Substation power grid comprehensive grounding lead-out wire construction method

A construction method and lead-out technology, applied in the direction of electrical components, cable installation, cable installation devices, etc., can solve the problem of long overall span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

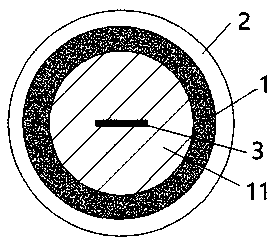

[0017] Example figure 1 and figure 2 As shown, the construction method of the comprehensive grounding lead wire of the substation power grid of the present invention comprises the following steps:

[0018] Step 1. Make casing 1 and water stop ring 2, and clean the surface stains. Insert water stop ring 2 into the outer ring of casing 1 and weld it at 1 / 3 of the length of casing 1. After welding, wait for After cooling, apply two layers of zinc-rich paint to the weld, and then another layer of anti-rust paint;

[0019] Step 2: Put the ground lead-out wire 3 into the bushing 1 and install an insulating fixing ring 4 between the ground lead-out wire 3 and the bushing 1, pour epoxy resin filler 11 from one end of the bushing 1, and turn it upside down after it is completely solidified Sleeve 1 and pour epoxy resin filler 11 from the other end of sleeve 1;

[0020] Step 3: Place the bottom end of the casing 1 on the civil construction cushion 5, and weld the ground lead wire 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com