Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "With puffing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

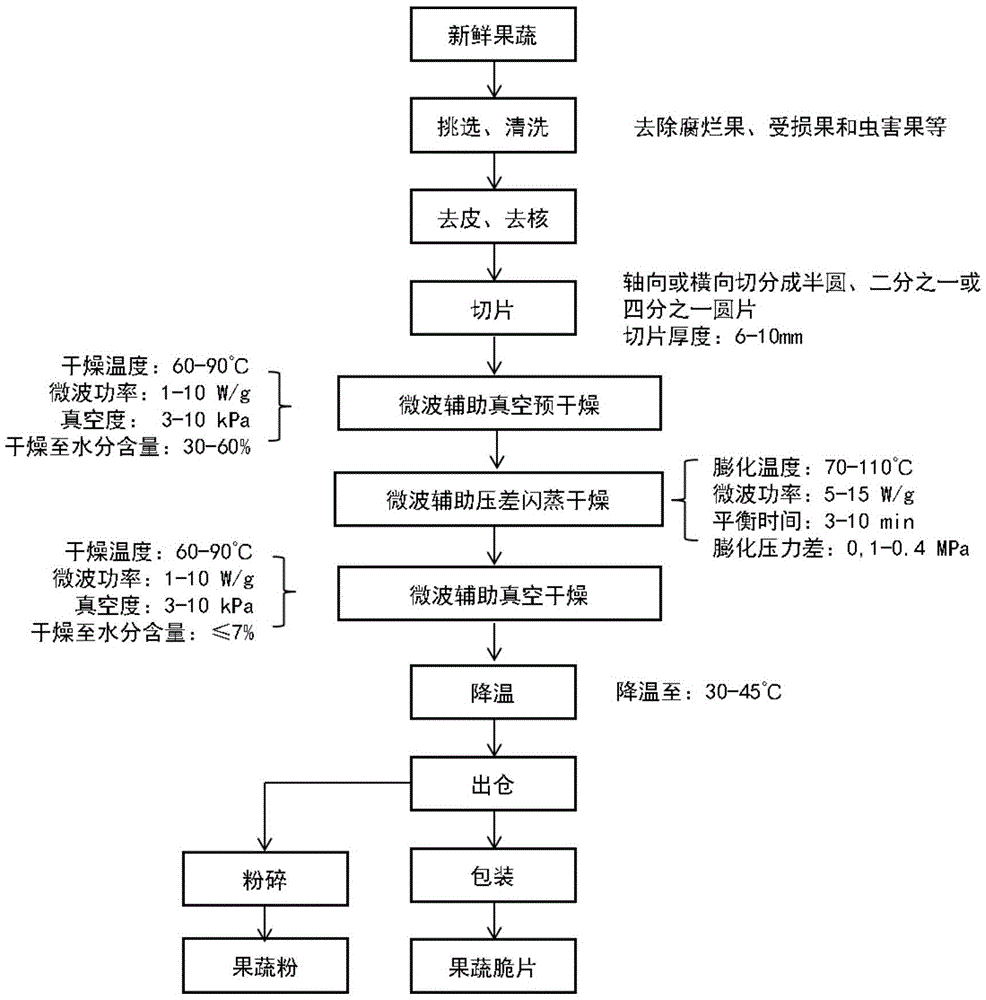

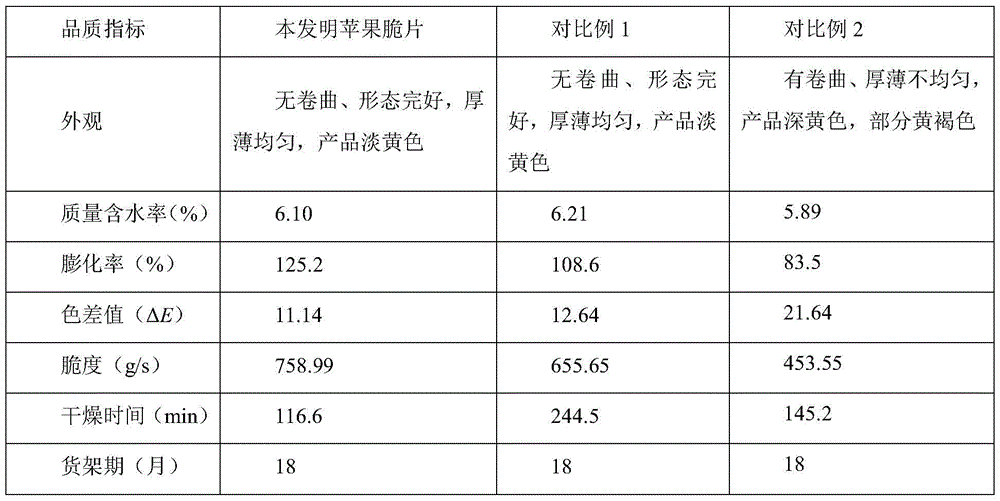

Fruit and vegetable crisp slice production method by using microwave assisted pressure-difference flash evaporation and drying

InactiveCN105533541AHigh expansion rateCrispy tasteFood thermal treatmentFood shapingPressure differencePre treatment

The present invention discloses a fruit and vegetable crisp slice production method by using microwave assisted pressure-difference flash evaporation and drying, comprising the following steps: (1) fruits and vegetables are sorted, washed, peeled, pitted and sliced to obtain fruit and vegetable slices; (2) the fruit and vegetable slices are subjected to pretreatment; (3) the pretreated fruit and vegetable slices are placed into a puffing cabin to conduct microwave assisted vacuum pre-driying; (4) the pre-dried semi-dried fruit and vegetable slices are subjected to microwave assisted pressure-difference flash evaporation and drying; and (5) the puffed fruit and vegetable slices are subjected to microwave assisted vacuum drying and the fruit and vegetable slices are dried to a final moisture content. The fruit and vegetable crisp slice has the following advantages: the drying efficiency of the fruit and vegetable slices is significantly shortened and the puffing degree and crispness of the fruit and vegetable slices are significantly improved. At the same time, the color and luster, and the nutrients of the raw materials are maintained. In addition, the production devices are mature and the production technology is simple. The present invention also provides the fruit and vegetable crisp slices and a fruit and vegetable powder using the fruit and vegetable crisp slices as raw materials.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

