Injection molding machine drying cabinet

A drying oven and injection molding machine technology, applied in the field of injection molding machines, can solve problems such as inability to utilize waste heat of cooling water and affect product quality, and achieve the effects of improving product quality, simple structure, and improving heat conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

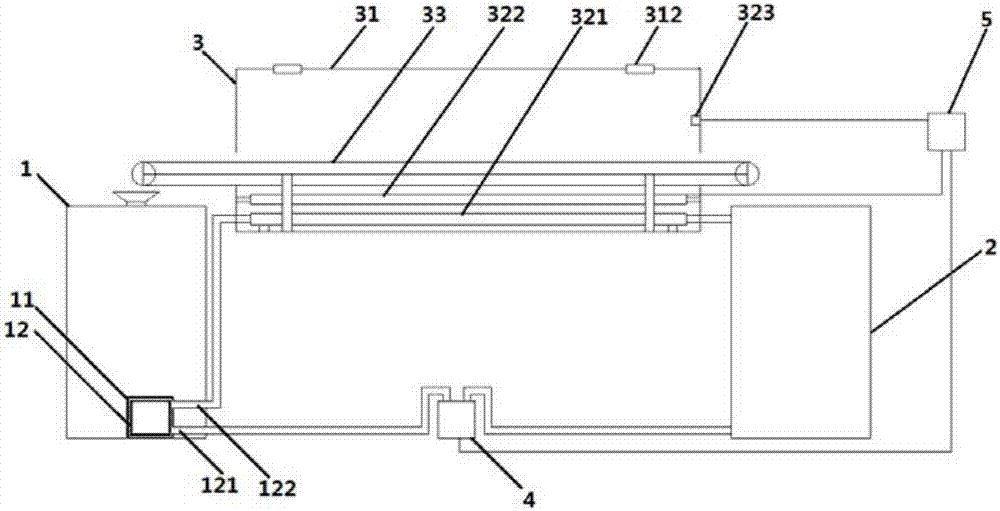

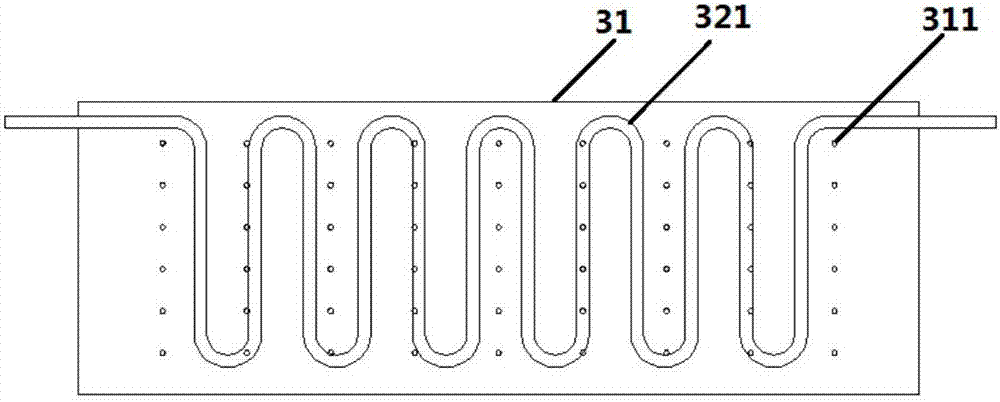

[0015] An injection molding machine drying box, such as figure 1 , 2 As shown, it includes an injection molding machine 1, a cooling water tower 2, and a drying box 3. The injection molding machine 1 is provided with an oil tank 11, and a hollow water chamber 12 is arranged in the box plate of the oil tank 11. The water chamber 12 is provided with a water inlet 121 and The water outlet 122 and the water inlet 121 are connected to the water pump 4, and the water inlet end of the water pump 4 is connected to the cooling water tower 2. The drying box 3 includes a box body 31 and a heater 32, and the heater 32 includes a hot water pipe coil 321, an electric heater 322, a temperature sensor 323, the hot water tube coil 321 is installed and fixed in the box body 31, one end of the hot water tube coil 321 is connected with the water outlet 122 of the water chamber 12, the hot water tube coil 321 The other end is connected to the cooling water tower 2, the electric heater 322 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com