Production system for producing building plaster by using desulphurization gypsum and realization method of production system

A technology of building gypsum and production system, applied in the field of gypsum production, can solve the problems of difficult product serialization, unstable product phase composition, difficult quality control, etc., to ensure drying time and effect, easy control, and stable product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

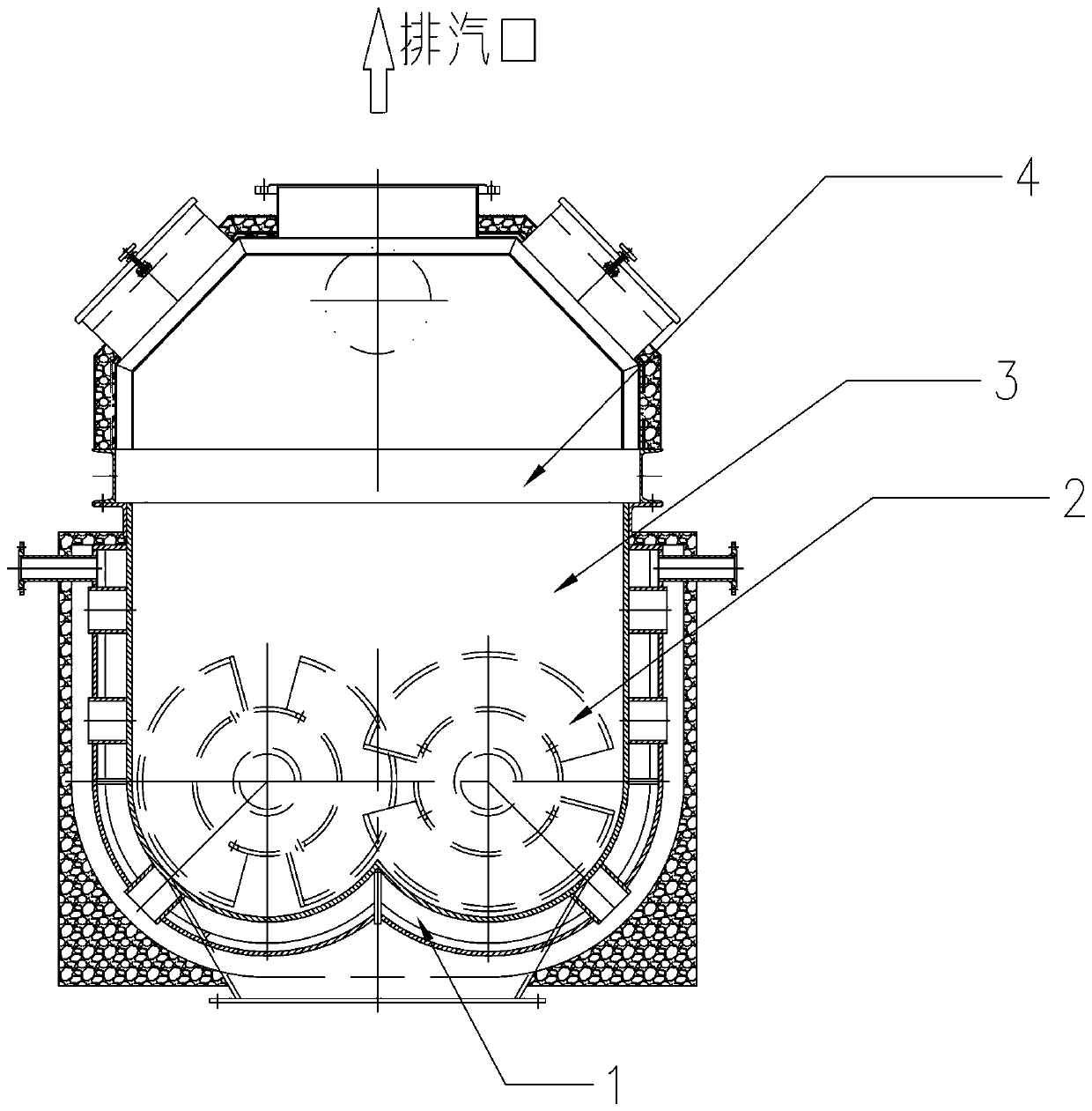

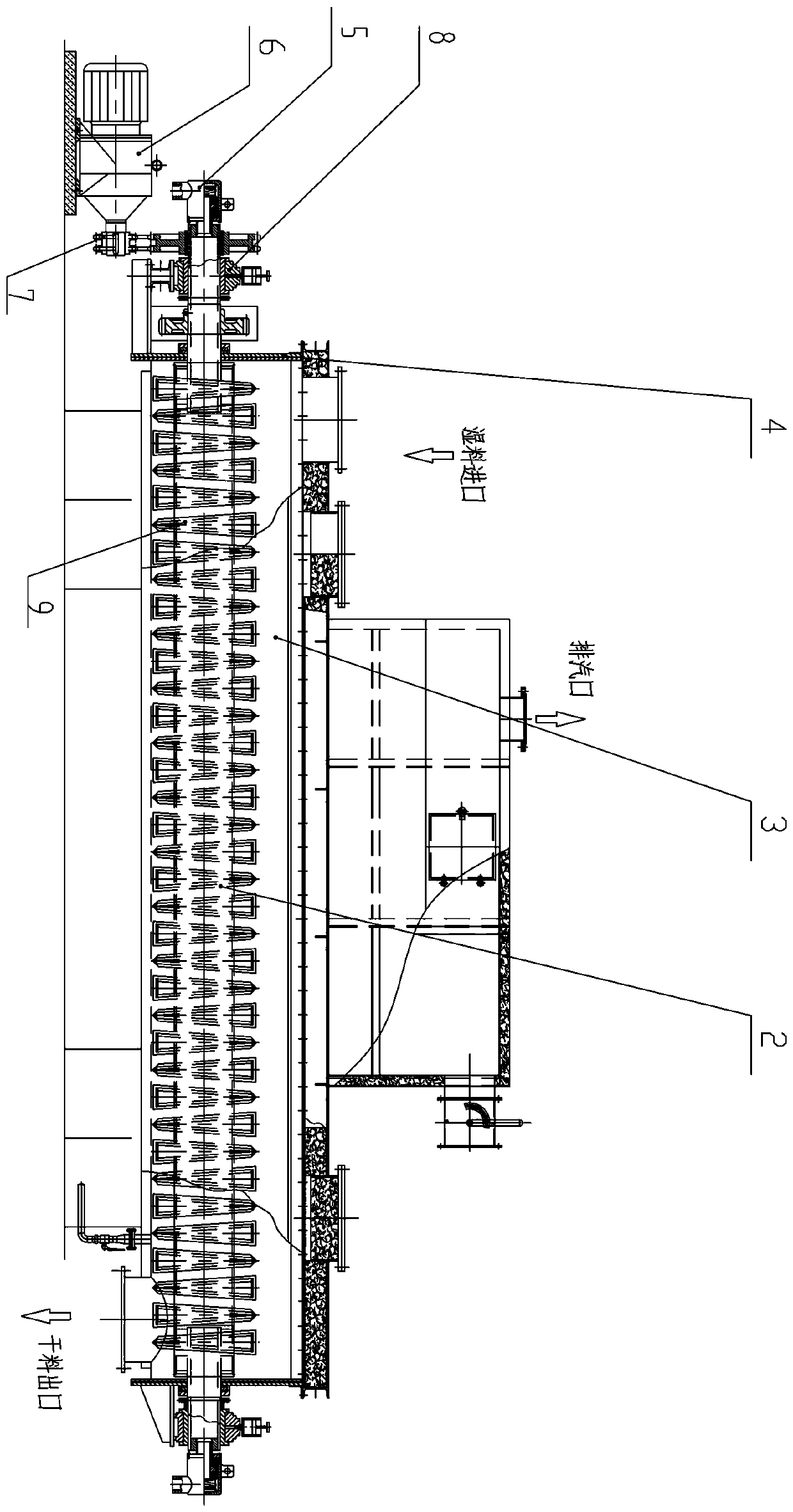