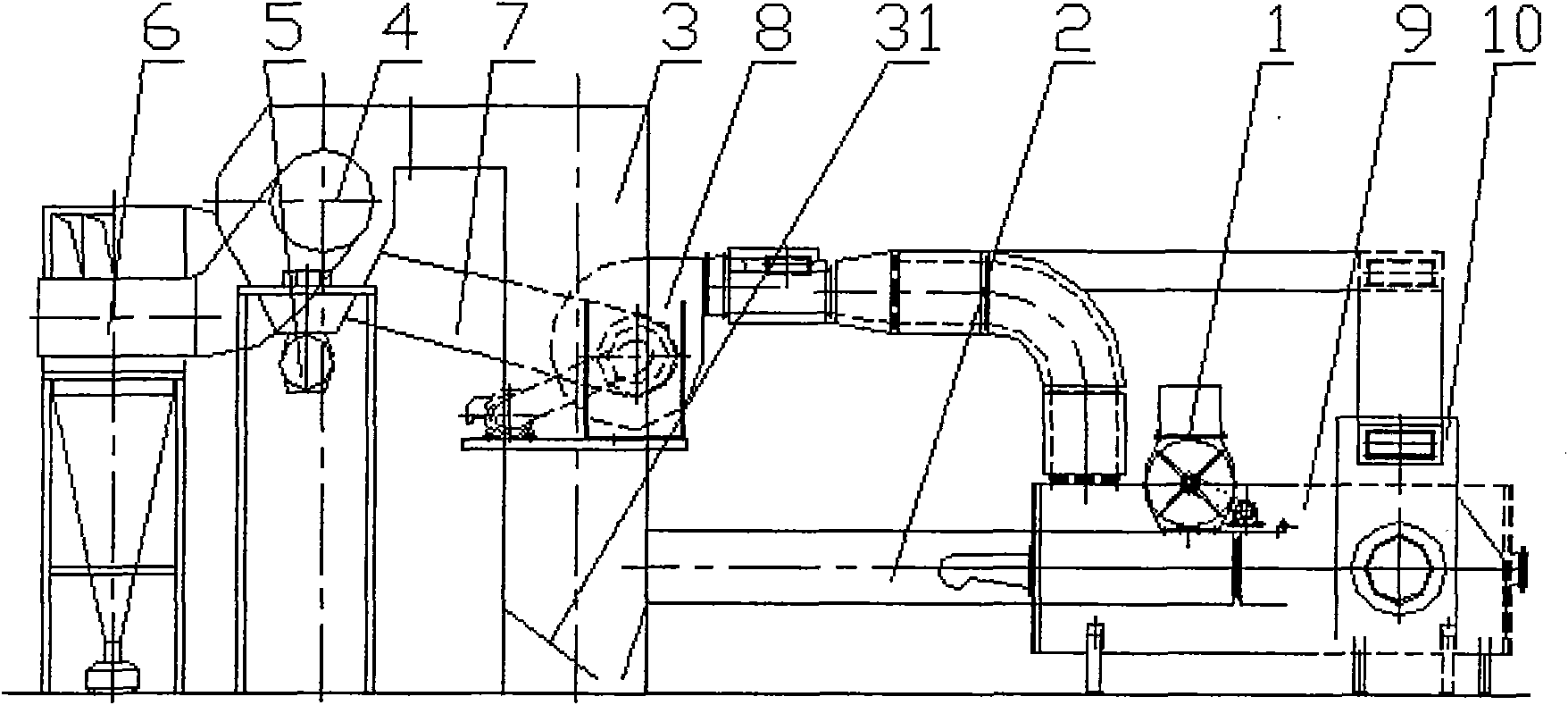

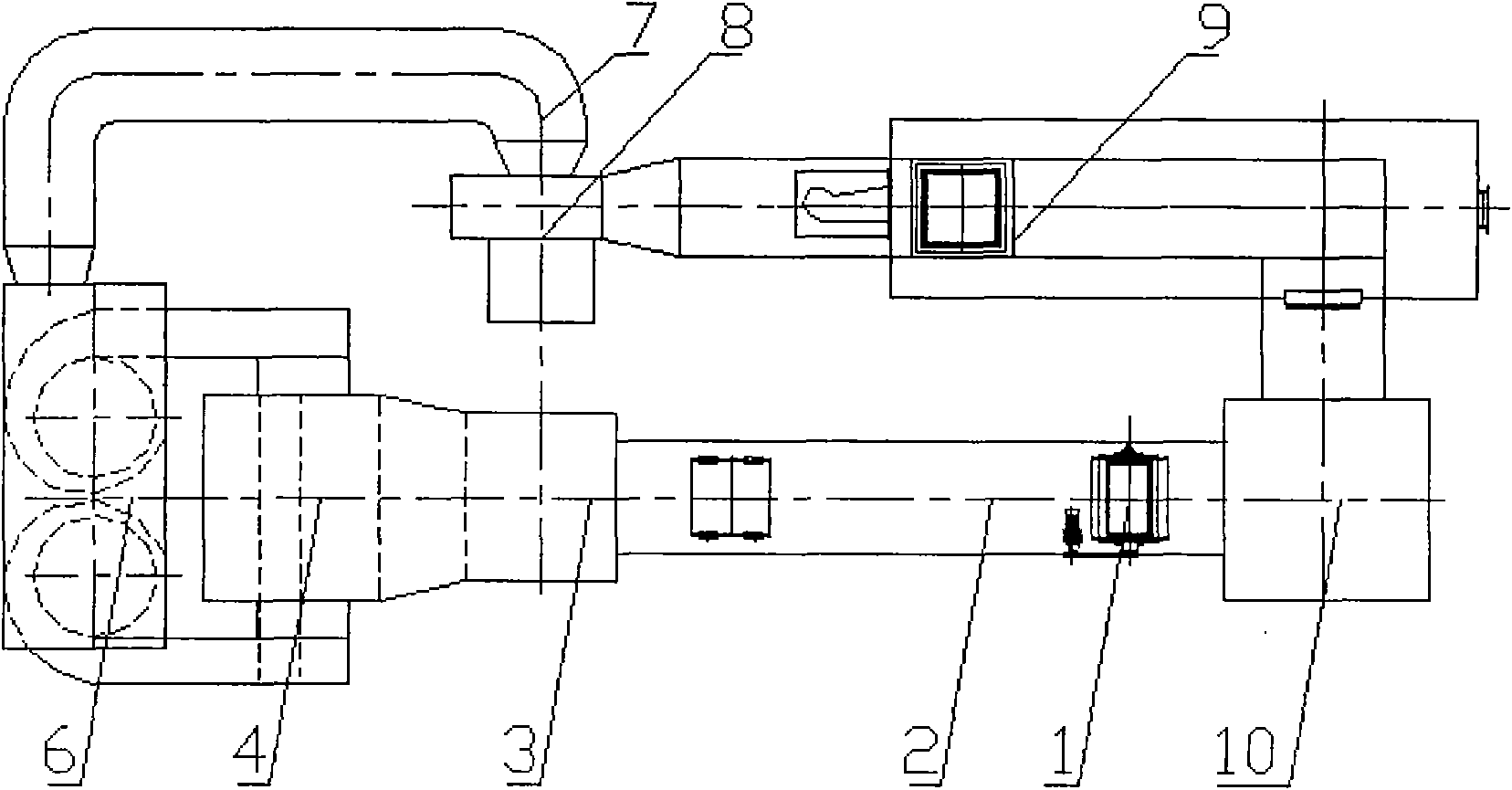

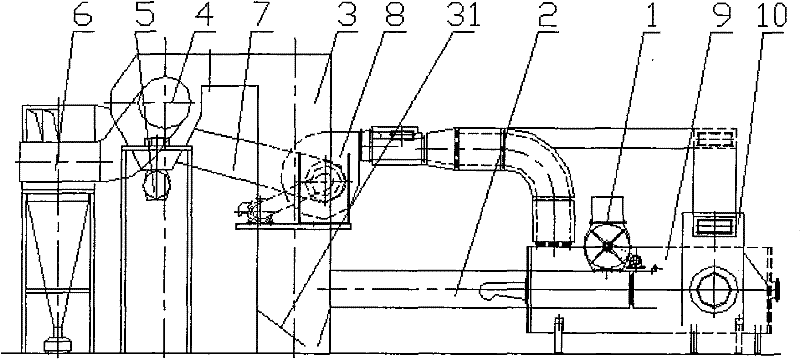

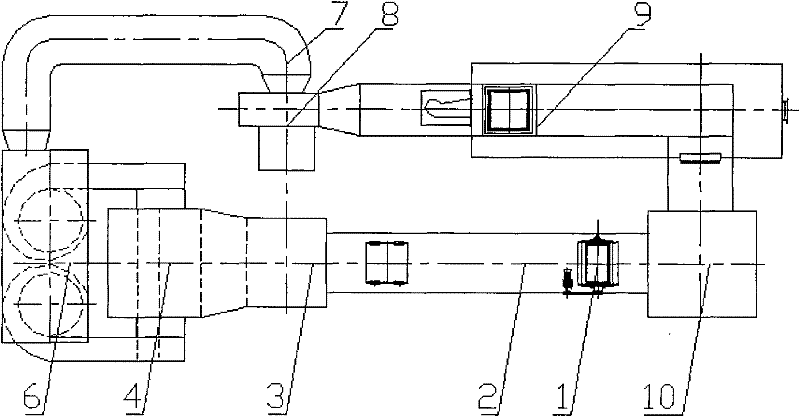

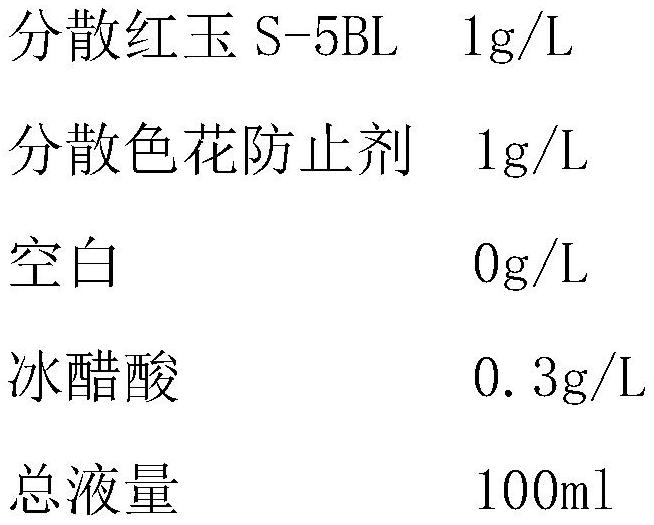

Tobacco material pneumatic drying process and equipment

ActiveCN101601500AShorten speedExtended drying timeTobacco preparationVolumetric Mass DensityEngineering

The invention provides a pneumatic drying method and equipment thereof for realizing large-flow tobacco material puffing drying treatment; the method comprises the following steps: puffed tobacco material is conveyed to a drying pipe for being dried by hot air flows, and then the tobacco material is separated from hot sir; the drying pipe is composed of a horizontal drying pipe and a vertical drying pipe of which the cross section is more than the cross section of the horizontal drying pipe; hot air with the temperature at 100-250 DEG C and air flow speed of10-50m / s of is sent in the horizontal drying pipe, wherein the air flow feeding direction is vertical to the material feeding direction; the material driven by hot air flows enters in the vertical drying pipe and is ascended in a suspension way, and the ascending speed of the material is reduced to 0.5-5m / s; meanwhile, sundries such as slivers with large density in the material can not be suspended and are separated pneumatically under the wind speed. By arranging the vertical drying pipe with large caliber, the speed of the material, moving upwards along the air flow direction, is reduced, on the premise of not increasing the drying route, the drying time of the material is prolonged, heat-transferring and mass transferring coefficient is improved, and the drying time of the material is improved.

Owner:ZHISI HLDG GRP

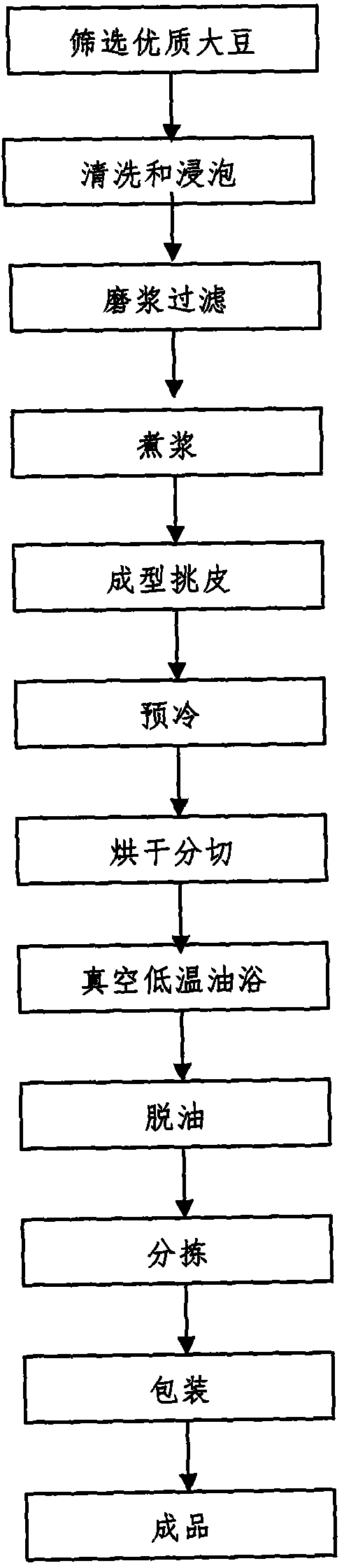

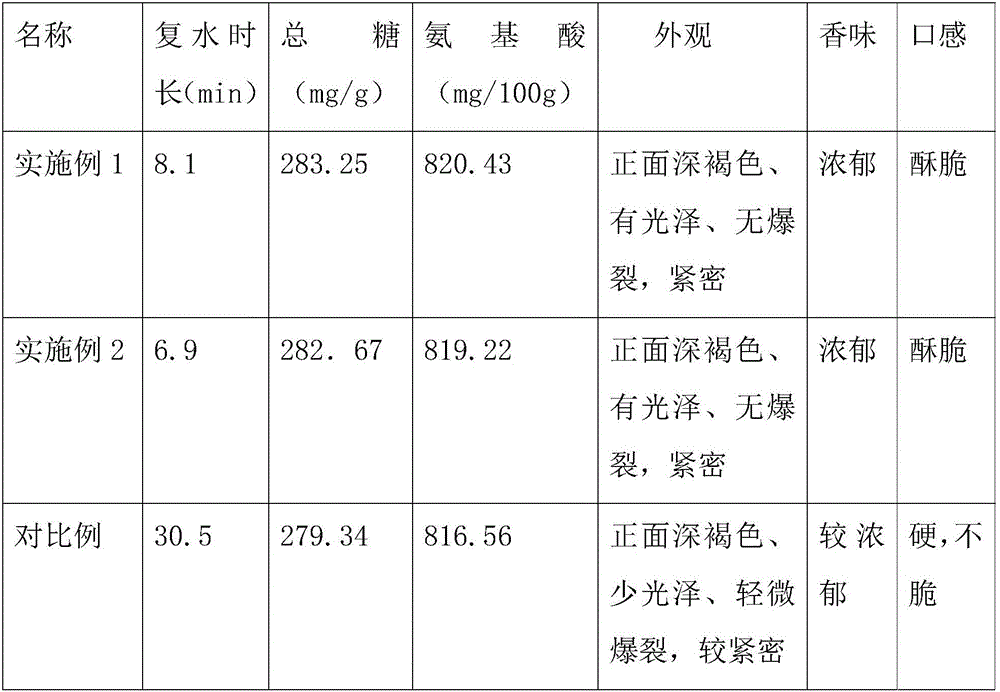

VF tofu skin crisp chips and preparation method thereof

InactiveCN103749737ANo side effectsNo adverse stimuliCheese manufactureFood scienceVitaminPre cooling

The invention discloses VF tofu skin crisp chips and preparation method of the VF tofu skin crisp chips. The preparation method of the VF tofu skin crisp chips comprises the following steps: taking high-grade soybeans as a raw material, cleaning, soaking and then grinding into thick liquid and filtering, boiling to form ripe thick liquid, continuously heating the ripe thick liquid in a dried beancurd sticks pot and maintaining at 85-90 DEG.C, forming and picking skin, pre-cooling, drying and cutting the formed skin, performing low-temperature oil bath in vacuum, wherein the low-temperature oil bath in vacuum condition is that the vacuum degree is 0.09 MPa, the temperature is 90-95 DEG.C, and the time is 20-25 min, and then performing the de-oiling treatment. The obtained tofu skin crisp chips are rich in soybean protein and a plurality of vitamin minerals, brilliant yellow in color, crisp in taste, high in nutrient value, and are optimal selection on leisure food in daily life of people.

