Floating double-axis synchronously moving mechanism

A floating, moving mechanism technology, applied in the field of laser repairing machines, can solve the problems that the two displacement devices cannot be started completely synchronously, the platform is pulled, and the force on the platform is uneven.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

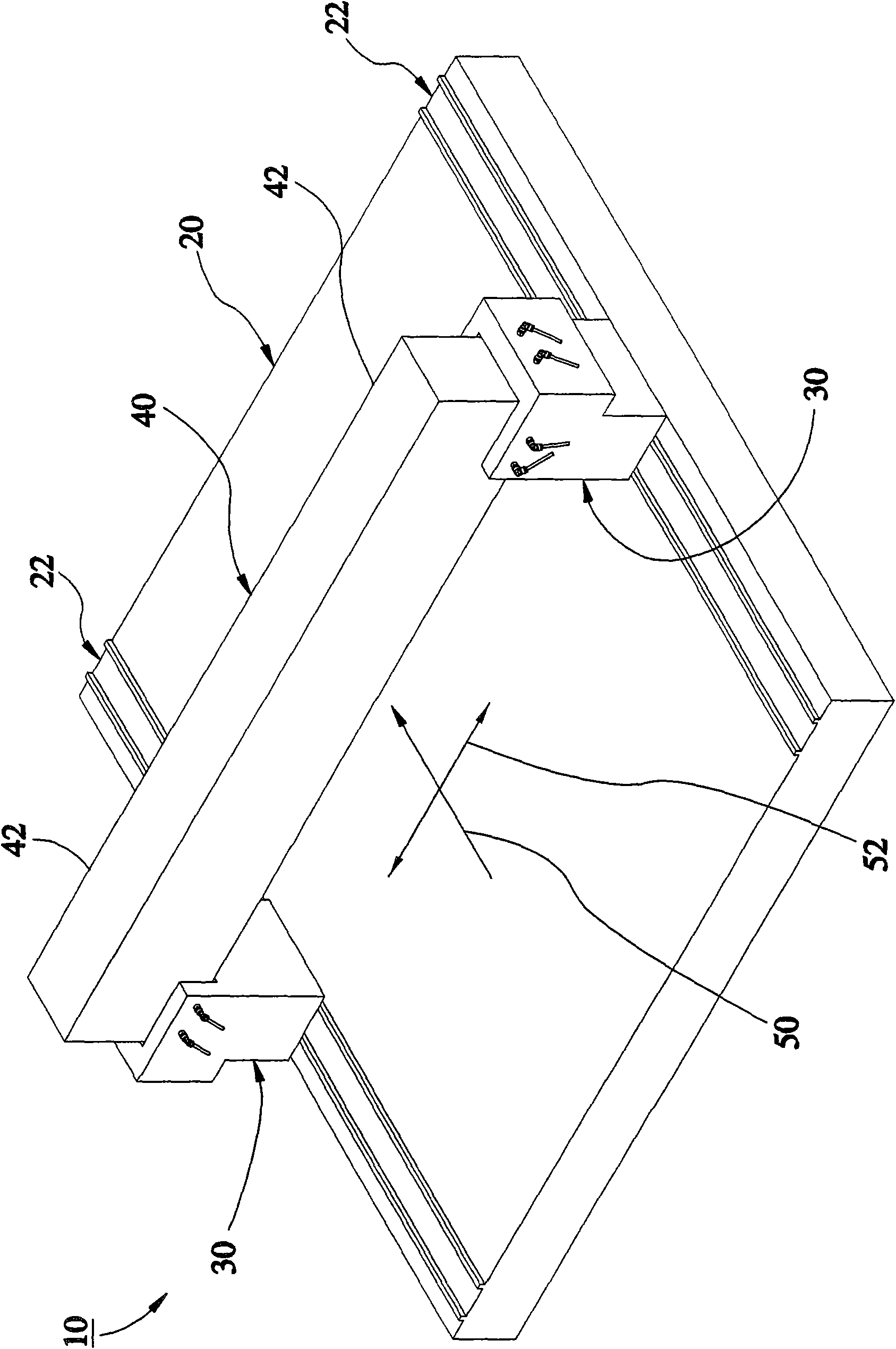

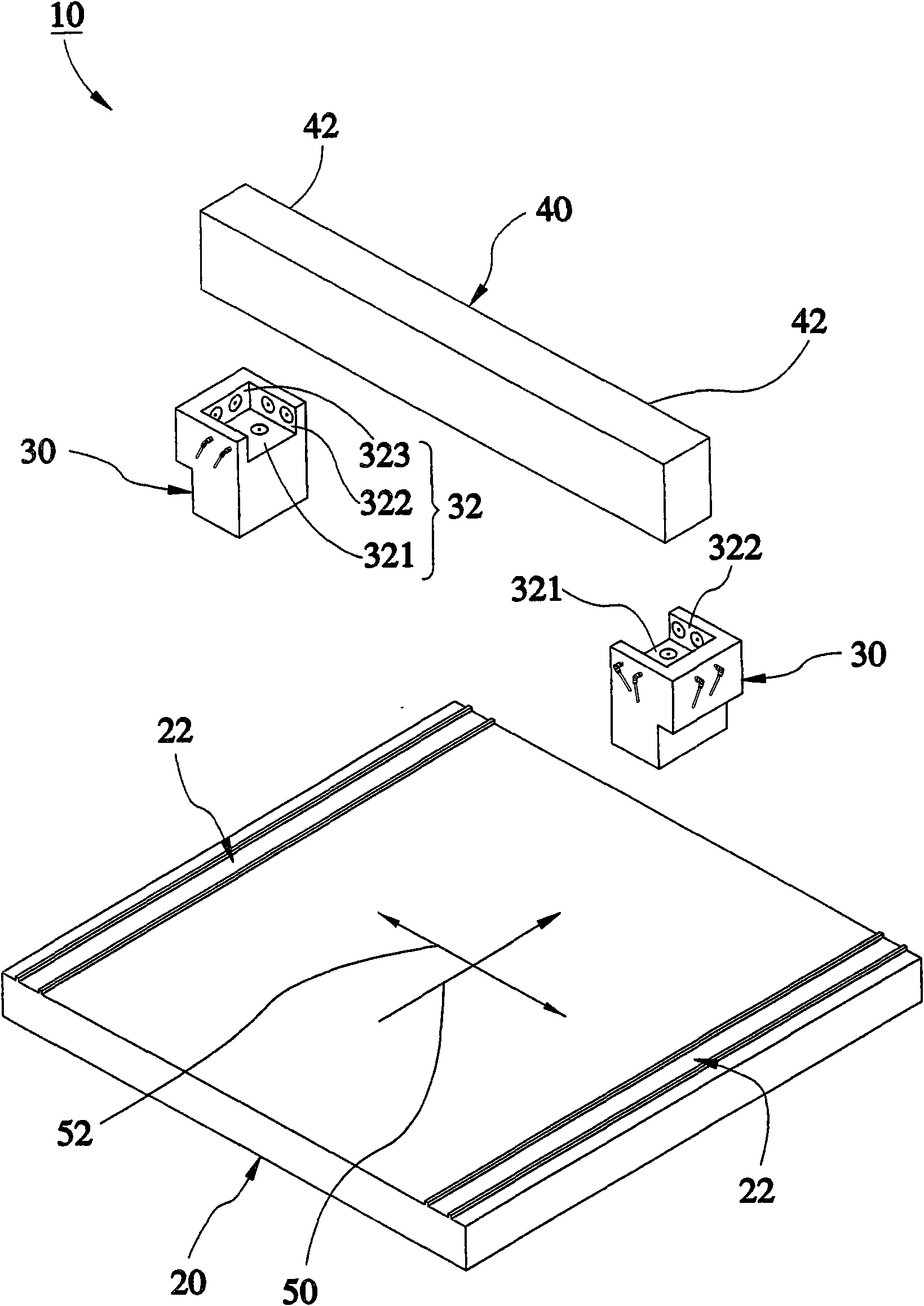

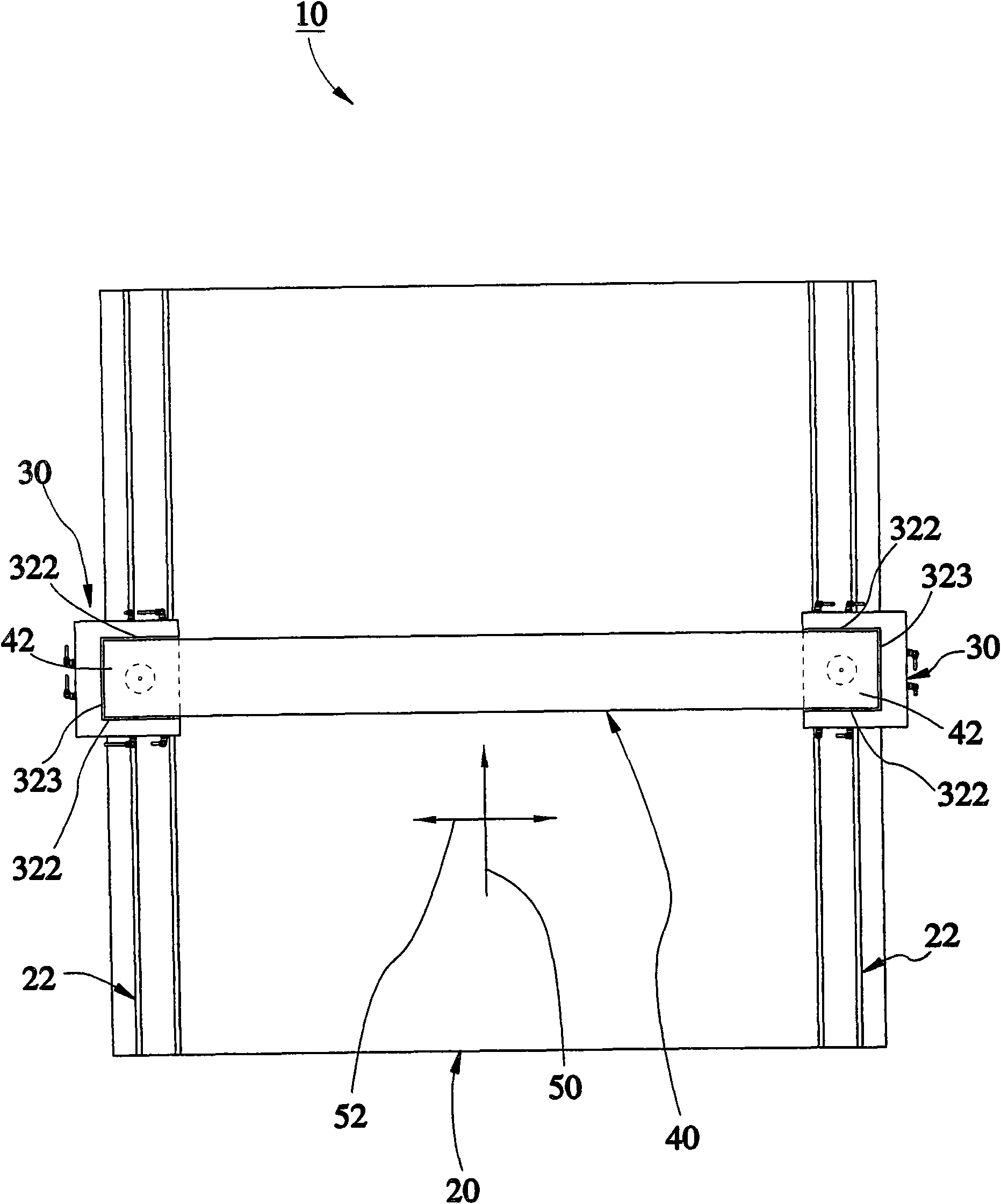

[0024] see Figure 1 to Figure 5 , a floating double-axis co-moving mechanism 10 provided in a preferred embodiment of the present invention includes a working platform 20 , a displacement device 30 and a platform 40 .

[0025] The working platform 20 has two rails 22 extending along an X-axis 50 , and the two displacement devices 30 are slidably mounted on the two rails 22 .

[0026] The two displacement devices 30 are respectively arranged on both sides of the working platform 20, and the displacement devices 30 can be displaced synchronously along the direction of the X-axis 50; each of the displacement devices 30 has a concave portion 32, and the concave portion 32 is defined along the direction of the X-axis 50 A bearing area 321 and two limiting areas 322; the bearing area 321 provides a vertical airflow; the two limiting areas 322 are located on both sides of the bearing area 321, and each of the limiting areas 322 provides two horizontal airflows; the two displacement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com