Non-fried high-temperature air micro-puffed instant noodle drying system

A high-temperature air, instant noodle technology, applied in drying, dryer, progressive dryer and other directions, can solve the problems of loss of wheat flavor, lack of nutrition, single nutritional structure of fried instant noodles, etc., and achieve the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

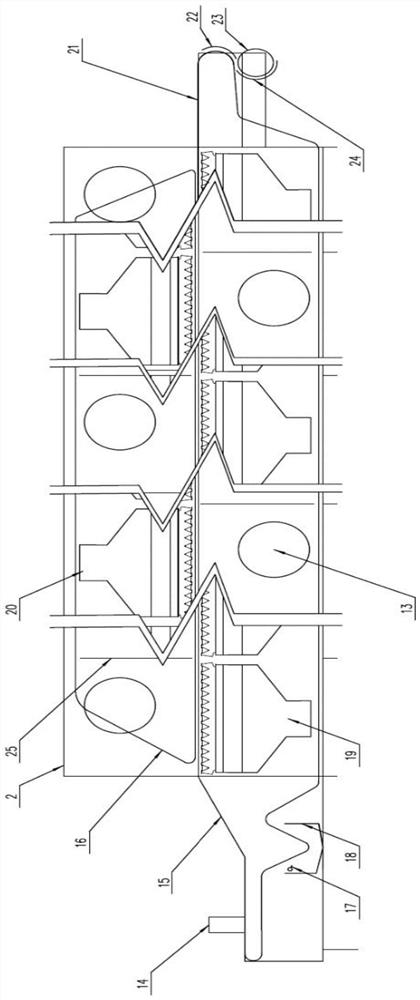

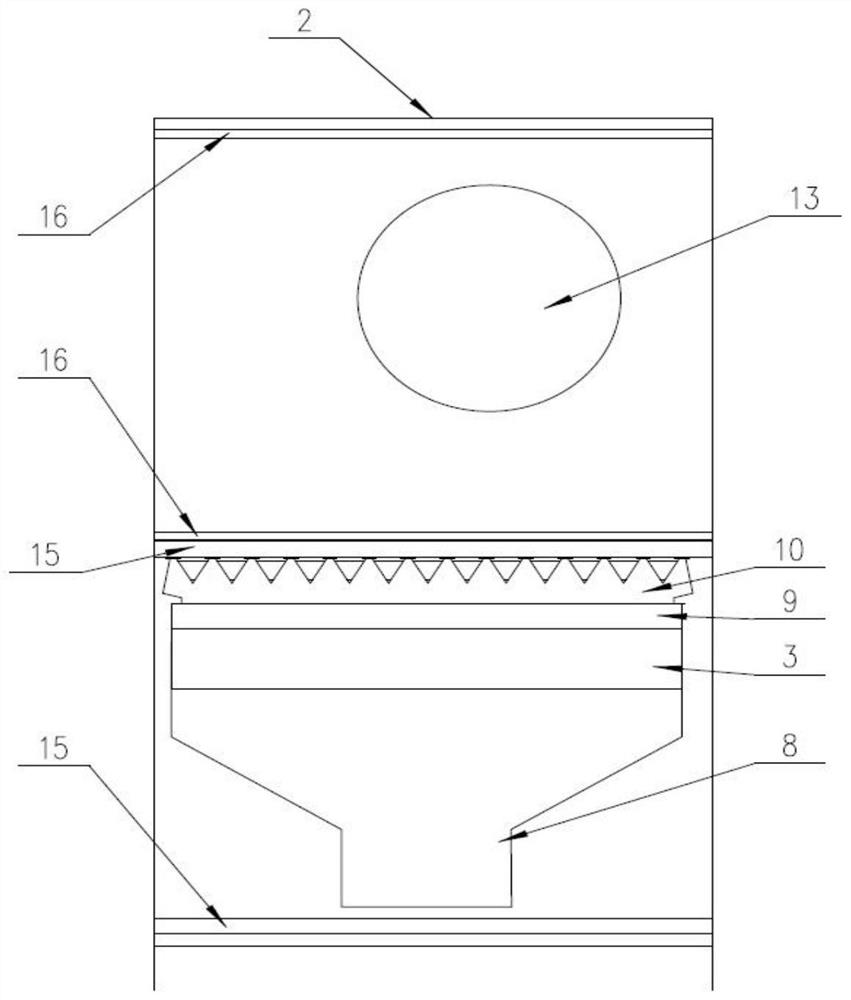

[0036] Example 1: Drying box unit

[0037] Such as Figure 3 to Figure 6As shown, a non-fried high-temperature air micro-expanded instant noodle drying box unit includes a drying box body 2, and the middle part of the drying box body is provided with a transmission assembly with a noodle box on it, and the transmission assembly includes Ring-shaped transmission chain, on which a noodle box 15 is fixed, and a noodle box cover 16 is arranged above the noodle box. The set sprocket assembly (the prior art, omitted in the figure) makes the noodle box transmission chain circulate in the box.

[0038] The top and bottom of the conveying assembly are set as drying chambers, and the drying chamber above or below the noodle box is provided with a drying assembly (wherein, when the drying assembly is arranged above the noodle box conveying assembly, it is called upper air supply, such as Figure 5 and Figure 6 shown; when the drying assembly is set under the noodle box conveyor assem...

