Tobacco material pneumatic drying process and equipment

A technology for drying tobacco materials and air flow, which is applied in the fields of tobacco, tobacco preparation, food science, etc. to achieve good compatibility, facilitate rapid and uniform drying, and prolong drying time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

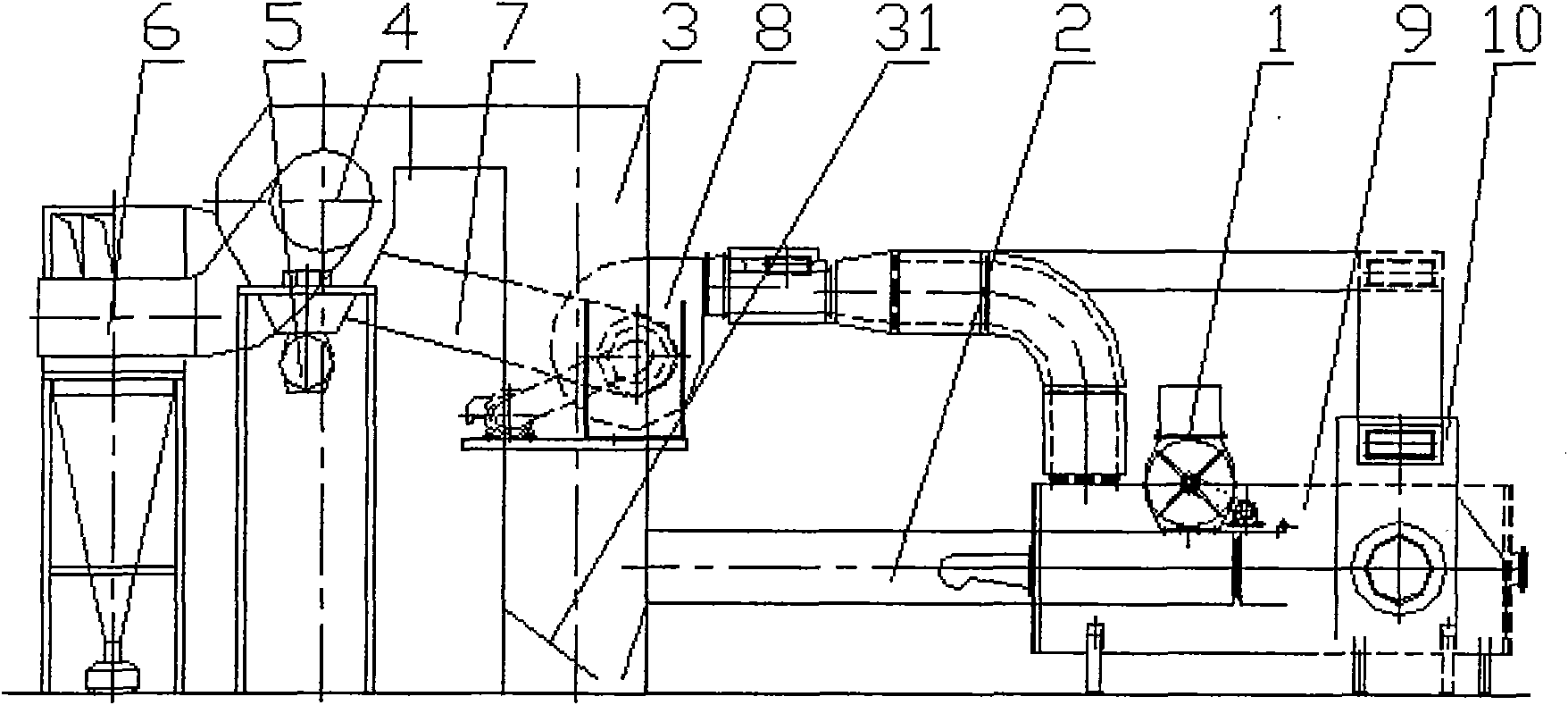

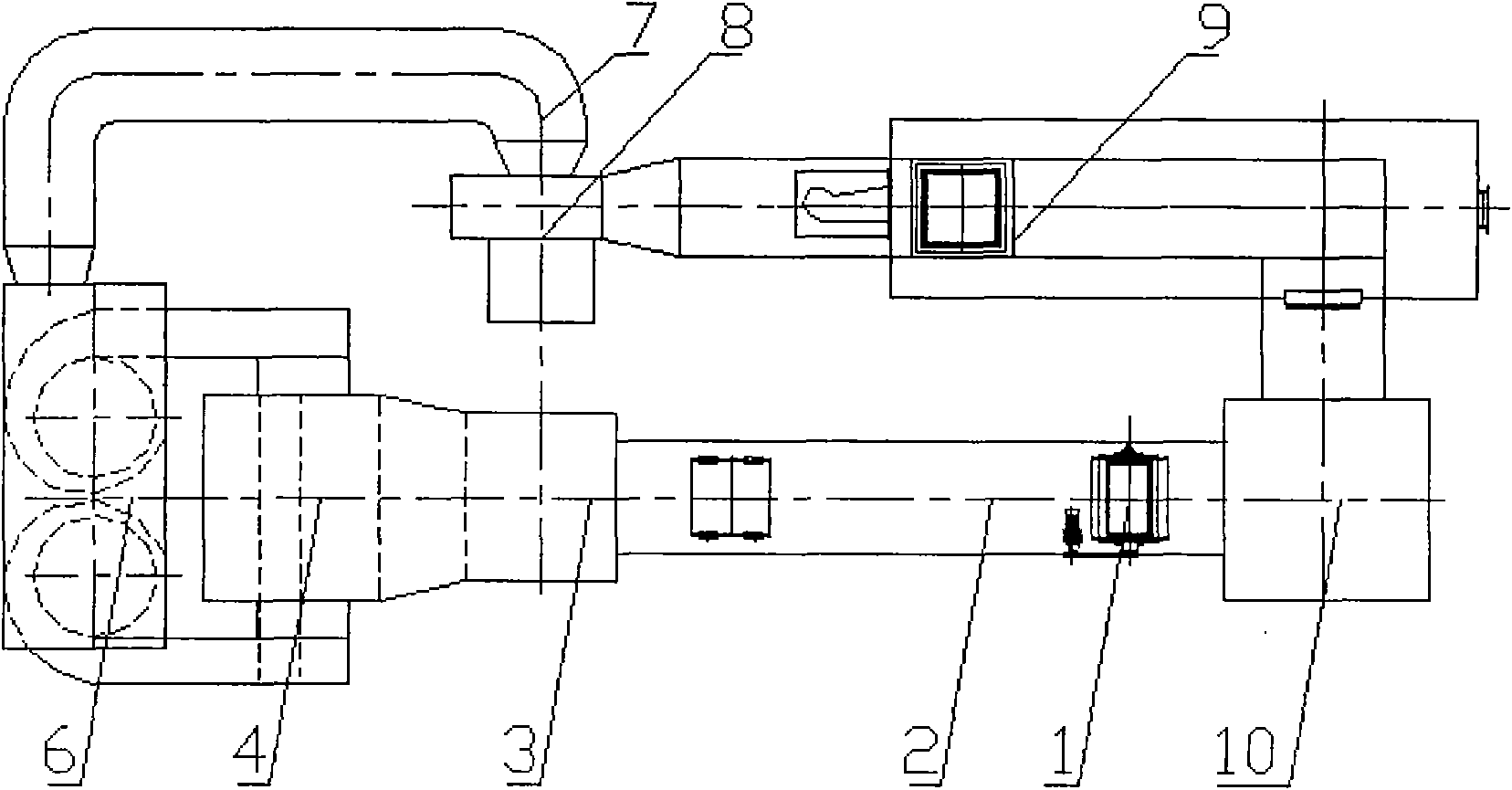

[0032] Such as figure 1 , figure 2 As shown, the processing equipment of the present invention comprises a feed valve 1, a horizontal drying pipe 2, a vertical drying pipe 3, a tangential feeder 4, and a discharge valve 5, wherein: the vertical drying pipe 3 has a diameter significantly larger than that of the horizontal drying pipe. The straight pipe of pipe 2 pipe diameter; Feed valve 1 is arranged on the upper end side wall of horizontal drying pipe 2, and is connected with a vibrating tank feeding device; Tangential feeder 4 is arranged side by side with vertical drying pipe 3 upper ends, and The upper port of the vertical drying pipe 3 is connected; the lower end of the vertical drying pipe 3 is connected with the outlet end of the horizontal drying pipe 2, and the bottom end of the vertical drying pipe 3 is equipped with a sundry discharge port 31, which is an adjustable damper or gas valve. Lock. The dust remover 6 connected with the tangential blanker 4, and the ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com