Owner:BEIJING KAIDA HENGYE AGRI TECH DEV

Nutrient powder using crops as raw material

InactiveCN101416733AIncreased sensitivityPromote peristalsisFood preparationAdditive ingredientRed bean

The present invention discloses a nutrient powder suing coarse cereals comprising: millet, glutinous millet, rice-gruel, red bean, oat as raw materials, wherein the processing technology comprising removing impurities and skins of the millet, glutinous millet, rice-gruel, red bean and oat, aging by dry method, smashing the cured coarse cereals to mix and stir,, sterilizing at low temperature and packaging. The nutrient powder is characterized by rational mixture ratio, balanced nutrient composition, and scientific processing technology, wherein the red bean is matched with the millet, glutinous millet and rice-gruel in which the defect of lack in lysine is made up to complement nutrition, moreover, because of using the dry method to heat, the natural nutrient components in the millet, glutinous millet, rice-gruel are effectively protected with the functions of swelling and sterilizing. The foods processed by low-temperature sterilization and microwave can keep more nutrient components and flavours of colour, fragrance and taste, and the swelling function makes the nutrient powder fresh, fragrant, sticky, and sweet with good taste and absorption.

Owner:寿百文

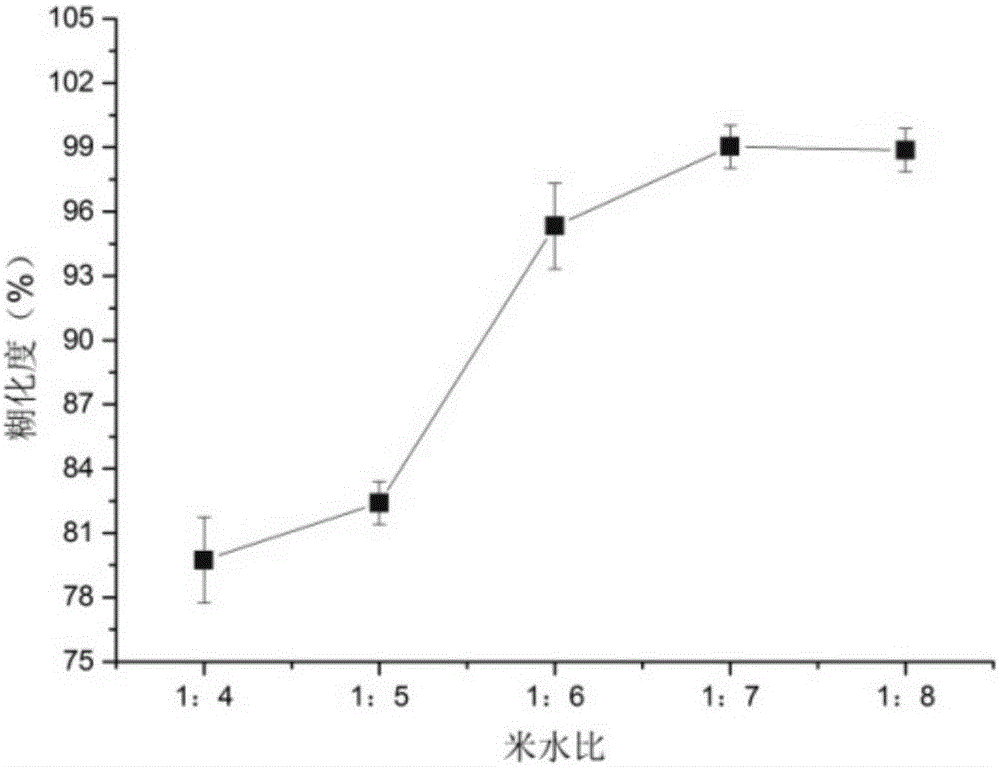

Method for improving production efficiency of rice cracker employing microwave and hot air combined drying

InactiveCN104431802AIncrease productivitySpeed up evaporationFood shapingFood preparationMicrowaveProcess engineering

The invention discloses a method for improving production efficiency of a rice cracker employing microwave and hot air combined drying, and belongs to the technical field of processing of rice puffed leisure foods. The method has the characteristics that formed green bodies of the rice cracker adopt a novel microwave and hot air combined drying process; rapid rise of internal temperature of the rice cracker is achieved by using the characteristics of internal microwave heating and high heating rate; meanwhile, the balance of mass and heat transfer of the green bodes in the drying process is enhanced by adopting forced convective drying of hot air; the moisture in the green bodies is rapidly and uniformly reduced to 12%-15% required for late baking from about 40% under the combined drying action; the drying time is shortened to tens of minutes from several hours, and thus the target of improving the production efficiency of the rice cracker is achieved; in addition, the microwave drying has a certain puffing effect on materials; the puffing degree of the rice cracker can be further improved; the product quality of the rice cracker is finally improved, and therefore, through the method for drying the green bodies of the rice cracker employing the microwave combined with hot air, so that the drying time can be shortened; the energy consumption for production is reduced; and the product quality is improved.

Owner:FUWA GROUP

Method for preparing beef liver powder

InactiveCN105105166ARemove fishy smellIncrease nutritional contentFood preparationSodium bicarbonateTemperature control

The invention discloses a method for preparing beef liver powder. The method includes the steps that 1, beef livers, shredded chicken, fat pork and onions are triturated in a triturating machine; 2, the triturated raw materials are put into a reaction kettle, water is added, the mixture is heated to 120 DEG C, and the temperature is reduced to 60 DEG C to 70 DEG C after heating is carried out for 60 minutes to 90 minutes; 3, the mixture obtained in the step 2 is placed into a colloid mill to be milled into slurry, then the slurry is pumped into another reaction kettle, emulsifying agents and TBHQ are added, and stirring is carried out for 10 minutes; corn starch is added when the temperature is adjusted to 50 DEG C to 60 DEG C, stirring is carried out for 15 minutes, sodium bicarbonate is added, and stirring is carried out for 5 minutes; then the mixture is triturated through the colloid mill to be loaded into a storage bucket for standby application; 4, the liquid in the storage bucket is poured into a storage device of a microwave drying device, the microwave drying device is started, the temperature is controlled to range from 140 DEG C to 145 DEG C, and sheet-shaped objects are obtained through an air cooling device and a smashing device after drying and sterilizing are carried out for 5 minutes to 8 minutes; 5, the sheet-shaped objects are placed into a smashing machine to be circularly smashed twice, powder obtained after smashing is filtered through a 60-mesh vibrating screen, and quantitative sealing packaging is carried out through a packaging machine.

Owner:魏志华

Method for drying cashmere loose fibers through radio frequency

ActiveCN105066595AUniform drying effectWon't hurtDrying using combination processesEngineeringHigh water content

The invention discloses a method for drying cashmere loose fibers through the radio frequency, and relates to a method for drying the cashmere loose fibers with the higher water content. The method includes the four steps including centrifugal dewatering, radio frequency drying, strong air exhausting and collecting packaging. Compared with the prior art, the cashmere fibers are dried through the radio frequency so that damage to the surface state and the internal structure of the cashmere fibers can be greatly reduced, and the after-drying moisture regain of the cashmere fibers can be accurately controlled; and meanwhile, the cashmere fibers have the puffing effect, and the physical characteristics such as the elasticity and the compliance of the cashmere fibers are improved.

Owner:CONSINEE GRP CO LTD

Ultrasonic supercritical-low temperature vacuum frying drying technology of mushroom

InactiveCN106804694AKeep the aromaPreserve the flavorFruits/vegetable preservation by heatingFruits/vegetable preservation by freezing/coolingNutritive valuesDeep frying

The invention provides an ultrasonic supercritical-low temperature vacuum frying drying technology of mushroom. The technology comprises the following steps: grading, cleaning and decontaminating fresh mushroom; (2) while ultrasonic treatment, putting the treated mushroom in the step (1) into a mixed solution of a Chinese herbal medicine complex enzyme, and taking out the mushroom after soaking treatment; (3) putting the mushroom through treatment in the step (2) in a sealing drying room, introducing carbon dioxide so that carbon dioxide reaches a super-critical state, and standing in an ultrasonic environment; (4) freezing the mushroom through treatment in the step (3) to be a solid state; (5) putting the mushroom through treatment in the step (4) at the temperature of 80 to 85 DEG C, and deep-frying for 20 to 50 min under the condition that the vacuum degree is -0.1 MPa; (6) after hot air drying on the mushroom through treatment in the step (5), cooling and packaging. According to the ultrasonic supercritical-low temperature vacuum frying drying technology of the mushroom provided by the invention, the prepared mushroom is pure in taste and good in frangibility, and the nutritive value of the fresh mushroom is basically maintained.

Owner:XUCHANG UNIV

Method for preparing raw purple potato flour in puffing drying mode at variable temperature and pressure difference

InactiveCN104938993ADissipate quicklyReduce degradationFood ingredient functionsFood preparationFood industryDrying time

Provided is a method for preparing raw purple potato flour in a puffing drying mode at variable temperature and pressure difference. The method comprises the steps that fresh purple potatoes are washed, peeled, sliced, soaked in color fixative and leached, purple potato slices are laid in a dry container, then the container is arranged in a variable temperature and pressure difference puffing tank for variable temperature and pressure difference puffing drying, and finally the dried purple potato slices are smashed and sieved to obtain the raw purple potato flour. The method is adopted for processing the raw purple potato flour, the drying rate is obviously increased, the preserving rate of pigment of the purple potatoes is high, the water absorption rate and oil absorption rate of the raw purple potato flour are greatly increased, the novel method is provided for processing the raw purple potato flour, and the application range in the food industry is further extended.

