Construction method of post-pouring with side form for raft slab

A construction method and technology of post-pouring tape, applied in the field of construction, can solve problems such as inability to control construction quality, steel wire mesh cannot bear side pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

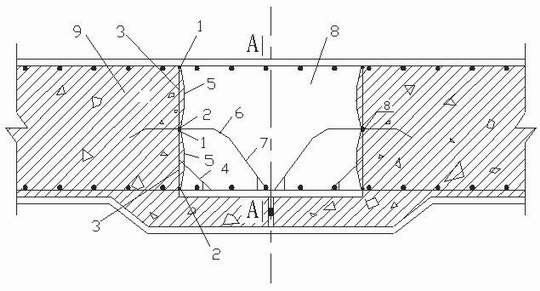

[0022] Example figure 1 with figure 2 Shown, the construction method of raft slab post-casting band sideform of the present invention comprises the steps:

[0023] Step 1, making upper chord steel bar 1, lower chord steel bar 2, belly bracing steel bar 3, side form brace 4, steel wire mesh 5, water-stop steel plate 6 and water-stop steel plate diagonal brace 7;

[0024] Step 2: Wrap the upper and lower sides of the wire mesh 5 around the upper chord steel bar 1 and the lower chord steel bar 2 for one turn, and then tie them firmly at intervals of 150mm;

[0025] Step 3. Place the water-stop steel plate 6 belly down symmetrically in the post-casting belt 8 and in the middle of the post-casting belt 8. Above the water-stop steel plate 6 is the upper side mold, and below is the lower side mold;

[0026] Step 4: The steel wire mesh 5 wound with the upper chord reinforcement 1 and the lower chord reinforcement 2 is respectively placed on the side wall of the post-casting belt 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com