Construction method of corrugated guardrail above highway retaining wall

A construction method and retaining wall technology, applied to fences, building types, buildings, etc., can solve the problems of high material and labor costs, inability to adapt to the rapid development of road construction, and long periods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

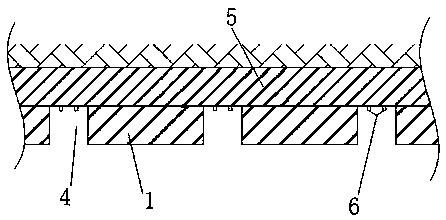

[0020] Example Figure 1 to Figure 4 As shown, the construction method of the corrugated guardrail above the highway retaining wall of the present invention comprises the steps:

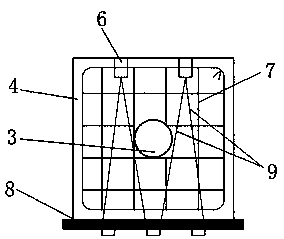

[0021] Step 1. Carry out the masonry construction of the retaining wall 1 according to the highway axis, and ensure the integrity of the masonry wall of the retaining wall 1. According to the measurement and positioning of the wave guardrail 2, the foundation pit 4 and the foundation pit of the wave guardrail column 3 are reserved. The front of the groove 4 wall is the road concrete shoulder 5, the two sides are respectively the retaining wall 1, and the back opening;

[0022] Step 2: Use an impact drill on the front of the foundation pit 4 to drill holes on the road concrete shoulder 5 and install expansion bolts 6. The steel cage 7 is cut and bound and sunk into the foundation pit 4. The wave guardrail column 3 is positioned according to the reinforcement cage 7 welding positioning;

[0023] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com