Paddle shaft provided with reverse blade of steam dryer

A technology of reverse blades and paddle shafts, which is applied in the field of steam dryers, can solve the problems of self-cleaning of unfavorable materials, which affect the drying effect of materials, and cannot guarantee the residence time of materials, so as to increase the residence time, Guaranteed drying time and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

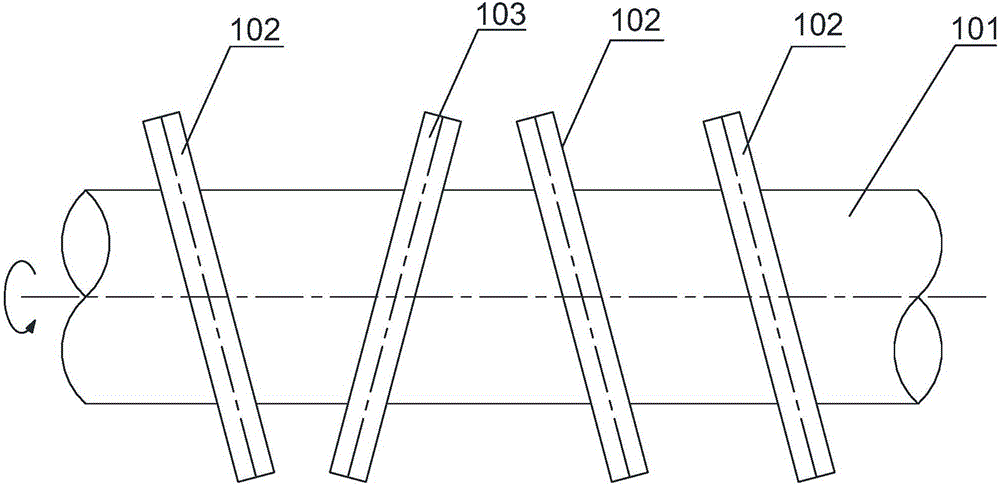

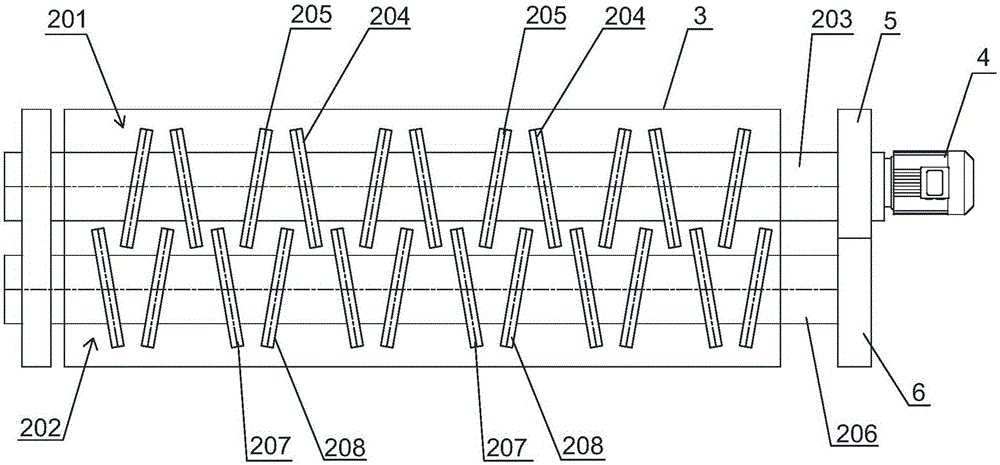

[0016] like figure 1 As shown, a paddle shaft of a steam dryer with reverse blades includes a shaft body 101 on which blades are arranged. The blades include positive blades 102 that push the material forward when the shaft rotates clockwise, and reverse blades 103 that push the material reversely (backward) when the shaft rotates clockwise. The quantity ratio of the positive blades 102 and the reverse blades 103 is 3:1. The size and angle of the positive vane 102 and the counter vane 103 can be reasonably set as required.

[0017] In the paddle steam dryer manufacturing technology, the paddle shaft is the most critical component. The traditional blade arrangement generally pushes the material forward after the blade rotates. In order to distinguish the blade form of the present invention, the blade that pushes the material forward during normal rotation (clockwise rotation) is called the positive blade here, and the normal blade is called the normal blade. The blade that p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com