Drying method of convenient rice porridge

A drying method and drying technology, applied in food science, food preservation, application, etc., can solve the problems of unsuitability for industrial production, high energy consumption, and long drying time, and achieve the advantages of industrial production, good sensory quality, and long drying time short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Material: high-quality japonica rice with full grains and cleanness.

[0029] Equipment: induction cooker, vacuum microwave dryer, steamer, electronic balance.

[0030] The specific steps are:

[0031] (1) Dry heat pretreatment: select high-quality japonica rice that is clean, free of sand, gravel, and bran hulls, and other impurities. Rice bran, gravel, and iron filings need to be removed during screening, and then roasted at 60°C for 30 minutes;

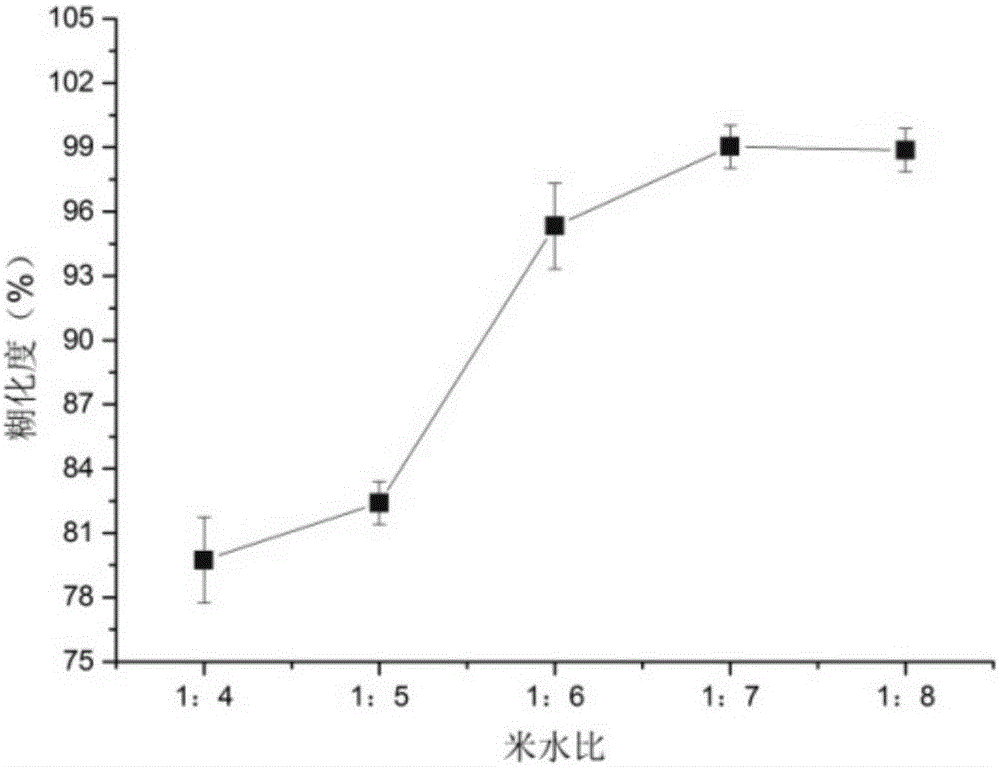

[0032] (2) Boil in boiling water: add the round-grained rice after the dry heat pretreatment into boiling water, and stop heating until the grains of rice have no hard core; wherein, the mass ratio of boiling water to round-grained rice is 5:1;

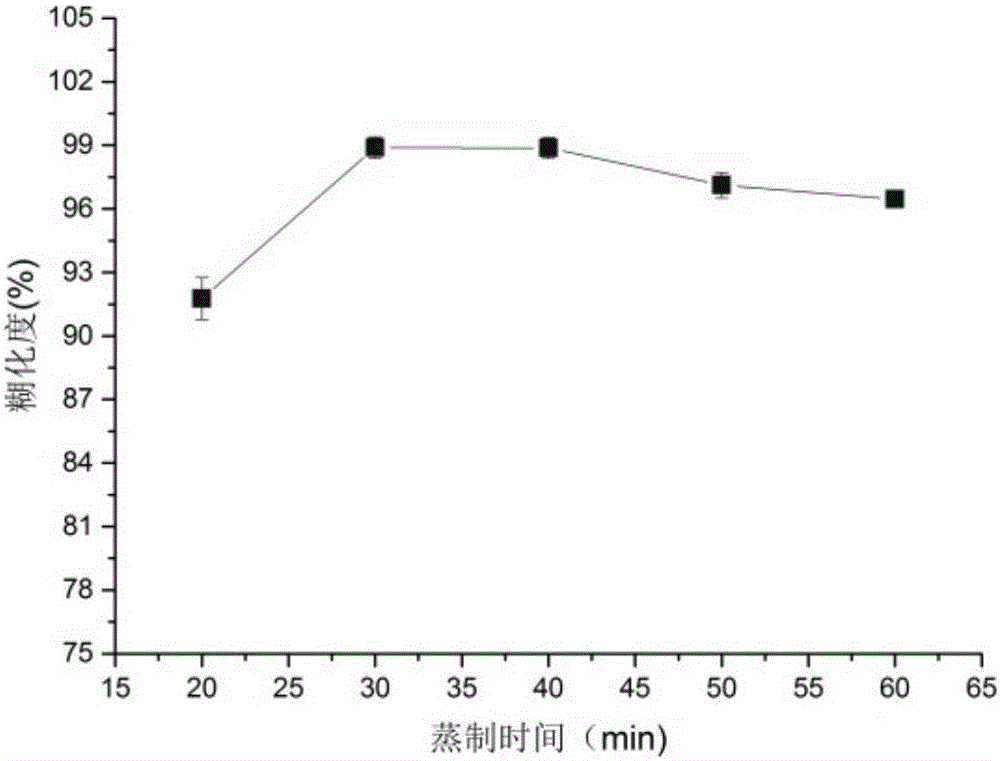

[0033] (4) Atmospheric pressure steaming: take out the rice grains and drain them, put them in an atmospheric pressure steamer, and steam for 30-50 minutes;

[0034] (5) tiling: the non-pressure steamed japonica rice is tiled into a thin layer with a thickness of about 5mm;

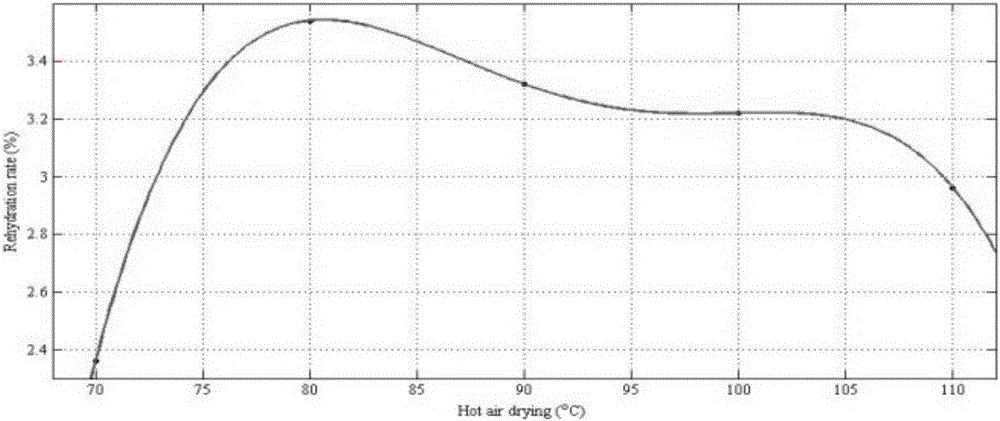

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com