Owner:HUNAN AGRICULTURAL UNIV

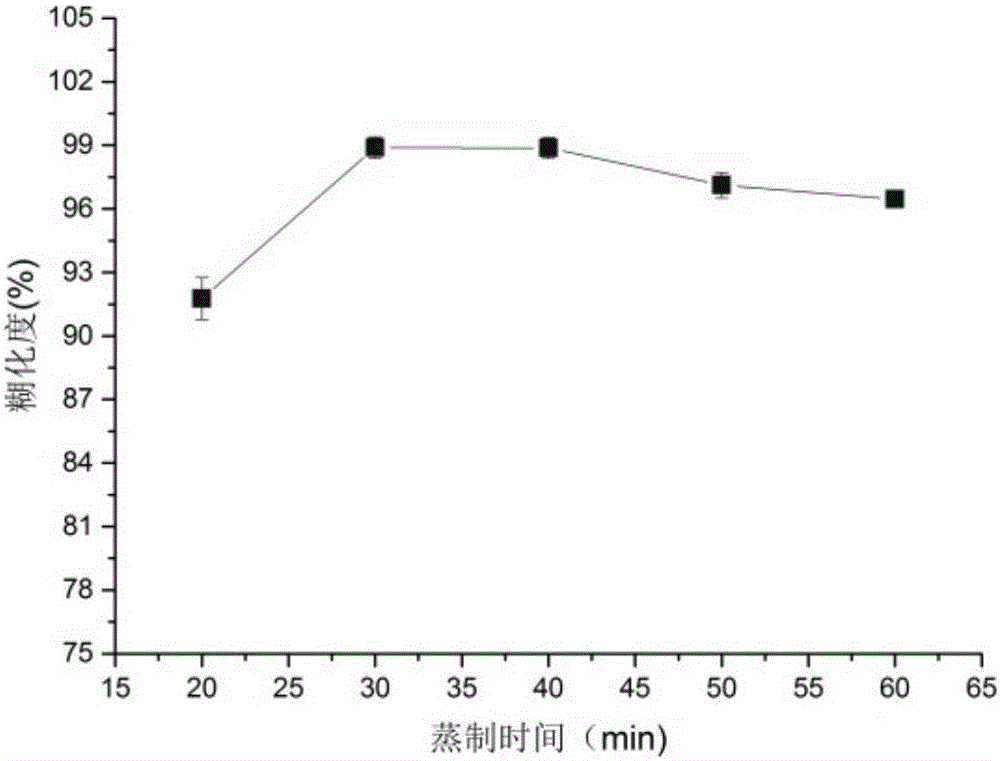

Variable temperature and pressure difference puffing and drying method to prepare purple sweet potato cooked full flour

InactiveCN105077075ADissipate quicklyReduce degradationFood preservationFood preparationFood industryPigment

The present invention discloses a variable temperature and pressure difference puffing and drying method to prepare purple sweet potato cooked full flour. The method comprises the following steps: fresh purple sweet potatoes are washed, the washed purple sweet potatoes are steamed, the steamed purple sweet potatoes are peeled, and the peeled purple sweet potatoes are smashed, an emulsifier is added into the smashed purple sweet potatoes, and the mixture is stirred evenly; then the smashed purple sweet potatoes are spread evenly and the spread smashed purple sweet potatoes are put into a variable temperature and pressure difference puffing tank to conduct variable temperature and pressure difference puffing and drying; and finally the puffed and dried purple sweet potatoes are crushed and the crushed purple sweet potatoes are sieved to obtain purple sweet potato cooked full flour. The puffing and drying method is used to process the purple sweet potato cooked full flour and significantly increases drying rate. The pigment saving rate of the purple sweet potato is high, and at the same time the water and oil absorption rates of the purple sweet potato cooked full flour are greatly improved. The variable temperature and pressure difference puffing and drying method provides a new method for the processing of the purple sweet potato cooked full flour and further expands the range of application ranges of the food industry field.

Owner:SHAOYANG FUMIN NATURAL PIGMENT CO LTD

Preparation method of stewed pork

The invention discloses a preparation method of stewed pork, which comprises the following steps: a, cutting fresh meat into strips, then salting the fresh meat by using common salt with the weight of 15 to 20 percent of that of the fresh meat, and dipping for 28 to 30 hours; b, marinating for 15 to 30 minutes in marinade with a temperature of 60 to 90 DEG C, so as to obtain the stewed pork; c, draining off the stewed pork after being placed into a microwave environment with the wave length of 319 mm to 337 mm, carrying out microwave treatment for 15 minutes, sterilizing and dewatering, and controlling the water content of the stewed pork within 30 to 35 percent; d, taking out the stewed pork for airing and cooling, and using a vacuum package machine for packing; e, putting the stewed pork well packed into a microwave environment with the wave length of 120 mm to 125 mm for microwave treatment for 15 minutes, carrying out secondary sterilization and putting into storage. The special formula and process for marinating, and the stewed pork is fresh and tasty and has tasty color. No preservative agent is added, the quality of stewed pork can be guaranteed for about 12 months, and the tincture and taste are kept to be excellent always.

Owner:巫溪县红池腊鲜食品有限公司

Processing technique for wild mushroom leisure food

InactiveCN106036812AReduce moisture contentWith puffing effectFood freezingFood dryingFlavorSide effect

The invention discloses a processing technique for wild mushroom leisure food. The processing technique for wild mushroom leisure food comprises the following steps: cleaning the wild mushroom; marinating and freezing, and then performing vacuum oil bath dewatering; and deoiling and finally seasoning, thereby acquiring a finished product. The processing technique has the beneficial effects that no chemical addition agent is added in the production process according to the processing technique for wild mushroom leisure food, so that no side effect is brought to the human body after people eat the food for a long time; according to the processing technique for wild mushroom leisure food, provided by the invention, the nutritional ingredients of the wild mushroom and auxiliary materials thereof are extremely maintained and the taste and flavor are excellent; and after the wild mushroom is frozen and subjected to vacuum oil bath dewatering, water content in the wild mushroom is ultra-low, so that the storage time is prolonged.

Owner:马丽

Vacuum dehydrated food and method for producing the same

InactiveCN101485487AReduce production energy consumptionLess investmentFood shapingReady to eatShrimp

The invention discloses a vacuum dehydrated food and a method for producing the same. The food comprises the following raw materials in weight portion: 30 to 40 portions of pork, 30 to 40 portions of beef, 30 to 40 portions of mutton, 5 to 15 portions of shrimp, 5 to 15 portions of fish, 5 to 15 portions of corns, 5 to 15 portions of beans, 30 to 40 portions of starch, 0.5 to 1.5 portions of seasonings and 0.5 to 1.5 portions of spices. The raw materials are premixed, the premixed mixture is processed into primary pretreated product in a strip, granular or flaky shape, and the primary pretreated product is processed in a vacuum kettle in a vacuum state into a crisp and delicious ready-to-eat product. The vacuum dehydrated food has the advantages of unique flavor, rich nutrients, long storage period and the like.

Owner:郭伟 +2

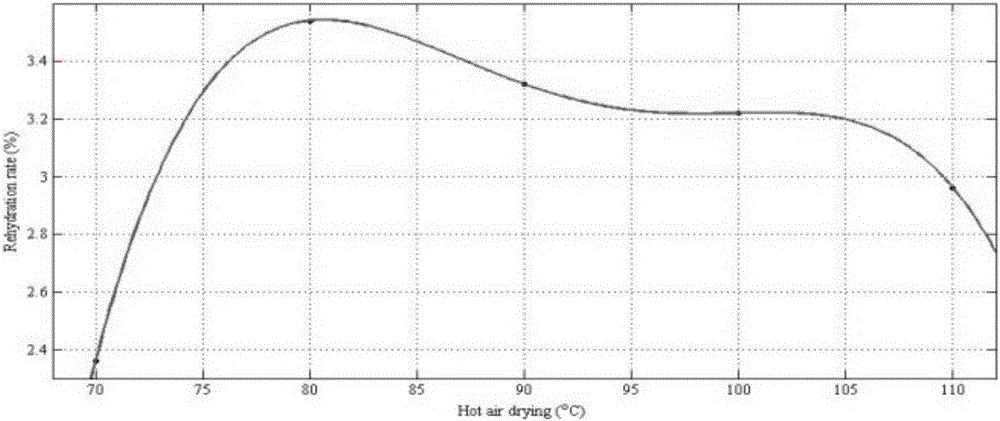

Drying method of convenient rice porridge

The invention belongs to the technical field of preparation of foods, and particularly relates to a drying method of convenient rice porridge. The drying method is a vacuum microwave drying method comprising the following steps of performing dry heat pretreatment, performing cooking in boiling water, performing constant-pressure steaming, performing spreading, performing vacuum microwave drying and the like. The convenient rice porridge is dried by the vacuum microwave drying method, and the drying method has the advantages that the drying time is short, the energy consumption is small, the rehydration rate is high, the organoleptic quality is good, the yield is high, and industrialized production is facilitated.

Owner:CHINA AGRI UNIV

Processing method of ready-to-eat stropharia rugosoannulata chips

The invention discloses a processing method of ready-to-eat stropharia rugosoannulata chips. The processing method comprises the following steps of step I, preparing raw materials; step II, performingprecooking and fixation; step III, performing centrifugation draining; step IV, performing vacuum impregnation; step V, performing low-temperature quick freezing; step VI, performing vacuum deep frying; step VII, performing vacuum oil removing; step VIII, performing cooling and seasoning; and step IX, performing inspection and package. The processing method is low in deep-frying temperature, lowin nutrient loss, and short in dehydrating time, original color and original properties of food materials can be maintained to the maximum extent, self fragrance and flavor of the food materials can be reserved, the ready-to-eat stropharia rugosoannulata chips have certain puffing effects, are low in oil consumption, and are not liable to oxidate, besides, the problems that stropharia rugosoannulata inferior goods are backward in processing manner and low in added value, are solved, besides, the defects that foods made by a conventional deep-frying method are poor in taste, are high in oil content, high in loss of nutrient substances and the like, are overcome, shape, color, flavor and nutrient value of the stropharia rugosoannulata are reserved, and the added value of products is increased.

Owner:山东三生万物生物科技有限公司

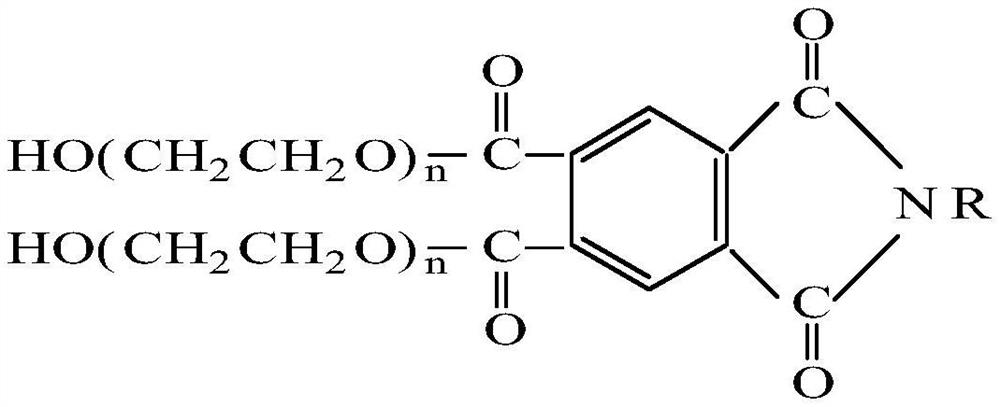

Environment-friendly repairing agent and performance contrast experiment process

InactiveCN111021106AWith puffing effectDisperse fastWeather/light/corrosion resistanceDyeing processDisperse dyeTextile printer

The invention belongs to the technical field of textile printing and dyeing processing, and particularly relates to an environment-friendly repairing agent and a performance contrast experiment process. The environment-friendly repairing agent is composed of a polyoxyethylene ether compound. The beneficial effects are that the solubility in water is good and the stability is high; the repairing agent has a swelling effect on fibers and can promote rapid dispersion and uniform permeation of dye in the fibers; the repairing agent has excellent dispersibility and extremely strong migration performance on the disperse dye dispersant and is continuously desorbed to generate obvious migration so that the dye on the cloth cover is uniformly distributed, and thus the ideal reconditioning effect ondyeing defects such as dyeing defects, color spots, streaks and the like formed on fabrics can be realized and the repairing agent is excellent in various fastnesses.

