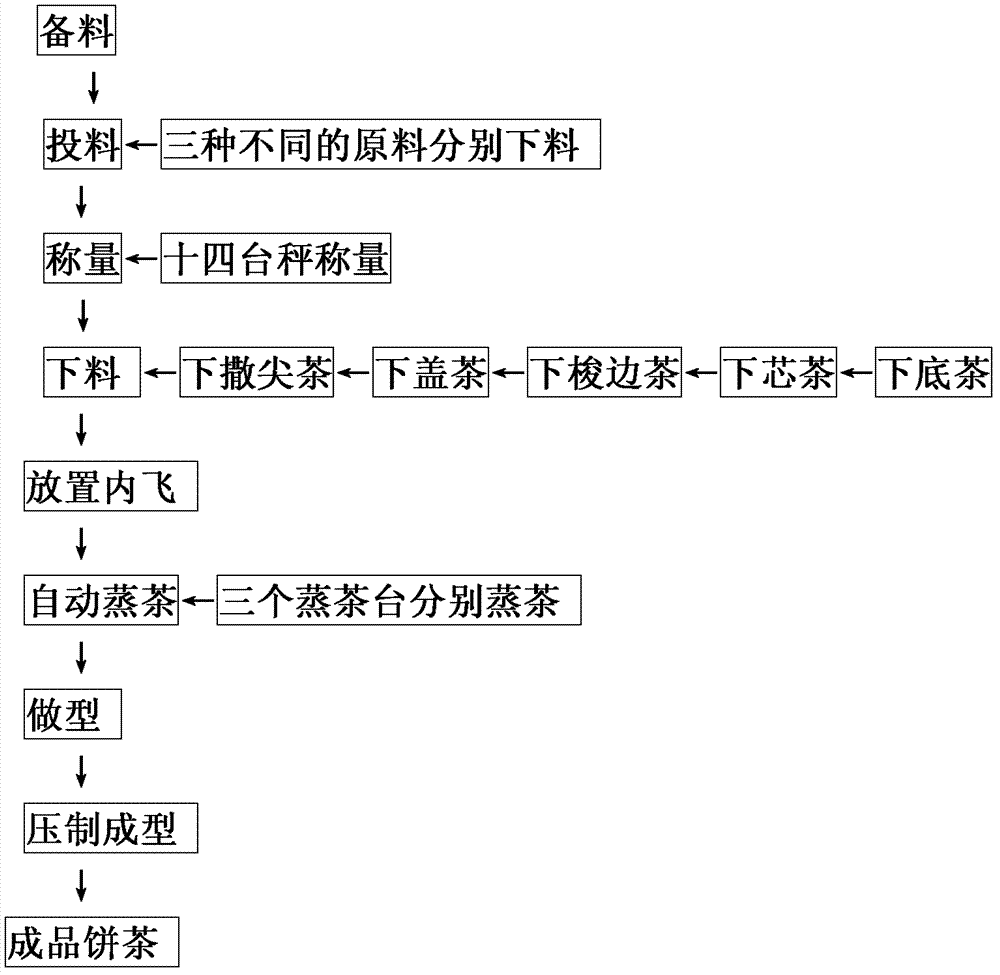

Pu'er tea cake flow line forming method

A Pu-erh tea cake and molding method technology, which is applied in tea processing before extraction, etc., can solve the problems of heavy labor workload, high labor cost, and low efficiency, so as to reduce the labor intensity, reduce the number of laborers, and improve the product. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] 1. Material preparation process

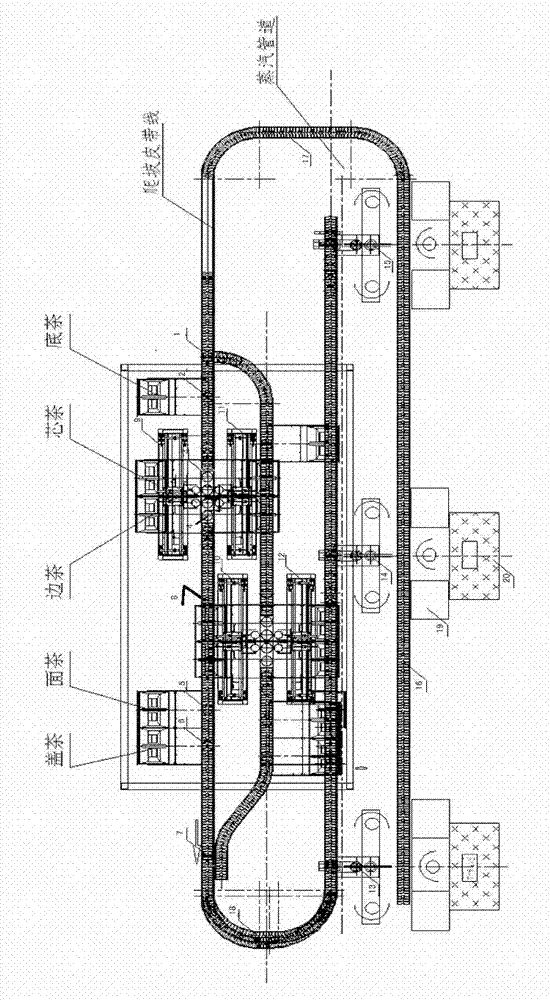

[0043] On the second floor where the feeder is placed, that is, the area where the chain plate assembly line is placed, take the production of conventional 357g cake tea as an example, prepare the three kinds of tea leaves to be used, and prepare according to the ratio of tip, heart and lid 15:43:42.

[0044] 2. Feeding

[0045] Pour the prepared tea leaves into each feeder. Under the action of the vibrating feeder and the horizontal screw of the feeder, the tea leaves are evenly fed into the scale through the feeder pipe. When the tea in the scale hopper reaches a certain amount, Under the function of photoelectricity and the control of the setting program, the feeder stops feeding to the scale. When the tea leaves in the scale hopper decrease to a certain extent, the feeder resumes feeding the scale, and the whole process realizes automatic control.

[0046] 3. Weighing

[0047] When the tea leaves go down to the inside of the scale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com