A suction cup climbing robot

A suction cup type, robot technology, applied in the field of robots, can solve the problems of weak adsorption capacity, large space size and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

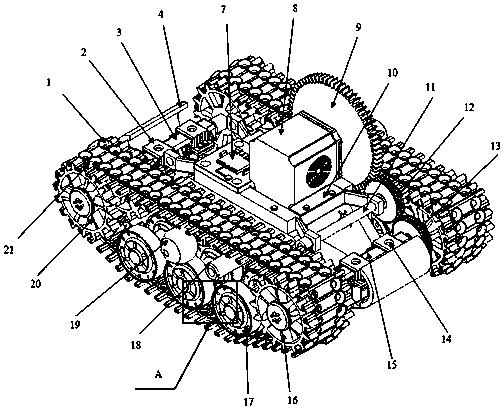

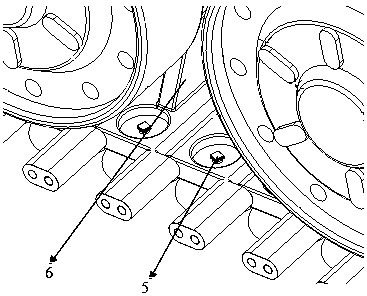

[0023] Embodiment 1: as Figure 1-2 Shown, a kind of sucker type climbing robot comprises chassis 4, secondary gear transmission mechanism, transmission mechanism, suction cup type crawler climbing mechanism, investigation unit; The driving wheel shaft 15 is installed on the chassis 4, and then connected with the transmission mechanism through the driven wheel 20 and the driving gear 13; Between the crawlers 21 on both sides.

Embodiment 2

[0024] Embodiment 2: as Figure 1-2 Shown, a kind of sucker type climbing robot comprises chassis 4, secondary gear transmission mechanism, transmission mechanism, suction cup type crawler climbing mechanism, investigation unit; The driving wheel shaft 15 is installed on the chassis 4, and then connected with the transmission mechanism through the driven wheel 20 and the driving gear 13; Between the crawlers 21 on both sides.

[0025] Described secondary gear transmission mechanism comprises motor 8, motor gear 9, transmission gear support 10, transmission gear shaft 11, transmission gear 12; Transmission gear support 10 is installed on chassis 4, and transmission gear support 10 is installed transmission gear shaft 11; speed change gear 12 is installed on the speed change gear shaft 11 of one end; Motor 8 is installed on the transmission gear support 10, and motor gear 9 is meshed with speed change gear 12; Speed change gear 12 is meshed with the driving gear 13 of transmi...

Embodiment 3

[0026] Embodiment 3: as Figure 1-2 Shown, a kind of sucker type climbing robot comprises chassis 4, secondary gear transmission mechanism, transmission mechanism, suction cup type crawler climbing mechanism, investigation unit; The driving wheel shaft 15 is installed on the chassis 4, and then connected with the transmission mechanism through the driven wheel 20 and the driving gear 13; Between the crawlers 21 on both sides.

[0027] Described secondary gear transmission mechanism comprises motor 8, motor gear 9, transmission gear support 10, transmission gear shaft 11, transmission gear 12; Transmission gear support 10 is installed on chassis 4, and transmission gear support 10 is installed transmission gear shaft 11; speed change gear 12 is installed on the speed change gear shaft 11 of one end; Motor 8 is installed on the transmission gear support 10, and motor gear 9 is meshed with speed change gear 12; Speed change gear 12 is meshed with the driving gear 13 of transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com