Owner:江苏斯潍德新材料科技有限公司

Nutrient powder using crops as raw material

InactiveCN101416733BPotent Natural NutrientsEffective protection of natural nutrientsFood preparationAdditive ingredientRed bean

The present invention discloses a nutrient powder suing coarse cereals comprising: millet, glutinous millet, rice-gruel, red bean, oat as raw materials, wherein the processing technology comprising removing impurities and skins of the millet, glutinous millet, rice-gruel, red bean and oat, aging by dry method, smashing the cured coarse cereals to mix and stir,, sterilizing at low temperature andpackaging. The nutrient powder is characterized by rational mixture ratio, balanced nutrient composition, and scientific processing technology, wherein the red bean is matched with the millet, glutinous millet and rice-gruel in which the defect of lack in lysine is made up to complement nutrition, moreover, because of using the dry method to heat, the natural nutrient components in the millet, glutinous millet, rice-gruel are effectively protected with the functions of swelling and sterilizing. The foods processed by low-temperature sterilization and microwave can keep more nutrient components and flavours of colour, fragrance and taste, and the swelling function makes the nutrient powder fresh, fragrant, sticky, and sweet with good taste and absorption.

Owner:寿百文

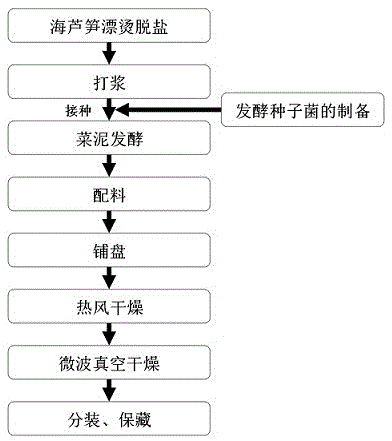

A kind of Lactobacillus plantarum strain jp-8 and application thereof

InactiveCN103642720BImprove qualityAchieve long-term storage and preservationBacteriaMicroorganism based processesBiotechnologyAsparagus adscendens

Owner:JIANGSU ACAD OF AGRI SCI +1

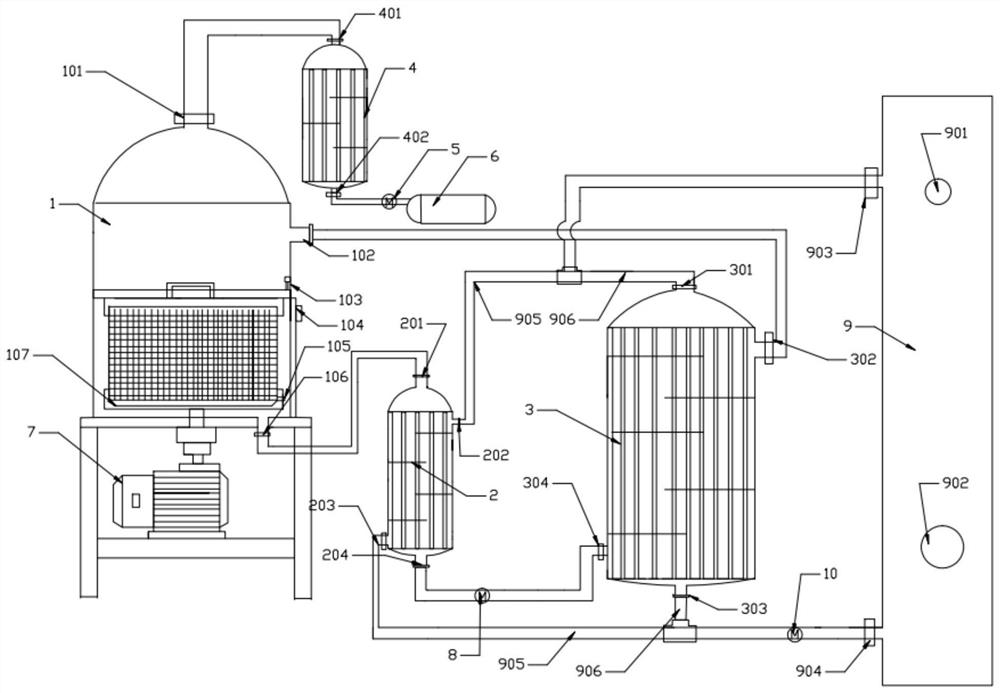

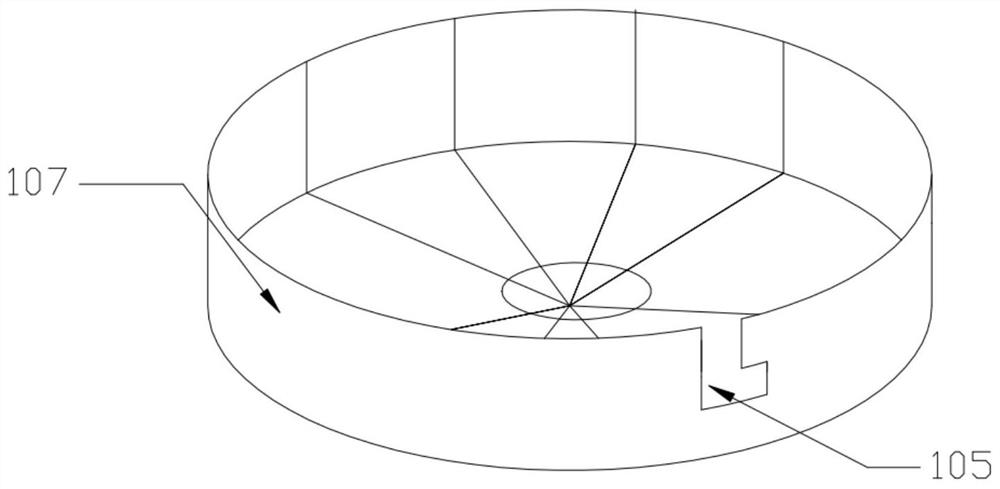

A kind of low-temperature vacuum frying equipment and processing method

The invention relates to the field of food processing equipment, in particular to a low-temperature vacuum frying equipment and processing method, comprising: a frying chamber, a water vapor heat source, an oil storage tank, a heating oil tank and a vacuum condensing device, the bottom of the frying chamber A pallet is arranged at the center, and the pallet is connected with the motor at the bottom. The low-temperature vacuum frying machine provided by the present invention can solve the problems of unstable oil temperature, excessive oil temperature, fruit and vegetable sticking, and complicated frying oil recovery. High quality, suitable for industrial production.

Owner:青岛六一机械有限公司 +1

Tobacco material pneumatic drying process and equipment

ActiveCN101601500BImprove the effect of puffing and dryingReach drying timeTobacco preparationThermodynamicsDrying time

Owner:ZHISI HLDG GRP

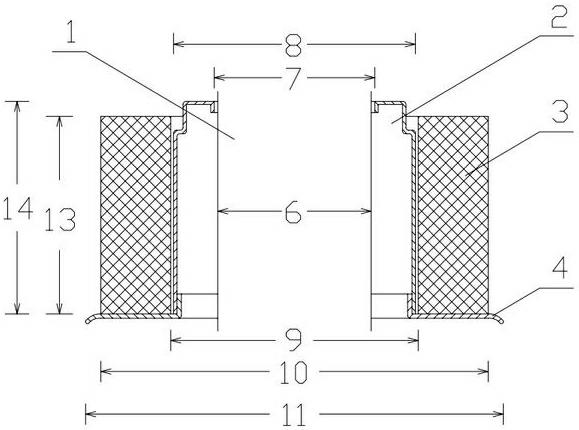

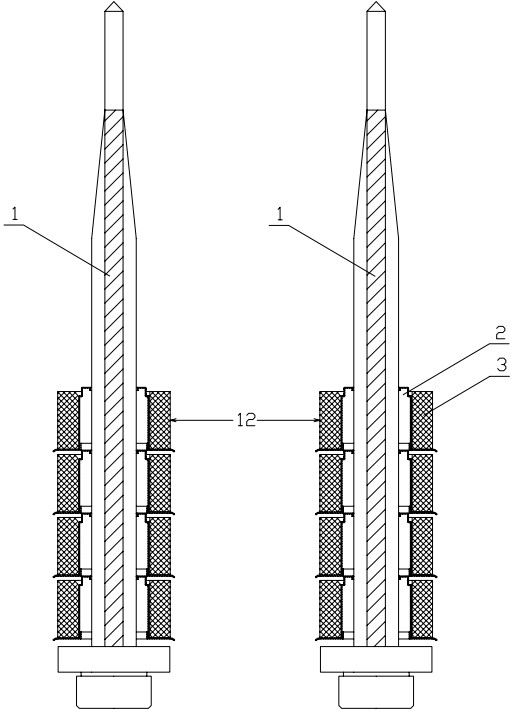

Wet spinning cake dyeing process of viscose filament yarns

ActiveCN102628204BUniform dyeingLow costLiquid/gas/vapor removal by centrifugal forceTextile treatment carriersPolymer scienceSpinning

