Rotary medicament packaging machine

A packaging machine, a rotary technology, applied in the field of rotary pharmaceutical packaging machines, can solve the problems of delayed production progress, discontinuous bottle infusion process, and reduced packaging efficiency, so as to save equipment costs, avoid liquid medicine splashing, and improve finished products rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0052] The rotary pharmaceutical packaging machine in this embodiment can continuously infuse eight bottles 1 at the same time, and other numbers of bottles 1 for infusion are also applicable to the principle structure in this embodiment, so no more details are given here.

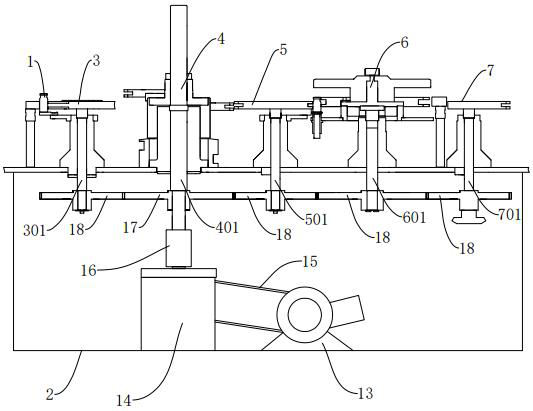

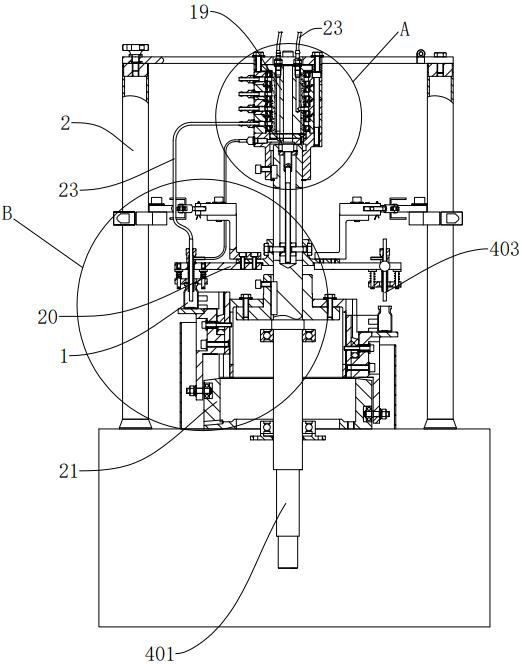

[0053] refer to figure 1 and figure 2 , a rotary medicine packaging machine disclosed in the present invention is used for packaging medicine bottles 1 (especially vials), including a frame 2, which is sequentially mounted along the conveying direction of the bottle body 1. It is provided with a bottle feeding mechanism 3 , a continuous infusion mechanism 4 , a transition mechanism 5 , a plugging mechanism 6 and a bottle discharging mechanism 7 . Each mechanism is connected with a conveying track, and the conveying track mainly includes a bottle-in track 8 and a bottle-out track 9. At ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com