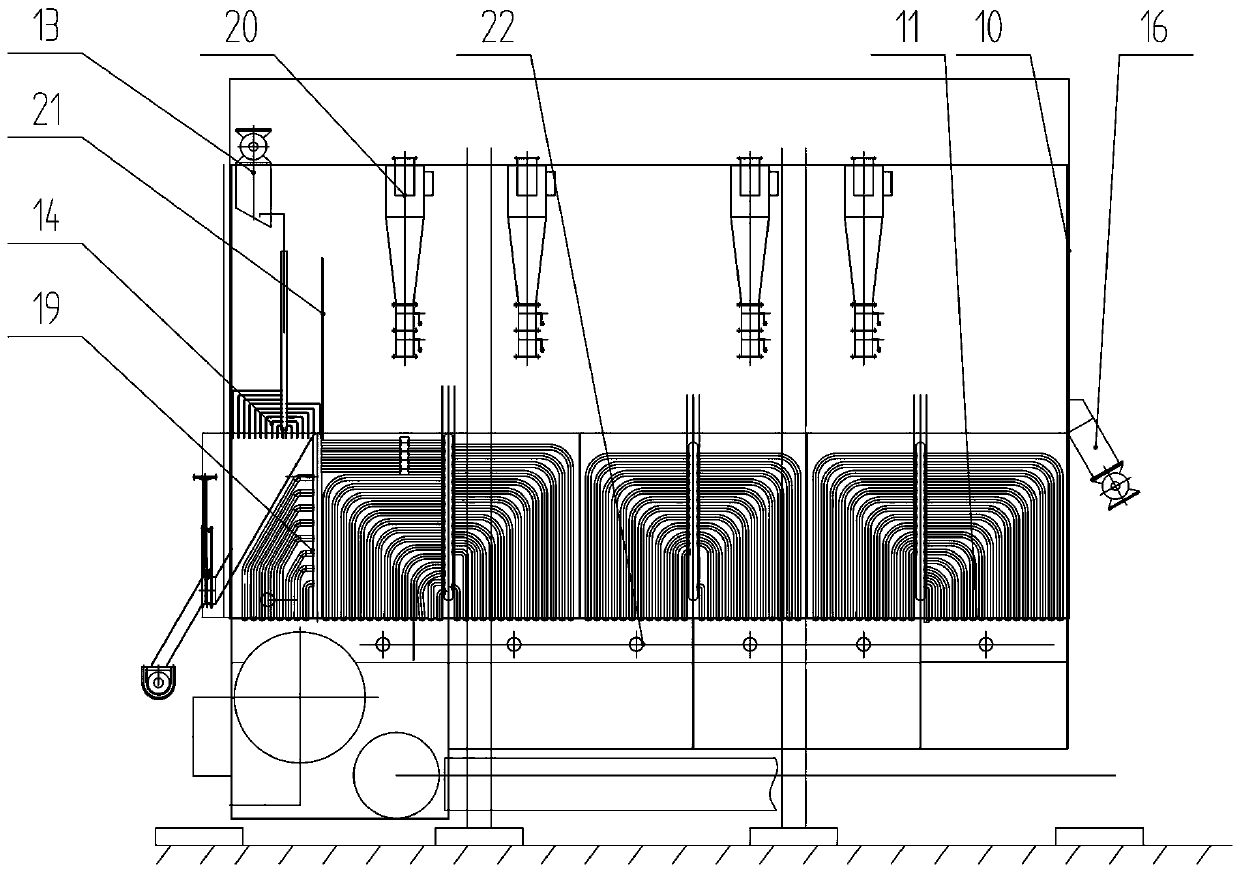

[0034] Examples such as Figures 1 to 6 As shown, a production system for producing building gypsum with desulfurized gypsum, including a feeding system, a drying system, a calcination system, a dust removal system, a control system, a TV monitoring and prevention system, a combustion system, a material storage and packaging system, and a feeding system for For feeding gypsum materials, the gypsum materials are output from the feeding system to the drying system. The drying system is used for drying the gypsum materials. The gypsum materials are output from the drying system to the calcination system and combustion system. The calcination system and the combustion system are used to The gypsum material is calcined into building gypsum. The building gypsum is output from the calcination system and combustion system to the material storage and packaging system. The material storage and packaging system is used to package the building gypsum. The dust removal system is used in eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com