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN +1

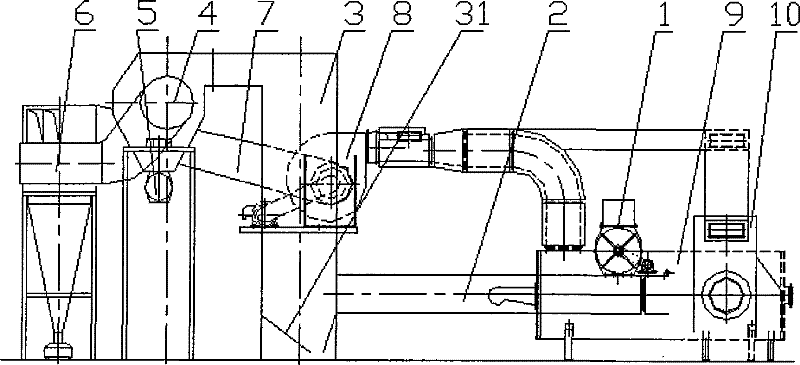

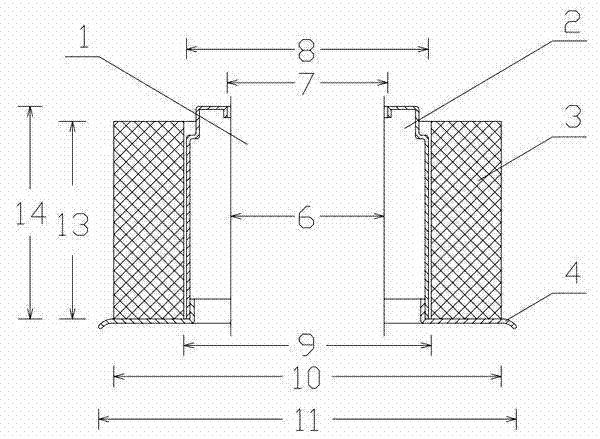

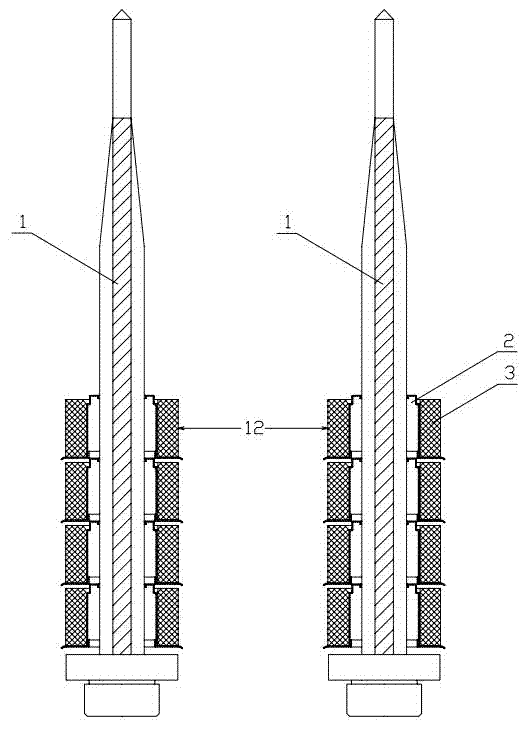

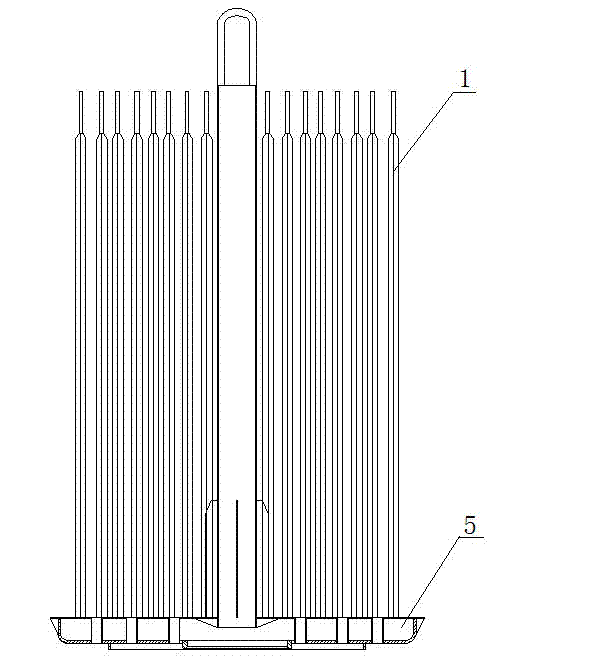

Dyeing process of dry spinning cakes of viscose filaments

ActiveCN102605577AUniform dyeingLow costLiquid/gas/vapor removal by centrifugal forceVegetal fibresYarnPolymer science

The invention discloses a dyeing process of dry spinning cakes of viscose filaments, belonging to the technical field of dyeing dry spinning cakes in the dyeing industry, wherein the process comprises the following steps of drying the spinning cakes, installing a cylinder liner, arranging a creel, pre-treating, dyeing, post-treating and tubing; the horizontal distance between outer sides of the dry spinning cakes on each two adjacent yarn posts is controlled at 2-50 mm in the process of arranging a creel; in the pre-treating process water is added into a dye vat to completely immerse the dry spinning cakes and swell the yarns; and the yarns are swollen until the pressure difference between the pressure at the outer side of the dry spinning cake and that in the cylinder liner is at least 0.6 kg. The sealability of the dry spinning cakes is maximized by adopting the complete technical scheme in the invention so as to achieve a uniform state for final dyeing; meanwhile, the efficiency of the whole dry spinning cake dyeing process can be improved; the production cost is greatly reduced; and pollution to the environment is reduced.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN +1

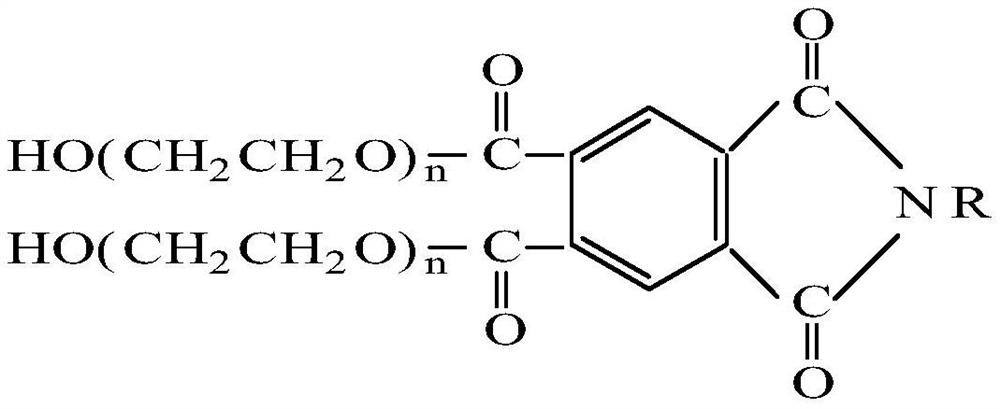

Preparation method of high-temperature leveling agent for polyester dyeing

The invention discloses a preparation method of a high-temperature leveling agent for polyester dyeing. The preparation method comprises the following steps: adding pyromellitic dianhydride into alkylamine and part of polyethylene glycol to carry out ring-opening amidation and esterification reaction; carrying out dehydration ring-closure reaction in a nitrogen atmosphere, so as to obtain N-alkyl-4-carboxyl-5-polyethylene glycol ester group-phthalimide; and carrying out dehydration esterification reaction on the N-alkyl-4-carboxyl-5-polyethylene glycol ester-phthalimide and the residual polyethylene glycol for 4-7 hours under the action of a catalyst methanesulfonic acid in a nitrogen atmosphere to obtain the product. According to the preparation method of the high-temperature leveling agent for polyester dyeing, which adopts the structure, the prepared high-temperature leveling agent for polyester dyeing has excellent dispersion and migration capacities on disperse dyes, and has a certain puffing effect on polyester fibers, so that the migration property of the dyes is further improved; the dye is easier to diffuse and uniformly migrate from the dye liquor to the interior of the fiber, and the problem of dyeing defects in the dyeing process is avoided.

Owner:浙江联胜新材股份有限公司

Microbial feed stirring and granulating integrated system

The invention provides a microbial feed stirring and granulating integrated system, and belongs to the field of feed processing. The system comprises a double-drum grinding roller, a spiral conveyingpipe, a stirrer, a fermentation tank and a spiral extruder. The double-drum grinding roller is provided with a feed hole and a discharge hole, and the discharge hole is connected with the fermentationtank. The spiral conveying pipe is mounted above the fermentation tank. The spiral conveying pipe is of a vertically-installed hollow cylindrical structure, the top end of the spiral conveying pipe is an outlet, and the bottom end of the spiral conveying pipe is an inlet. The inlet is connected with the fermentation tank. A magnetron is mounted in the spiral conveying pipe. The outlet faces the screw extruder. An ultrasonic vibrator is arranged in the fermentation tank. According to the microbial feed stirring and granulating integrated system, through the effects of grinding, fermentation, microwave treatment and extrusion molding, materials can conveniently enter the fermentation tank to be fermented, moisture in the fermented feed can be transpired and exploded, good sterilization anddisinfection effects are achieved, a certain puffing effect can be achieved, and a good feed preparation effect is achieved.

Owner:金银卡(广州)生物科技股份有限公司

Dyeing process of dry spinning cakes of viscose filaments

ActiveCN102605577BUniform dyeingLow costLiquid/gas/vapor removal by centrifugal forceVegetal fibresYarnPolymer science

The invention discloses a dyeing process of dry spinning cakes of viscose filaments, belonging to the technical field of dyeing dry spinning cakes in the dyeing industry, wherein the process comprises the following steps of drying the spinning cakes, installing a cylinder liner, arranging a creel, pre-treating, dyeing, post-treating and tubing; the horizontal distance between outer sides of the dry spinning cakes on each two adjacent yarn posts is controlled at 2-50 mm in the process of arranging a creel; in the pre-treating process water is added into a dye vat to completely immerse the dry spinning cakes and swell the yarns; and the yarns are swollen until the pressure difference between the pressure at the outer side of the dry spinning cake and that in the cylinder liner is at least 0.6 kg. The sealability of the dry spinning cakes is maximized by adopting the complete technical scheme in the invention so as to achieve a uniform state for final dyeing; meanwhile, the efficiency of the whole dry spinning cake dyeing process can be improved; the production cost is greatly reduced; and pollution to the environment is reduced.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN +1

