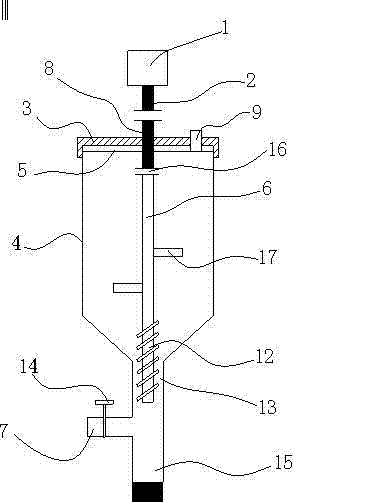

Uniform adjustable powder feeding device

A powder feeding device and uniform technology, applied in packaging and other directions, can solve the problems of difficulty in accurately conveying small flow powder materials, large differences in powder feeding uniformity, poor feeding uniformity, etc., achieving simple structure and wide powder volume adjustment range. , The effect of powder feeding is even and adjustable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Using ZrCl 4 -CH 4 -H 2 -Ar system, atmospheric pressure chemical vapor deposition ZrC coating, the powder feeder is installed in the middle of the furnace roof of the vertical vapor deposition furnace, ZrCl 4 The powder is loaded into the material tank 4 from the charging port 9, and the carbon source gas CH 4 , reducing gas H 2 And the dilution gas Ar is introduced by the intake pipe 7, and the speed regulating motor 1 is started to make the screw shaft 12 rotate at a specified speed, and the ZrCl 4 The powder flows down steadily from the lower end of the screw shaft 12, mixes with the gas entering the inlet pipe 7, and directly enters the vapor phase deposition furnace through the gas outlet and powder outlet pipe 15, and the ZrCl 4 After the powder enters the furnace, it is heated and gasified, and then reduced and carbonized on the substrate to form a ZrC coating.

[0018] When the diameter of the screw shaft is 25mm and the diameter of the feeding tube is 25....

Embodiment 2

[0022] Using TaCl 5 -C 3 h 6 -H 2 -Ar system, chemical vapor deposition TaC coating, the powder feeder is installed in the upper part of the furnace of the vertical vapor deposition furnace, TaCl 5 The powder is loaded into the material tank 4 from the charging port 9, and the carbon source gas C 3 h 6 , reducing gas H 2 And the dilution gas Ar is introduced by the intake pipe 7, and the speed regulating motor 1 is started to make the screw shaft 12 rotate at a specified speed, and TaCl 5 The powder flows down steadily from the lower end of the screw shaft 12, mixes with the gas entering the inlet pipe 7, and directly enters the vapor deposition furnace through the gas outlet and powder outlet pipe 15, and the TaCl 5 After the powder enters the furnace, it is heated and gasified, and then reduced and carbonized on the substrate to form a TaC coating.

[0023] When the diameter of the screw shaft is 20mm, under the same screw pitch (5mm), the same screw shaft speed (20r / ...

Embodiment 3

[0027]In the Ar environment, the submicron WC-Co composite powder is conveyed under normal pressure and positive pressure. When the diameter of the screw shaft is 15mm, different screw pitches (mm) and 12 rotation speeds (r / min) of the screw shaft are conveyed. The powder feeding rate of 0.30~0.50μm WC-Co composite powder is shown in Table 3. It can be seen that in the case of different screw pitches and screw shaft speeds, the error of normal pressure powder feeding is not higher than 0.02 g / min, and the relative error is less than 1%. The rate and error of powder feeding are close to normal pressure under the condition that the pressure of air supply pipe 7 is 3 atmospheres, and there is no obvious change.

[0028] Table 3: ZrCl 4 Powder feeding rate

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com