Fruit and vegetable crisp slice production method by using microwave assisted pressure-difference flash evaporation and drying

A technology of flash drying and fruit and vegetable crisps, which is applied in the field of food processing, can solve the problems of low drying efficiency and cannot be used alone, and achieve the effects of convenient operation, less loss of nutrients, and maintaining color quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

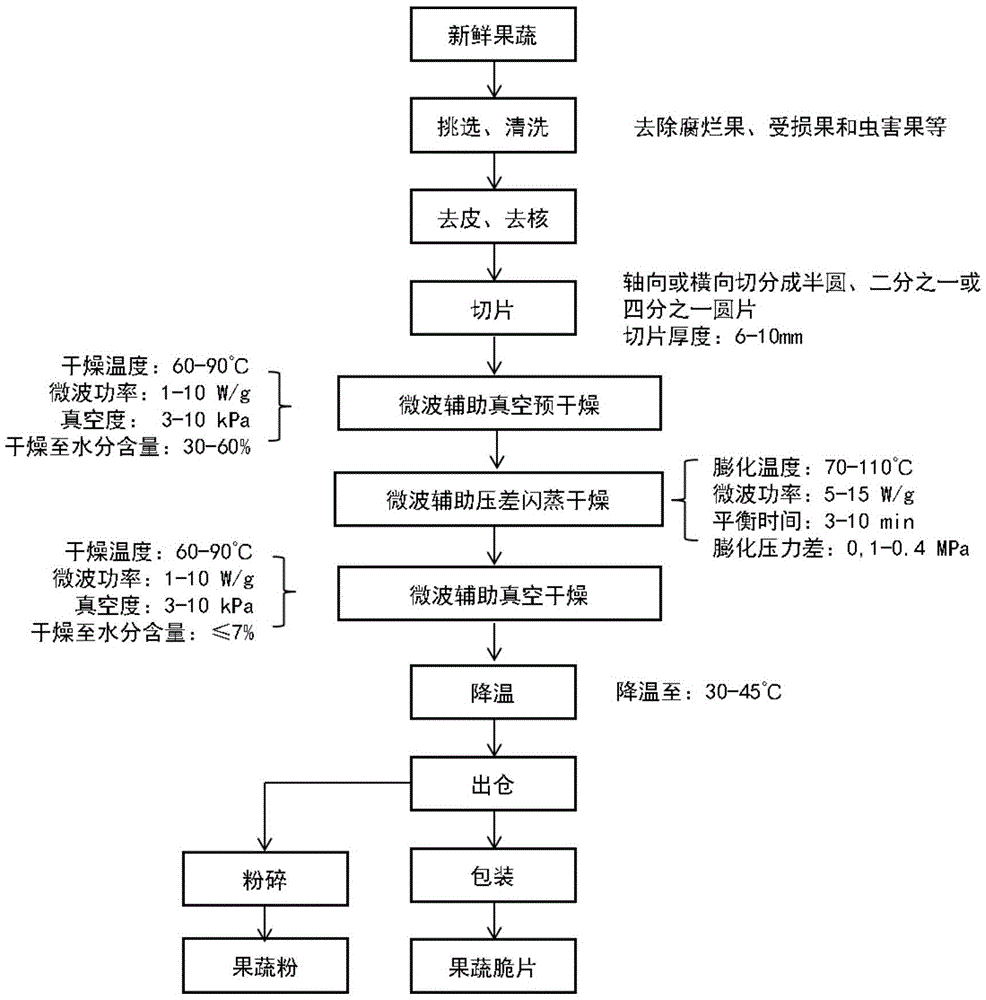

[0045] In the above-mentioned preparation method, the processing method in the step (1) is different due to different types of fruit raw materials. Specifically, you can select eight to nine mature apples, remove damaged, deformed and pest fruits, and then clean them, and then use manual or mechanical methods to peel and core the cleaned apples;

[0046] In the above preparation method, in step (1), the thickness of the fruit and vegetable slices can be 4mm-10mm, and the slicing method can be along the axial or transverse direction of the fruit and vegetable, and can be cut into round slices, semi-circular slices or quarter circles. sheet.

[0047] In the above preparation method, in step (2), the pretreatment method of the fruits and vegetables can be blanching with hot water at 90°C-100°C for 0.5min-5min;

[0048] In the above preparation method, in step (2), the pretreatment may also include using different concentrations of sodium erythorbate, citric acid, calcium chloride, and ...

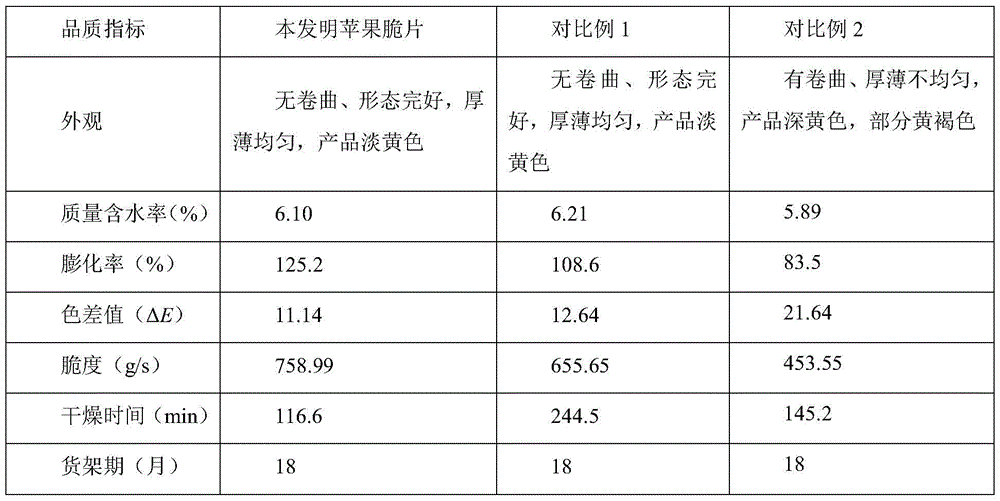

Embodiment 1

[0067] Example 1. Preparation of Apple Crisp Chips

[0068] The schematic flow diagram of the preparation method of the present invention is as follows figure 1 Shown.

[0069] 1. Preparation of Apple Chips

[0070] (1) Sorting, cleaning, peeling and core removal:

[0071] 1a) Fruit selection and cleaning: choose ripe red Fuji apples, remove damaged, deformed and pest fruits, and then clean them;

[0072] 1b) Peeling and core removal: use manual or mechanical methods to peel and core the cleaned apples in step 1);

[0073] 1c) Slicing: the peeled and cored apples in step (2) are axially sliced into 6mm thick quarter-round slices to obtain apple slices.

[0074] (2) Pretreatment: The apple slices obtained in step (1) are placed in a 0.1% Vc solution, immersed for 1 minute and then removed, and drained.

[0075] (3) Put the pretreated apple slices in a puffing bin. Open the pressure relief valve and close the intake valve. Microwave-assisted vacuum drying is used to pre-dry the pre-treat...

Embodiment 2

[0117] Example 2. Preparation of pear chips

[0118] The preparation method of the pear chips in this example is basically the same as the steps in Example 1, except that:

[0119] The slice thickness of the pear slice in step (1) is 8mm;

[0120] Step (2) in pretreatment: blanch the pear slices obtained in step (1) in 95°C hot water for 0.5 min, then immerse them in a 0.1% Vc solution for 2 min, remove and drain the water.

[0121] Table 2 shows the quality analysis results of the pear crisps prepared in Example 2 of the present invention.

[0122] Table 2 Quality analysis results of pear chips

[0123]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com