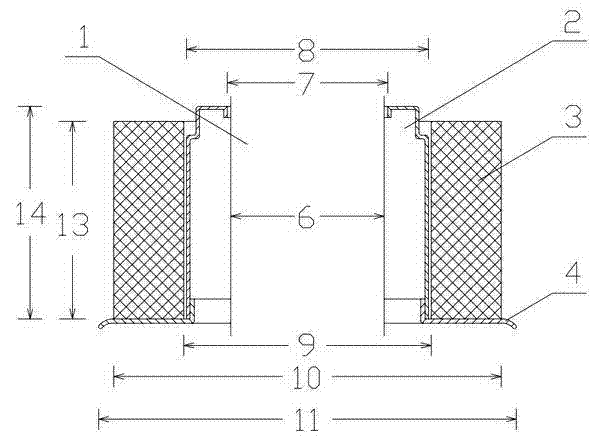

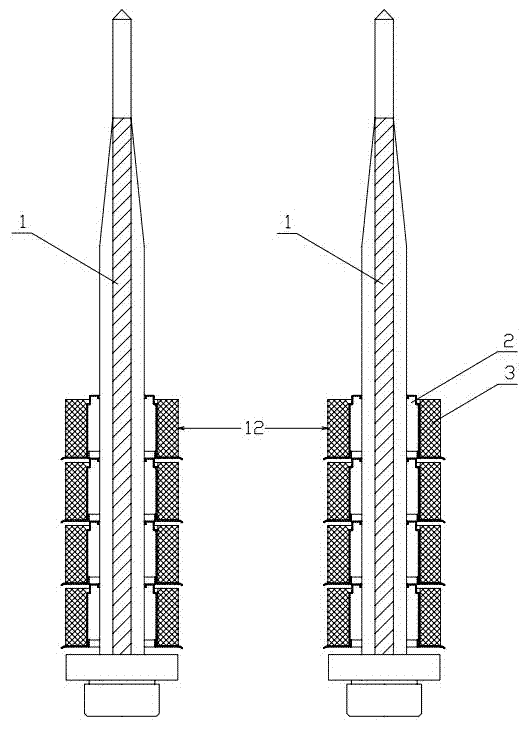

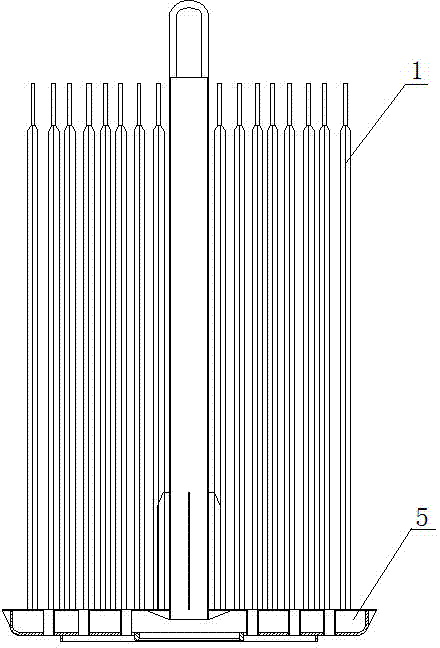

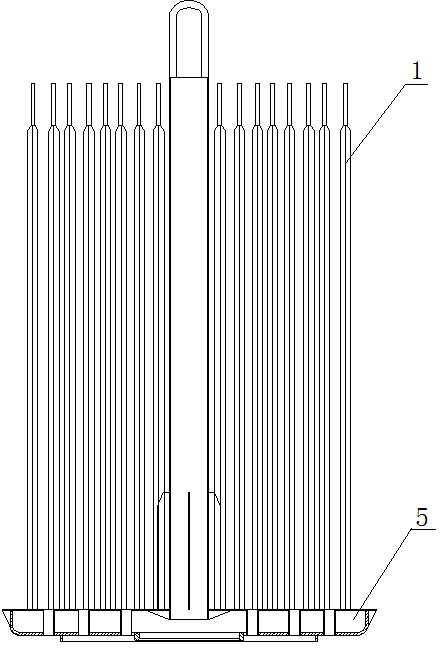

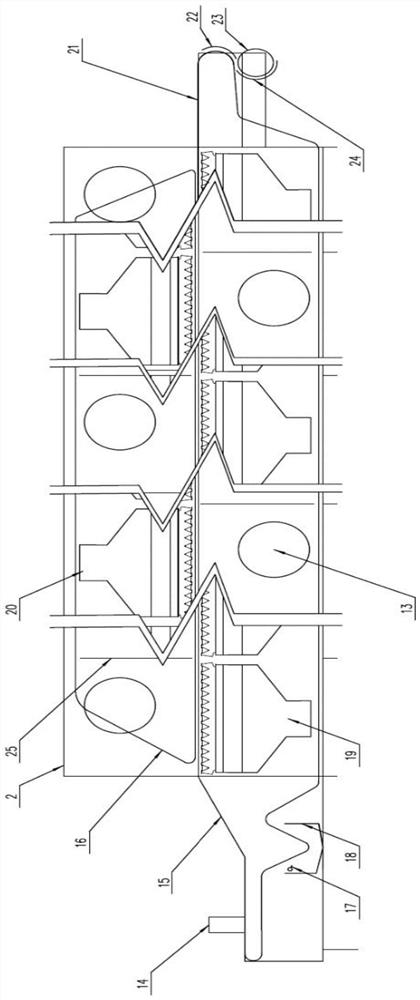

Non-fried high-temperature air micro-puffed instant noodle drying system

PendingCN114440608AWith puffing effectAvoid healthDrying gas arrangementsDrying chambers/containersFried noodlesProcess engineering

The invention discloses a non-fried high-temperature air micro-puffed instant noodle drying system. The drying box is formed by connecting at least two or more non-fried high-temperature air micro-puffed instant noodle drying box units in series. The drying box unit comprises a drying box body, the middle part in the box body is provided with a conveying assembly on which a noodle box is arranged, drying cabins are arranged above and below the conveying assembly, and a drying assembly is arranged in the drying cabin above or below the noodle box; the drying assembly comprises an air source, an air pipe and an air bellow, a heat exchanger or a heating unit and an air uniformizing box are arranged at the front end of the air bellow, and an air supply nozzle array used for drying instant noodles in the noodle box is arranged on a panel at the front end of the air uniformizing box. Instant noodles baked by the system have a certain puffing effect, micropores are formed in the sections of the noodles, the noodles do not shrink, and the instant noodles can be eaten after being soaked with boiled water. The health problem of fried noodles worried by people is solved, and the problems that non-fried noodles in the market at the present stage are poor in rehydration property, and various potatoes, rice flour and other food materials which are not easy to digest by intestines and stomach are added are also solved.