Embodiment 2

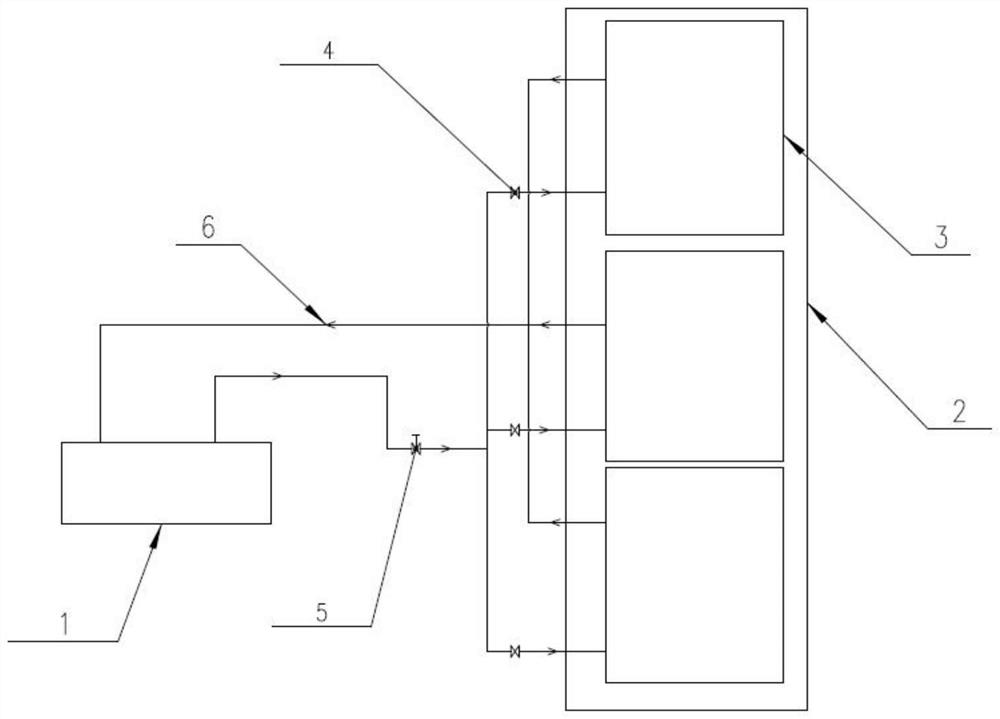

[0048] Example 2: drying system

[0049] Such as figure 1 As shown, a kind of non-fried high-temperature air micro-puffed instant noodle drying system provided by the present invention, said system is provided by at least two and above (as 10 to 20) non-fried high-temperature air micro-puffed instant noodles provided by embodiment 1 The drying box units are connected in series.

[0050] In the drying box unit, a part of the drying assembly in the drying cabin is arranged above the noodle box conveying assembly to form an upper air supply drying box unit 20, and the other part arranges the drying assembly in the drying cabin on Below the face box conveying assembly, constitute the air-supply drying box unit 19, between each unit is the air bin partition 25 (equivalent to the casing wall).

[0051] During work, the cut noodles first fall into the noodle box 15, are sorted by the pneumatic noodle trimmer 14, and then enter the drying chamber of the drying box unit through the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com