Construction and measurement method to ensure levelness of cast-in-place structure roof

A measuring method and technology for levelness, which are applied in measuring device, measuring inclination, formwork/template/work frame, etc., can solve the problems of affecting headroom size, affecting construction efficiency and construction cost, and unequal ceiling putty scraping. The effect of saving construction cost, improving construction efficiency and quality, and improving the qualification rate of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

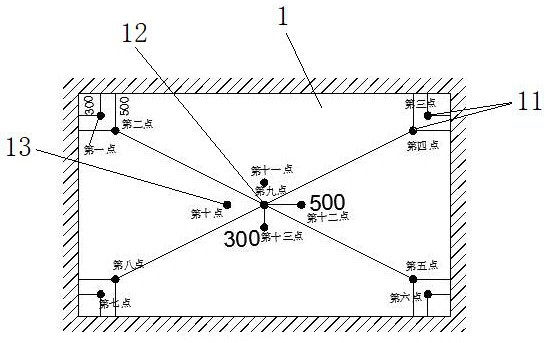

[0015] The construction and measurement method for ensuring the levelness of the cast-in-place roof of the present invention comprises the following steps:

[0016] Step 1. According to the structural design drawings and the positions of the shear walls and beams, use aluminum formwork, GMT formwork or wooden formwork to support the roof of the cast-in-place structure to form a formwork system. The aluminum formwork is supported by shear walls and single poles , the GMT formwork adopts wheel buckle support, the primary and secondary ribs are square steel pipes, the wooden formwork adopts wheel buckle support, and the primary and secondary ribs are wooden beams; among them, the wheel buckle support is an in-line type with self-locking function The new steel pipe support has the characteristics of large bearing capacity, fast construction speed, strong stability, and easy site management. Its main components are vertical rods and horizontal rods. The three-dimensional space stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com