Owner:TIANJIN SHENGZHIHE FOOD CO LTD

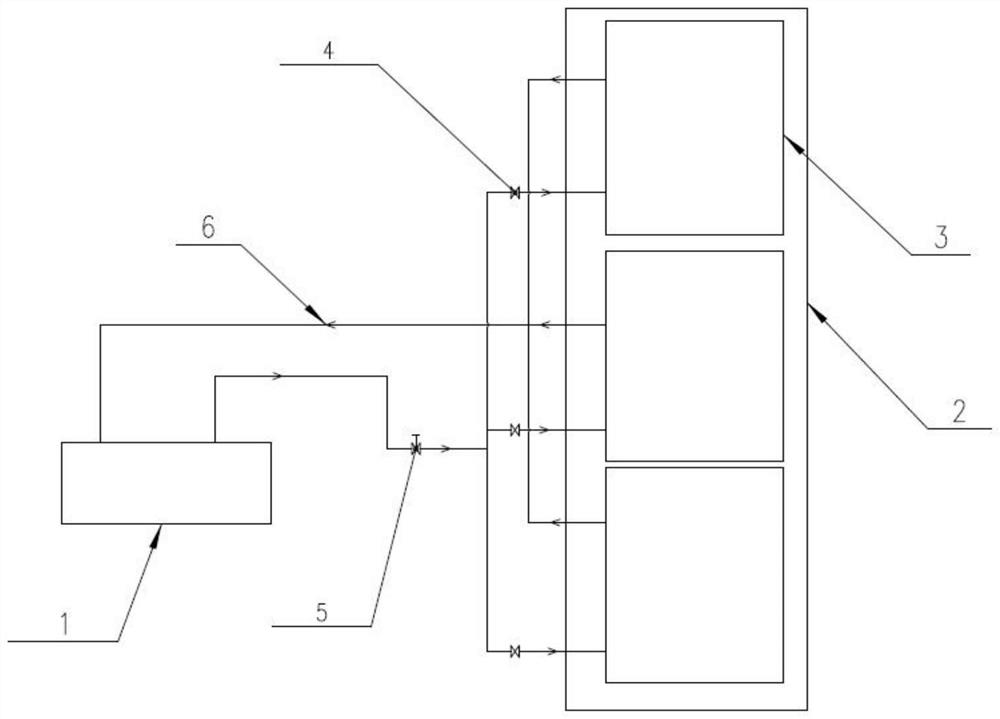

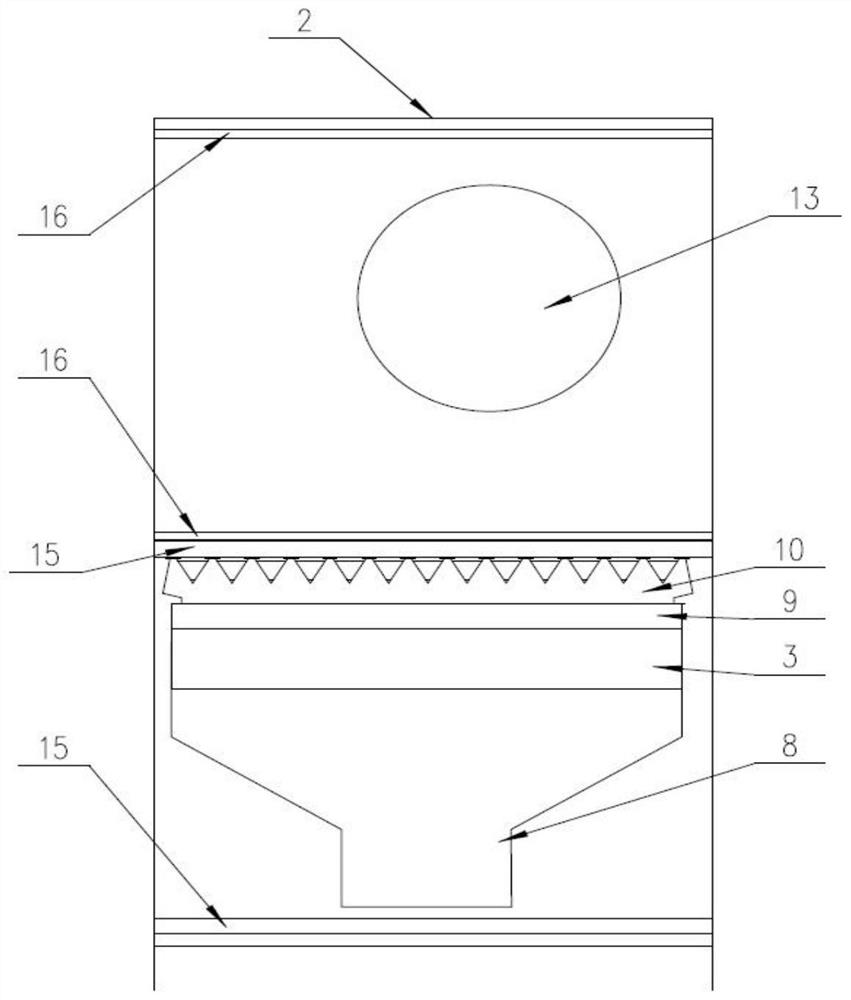

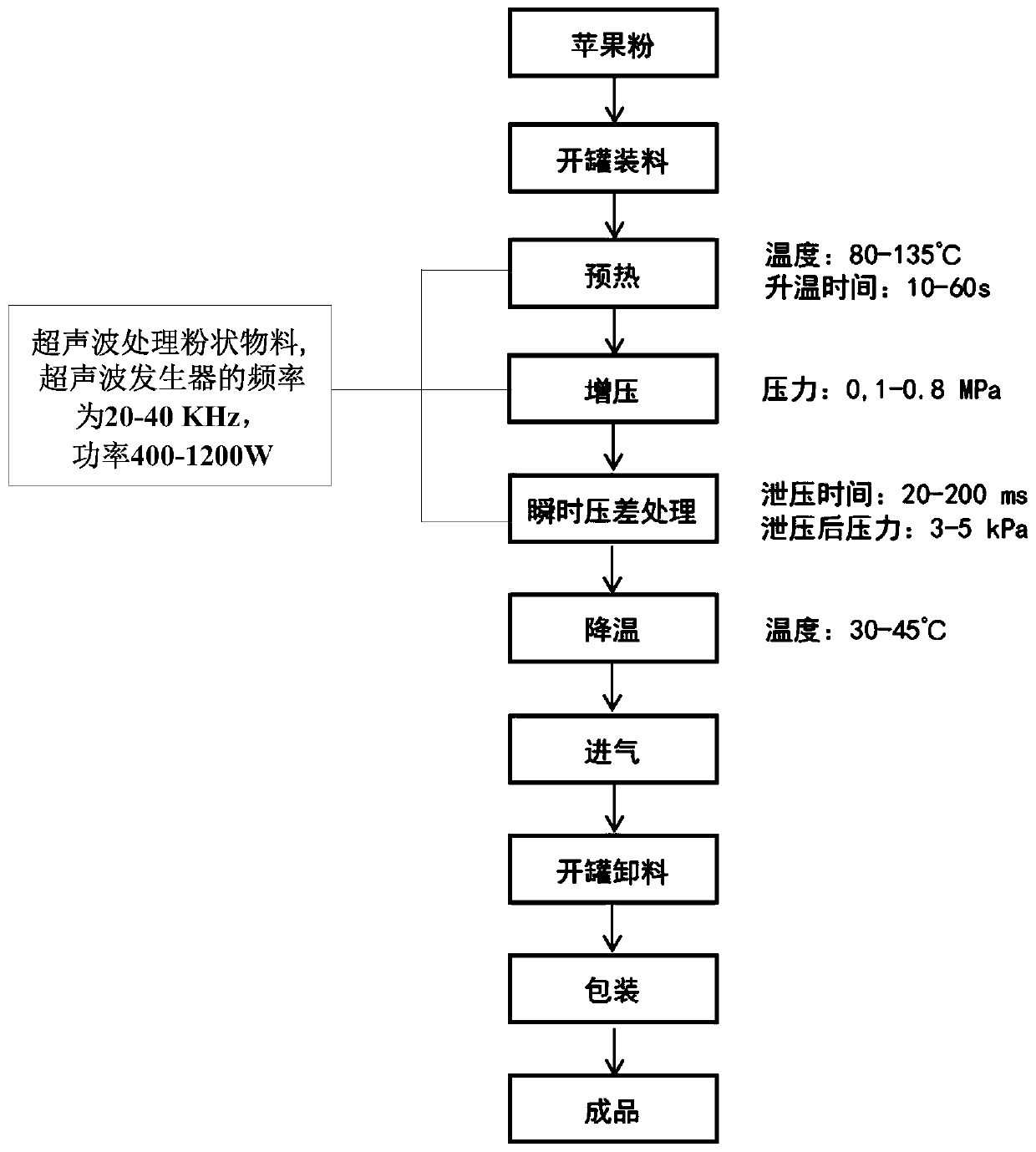

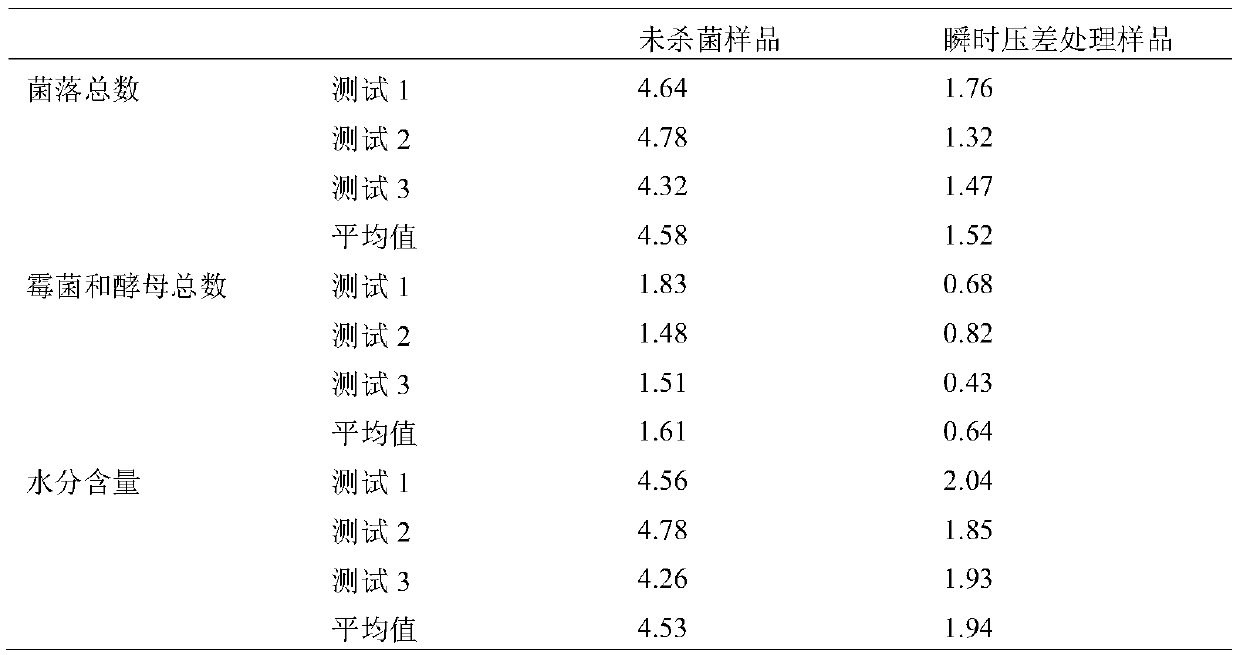

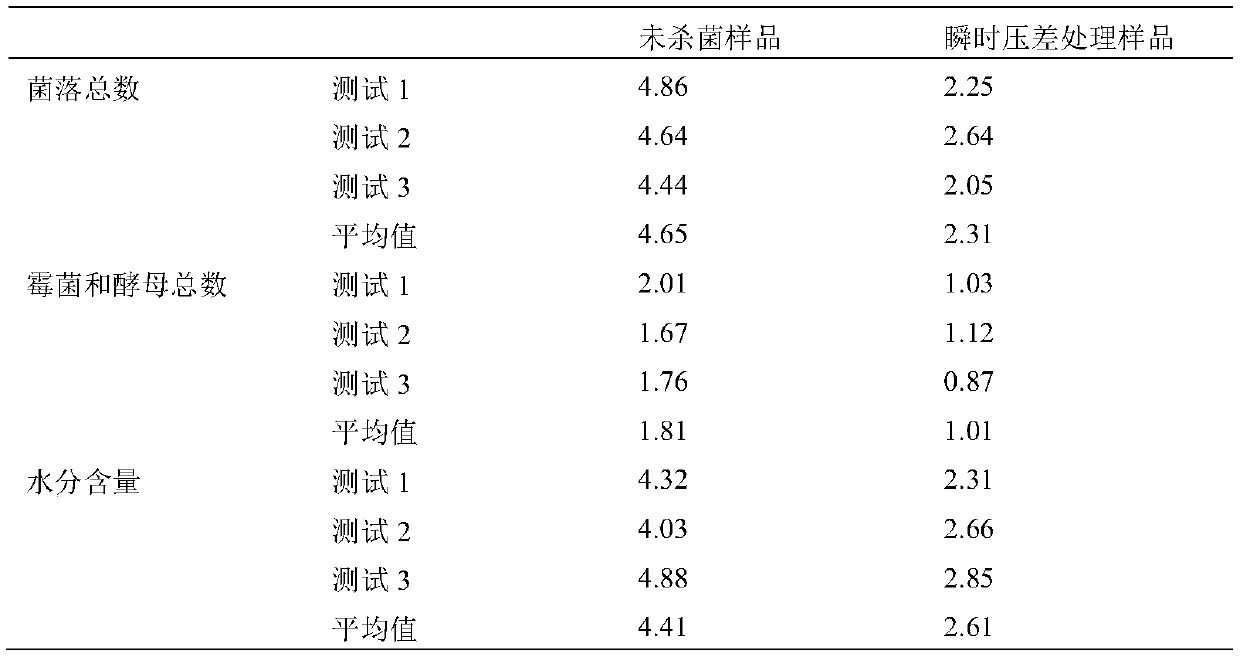

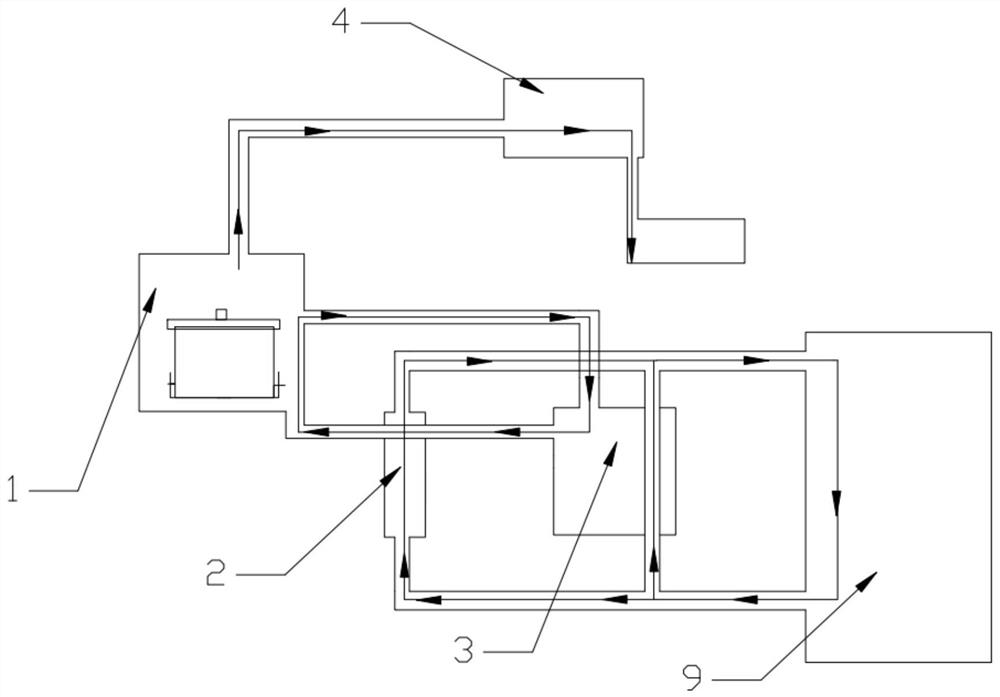

Instantaneous Pressure Difference Sterilization Method and Its Application in Apple Powder Sterilization

ActiveCN106261457BImprove penetration efficiencyIncrease flash volumeFood preservationChemical residueSurgery

The invention discloses an instantaneous differential pressure sterilization method. The instantaneous differential pressure sterilization method comprises the following steps of preheating: powdery materials are preheated to 80 to 135 DEG C within 10 to 60 s; pressurizing: the pressure of a processing bin in which the preheated powdery materials are put is increased to 0.1 to 0.8 MPa within 10 to 90 s; depressurizing: the pressure of the processing bin in which the preheated powdery materials are put is reduced to 3 to 5 kPa within 20 to 200 ms, wherein ultrasonic wave is used for treating the powdery materials during the preheating, pressurizing and depressurizing processes. The invention further discloses an application of the instantaneous differential pressure sterilization method to apple powder sterilization. According to the sterilization method disclosed by the invention, sterilization is completed by adopting the change of instantaneous differential pressure of the preheated powdery materials, and the sterilization method belongs to physical sterilization and has the advantages of no chemical residue, short sterilization time and thoroughness in sterilization; in addition, instantaneous differential pressure sterilization equipment has the advantages of low.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Low-temperature vacuum frying equipment and processing method that are easy to control temperature

ActiveCN111066834BGood lookingMaintain colorOven air-treatment devicesOil/fat bakingTemperature controlProcess engineering

Owner:青岛六一机械有限公司 +1

A method of drying cashmere loose fibers using radio frequency

ActiveCN105066595BUniform drying effectWon't hurtDrying using combination processesEngineeringHigh water content

Owner:CONSINEE GRP CO LTD

Vacuum dehydrated food and method for producing the same

InactiveCN101485487BReduce production energy consumptionLess investmentFood shapingFlavorReady to eat

The invention discloses a vacuum dehydrated food and a method for producing the same. The food comprises the following raw materials in weight portion: 30 to 40 portions of pork, 30 to 40 portions of beef, 30 to 40 portions of mutton, 5 to 15 portions of shrimp, 5 to 15 portions of fish, 5 to 15 portions of corns, 5 to 15 portions of beans, 30 to 40 portions of starch, 0.5 to 1.5 portions of seasonings and 0.5 to 1.5 portions of spices. The raw materials are premixed, the premixed mixture is processed into primary pretreated product in a strip, granular or flaky shape, and the primary pretreated product is processed in a vacuum kettle in a vacuum state into a crisp and delicious ready-to-eat product. The vacuum dehydrated food has the advantages of unique flavor, rich nutrients, long storage period and the like.

Owner:郭伟 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com