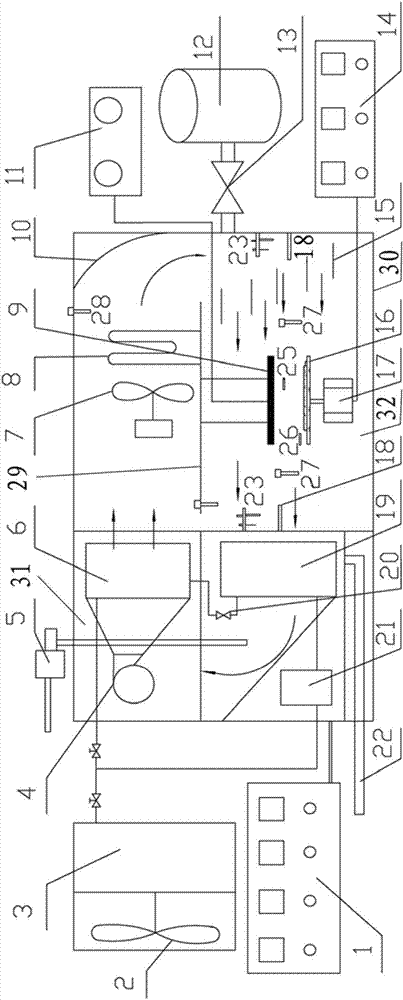

Ultrasonic-reinforced controlled atmosphere drying method and device

A drying method and a gas-enhancing technology, applied in the fields of ultrasonic-enhanced controlled atmosphere drying and ultrasonic-enhanced controlled atmosphere drying devices, can solve the problems of long drying time, low drying efficiency, loss of effective components, etc. High drying efficiency and the effect of improving tissue structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The ultrasonically enhanced controlled atmosphere drying method of the present embodiment comprises the following steps:

[0037] 1) After washing the carrots, peel them and cut them into thin slices with a thickness of 4mm to obtain carrot slices;

[0038] 2) 200g carrot slices are placed in the drying box of the controlled atmosphere drying device, placed on the ultrasonic radiating plate, and the infrared radiating plate is installed above the ultrasonic radiating plate at a distance of 10 cm from the material;

[0039] Turn on the controlled atmosphere drying device, feed nitrogen into the drying box to adjust the volume content of oxygen in the drying medium to 5%, then carry out controlled atmosphere hot air drying to the carrot slices, the drying temperature is 50 ° C, and the wind speed is 0.5m / s; While the hot air is drying, ultrasonic treatment and infrared radiation treatment (i.e. ultrasonic-infrared radiation enhanced modified atmosphere drying) are carried...

Embodiment 2

[0042] The ultrasonically enhanced controlled atmosphere drying method of the present embodiment comprises the following steps:

[0043] 1) Get the carrots, wash them, peel them, and cut them into thin slices with a thickness of 5 mm to obtain carrot slices;

[0044] 2) 200g carrot slices are placed in the drying box of the controlled atmosphere drying device, placed on the ultrasonic radiating plate, and the infrared radiating plate is installed above the ultrasonic radiating plate at a distance of 10 cm from the material;

[0045] Turn on the controlled atmosphere drying device, feed nitrogen into the drying box to adjust the volume content of oxygen in the drying medium to 6%, then carry out controlled atmosphere hot air drying to the carrot slices, the drying temperature is 55 ° C, and the wind speed is 1.0 m / s; While the heat-adjusting air is drying, ultrasonic treatment and infrared radiation treatment (i.e. ultrasonic-infrared radiation enhanced modified atmosphere dryi...

Embodiment 3

[0048] The ultrasonically enhanced controlled atmosphere drying method of the present embodiment comprises the following steps:

[0049] 1) Get the carrots, wash them, peel them, and cut them into thin slices with a thickness of 6 mm to obtain carrot slices;

[0050] 2) 200g carrot slices are placed in the drying box of the controlled atmosphere drying device, placed on the ultrasonic radiating plate, and the infrared radiating plate is installed above the ultrasonic radiating plate at a distance of 10 cm from the material;

[0051] Turn on the controlled atmosphere drying device, feed nitrogen into the drying box to adjust the volume content of oxygen in the drying medium to 5%, then carry out controlled atmosphere hot air drying to the carrot slices, the drying temperature is 60 ° C, and the wind speed is 1.5m / s; While the heat-adjusting air is drying, ultrasonic treatment and infrared radiation treatment (i.e. ultrasonic-infrared radiation enhanced modified atmosphere dryin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com