Sandy soil screening equipment capable of distinguishing dryness and wetness

A technology of sand and soil sub-sieving, which is applied in the direction of filtration, solid separation, and separation of solids from solids with airflow, which can solve the problems of consuming more manpower and time, sieving, difficult sandy soil, etc., and achieve high-efficiency stirring and dehumidification , high-efficiency screening, and guaranteed drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

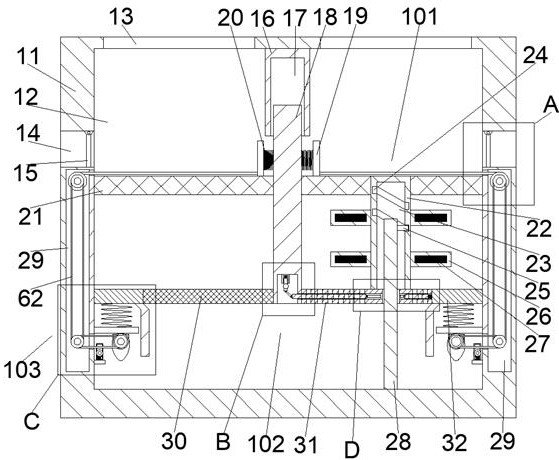

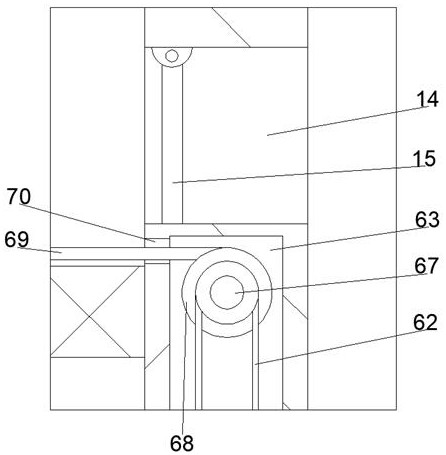

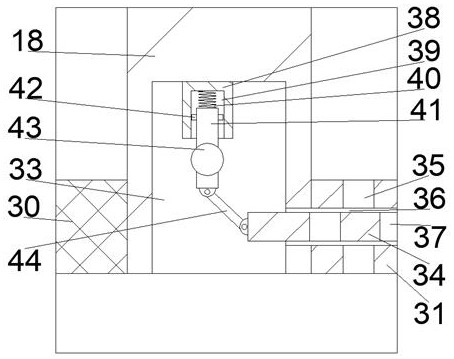

[0017] Combine below Figure 1-5 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0018] A kind of dry and wet sand screening equipment according to the present invention comprises a main box body 11, a screening chamber 12 is arranged inside the main box body 11, and the upper wall of the screening chamber 12 is connected with an opening upwards and Left and right symmetrical feed ports 13, the upper wall of the screening chamber 12 is fixedly connected with a telescopic block 16 between the left and right feed ports 13, and the telescopic block 16 is provided with a downward telescopic chamber 17, The left and right walls of the screening chamber 12 are slidingly connected with primary filter plates 21 up and down, the telescopic cavity 17 is connected with slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com