Deep Foundation Pit Large Slope Upside-Down Steel Bolt-spray Support Structure and Its Construction Method

A technology of bolting and shotcrete support and construction method, which is applied in basic structure engineering, excavation, construction, etc., can solve the problems of inconspicuous distinction of key areas, increased construction cost and construction period, etc., and is conducive to soil unloading and foundation pit safety. Reliable and effective in improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The embodiments of the present invention are described below through specific specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification. The present invention can also be implemented or applied through other different specific embodiments, and various details in this specification can also be modified or changed based on different viewpoints and applications without departing from the spirit of the present invention.

[0049] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

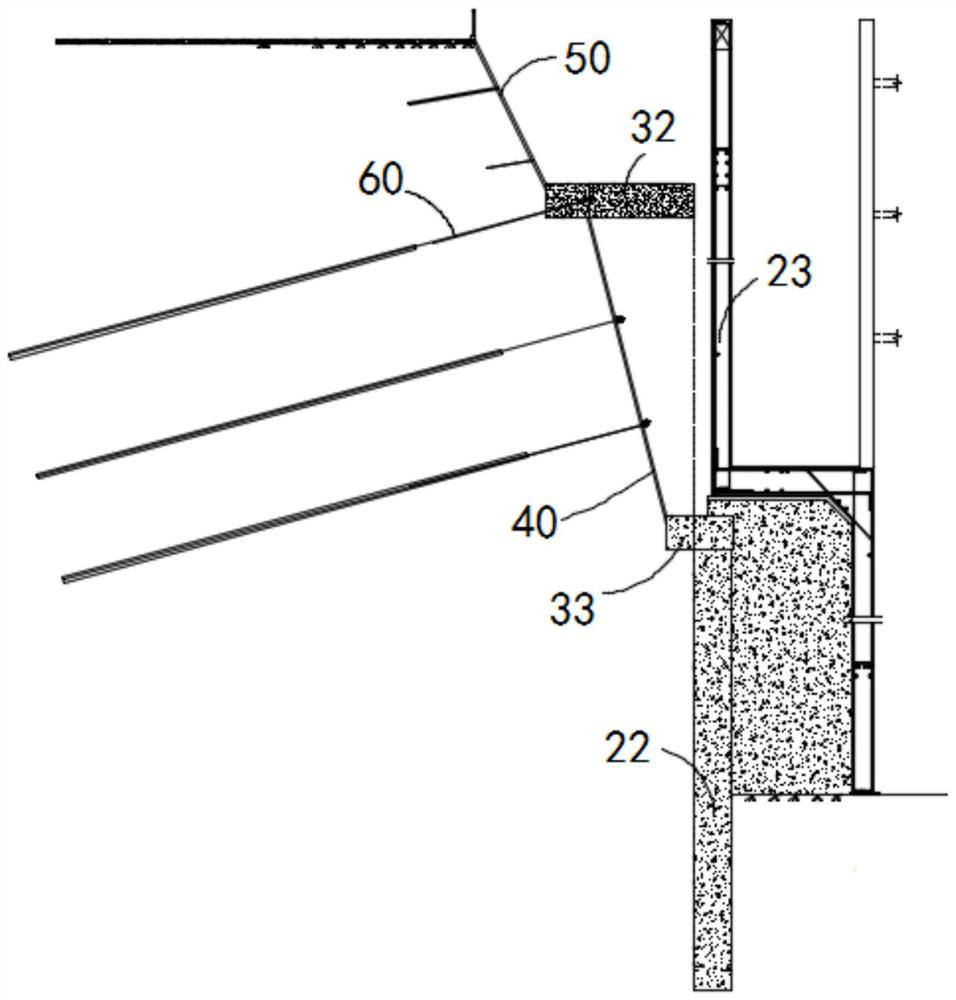

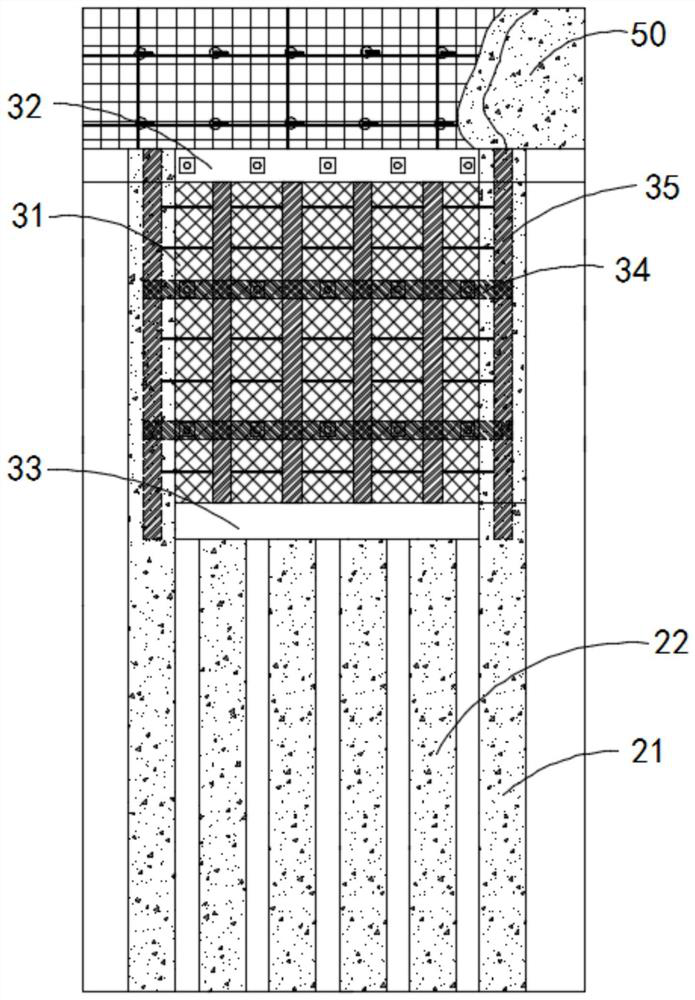

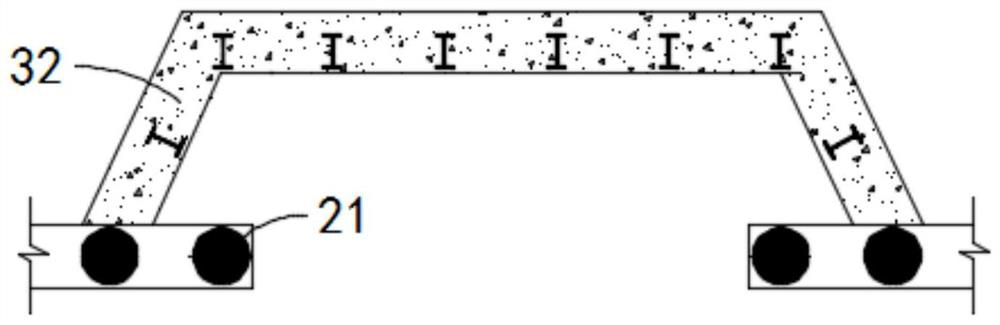

[0050] The invention provides a construction method for a large-slope upside-down type steel bolt-and-shot support structure in a deep foundation pit. The basement in the foundation pit is excavated and supported at the position to be extended, and the construction method includes the following steps: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com